Abstract

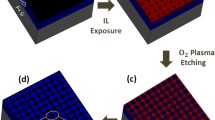

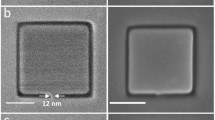

We present a lithography-free technique for fabrication of clean, high quality graphene devices. This technique is based on evaporation through hard Si shadow masks, and eliminates contaminants introduced by lithographical processes. We demonstrate that devices fabricated by this technique have significantly higher mobility values than those obtained by standard electron beam lithography. To obtain ultra-high mobility devices, we extend this technique to fabricate suspended graphene samples with mobilities as high as 120 000 cm2/(V·s).

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Zhang, Y. B.; Tan, Y. W.; Stormer, H. L.; Kim, P. Experimental observation of the quantum Hall effect and Berry’s phase in graphene. Nature 2005, 438, 201–204.

Novoselov, K. S.; Geim, A. K.; Morozov, S. V.; Jiang, D.; Katsnelson, M. I.; Grigorieva, I. V.; Dubonos, S. V.; Firsov, A. A. Two-dimensional gas of massless Dirac fermions in graphene. Nature 2005, 438, 197–200.

Novoselov, K. S.; Geim, A. K.; Morozov, S. V.; Jiang, D.; Zhang, Y.; Dubonos, S. V.; Grigorieva, I. V.; Firsov, A. A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669.

Lee, C.; Wei, X. D.; Kysar, J. W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388.

Bao, W. Z.; Miao, F.; Chen, Z.; Zhang, H.; Jang, W. Y.; Dames, C.; Lau, C. N. Controlled ripple texturing of suspended graphene and ultrathin graphite membranes. Nat. Nanotechnol. 2009, 4, 562–566.

Balandin, A. A.; Ghosh, S.; Bao, W. Z.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C. N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907.

Cheianov, V. V.; Fal’ko, V. I. Selective transmission of Dirac electrons and ballistic magnetoresistance of np junctions in graphene. Phys. Rev. B 2006, 74, 041403.

Katsnelson, M. I.; Novoselov, K. S.; Geim, A. K. Chiral tunnelling and the Klein paradox in graphene. Nat. Phys. 2006, 2, 620–625.

Peres, N. M. R.; Guinea, F.; Neto, A. H. C. Electronic properties of disordered two-dimensional carbon. Phys. Rev. B 2006, 73, 125411.

Du, X.; Skachko, I.; Barker, A.; Andrei, E. Y. Approaching ballistic transport in suspended graphene. Nat. Nanotechnol. 2008, 3, 491–495.

Bolotin, K. I.; Sikes, K. J.; Jiang, Z.; Fundenberg, G.; Hone, J.; Kim, P.; Stormer, H. L. Ultrahigh electron mobility in suspended graphene. Solid State Comm. 2008, 146, 351–355.

Chen, J. H.; Jang, C.; Adam, S.; Fuhrer, M. S.; Williams, E. D.; Ishigami, M. Charged-impurity scattering in graphene. Nat. Phys. 2008, 4, 377–381.

Moser, J.; Barreiro, A.; Bachtold, A. Current-induced cleaning of graphene. Appl. Phys. Lett. 2007, 91, 163513.

Girit, C. O.; Zettl, A. Soldering to a single atomic layer. Appl. Phys. Lett. 2007, 91, 193512.

Staley, N.; Wang, H.; Puls, C.; Forster, J.; Jackson, T. N.; McCarthy, K.; Clouser, B.; Liu, Y. Lithography-free fabrication of graphene devices. Appl. Phys. Lett. 2007, 90, 143518.

Deshmukh, M. M.; Ralph, D. C.; Thomas, M.; Silcox, J. Nanofabrication using a stencil mask. Appl. Phys. Lett. 1999, 75, 1631–1633.

Zhou Y. X.; Johnson, A. T. Simple fabrication of molecular circuits by shadow mask evaporation. Nano Lett. 2003, 3, 1371–1374.

Lishchynska, M.; Bourenkov, V.; van den Boogaart, M. A. F.; Doeswijk, L.; Brugger, J.; Greer, J. C. Predicting mask distortion, clogging and pattern transfer for stencil lithography. Microelectron. Eng. 2007, 84, 42–53.

Egger, S.; Ilie, A.; Fu, Y. T.; Chongsathien, J.; Kang, D. J.; Welland, M. E. Dynamic shadow mask technique: A universal tool for nanoscience. Nano Lett. 2005, 5, 15–20.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License ( https://creativecommons.org/licenses/by-nc/2.0 ), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Bao, W., Liu, G., Zhao, Z. et al. Lithography-free fabrication of high quality substrate-supported and freestanding graphene devices. Nano Res. 3, 98–102 (2010). https://doi.org/10.1007/s12274-010-1013-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-010-1013-5