Abstract

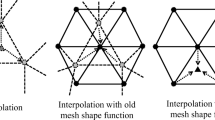

A Multi-Mesh Multi-Physics (MMMP) method is developed to reduce the very long computational time required for simulating incremental forming processes such as cogging or ring rolling. It consists in using several finite element meshes on the same domain to solve the different physics of the problem. A reference mesh is used to accurately store the results and history variables, while the different computational meshes are optimized to solve each physic of the problem. The MMMP algorithm consists in two main key-steps: the generation of the different unstructured meshes and the data transfer between the meshes. The accuracy of the method is supported by using meshes that are embedded by nodes. The method is applied to the simulation of the cogging metal forming process for which it shows as accurate and more than ten times faster than the standard method with a single mesh.

Similar content being viewed by others

References

Groche P, Fritsche D, Tekkaya EA, Allwood JM, Hirt G, Neugebauer R (2007) Incremental Bulk Metal Forming. CIRP Ann Manuf Technol 56(2):635–656

Chenot JL (1989) Three dimensional finite element modeling of forging process. Computational Plasticity Pineridge press, Swansea, pp 793–816

Hadoush A, Van den Boogaard AH (2008) Time reduction in implicit single point incremental sheet forming simulation by refinement-derefinement. Int J Mater Form 1(1):1167–1170

Hadoush A, Van den Boogaard AH (2009) Substructuring in the implicit simulation of single point incremental sheet forming. Int J Mater Form 2(3):181–189

El Hadj M (1987) Application des méthodes multi-grilles aux calculs des structures élastiques et visco-plastiques. Ph.D. Thesis, Mines Paristech, France

Le Dain M A (1991) Méthodes multigrille et H-adaptation : application au calcul de structures élastiques bidimensionnelles. Ph.D. Thesis, Mines Paristech, France

Mocellin K, Fourment L, Coupez T, Chenot JL (2001) Toward large scale F.E. computation of hot forging process using iterative solvers, parallel computation and multigrid algorithms. Int J Numer Meth Eng 52(5–6):473–488

Rey B, Mocellin K, Fourment L (2008) A node-nested Galerkin multigrid method for metal forging simulation. Comput Visual Sci 11(1):17–25

Ramadan M (2010) Une Méthode MultiMaillages MultiPhysiques Parallèles pour accélérer les calculs des procédés multiphysiques incrémentaux. Ph.D. Thesis, Mines Paristech, France

Rannou J, Gravouil A, Baïetto-Dubourg MC (2007) Éléments finis étendus multi-grilles avec raffinement local pour la mécanique de la rupture. Acte du 8ème Colloque National en Calcul des Structures 1:69–74, Giens France

Kim NS, Machida S, Kobayashi S (1990) Ring rolling process simulation by the three dimensional finite element method. Int J Mach Tools Manuf 30(4):569–577

Hu ZM, Pillinger I, Hartley P, McKenzie S, Spence PJ (1994) Three dimensional finite-element modeling of ring rolling. J Mater Process Technol 45(1–4):143–148

Keun Moon H, Cheol Lee M, Soo Joun M (2008) Predicting polygonal-shaped defects during hot ring rolling using a rigid-viscoplastic finite element method. Int J Mech Sci 50:306–314

Barton G, Li X, Hirt G (2007) Finite-element modeling of multi-pass forging of nickel-base alloys using a Multi-Mesh method. Mater Sci Forum 539–543:2503–2508

Hirt G, Kopp R, Hofmann O, Franzke M, Barton G (2007) Implementing a high accuracy Multi-Mesh Method for incremental Bulk Metal Forming. CIRP Ann Manuf Technol 56(1):313–316

Li R (2005) On Multi-Mesh h-adaptive methods. J Sci Comput 24(3):321–341

Hu X, Li R, Tang T (2009) A Multi-Mesh adaptive finite element approximation to phase field models. Comm Comput Phys 5(5):1012–1029

Di Y, Wang XP (2009) Precursor simulations in spreading using a Multi-Mesh adaptive finite element method. J Comput Phys 228(5):1380–1390

Terzolo L (2004) Vers une prédiction de la durée de vie des outils de forge à chaud par la modélisation numérique du régime thermique et de l’usure abrasive. Ph.D. Thesis, Mines Paristech, France

Arnold DN, Brezzi F, Fortin M (1984) A stable finite element for the Stokes equations. Calcolo 21(4):337–344

Fourment L, Chenot JL, Mocellin K (1999) Numerical formulations and algorithms for solving contact problems in metal forming simulation. Int J Numer Meth Eng 46(9):1435–1462

Zlamal M (1980) Finite element method in physical and technical applications. Comput Phys Comm 20(1):37–42

Ramadan M, Fourment L, Perchat E (2008) A Bimesh Method for Speeding-up Incremental Processes such as Cogging. Proceedings of the 9th International Conference on Technology of Plasticity (ICTP), Gyeongju, Korea

Ramadan M, Fourment L, Digonnet H (2009) A parallel two mesh method for speeding-up processes with localized deformations: application to cogging. Int J Mater Form 2(1):581–584

Ramadan M, Fourment L, Digonnet H (2009) Une méthode Bimaillages parallèle pour accélérer le temps de calcul des procédés incrémentaux. Acte du 9ème Colloque National en Calcul des Structures 1:999–104, Giens France

Ramadan M, Gavoille S, Fourment L, Digonnet H (2011) Une méthode MultiMaillages MultiPhysiques parallèle pour accélérer les calculs des procédés multiphysiques incrémentaux. Clé USB 10e colloque national en calcul des structures, Giens France

Coupez T (1994) A mesh improvement method for 3d automatic remeshing . In N P Weatherill et al. (Eds.), Numerical Grid Generation in Computational Fluid Dynamics and Related Fields, Pineridge Press, pp 615–626

Coupez T (2000) Génération de maillage et adaptation de maillage par optimisation locale. Revue européenne des éléments finis 9:403–423

Alfaro I, Yvonnet J, Cueto E, Chinesta F, Doblare M (2006) Meshless methods with application to metal forming. Comput Meth Appl Mech Eng 195(48–49):6661–6675

Alfaro I, Gonzalez D, Bel D, Cueto E, Doblare M, Chinesta F (2006) Recent advances in the meshless simulation of aluminium extrusion and other related forming processes. Arch Comput Meth Eng 13(1):3–44

Filice L, Alfaro I, Gagliardi F, Cueto E, Micari F, Chinesta F (2009) A preliminary comparison between finite element and meshless simulations of extrusion. J Mater Process Tech 209(6):3039–3049

Acknowledgments

This work was supported by the consortium « club forgeage libre » which gathers the following industries: ArcelorMittal, Cézus (Areva), Sfarsteel (Areva), Aubert & Duval and Manoir industries.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ramadan, M., Fourment, L. & Digonnet, H. Fast resolution of incremental forming processes by the Multi-Mesh method. Application to cogging. Int J Mater Form 7, 207–219 (2014). https://doi.org/10.1007/s12289-012-1121-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-012-1121-8