Abstract

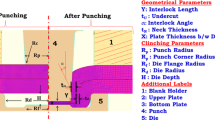

This experimental work concerns the study of the preforming of a specific highly double curved geometry with a triple point (case corner) by the sheet forming process using powdered interlock reinforcement (G1151®). Three different punches (square box, prism, tetrahedron) were used in this study, each of them presenting highly double curved geometry with a case corner. A specific sheet forming device specially designed for the preforming of textile reinforcement was used. The expected shapes with the three punches have been obtained with an optimized blank-holder pressure. No classical defaults such as wrinkling or yarn damage are present in the useful zone of the preforms. However, a new default, not observed for spherical or hemispherical shape has been identified. It concerns the out of plane buckling of yarns. This phenomenon not observed on the square box is visible on some faces and edges of the prismatic and tetrahedron shapes. For the square box, it is easily possible to control the orientation of the yarn within the preform in the faces, whereas this is not possible for triangular faces of the prismatic and tetrahedron shapes. The square box punch is therefore more adapted to preform the highly doubled curved shape with the case corner.

Similar content being viewed by others

References

Advani SG (1994) Flow and rheology in polymeric composites manufacturing. Elsevier, ISBN0 444 89347 4

Rudd CD, Long AC (1997) Liquid molding technologies. Woodhead Publishing Limited

Lee SH, Han JH, Kim SY, Youn JR, Song YS (2010) Compression and relaxation behavior of dry fiber preforms for resin transfer molding. J Compos Mater 44(15):1801–1820

Brouwer WD, Van Herpt ECFC, Labordus M (2003) Vacuum injection moulding for large structural applications. Compos Part A 34:551–558

Arbter R, Beraud JM, Binetruy C, Bizet L, Bréard J, Comas-Cardona S, Demaria C, Endruweit A, Ermanni P, Gommer F, Hasanovic S, Henrat P, Klunker F, Laine B, Lavanchy S, Lomov SV, Long A, Michaud V, Morren G, Ruiz E, Sol H, Trochu F, Verleye B, Wietgrefe M, Wu W, Ziegmann G (2011) Experimental determination of the permeability of textiles: a benchmark exercise. Compos Part A 42(9):1157–1168

Heardmann E, Lekakou C, Bader MG (2001) In plane permeability of sheared fabrics. Compos Part A 32:933–940

Ouagne P, Bréard J (2010) Continuous transverse permeability of fibrous media. Compos Part A 41(1):22–28

Prodromou AG, Chen J (1997) On the relationship between shear angle and wrinkling of textile composite preforms. Compos Part A 28:491–503

Skordos AA, Aceves CM, Sutcliffe MPF (2007) A simplified rate dependent model of forming and wrinkling of pre-impregnated woven composites. Compos Part A 38:1318–1330

Hancock SG, Potter KD (2006) The use of kinematic drape modelling to inform the hand lay-up of complex composite components using woven reinforcements. Compos Part A 37:413–422

Peng XQ, Rehman ZU (2011) Textile composite double dome stamping simulation using a non-orthogonal constitutive model. Compos Sci Tech 71(8):1075–1081

Hamila N, Boisse P (2008) Simulations of textile composite reinforcement draping using a new semi discrete three node finite element. Compos B 39:999–1010

Boisse P, Hamila N, Vidal-Sallé E, Dumont F (2011) Simulation of wrinkling during textile composite reinforcement forming. Influence of tensile, in-plane shear and bending stiffnesses. Compos Sci Tech 71(5):683–692

Kelly PA, Bickerton S (2009) A comprehensive filling and tooling force analysis for rigid mould LCM processes. Compos A 40(11):1685–1697

Lin H, Wang J, Long AC, Clifford MJ, Harrison P (2007) Predictive modelling for optimization of textile composite forming. Compos Sci Tech 67:3242–3252

Mohammed U, Lekakou C, Bader MG (2000) Experimental studies and analysis of the draping of woven fabrics. Compos A 31(12):1409–1420

Lee J, Hong S, Yu W, Kang T (2007) The effect of blank holder force on the stamp forming behavior of non-crimp fabric with a chain stitch. Compos Sci Tech 67(3–4):357–366

Sidhu RMJS, Averill RC, Riaz M, Pourboghrat F (2001) Finite element analysis of textile composite perform stamping. Compos Struct 52(3–4):483–497

Cherouat A, Borouchaki H, Giraud-Moreau L (2010) Mechanical and geometrical approaches applied to composite fabric forming. Int J Mater Form 3(2):1189–1204

Woven Composites Benchmark Forum. http://www.wovencomposites.org

Khan MA, Mabrouki T, Vidal-Sallé E, Boisse P (2010) Numerical and experimental analyses of woven composite reinforcement forming using a hypoelastic behavior: application to the double dome benchmark. J Mater Process Tech 210:378–388

Vanclooster K, Lomov SV, Verpoest I (2009) Experimental validation of forming simulations of fabric reinforced polymers using an unsymmetrical mould configuration. Compos A 40:530–539

Allaoui S, Boisse P, Chatel S, Hamila N, Hivet G, Soulat D, Vidal-Salle E (2011) Experimental and numerical analyses of textile reinforcement forming of a tetrahedral shape. Compos A 42(6):612–622

Allaoui S, Launay J, Soulat D, Chatel S (2008) Experimental tool of woven reinforcement forming. Inter J Mater Form 2(1):815–818

Dumont F, Hivet G, Rotinat R, Launay J, Boisse P, Vacher P (2003) Field measurements for shear tests on woven reinforcements. Mec Indust 4:627–635

Willems A, Lomov SV, Verpoest I, Vandepitte D (2008) Optical strain fields in shear and tensile testing of textile reinforcements. Compos Sci Tech 68:807–819

Launay J, Lahmar F, Boisse P, Vacher P (2002) Strain measurement in tests of fibre fabric by image correlation method. Adv Compos Lett 11(1):7–12

Bretagne N, Valle V, Dupré JC (2005) Development of the marks traking technique for strain field and volume variation measurements. NDT & E International 38(4):290–298

Bremand F, Dupre JC, Lagarde A (1995) Mesure de déformations sans contact par analyse d’images. Proceedings of Photomechanics: 171–177

Cao J, Akkerman R, Boisse P, Chen J et al (2008) Characterization of mechanical behavior of woven fabrics: experimental methods and benchmark results. Compos A 39(6):1037–1053

Hivet G, Duong AV (2011) A contribution to the analysis of the intrinsic shear behaviour of fabrics. J Compos Mater 45(6):695–717

Launay J, Hivet G, Duong AV, Boisse P (2008) Experimental analysis of the influence of tensions on in plane shear behaviour of woven composite reinforcements. Compos Sci Tech 68(2):506–515

Anh Vu Duong (2008) Étude expérimentale du comportement mécanique de renforts composites tissés lors de la mise en forme sur géométrie non développables. PhD thesis, Université d’Orléans

De Bilbao E, Soulat D, Hivet G, Gasser A (2010) Experimental study of bending behaviour of reinforcements. Exp Mech 50:333–351

Allaoui S, Hivet G, Wendling A, Ouagne P, Soulat D (2012) Influence of the dry woven fabrics meso-architecture on fabric/fabric contact behaviour. J Compos Mater 46(6):202–210

Lomov SV, Verpoest I (2006) Model of shear of woven fabric and parametric description of shear resistance of glass woven reinforcements. Compos Sci Tech 66(7–8):919–933

Sachs U, Fetfatsidis K, Schumacher J, Ziegmann G, Allaoui S, Hivet G, Vidal-Sallé E, Akkerman R (2012) A friction-test benchmark with Twintex PP. Key Eng mater 504–506:307–312

Acknowledgements

The work reported here has been carried out in the scope of the project LCM3M (ANR, French National Research Agency) and has been supported by EADS IW company.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Allaoui, S., Hivet, G., Soulat, D. et al. Experimental preforming of highly double curved shapes with a case corner using an interlock reinforcement. Int J Mater Form 7, 155–165 (2014). https://doi.org/10.1007/s12289-012-1116-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-012-1116-5