Abstract

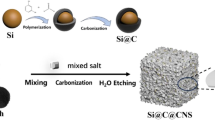

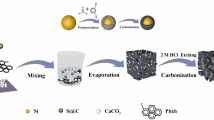

Si materials are widely considered to be the next-generation anode to replace the current commercial graphite-based anode due to its high energy density. However, the large volume variation of silicon during (de)lithiation process leads to rapid capacity decay, hindering its commercial application. Although the various hollow structure designs of Si nanomaterials have improved their cycling stability in the laboratory, the high-pressure calendering process in the current industrial electrode preparation process might collapse the hollow structure and weaken the structural advantages of hollow silicon anode materials. In this work, a silicon carbon composite material (Si@3DC) in which Si nanoparticles were anchored on a three-dimensional carbon framework through carbon films was prepared by a simple proton exchange method. The three-dimensional carbon framework with multiple hierarchical pores of Si@3DC was compatible with the high-pressure calendering process, but also could provide expansion space for Si nanoparticles during the lithiation process, and ensure good electronic and ionic conductivity. The carbon film on the surface of Si nanoparticles promoted the formation of stable solid electrolyte interphase (SEI) films, ensuring the good cycle stability of Si@3DC.

Similar content being viewed by others

References

Jia, H. P.; Li, X. L.; Song, J. H.; Zhang, X.; Luo, L. L.; He, Y.; Li, B. S.; Cai, Y.; Hu, S. Y.; Xiao, X. C. et al. Hierarchical porous silicon structures with extraordinary mechanical strength as high-performance lithium-ion battery anodes. Nat. Commun. 2020, 11, 1474.

Sung, J.; Kim, N.; Ma, J.; Lee, J. H.; Joo, S. H.; Lee, T.; Chae, S.; Yoon, M.; Lee, Y.; Hwang, J. et al. Subnano-sized silicon anode via crystal growth inhibition mechanism and its application in a prototype battery pack. Nat. Energy 2021, 6, 1164–1175.

Jeong, Y. K.; Huang, W.; Vilá, R. A.; Huang, W. X.; Wang, J. Y.; Kim, S. C.; Kim, Y. S.; Zhao, J.; Cui, Y. Microclusters of kinked silicon nanowires synthesized by a recyclable iodide process for high-performance lithium-ion battery anodes. Adv. Energy Mater. 2020, 10, 2002108.

Wang, F.; Wang, B.; Li, J. X.; Wang, B.; Zhou, Y.; Wang, D. L.; Liu, H. K.; Dou, S. X. Prelithiation: A crucial strategy for boosting the practical application of next-generation lithium ion battery. ACS Nano. 2021, 15, 2197–2218.

Xiang, B.; An, W. L.; Fu, J. J.; Mei, S. X.; Guo, S. G.; Zhang, X. M.; Gao, B.; Chu, P. K. Graphene-encapsulated blackberry-like porous silicon nanospheres prepared by modest magnesiothermic reduction for high-performance lithium-ion battery anode. Rare Metals 2021, 40, 383–392.

Zhang, F. Z.; Ma, Y. Y.; Jiang, M. M.; Luo, W.; Yang, J. P. Boron heteroatom-doped silicon-carbon peanut-like composites enables long life lithium-ion batteries. Rare Metals 2022, 41, 1276–1283.

Xu, Q.; Li, J. Y.; Sun, J. K.; Yin, Y. X.; Wan, L. J.; Guo, Y. G. Watermelon-inspired Si/C microspheres with hierarchical buffer structures for densely compacted lithium-ion battery anodes. Adv. Energy Mater. 2017, 7, 1601481.

Zhang, X. H.; Wang, D. H.; Qiu, X. Y.; Ma, Y. J.; Kong, D. B.; Müllen, K.; Li, X. L.; Zhi, L. J. Stable high-capacity and high-rate silicon-based lithium battery anodes upon two-dimensional covalent encapsulation. Nat. Commun. 2020, 11, 3826.

Wang, J. Y.; Cui, Y. Electrolytes for microsized silicon. Nat. Energy 2020, 5, 361–362.

Mu, T. S.; Shen, B. C.; Lou, S. F.; Zhang, Z. G.; Ren, Y.; Zhou, X. M.; Zuo, P. J.; Du, C. Y.; Ma, Y. L.; Huo, H. et al. Scalable mesoporous silicon microparticles composed of interconnected nanoplates for superior lithium storage. Chem.—Eng. J. 2019, 375, 121923.

Zeng, K.; Li, T.; Qin, X. Y.; Liang, G. M.; Zhang, L. H.; Liu, Q.; Li, B. H.; Kang, F. Y. A combination of hierarchical pore and buffering layer construction for ultrastable nanocluster Si/SiOx anode. Nano Res. 2020, 13, 2987–2993.

Liu, N. T.; Liu, J.; Jia, D. Z.; Huang, Y. D.; Luo, J.; Mamat, X.; Yu, Y.; Dong, Y. M.; Hu, G. Z. Multi-core yolk-shell like mesoporous double carbon-coated silicon nanoparticles as anode materials for lithium-ion batteries. Energy Storage Mater. 2019, 18, 165–173.

Mu, T. S.; Zhao, Y.; Zhao, C. T.; Holmes, N. G.; Lou, S. F.; Li, J. J.; Li, W. H.; He, M. X.; Sun, Y. P.; Du, C. Y. et al. Stable silicon anodes by molecular layer deposited artificial zincone coatings. Adv. Funct. Mater. 2021, 31, 2010526.

Liu, H. B.; Chen, Y.; Jiang, B.; Zhao, Y.; Guo, X. L.; Ma, T. L. Hollow-structure engineering of a silicon-carbon anode for ultra-stable lithium-ion batteries. Dalton Trans. 2020, 49, 5669–5676.

Xue, H. J.; Wu, Y. Q.; Wang, Z. M.; Shen, Y. B.; Sun, Q. J.; Liu, G.; Yin, D. M.; Wang, L. M.; Li, Q.; Ming, J. Unraveling the new role of metal-organic frameworks in designing silicon hollow nanocages for high-energy lithium-ion batteries. ACS Appl. Mater. Interfaces 2021, 13, 40471–40480.

Yi, Y.; Lee, G. H.; Kim, J. C.; Shim, H. W.; Kim, D. W. Tailored silicon hollow spheres with Mirococcuus for Li-ion battery electrodes. Chem.—Eng. J. 2017, 327, 297–306.

Wan, X. H.; Tang, Z. H.; Chen, J. L.; Xue, Y. C.; Zhang, J. H.; Guo, X. M.; Liu, Y. J.; Kong, Q. H.; Yuan, A. H.; Fan, H. Molten salt-assisted magnesiothermic reduction synthesis of spherical Si hollow structure as promising anode materials of lithium ion batteries. Chem. Lett. 2019, 48, 1547–1550.

Ma, T. Y.; Yu, X. N.; Li, H. Y.; Zhang, W. G.; Cheng, X. L.; Zhu, W. T.; Qiu, X. P. High volumetric capacity of hollow structured SnO2@Si nanospheres for lithium-ion batteries. Nano Lett. 2017, 17, 3959–3964.

Wang, J. Y.; Cui, Y.; Wang, D. Design of hollow nanostructures for energy storage, conversion and production. Adv. Mater. 2019, 31, 1801993.

Wang, F.; Wang, B.; Ruan, T. T.; Gao, T. T.; Song, R. S.; Jin, F.; Zhou, Y.; Wang, D. L.; Liu, H. K.; Dou, S. X. Construction of structure-tunable Si@void@C anode materials for lithium-ion batteries through controlling the growth kinetics of resin. ACS Nano. 2019, 13, 12219–12229.

Liu, N.; Wu, H.; McDowell, M. T.; Yao, Y.; Wang, C. M.; Cui, Y. A yolk-shell design for stabilized and scalable Li-ion battery alloy anodes. Nano Lett. 2012, 12, 3315–3321.

Chen, S. R.; Gordin, M. L.; Yi, R.; Howlett, G.; Sohn, H.; Wang, D. H. Silicon core-hollow carbon shell nanocomposites with tunable buffer voids for high capacity anodes of lithium-ion batteries. Phys. Chem. Chem. Phys. 2012, 14, 12741–12745.

Liu, N.; Lu, Z. D.; Zhao, J.; McDowell, M. T.; Lee, H. W.; Zhao, W. T.; Cui, Y. A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat. Nanotechnol. 2014, 9, 187–192.

Son, Y.; Kim, N.; Lee, T.; Lee, Y.; Ma, J.; Chae, S.; Sung, J.; Cha, H.; Yoo, Y.; Cho, J. Calendering-compatible macroporous architecture for silicon-graphite composite toward high-energy lithium-ion batteries. Adv. Mater. 2020, 32, 2003286.

Zhu, G. J.; Chao, D. L.; Xu, W. L.; Wu, M. H.; Zhang, H. J. Microscale silicon-based anodes: Fundamental understanding and industrial prospects for practical high-energy lithium-ion batteries. ACS Nano 2021, 15, 15567–15593.

Feng, L. X.; Ji, Y.; Zhu, Z. W.; Yu, P.; Fu, X. W.; Yang, M.; Wang, Y.; Yang, W. Rational design and superfast production of biomimetic, calendering-compatible, catalytic, sulfur-rich secondary particles for advanced lithium-sulfur batteries. Energy Storage Mater. 2021, 40, 415–425.

Ge, M. Z.; Cao, C. Y.; Biesold, G. M.; Sewell, C. D.; Hao, S. M.; Huang, J.; Zhang, W.; Lai, Y. K.; Lin, Z. Q. Recent advances in silicon-based electrodes: From fundamental research toward practical applications. Adv. Mater. 2021, 33, 2004577.

Smekens, J.; Gopalakrishnan, R.; Steen, N. V. D.; Omar, N.; Hegazy, O.; Hubin, A.; Van Mierlo, J. Influence of electrode density on the performance of Li-ion batteries: Experimental and simulation results. Energies 2016, 9, 104.

Meyer, C.; Bockholt, H.; Haselrieder, W.; Kwade, A. Characterization of the calendering process for compaction of electrodes for lithium-ion batteries. J. Mater. Process. Technol. 2017, 249, 172–178.

Zhu, R. Y.; Hu, X. J.; Chen, K.; Dang, J.; Wang, X. J.; Liu, X. J.; Wang, H. Double-shelled hollow carbon nanospheres as enclosed electrochemical reactors to enhance the lithium storage performance of silicon nanodots. J. Mater. Chem. A 2020, 8, 12502–12517.

Tian, H.; Tian, H. J.; Yang, W.; Zhang, F.; Yang, W.; Zhang, Q. B.; Wang, Y.; Liu, J.; Silva, S. R. P.; Liu, H. et al. Stable hollow-structured silicon suboxide-based anodes toward high-performance lithium-ion batteries. Adv. Funct. Mater. 2021, 31, 2101796.

Xie, J.; Tong, L.; Su, L. W.; Xu, Y. W.; Wang, L. B.; Wang, Y. H. Core-shell yolk-shell Si@C@void@C nanohybrids as advanced lithium ion battery anodes with good electronic conductivity and corrosion resistance. J. Power Sources 2017, 342, 529–536.

Wang, H. W.; Fu, J. Z.; Wang, C.; Wang, J. W.; Yang, A. K.; Li, C. C.; Sun, Q. F.; Cui, Y.; Li, H. Q. A binder-free high silicon content flexible anode for Li-ion batteries. Energy Environ. Sci. 2020, 13, 848–858.

Ren, W. F.; Li, J. T.; Huang, Z. G.; Deng, L.; Zhou, Y.; Huang, L.; Sun, S. G. Fabrication of Si nanoparticles@conductive carbon framework@polymer composite as high-areal-capacity anode of lithium-ion batteries. ChemElectroChem 2018, 5, 3258–3265.

Harpak, N.; Davidi, G.; Schneier, D.; Menkin, S.; Mados, E.; Golodnitsky, D.; Peled, E.; Patolsky, F. Large-scale self-catalyzed spongelike silicon nano-network-based 3D anodes for high-capacity lithium-ion batteries. Nano Lett. 2019, 19, 1944–1954.

Chang, P.; Liu, X. X.; Zhao, Q. J.; Huang, Y. Q.; Huang, Y. H.; Hu, X. L. Constructing three-dimensional honeycombed graphene/silicon skeletons for high-performance Li-ion batteries. ACS Appl. Mater. Interfaces 2017, 9, 31879–31886.

Huang, G.; Han, J. H.; Lu, Z.; Wei, D. X.; Kashani, H.; Watanabe, K.; Chen, M. W. Ultrastable silicon anode by three-dimensional nanoarchitecture design. ACS Nano 2020, 14, 4374–4382.

Lee, J.; Moon, J.; Han, S. A.; Kim, J.; Malgras, V.; Heo, Y. U.; Kim, H.; Lee, S. M.; Liu, H. K.; Dou, S. X. et al. Everlasting living and breathing gyroid 3D network in Si@SiOx/C nanoarchitecture for lithium ion battery. ACS Nano 2019, 13, 9607–9619.

He, Z. C.; Wu, F.; Guan, S. J.; Liu, L.; Li, J.; Huang, Y. D. Polyamide amine/aramid nanofiber composite aerogels as an ultrahigh capacity adsorbent for Congo red removal. J. Mater. Chem. A 2021, 9, 13320–13331.

Yang, B.; Wang, L.; Zhang, M. Y.; Li, W. W.; Zhou, Q. K.; Zhong, L. X. Advanced separators based on aramid nanofiber (ANF) membranes for lithium-ion batteries: A review of recent progress. J. Mater. Chem. A 2021, 9, 12923–12946.

Mu, T. S.; Lou, S. F.; Holmes, N. G.; Wang, C. H.; He, M. X.; Shen, B. C.; Lin, X. T.; Zuo, P. J.; Ma, Y. L.; Li, R. Y. et al. Reversible silicon anodes with long cycles by multifunctional volumetric buffer layers. ACS Appl. Mater. Interfaces 2021, 13, 4093–4101.

Salah, M.; Hall, C.; De Eulate, E. A.; Murphy, P.; Francis, C.; Kerr, R.; Pathirana, T.; Fabretto, M. Compressively stressed silicon nanoclusters as an antifracture mechanism for high-performance lithium-ion battery anodes. ACS Appl. Mater. Interfaces 2020, 12, 39195–39204.

Liang, G. M.; Qin, X. Y.; Zou, J. S.; Luo, L. Y.; Wang, Y. Z.; Wu, M. Y.; Zhu, H.; Chen, G. H.; Kang, F. Y.; Li, B. H. Electrosprayed silicon-embedded porous carbon microspheres as lithium-ion battery anodes with exceptional rate capacities. Carbon 2018, 127, 424–431.

Yang, Z. W.; Wu, C.; Li, S.; Qiu, L.; Yang, Z. G.; Zhong, Y. J.; Zhong, B. H.; Song, Y.; Wang, G. K.; Liu, Y. X. et al. A unique structure of highly stable interphase and self-consistent stress distribution radial-gradient porous for silicon anode. Adv. Funct. Mater. 2021, 2107897.

Chen, X. X.; Ge, G. F.; Wang, W. Y.; Zhang, B.; Jiang, J. J.; Yang, X. L.; Li, Y. Z.; Wang, L.; He, X. M.; Sun, Y. M. In situ formation of ionically conductive nanointerphase on Si particles for stable battery anode. Sci. China Chem. 2021, 64, 1417–1425.

Li, W. L.; Chen, K.; Xu, Q. C.; Li, X. Y.; Zhang, Q.; Weng, J.; Xu, J. Mo2C/C hierarchical double-shelled hollow spheres as sulfur host for advanced Li-S batteries. Angew. Chem., Int. Ed. 2021, 60, 21512–21520.

Wang, W. C.; Liang, H. C.; Zhang, L.; Savilov, S. V.; Ni, J. F.; Li, L. Carbon nanotube directed three-dimensional porous Li2FeSiO4 composite for lithium batteries. Nano Res. 2017, 10, 229–237.

Han, M.; Lin, Z.; Ji, X.; Mu, Y.; Li, J.; Yu, J. Growth of flexible and porous surface layers of vertical graphene sheets for accommodating huge volume change of silicon in lithium-ion battery anodes. Mater. Today Energy 2020, 17, 100445.

Zeng, W. W.; Wang, L.; Peng, X.; Liu, T. F.; Jiang, Y. Y.; Qin, F.; Hu, L.; Chu, P. K.; Huo, K. F.; Zhou, Y. H. Enhanced ion conductivity in conducting polymer binder for high-performance silicon anodes in advanced lithium-ion batteries. Adv. Energy Mater. 2018, 8, 1702314.

Meng, T.; Li, B.; Wang, Q. S.; Hao, J. N.; Huang, B. B.; Gu, F. L.; Xu, H. M.; Liu, P.; Tong, Y. X. Large-scale electric-field confined silicon with optimized charge-transfer kinetics and structural stability for high-rate lithium-ion batteries. ACS Nano 2020, 14, 7066–7076.

Li, P. C.; Chen, G.; Zhang, N.; Ma, R. Z.; Liu, X. H. β-cyclodextrin as lithium-ion diffusion channel with enhanced kinetics for stable silicon anode. Energy Environ. Mater. 2021, 4, 72–80.

Chen, M.; Zhou, Q. N.; Zai, J. T.; Iqbal, A.; Tsega, T.; Dong, B. X.; Liu, X. J.; Zhang, Y. C.; Yan, C. Y.; Zhao, L. et al. High power and stable P-doped yolk-shell structured Si@C anode simultaneously enhancing conductivity and Li+ diffusion kinetics. Nano Res. 2021, 14, 1004–1011.

Ge, M. Y.; Wi, S.; Liu, X.; Bai, J. M.; Ehrlich, S.; Lu, D. Y.; Lee, W. K.; Chen, Z. H.; Wang, F. Kinetic limitations in single-crystal high-nickel cathodes. Angew. Chem., Int. Ed. 2021, 66, 17350–17355.

Acknowledgements

This work was supported financially by the National Key Research and Development Program of China (No. 2017YFB0307701).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

12274_2022_4264_MOESM1_ESM.pdf

Construction of three-dimensional carbon framework-loaded silicon nanoparticles anchored by carbon film for high-performance lithium-ion battery anode materials

Rights and permissions

About this article

Cite this article

Wu, F., He, Z., Wang, M. et al. Construction of three-dimensional carbon framework-loaded silicon nanoparticles anchored by carbon film for high-performance lithium-ion battery anode materials. Nano Res. 15, 6168–6175 (2022). https://doi.org/10.1007/s12274-022-4264-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-022-4264-z