Abstract

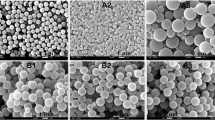

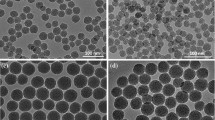

This paper explores the capability of the “surface-protected etching” process for the creation of rattle-type SiO2@void@SiO2 colloidal structures featuring a mesoporous silica shell and a mesoporous movable silica core. The surface-protected etching process involves stabilization of the particle surface using a polymer ligand, and then selective etching of the interior to form hollow structures. In this paper, this strategy has been extended to the formation of rattle-like structures by etching SiO2@SiO2 core shell particles which are synthesized by a two-step sol gel process. The key is to introduce a protecting polymer of polyvinylpyrrolidone (PVP) to the surface of both core and shell in order to tailor their relative stability against chemical etching. Upon reacting with NaOH, the outer layer silica becomes a hollow shell as only the surface layer is protected by PVP and the interior is removed, while the core remains its original size thanks to the protection of PVP on its surface. This process can be carried out at room temperature without the need of additional templates or complicated heterogeneous coating procedures. The etching process also results in the rattle-type colloids having mesoscale pores with two distinct average sizes. In our demonstration of a model drug delivery process, such mesoporous structures show an interesting two-step elution profile which is believed to be related to the unique porous rattle structures.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Sun, X. M.; Liu, J. F.; Li, Y. D. Oxides@C core-shell nanostructures: One-pot synthesis, rational conversion, and Li storage property. Chem. Mat. 2006, 18, 3486–3494.

Zhang, L.; Tu, R.; Dai, H. J. Parallel core-shell metal-dielectric-semiconductor germanium nanowires for high-current surround-gate field-effect transistors. Nano Lett. 2006, 6, 2785–2789.

Xie, R. G.; Chen, K.; Chen, X. Y.; Peng, X. G. InAs/InP/ZnSe core/shell/shell quantum dots as near-infrared emitters: Bright, narrow-band, non-cadmium containing, and biocompatible. Nano Res. 2008, 1, 457–464.

Wan, Y.; Min, Y. L.; Yu, S. H. Synthesis of silica/carbon-encapsulated core-shell spheres: Templates for other unique core shell structures and applications in in situ loading of noble-metal nanoparticles. Langmuir 2008, 24, 5024–5028.

Kamata, K.; Lu, Y.; Xia, Y. N. Synthesis and characterization of monodispersed core-shell spherical colloids with movable cores. J. Am. Chem. Soc. 2003, 125, 2384–2385.

Lou, X. W.; Archer, L. A.; Yang, Z. C. Hollow micro-/nanostructures: Synthesis and applications. Adv. Mater. 2008, 20, 3987–4019.

Zhang, Q.; Zhang, T. R.; Ge, J. P.; Yin, Y. D. Permeable silica shell through surface-protected etching. Nano Lett. 2008, 8, 2867–2871.

Sun, Y. G.; Wiley, B.; Li, Z. Y.; Xia, Y. N. Synthesis and optical properties of nanorattles and multiple-walled nanoshells/nanotubes made of metal alloys. J. Am. Chem. Soc. 2004, 126, 9399–9406.

Yin, Y. D.; Rioux, R. M.; Erdonmez, C. K.; Hughes, S.; Somorjai, G. A.; Alivisatos, A. P. Formation of hollow nanocrystals through the nanoscale Kirkendall effect. Science 2004, 304, 711–714.

Lee, J.; Park, J. C.; Song, H. A nanoreactor framework of a Au@SiO2 yolk/shell structure for catalytic reduction of p-nitrophenol. Adv. Mater. 2008, 20, 1523–1528.

Yin, Y. D.; Lu, Y.; Sun, Y. G.; Xia, Y. N. Silver nanowires can be directly coated with amorphous silica to generate well-controlled coaxial nanocables of silver/silica. Nano Lett. 2002, 2, 427–430.

Zhang, T. R.; Ge, J. P.; Hu, Y. X.; Zhang, Q.; Aloni, S.; Yin, Y. D. Formation of hollow silica colloids through a spontaneous dissolution-regrowth process. Angew. Chem. Int. Ed. 2008, 47, 5806–5811.

Wang, L.; Zhao, W. J.; Tan, W. H. Bioconjugated silica nanoparticles: Development and applications. Nano Res. 2008, 1, 99–115.

Zhang, T. R.; Zhang, Q.; Ge, J. P.; Goebl, J.; Sun, M. W.; Yan, Y. S.; Liu, Y. S.; Chang, C. L.; Guo, J. H.; Yin, Y. D. A self-templated route to hollow silica microspheres. J. Phys. Chem. C 2009, 113, 3168–3175.

Ikeda, S.; Ikoma, Y.; Kobayashi, H.; Harada, T.; Torimoto, T.; Ohtani, B.; Matsumura, M. Encapsulation of titanium(IV) oxide particles in hollow silica for size-selective photocatalytic reactions. Chem. Comm. 2007, 3753–3755.

Hu, Y. X.; Ge, J. G.; Sun, Y. G.; Zhang, T. R.; Yin, Y. D. A self-templated approach to TiO2 microcapsules. Nano Lett. 2007, 7, 1832–1836.

Deng, Y. H.; Qi, D. W.; Deng, C. H.; Zhang, X. M.; Zhao, D. Y. Superparamagnetic high-magnetization microspheres with an Fe3O4@SiO2 core and perpendicularly aligned mesoporous SiO2 shell for removal of microcystins. J. Am. Chem. Soc. 2008, 130, 28–29.

Stöber, W.; Fink, A.; Bohn, E. Controlled growth of monodisperse silica spheres in micron size range. J. Colloid Interface Sci. 1968, 26, 62–69.

Graf, C.; Dembski, S.; Hofmann, A.; Ruhl, E. A general method for the controlled embedding of nanoparticles in silica colloids. Langmuir 2006, 22, 5604–5610.

Ge, J. P.; Zhang, Q.; Zhang, T. R.; Yin, Y. D. Core-satellite nanocomposite catalysts protected by a porous silica shell: Controllable reactivity, high stability, and magnetic recyclability. Angew. Chem. Int. Ed. 2008, 47, 8924–8928.

Ohta, K. M.; Fuji, M.; Takei, T.; Chikazawa, M. Development of a simple method for the preparation of a silica gel based controlled delivery system with a high drug content. Eur. J. Pharm. Sci. 2005, 26, 87–96.

Liu, R.; Zhao, X.; Wu, T.; Feng, P. Y. Tunable redox-responsive hybrid nanogated ensembles. J. Am. Chem. Soc. 2008, 130, 14418–14419.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Zhang, Q., Ge, J., Goebl, J. et al. Rattle-type silica colloidal particles prepared by a surface-protected etching process. Nano Res. 2, 583–591 (2009). https://doi.org/10.1007/s12274-009-9060-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-009-9060-5