Abstract

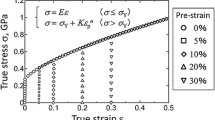

Biaxial stress tests and in-plane tension/compression tests of pure titanium sheet (JIS #1) have been carried out in order to elucidate its anisotropic plastic deformation behavior under linear stress paths. Contours of plastic work and the directions of plastic strain rates at different levels of plastic work have been precisely measured in the stress space. The measured work contours bulged significantly toward the equibiaxial direction and showed strong asymmetry, and moreover, changed its shapes significantly with increasing plastic work (differential work hardening). Using the data of the measured work contours, the applicability of selected anisotropic yield functions, i.e., Hill’s quadratic, the Yld2000-2d and Cazacu’s yield functions, to the accurate prediction of the plastic deformation behavior of the pure titanium has been discussed. It was found that these yield functions were not able to reproduce the measured data. A new method for analyzing the differential work hardening behavior of the pure titanium sheet has been developed. This method uses the spline function of Bezier curves which approximates a work contour, inspired by the methodology proposed by Vegter and Boogaard (Int. J. Plasticity 22 (2006) 557-580). The procedure for determining the spline function is described in detail. The calculated results have been in good agreement with the differential work hardening behavior of the pure titanium sheet.

Similar content being viewed by others

References

Kuwabara T (2007) Advances in experiments on metal sheets and tubes in support of constitutive modeling and forming simulations. Int J Plast 23:385–419

Hill R, Hecker SS, Stout MG (1994) An investigation of plastic flow and differential work hardening in orthotropic brass tubes under fluid pressure and axial load. Int J Solid Struct 31(21):2999–3021

Vegter H, Van den Boogaard AH (2006) A plane stress yield function for anisotropic sheet material by interpolation of biaxial stress states. Int J Plast 22:557–580

Kuwabara T, Katami C, Kikuchi M, Shindo T, Ohwue T (2001) Cup drawing of pure titanium sheet-finite element analysis and experimental Validation-. Proc 7th Int Conf Numerical Methods in Industrial Forming Processes: pp 781-787.

Kuwabara T, Ikeda S, Kuroda K (1998) Measurement and analysis of differential work hardening in cold-rolled steel sheet under biaxial tension. J Mater Process Tech 80–81:517–523

Kuwabara T, Ishiki M, Kuroda M, Takahashi S (2003) Yield locus and work-hardening behavior of a thin-walled steel tube subjected to combined tension-internal pressure. J Phys IV 105:347–354

Kuwabara T, Yoshida K, Narihara K, Takahashi S (2005) Anisotropic plastic deformation of extruded aluminum alloy tube under axial forces and internal pressure. Int J Plast 21–1:101–117

Kuwabara T, Horiuchi Y, Uema N, Ziegelheimova J (2008) Material testing method of applying in-plane combined tension-compression stresses to sheet specimen. IDDRG '08: pp 163–171

Lee D, Backofen WA (1966) An experimental determination of the yield locus for titanium and titanium-alloy sheet. Trans AIME 236:1077–1054

Kuwabara T, Morita Y, Miyashita Y, Takahashi S (1995) Elastic-plastic behavior of sheet metal subjected to in-plane reverse loading. Proc fifth international symposium on plasticity and its current applications: pp 841–844

Kuwabara T, Kumano Y, Ziegelheim J, Kurosaki I (2009) Tension-compression asymmetry of phosphor bronze for electronic parts and its effect on bending behavior. Int J Plast 25:1759–1776

Kuwabara T, Van Bael A, Iizuka E (2002) Measurement and analysis of yield locus and work hardening characteristics of steel sheets with different r-values. Acta Mater 50(14):3717–3729

Hill R (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc Roy Soc London A193:281–297

Barlat F, Brem JC, Yoon JW, Chung K, Dick RE, Lege DJ, Pourboghrat F, Choi S-H, Chu E (2003) Plane stress yield function for aluminum alloy sheet—part1: theory. Int J Plast 19(9):1297–1319

Cazacu O, Plukett B, Barlat F (2006) Orthotropic yield function for hexagonal closed packed metals. Int J Plast 22:1171–1194

Plunkett B, Cazacu O, Barlat F (2008) Orthotropic yield criteria for description of the anisotropy in tension and compression of sheet metals. Int J Plast 24:847–866

Ishiki M, Kuwabara T, Yamaguchi M, Maeda Y, Hayashida Y (2008) Differential wok hardening Behavior of pure titanium sheet under biaxial loading. 7th International conference and workshop on Numerical Simulation of 3D Sheet Metal Forming Processes: pp 161–166

Acknowledgements

We express deep appreciation to the Nonferrous Metals Division of the Ministry of Economy, Trade and Industry for the assistance rendered in various aspects of this research.

Author information

Authors and Affiliations

Corresponding author

Appendix: derivation of Eq. 2

Appendix: derivation of Eq. 2

When the coordinates of stress points making up a work contour in stress space are given in polar coordinates \( ({\sigma_x} = l\cos \varphi \), \( {\sigma_y} = l\sin \varphi ) \), a slope of a tangent to the work contour is given by

where l is expressed as a function of φ. \( l\prime \equiv dl/d\varphi \).

From the associated flow rule, a slope of a tangent to the work contour is determined as

using the direction of plastic strain rate β. From Eqs. A.1 and A.2,

Indefinite integral of Eq. A.3 with respect to φ leads to

Expressing β and φ using the cubic Bezier curve parameter, t, l is given as

where φ' ≡ dφ/dt.

Rights and permissions

About this article

Cite this article

Ishiki, M., Kuwabara, T. & Hayashida, Y. Measurement and analysis of differential work hardening behavior of pure titanium sheet using spline function. Int J Mater Form 4, 193–204 (2011). https://doi.org/10.1007/s12289-010-1024-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-010-1024-5