Abstract

In the present study the reliability estimation of the pultrusion process of a flat plate is analyzed by using the first order reliability method (FORM). The implementation of the numerical process model is validated by comparing the deterministic temperature and cure degree profiles with corresponding analyses in the literature. The centerline degree of cure at the exit (CDOCE) being less than a critical value and the maximum composite temperature (T max) during the process being greater than a critical temperature are selected as the limit state functions (LSFs) for the FORM. The cumulative distribution functions of the CDOCE and T max as well as the correlation coefficients are obtained by using the FORM and the results are compared with corresponding Monte-Carlo simulations (MCS). According to the results obtained from the FORM, an increase in the pulling speed yields an increase in the probability of T max being greater than the resin degradation temperature. A similar trend is also seen for the probability of the CDOCE being less than 0.8.

Similar content being viewed by others

References

Palikhel, D.R., Roux, J.A., Jeswani, A.L.: Die-attached versus die-detached resin injection chamber for pultrusion. Appl. Compos. Mater. (2012). doi:10.1007/s10443-012-9251-1

Joshi, S.C., Chen, X.: Time-variant simulation of multi-material thermal pultrusion. Appl. Compos. Mater. 18, 283–296 (2010)

Joshi, S.C., Lam, Y.C., Win Tun, U.: Improved cure optimization in pultrusion with pre-heating and die-cooler temperature. Compos. Part A Appl. Sci. Manuf. 34, 1151–1159 (2003)

Liu, X.L., Crouch, I.G., Lam, Y.C.: Simulation of heat transfer and cure in pultrusion with a general-purpose finite element package. Compos. Sci. Technol. 60, 857–864 (2000)

Gorthala, R., Roux, J.A., Vaughan, J.G.: Resin flow, cure and heat transfer analysis for pultrusion process. J. Compos. Mater. 28, 486–506 (1994)

Chachad, Y.R., Roux, J.A., Vaughan, J.G., Arafat, E.S.: Thermal model for three dimensional irregular shaped pultruded fiberglass composites. J. Compos. Mater. 30, 692–721 (1996)

Carlone, P., Palazzo, G.S., Pasquino, R.: Pultrusion manufacturing process development by computational modelling and methods. Math. Comput. Model. 44, 701–709 (2006)

Valliappan, M., Roux, J.A., Vaughan, J.G., Arafat, E.S.: Die and post-die temperature and cure in graphite–epoxy composites. Compos. Part B Eng. 27, 1–9 (1996)

Chachad, Y.R., Roux, J.A., Vaughan, J.G.: Three-dimensional characterization of pultruded fiberglass–epoxy composite materials. J. Reinf. Plast. Compos. 14, 495–512 (1995)

Ding, Z., Li, S., Lee, L.J.: Influence of heat transfer and curing on the quality of pultruded composites II: Modeling and simulation. Polym. Compos. 23, 957–969 (2002)

Chachad, Y.R., Roux, J.A., Vaughan, J.G.: Thermal investigation of pultruded graphite composites for various processing conditions and thickness. Eng. Plast. 9, 91–108 (1996)

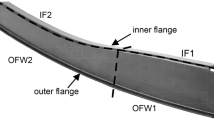

Roux, J.A., Vaughan, J.G., Shanku, R., Arafat, E.S., Bruce, J.L., Johnson, V.R.: Comparison of measurements and modeling for pultrusion of a fiberglass/epoxy I-beam. J. Reinf. Plast. Compos. 17, 1557–1578 (1998)

Liu, X.L., Hillier, W.: Heat transfer and cure analysis for the pultrusion of a fiberglass-vinyl ester I beam. Compos. Struct. 47, 581–588 (1999)

Liu, X.L.: Numerical modeling on pultrusion of composite I beam. Compos. Part A Appl. Sci. Manuf. 32, 663–681 (2001)

Liu, X., Mahadevan, S.: Ultimate strength failure probability estimation of composite structures. J. Reinf. Plast. Compos. 19, 403–426 (2000)

Lee, O.S., Kim, D.H., Myoung, N.H.: Reliability estimation of buried pipelines using first-order reliability method. J. Thermoplast. Compos. 24, 303–315 (2011)

Dimitrov, N., Hansen, P.F., Berggreen, C.: Reliability analysis of a composite wind turbine blade section using the model correction factor method: Numerical study and validation. Appl. Compos. Mater. (2012). doi:10.1007/s10443-011-9246-3

Gomes, H.M., Awruch, A.M., Lopes, P.A.M.: Reliability based optimization of laminated composite structures using genetic algorithms and Artificial Neural Networks. Struct. Saf. 33, 186–195 (2011)

Smith, B., Banerjee, B.: Reliability of inserts in sandwich composite panels. Compos. Struct. 94, 820–829 (2012)

Padmanabhan, S.K., Pitchumani, R.: Stochastic analysis of isothermal cure of resin systems. Polym. Compos. 20(1), 72–85 (1999)

Padmanabhan, S.K., Pitchumani, R.: Stochastic modeling of nonisothermal flow during resin transfer molding. Int. J. Heat Mass Tranf. 42(16), 3057–3070 (1999)

Li, H., Foschi, R., Vaziri, R., Fernlund, G., Poursartip, A.: Probability-based modeling of composites manufacturing and its application to optimal process design. J. Compos. Mater. 36(16), 1967–1991 (2002)

Bebamzadeh, A., Haukaas, T., Vaziri, R., Poursartip, A., Fernlund, G.: Application of response sensitivity in composite processing. J. Compos. Mater. 44(15), 1821–1840 (2010)

Baran, I., Tutum, C.C., Hattel, J.H.: Optimization of the thermosetting pultrusion process by using hybrid and mixed integer genetic algorithms. Appl. Compos. Mater. (2012). doi:10.1007/s10443-012-9278-3

Hattel, J.H.: Fundamentals of Numerical Modelling of Casting Processes, 1st edn. Polyteknisk Forlag, Denmark (2005)

MATLAB (7.12.0.635) Reference Guide. The Mathworks Inc (2011)

Melchers, R.E.: Structural Reliability Analysis and Prediction. 2nd Ed. John Wiley & Sons (1999)

Huang, B., Du, X.: Probabilistic uncertainty analysis by mean-value first order saddlepoint approximation. Reliab. Eng. Syst. Saf. 93, 325–336 (2008)

Hohenbichler, M., Rackwitz, R.: Non-normal dependent vectors in structural safety. J. Eng. Mech. Div. ASCE 107(6), 1227–1238 (1981)

Allen, M., Maute, K.: Reliability-based shape optimization of structures undergoing fluid–structure interaction phenomena. Comput. Method. Appl. Mech. Eng. 194(30–33), 3472–3495 (2005)

Baran, I., Tutum, C.C., Hattel, J.H.: Probabilistic thermo-chemical analysis of a pultruded composite rod. Proceedings of the 15th European Conference on Composite Materials, ECCM-15, Venice, Italy, 24–28 June 2012

Montgomery, D.C., Runger, G.C.: Applied Statistics and Probability for Engineers. 3rd Ed. John Wiley & Sons, Inc. (2003)

Acknowledgment

This work is a part of DeepWind project which has been granted by the European Commission (EC) under FP7 program platform Future Emerging Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baran, I., Tutum, C.C. & Hattel, J.H. Reliability Estimation of the Pultrusion Process Using the First-Order Reliability Method (FORM). Appl Compos Mater 20, 639–653 (2013). https://doi.org/10.1007/s10443-012-9293-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-012-9293-4