Abstract

The purpose of this review is to highlight developments in self-assembled nanostructured materials (i.e., mesoporous and nanoparticle-based materials) and their catalytic applications. Since there are many available reviews of metal-based nanoparticles as catalysts, this review will mainly focus on self-assembled oxide-based catalytic materials. The content includes: (1) design and synthetic strategies for self-assembled mesoporous catalysts, (2) polyoxometalate (POM)-based nanocatalysts, (3) dendrimer-based nanocatalysts, and (4) shaped nanomaterials and catalytic applications. We show that controlled assembly of molecules, crystalline seeds, and nano building blocks into organized mesoscopic structures or controlled morphologies is an effective approach for tailoring porosities of heterogeneous catalysts and controlling their catalytic activities.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

National Research Council Panel on New Directions in Catalytic Sciences and Technology, Catalysis Looks to the Future; National Academy Press: Washington D. C., 1992.

Huber, G. W.; Chheda, J. N.; Barrett, C. J.; Dumesic, J. A. Production of liquid alkanes by aqueous-phase processing of biomass-derived carbohydrates. Science 2005, 308, 1446–1450.

Armor, J. N. Catalysis and the hydrogen economy. Catal. Lett. 2005, 101, 131–135.

Olah, G. A. Beyond oil and gas: The methanol economy. Angew. Chem. Int. Edit. 2005, 44, 2636–2639.

Sheldon, R. A. The E factor: Fifteen years on. Green Chem. 2007, 9, 1273–1283.

Thomas, J. M.; Thomas, W. J. Principles and Practice of heterogeneous Catalysis; Wiley-VCH: Weinheim, 1996.

Jacobs, P. A.; Martens, J. A.; Weitkamp, J.; Beyer, H. K. Shape-selectivity changes in high-silica zeolites. Faraday Discuss. Chem. Soc. 1981, 72, 353–369.

Haag, W. O.; Lago, R. M.; Weisz, P. B. Transport and reactivity of hydrocarbon molecules in a shape-selective zeolite. Faraday Discuss. Chem. Soc. 1981, 72, 317–330.

Derouane, E. G.; Dejaifve, P.; Gabelica, Z.; Vedrine, J. C. Molecular shape selectivity of ZSM-5, modified ZSM-5 and ZSM-11 type zeolites. Faraday Discuss. Chem. Soc. 1981, 72, 331–344.

Thomas, J. M.; Millward, G. R.; Ramdas, S.; Bursill, L. A.; Audier, M. New methods for the structural characterization of shape-selective zeolites. Faraday Discuss. Chem. Soc. 1981, 72, 345–352.

Corma, A.; Rey, F.; Valencia, S.; Jorda, J. L.; Rius, J. A zeolite with interconnected 8-, 10- and 12-ring pores and its unique catalytic selectivity. Nat. Mater. 2003, 2, 493–497.

Bond, G. C.; Thompson, D. T. Catalysis by gold. Catal. Rev. Sci. Engin. 1999, 41, 319–388.

Bell, A. T. The impact of nanoscience on heterogeneous catalysis. Science 2003, 299, 1688–1691.

Herzing, A. A.; Kiely, C. J.; Carley, A. F.; Landon, P.; Hutchings, G. J. Identification of active gold nanoclusters on iron oxide supports for CO oxidation. Science 2008, 321, 1331–1335.

Nozaki, C.; Lugmair, C. G.; Bell, A. T.; Tilley, T. D. Synthesis, characterization, and catalytic performance of single-site iron(III) centers on the surface of SBA-15 silica. J. Am. Chem. Soc. 2002, 124, 13194–13203.

Fujdala, K. L.; Drake, I. J.; Bell, A. T.; Tilley, T. D. Atomic level control over surface species via a molecular precursor approach: Isolated Cu(I) sites and Cu nanoparticles supported on mesoporous silica. J. Am. Chem. Soc. 2004, 126, 10864–10866.

Maschmeyer, T.; Rey, F.; Sankar, G.; Thomas, J. M. Heterogeneous catalysis obtained by grafting metallocene complexes onto mesoporous silica. Nature 1995, 378, 159–162.

Corma, A. From microporous to mesoporous molecular sieve materials and their use in catalysis. Chem. Rev. 1997, 97, 2373–2419.

Breck, D. W. Zeolite Molecular Sieves; Robert E. Krieger Publishing Company Inc.: Malabar, FL, 1974.

Tao, Y. S.; Kanoh, H.; Abrams, L.; Kaneko, K. Mesoporemodified zeolites: Preparation, characterization, and applications. Chem. Rev. 2006, 106, 896–910.

van Donk, S.; Broersma, A.; Gijzeman, O. L. J.; van Bokhoven, J. A.; Bitter, J. H.; de Jong, K. P. Combined diffusion, adsorption, and reaction studies of n-hexane hydroisomerization over Pt/H-mordenite in an oscillating microbalance. J. Catal. 2001, 204, 272–280.

Herrmann, C.; Haas, J.; Fetting, F. Effect of the crystal size on the activity of ZSM-5 catalysts in various reactions. Appl. Catal. 1987, 35, 299–310.

Perez-Ramirez, J.; Kapteijn, F.; Groen, J. C.; Domenech, A.; Mul, G.; Moulijn, J. A. Steam-activated FeMFI zeolites. Evolution of iron species and activity in direct N2O decomposition. J. Catal. 2003, 214, 33–45.

Zhu, K.; Wang, D.; Liu, J. Self-assembled materials for catalysis. In Design of Heterogeneous Catalysis: New Approaches based on Synthesis, Characterization and Modeling, Ozkan, U. S. ed. Wiley-VCH: Weinheim, 2009.

Narayanan, R.; El-Sayed, M. A. Catalysis with transition metal nanoparticles in colloidal solution: Nanoparticle shape dependence and stability. J. Phys. Chem. B 2005, 109, 12663–12676.

Ott, L. S.; Finke, R. G. Transition-metal nanocluster stabilization for catalysis: A critical review of ranking methods and putative stabilizers. Coord. Chem. Rev. 2007, 251, 1075–1100.

Astruc, D.; Lu, F.; Aranzaes, J. R. Nanoparticles as recyclable catalysts: The frontier between homogeneous and heterogeneous catalysis. Angew. Chem. Int. Ed. 2005, 44, 7852–7872.

Chiola, V.; Ritsko, J. E.; Vanderpool, C. D. Process for producing low-bulk density silica. US Patent 3556725, 1971.

DiRenzo, F.; Cambon, H.; Dutartre, R. A 28-year-old synthesis of micelle-templated mesoporous silica. Micropor. Mater. 1997, 10, 283–286.

Yanagisawa, T.; Shimizu, T.; Kuroda, K.; Kato, C. The preparation of alkyltrimethylammonium-kanemite complexes and their conversion to microporous materials. Bull. Chem. Soc. Japan. 1990, 63, 988–992.

Inagaki, S.; Fukushima, Y.; Kuroda, K. Synthesis of highly ordered mesoporous materials from layered polysilicate. J. Chem. Soc. Chem. Commun. 1993, 680–682.

Kresge, C. T.; Leonowicz, M. E.; Roth, W. J.; Vartuli, J. C.; Beck, J. S. Ordered mesoporous molecular-sieves synthesized by a liquid-crystal template mechanism. Nature 1992, 359, 710–712.

Beck, J. S.; Vartuli, J. C.; Roth, W. J.; Leonowicz, M. E.; Kresge, C. T.; Schmitt, K. D.; Chu, C. T. W.; Olson, D. H.; Sheppard, E. W.; McCullen, S. B. et al. A new family of mesoporous molecular sieves prepared with liquid crystal templates. J. Am. Chem. Soc. 1992, 114, 10834–10843.

Huo, Q. S.; Margolese, D. I.; Ciesla, U.; Feng, P. Y.; Gier, T. E.; Sieger, P.; Leon, R.; Petroff, P. M.; Schuth, F.; Stucky, G. D. Generalized synthesis of periodic surfactant inorganic composite-materials. Nature 1994, 368, 317–321.

Huo, Q. S.; Margolese, D. I.; Stucky, G. D. Surfactant control of phases in the synthesis of mesoporous silicabased materials. Chem. Mater. 1996, 8, 1147–1160.

Yang, P. D.; Zhao, D. Y.; Margolese, D. I.; Chmelka, B. F.; Stucky, G. D. Generalized syntheses of largepore mesoporous metal oxides with semicrystalline frameworks. Nature 1998, 396, 152–155.

Bagshaw, S. A.; Prouzet, E.; Pinnavaia, T. J. Templating of mesoporous molecular-sieves by nonionic polyethylene oxide surfactants. Science 1995, 269, 1242–1244.

Tanev, P. T.; Pinnavaia, T. J. A neutral templating route to mesoporous molecular-sieves. Science 1995, 267, 865–867.

Zhao, D. Y.; Feng, J. L.; Huo, Q. S.; Melosh, N.; Fredrickson, G. H.; Chmelka, B. F.; Stucky, G. D. Triblock copolymer syntheses of mesoporous silica with periodic 50 to 300 angstrom pores. Science 1998, 279, 548–552.

Zhao, D. Y.; Huo, Q. S.; Feng, J. L.; Chmelka, B. F.; Stucky, G. D. Nonionic triblock and star diblock copolymer and oligomeric surfactant syntheses of highly ordered, hydrothermally stable, mesoporous silica structures. J. Am. Chem. Soc. 1998, 120, 6024–6036.

Chen, C. Y.; Burkett, S. L.; Li, H. X.; Davis, M. E. Studies on mesoporous materials II. Synthesis mechanism of MCM-41. Micropor. Mater. 1993, 2, 27–34.

Stucky, G. D.; Monnier, A; Schuth, F.; Huo, Q. S.; Margolese, D.; Kumar, D.; Krishnamurty, M.; Petroff, P.; Firouzi, A.; Janicke, M.; Chemlka, B. F. Molecular and atomic arrays in nanoporous and mesoporous materials synthesis. Mol. Cryst. Liq. Cryst. 1994, 240, 187–200.

Huo, Q. S.; Margolese, D. I.; Ciesla, U.; Demuth, D. G.; Feng, P. Y.; Gier, T. E.; Sieger, P.; Firouzi, A.; Chmelka, B. F.; Schuth, F.; Stucky, G. D. Organization of organicmolecules with inorganic molecular-species into nanocomposite biphase arrays. Chem. Mater. 1994, 6, 1176–1191.

Firouzi, A.; Kumar, D.; Bull, L. M.; Besier, T.; Sieger, P.; Huo, Q. S.; Walker, S. A.; Zasadzinski, J. A.; Glinka, C.; Nicol, J. et al. Cooperative organization of inorganicsurfactant and biomimetic assemblies. Science 1995, 267, 1138–1143.

Taguchi, A.; Schuth, F. Ordered mesoporous materials in catalysis. Micropor. Mesopor. Mater. 2005, 77, 1–45.

Tian, B. Z.; Liu, X. Y.; Tu, B.; Yu, C. Z.; Fan, J.; Wang, L. M.; Xie, S. H.; Stucky, G. D.; Zhao, D. Y. Self-adjusted synthesis of ordered stable mesoporous minerals by acidbase pairs. Nat. Mater. 2003, 2, 159–163.

On, D. T.; Desplantier-Giscard, D.; Danumah, C.; Kaliaguine, S. Perspectives in catalytic applications of mesostructured materials. Appl. Catal. A-Gen. 2003, 253, 545–602.

Yue, Y. H.; Gedeon, A.; Bonardet, J. L.; Melosh, N.; D’Espinose, J. B.; Fraissard, J. Direct synthesis of AlSBA mesoporous molecular sieves: Characterization and catalytic activities. Chem. Commun. 1999, 1967–1968.

Tuel, A. Modification of mesoporous silicas by incorporation of heteroelements in the framework. Micropor. Mesopor. Mater. 1999, 27, 151–169.

On, D. T.; Joshi, P. N.; Kaliaguine, S. Synthesis, stability and state of boron in boron-substituted MCM-41 mesoporous molecular sieves. J. Phys. Chem. 1996, 100, 6743–6748.

Fricke, R.; Kosslick, H.; Lischke, G.; Richter, M. Incorporation of gallium into zeolites: Syntheses, properties and catalytic application. Chem. Rev. 2000, 100, 2303–2405.

Kosslick, H.; Lischke, G.; Landmesser, H.; Parlitz, B.; Storek, W.; Fricke, R. Acidity and catalytic behavior of substituted MCM-48. J. Catal. 1998, 176, 102–114.

Kosslick, H.; Lischke, G.; Walther, G.; Storek, W.; Martin, A.; Fricke, R. Physico-chemical and catalytic properties of Al-, Ga- and Fe-substituted mesoporous materials related to MCM-41. Micropor. Mater. 1997, 9, 13–33.

Mokaya, R.; Jones, W. Post-synthesis grafting of Al onto MCM-41. Chem. Commun. 1997, 2185–2186.

O’Neil, A. S.; Mokaya, R.; Poliakoff, M. Supercritical fluid-mediated alumination of mesoporous silica and its beneficial effect on hydrothermal stability. J. Am Chem. Soc. 2002, 124, 10636–10637.

Corma, A.; Fornes, V.; Navarro, M. T.; Perez-Pariente, J. Acidity and stability of MCM-41 crystalline aluminosilicalites. J. Catal. 1994, 148, 569–574.

Gedeon, A.; Lassoued, A.; Bonardet, J. L.; Fraissard, J. Surface acidity diagnosis and catalytic activity of AlSBA materials obtained by direct synthesis. Micropor. Mesopor. Mater. 2001, 44–45, 801–806.

On, D. T.; Kaliaguine, S. Ultrastable and highly acidic, zeolite-coated mesoporous aluminosilicates. Angew. Chem. Int. Edit. 2002, 41, 1036–1040.

Huang, L. M.; Guo, W. P.; Deng, P.; Xue, Z. Y.; Li, Q. Z. Investigation of synthesizing MCM-41/ZSM-5 composites. J. Phys. Chem. B 2000, 104, 2817–2823.

Jacobsen, C. J. H.; Madsen, C.; Houzvicka, J.; Schmidt, I.; Carlsson, A. Mesoporous zeolite single crystals. J. Am. Chem. Soc. 2000, 122, 7116–7117.

Janssen, A. H.; Schmidt, I.; Jacobsen, C. J. H.; Koster, A. J.; de Jong, K. P. Exploratory study of mesopore templating with carbon during zeolite synthesis. Micropor. Mesopor. Mater. 2003, 65, 59–75.

Xiao, F. S.; Wang, L. F.; Yin, C. Y.; Lin, K. F.; Di, Y.; Li, J. X.; Xu, R. R.; Su, D. S.; Schlogl, R.; Yokoi, T.; Tatsumi, T. Catalytic properties of hierarchical mesoporous zeolites templated with a mixture of small organic ammonium salts and mesoscale cationic polymers. Angew. Chem.-Int. Edit. 2006, 45, 3090–3093.

Choi, M.; Cho, H. S.; Srivastava, R.; Venkatesan, C.; Choi, D. H.; Ryoo, R. Amphiphilic organosilane-directed synthesis of crystalline zeolite with tunable mesoporosity. Nat. Mater. 2006, 5, 718–723.

Christensen, C. H.; Johannsen, K.; Schmidt, I.; Christensen, C. H. Catalytic benzene alkylation over mesoporous zeolite single crystals: Improving activity and selectivity with a new family of porous materials. J. Am. Chem. Soc. 2003, 125, 13370–13371.

Tanev, P. T.; Chibwe, M.; Pinnavaia, T. J. Titanium-containing mesoporous molecular-sieves for catalytic-oxidation of aromatic-compounds. Nature 1994, 368, 321–323.

Zhang, W. H.; Froba, M.; Wang, J. L.; Tanev, P. T.; Wong, J.; Pinnavaia, T. J. Mesoporous titanosilicate molecular sieves prepared at ambient temperature by electrostatic (S+I−, S+X−I+) and neutral (S0I0) assembly pathways: A comparison of physical properties and catalytic activity for peroxide oxidations. J. Am. Chem. Soc. 1996, 118, 9164–9171.

Corma, A.; Navarro, M. T.; Perez-Pariente, J.; Sanchez, F. Zeolites and Related Microporous Materials: State of the Art. Stud. Surf. Sci. Catal. 1994, 84, 69–75.

Tozzola, G.; Mantegazza, M. A.; Ranghino, G.; Petrini, G.; Bordiga, S.; Ricchiardi, G.; Lamberti, C.; Zulian, R.; Zecchina, A. On the structure of the active site of Ti-silicalite in reactions with hydrogen peroxide: A vibrational and computational study. J. Catal. 1998, 179, 64–71.

Bordiga, S.; Bonino, F.; Damin, A.; Lamberti, C. Reactivity of Ti(IV) species hosted in TS-1 towards H2O2-H2O solutions investigated by ab initio cluster and periodic approaches combined with experimental XANES and EXAFS data: A review and new highlights. Phys. Chem. Chem. Phys. 2007, 9, 4854–4878.

Chen, H.; Dai, W. L.; Deng, J. F.; Fan, K. N. Novel heterogeneous W-doped MCM-41 catalyst for highly selective oxidation of cyclopentene to glutaraldehyde by aqueous H2O2. Catal. Lett. 2002, 81, 131–136.

Yang, X. L.; Dai, W. L.; Gao, R. H.; Chen, H.; Li, H. X.; Cao, Y.; Fan, K. N. Synthesis, characterization and catalytic application of mesoporous W-MCM-48 for the selective oxidation of cyclopentene to glutaraldehyde. J. Mol. Catal. A-Chem. 2005, 241, 205–214.

Reddy, K. M.; Moudrakovski, I.; Sayari, A. Synthesis of mesoporous vanadium silicate molecular-sieves. J. Chem. Soc. Chem. Commun. 1994, 1059–1060.

Reddy, J. S.; Sayari, A. Room-temperature synthesis of a highly-active vanadium-containing mesoporous molecular-sieve, V-HMS. J. Chem. Soc. Chem. Commun. 1995, 2231–2232.

Schlogl, R.; Abd Hamid, S. B. Nanocatalysis: Mature science revisited or something really new? Angew. Chem. Int. Edit. 2004, 43, 1628–1637.

Garcia, C.; Zhang, Y. M.; DiSalvo, F.; Wiesner, U. Mesoporous aluminosilicate materials with super-paramagnetic γ-Fe2O3 particles embedded in the walls. Angew. Chem. Int. Edit. 2003, 42, 1526–1530.

Dong, W. Y.; Sun, Y. J.; Lee, C. W.; Hua, W. M.; Lu, X. C.; Shi, Y. F.; Zhang, S. C.; Chen, J. M.; Zhao, D. Y. Controllable and repeatable synthesis of thermally stable anatase nanocrystal-silica composites with highly ordered hexagonal mesostructures. J. Am. Chem. Soc. 2007, 129, 13894–13904.

Corma, A.; Chane-Ching, J. Y.; Airiau, M.; Martinez, C. Synthesis and catalytic properties of thermally and hydrothermally stable, high-surface-area SiO2-CeO2 mesostructured composite materials and their application for the removal of sulfur compounds from gasoline. J. Catal. 2004, 224, 441–448.

Hu, J. C.; Chen, L. F.; Zhu, K. K.; Suchopar, A.; Richards, R. Aerobic oxidation of alcohols catalyzed by gold nanoparticles confined in the walls of mesoporous silica. Catal. Today 2007, 122, 277–283.

Wolf, A.; Schuth, F. A systematic study of the synthesis conditions for the preparation of highly active gold catalysts. Appl. Catal. A-Chem 2002, 226, 1–13.

Zhu, K. K.; Hu, J. C.; Richards, R. Aerobic oxidation of cyclohexane by gold nanoparticles immobilized upon mesoporous silica. Catal. Lett. 2005, 100, 195–199.

Song, H.; Rioux, R. M.; Hoefelmeyer, J. D.; Komor, R.; Niesz, K.; Grass, M.; Yang, P. D.; Somorjai, G. A. Hydrothermal growth of mesoporous SBA-15 silica in the presence of PVP-stabilized Pt nanoparticles: Synthesis, characterization, and catalytic properties. J. Am. Chem. Soc. 2006, 128, 3027–3037.

Schuth, F. Non-siliceous mesostructured and mesoporous materials. Chem. Mater. 2001, 13, 3184–3195.

Yang, P. D.; Zhao, D. Y.; Margolese, D. I.; Chmelka, B. F.; Stucky, G. D. Block copolymer templating syntheses of mesoporous metal oxides with large ordering lengths and semicrystalline framework. Chem. Mater. 1999, 11, 2813–2826.

Yuan, Q.; Yin, A. X.; Luo, C.; Sun, L. D.; Zhang, Y. W.; Duan, W. T.; Liu, H. C.; Yan, C. H. Facile synthesis for ordered mesoporous γ-aluminas with high thermal stability. J. Am. Chem. Soc. 2008, 130, 3465–3472.

Yoshitake, H.; Tatsumi, T. Vanadium oxide incorporated into mesoporous titania with a BET surface area above 1000 m2/g: Preparation, spectroscopic characterization, and catalytic oxidation. Chem. Mater. 2003, 15, 1695–1702.

Kapoor, M. P.; Ichihashi, Y.; Kuraoka, K.; Matsumura, Y. Catalytic methanol decomposition over palladium deposited on thermally stable mesoporous titanium oxide. J. Mol. Catal. A-Chem. 2003, 198, 303–308.

Serre, C.; Auroux, A.; Gervasini, A.; Hervieu, M.; Ferey, G. Hexagonal and cubic thermally stable mesoporous tin(IV) phosphates with acidic and catalytic properties. Angew. Chem. -Int. Edit. 2002, 41, 1594–1597.

Bhaumik, A.; Inagaki, S. Mesoporous titanium phosphate molecular sieves with ion-exchange capacity. J. Am. Chem. Soc. 2001, 123, 691–696.

Onaka, M.; Oikawa, T. Olefin metathesis over mesoporous alumina-supported rhenium oxide catalyst. Chem. Lett. 2002, 850–851.

Velu, S.; Kapoor, M. P.; Inagaki, S.; Suzuki, K. Vapor phase hydrogenation of phenol over palladium supported on mesoporous CeO2 and ZrO2. Appl. Catal. A-Chem 2003, 245, 317–331.

Farrusseng, D.; Schlichte, K.; Spliethoff, B.; Wingen, A.; Kaskel, S.; Bradley, J. S.; Schuth, F. Pore-size engineering of silicon imido nitride for catalytic applications. Angew. Chem. Int. Edit. 2001, 40, 4204–4207.

Wang, D. H.; Choi, D. W.; Yang, Z. G.; Viswanathan, V. V.; Nie, Z. M.; Wang, C. M.; Song, Y. J.; Zhang, J. G.; Liu, J. Synthesis and Li-ion insertion properties of highly crystalline mesoporous rutile TiO2. Chem. Mater. 2008, 20, 3435–3442.

Wang, D. H.; Ma, Z.; Dai, S.; Liu, J.; Nie, Z. M.; Engelhard, M. H.; Huo, Q. S.; Wang, C. M.; Kou, R. Lowtemperature synthesis of tunable mesoporous crystalline transition metal oxides and applications as Au catalyst supports. J. Phys. Chem. C 2008, 112, 13499–13509.

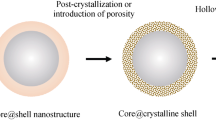

Wong, M. S.; Jeng, E. S.; Ying, J. Y. Supramolecular templating of thermally stable crystalline mesoporous metal oxides using nanoparticulate precursors. Nano Lett. 2001, 1, 637–642.

Chane-Ching, J. Y.; Cobo, F.; Aubert, D.; Harvey, H. G.; Airiau, M.; Corma, A. A general method for the synthesis of nanostructured large-surface-area materials through the self-assembly of functionalized nanoparticles. Chem-Eur. J. 2005, 11, 979–987.

Corma, A.; Atienzar, P.; Garcia, H.; Chane-Ching, J. Y. Hierarchically mesostructured doped CeO2 with potential for solar-cell use. Nat. Mater. 2004, 3, 394–397.

Corma, A.; Domine, M. E. Gold supported on a mesoporous CeO2 matrix as an efficient catalyst in the selective aerobic oxidation of aldehydes in the liquid phase. Chem. Commun. 2005, 4042–4044.

Pinnavaia, T. J. Intercalated clay catalysts. Science 1983, 220, 365–371.

Wang, L. Z.; Ebina, Y.; Takada, K.; Kurashima, K.; Sasaki, T. A new mesoporous manganese oxide pillared with double layers of alumina. Adv. Mater. 2004, 16, 1412–1416.

Kim, T. W.; Hwang, S. J.; Jhung, S. H.; Chang, J. S.; Park, H.; Choi, W.; Choy, J. H. Bifunctional heterogeneous catalysts for selective epoxidation and visible light driven photolysis: Nickel oxide-containing porous nanocomposite. Adv. Mater. 2008, 20, 539–542.

Ma, Y.; Suib, S. L.; Ressler, T.; Wong, J.; Lovallo, M.; Tsapatsis, M. Synthesis of porous CrOx pillared octahedral layered manganese oxide materials. Chem. Mater. 1999, 11, 3545–3554.

Yamanaka, S.; Kunii, K.; Xu, Z. L. Preparation and adsorption properties of microporous manganese titanate pillared with silica. Chem. Mater. 1998, 10, 1931–1936.

Wong, S. T.; Cheng, S. Synthesis and characterization of pillared buserite. Inorg. Chem. 1992, 31, 1165–1172.

Sasaki, T.; Watanabe, M. Osmotic swelling to exfoliation. Exceptionally high degrees of hydration of a layered titanate. J. Am. Chem. Soc. 1998, 120, 4682–4689.

Liu, Z. H; Ooi, K.; Kanoh, H.; Tang, W. P.; Tomida, T. Swelling and delamination behaviors of birnessitetype manganese oxide by intercalation of tetraalkylammoniumions. Langmuir 2000, 16, 4154–4164.

Hata, H.; Kobayashi, Y.; Salama, M.; Malek, R.; Mallouk, T. E. pH-dependent intercalation of gold nanoparticles into a synthetic fluoromica modified with poly(allylamine). Chem. Mater. 2007, 19, 6588–6596.

Hata, H.; Kubo, S.; Kobayashi, Y.; Mallouk, T. E. Intercalation of well-dispersed gold nanoparticles into layered oxide nanosheets through intercalation of a polyamine. J. Am. Chem. Soc. 2007, 129, 3064–3065.

Liu, Y.; Zhang, W. Z.; Pinnavaia, T. J. Steam-stable aluminosilicate mesostructures assembled from zeolite type Y seeds. J. Am. Chem. Soc. 2000, 122, 8791–8792.

Liu, Y.; Zhang, W. Z.; Pinnavaia, T. J. Steam-stable MSU-S aluminosilicate mesostructures assembled from zeolite ZSM-5 and zeolite beta seeds. Angew. Chem. Int. Edit. 2001, 40, 1255–1258.

Zhang, Z. T.; Han, Y.; Zhu, L.; Wang, R. W.; Yu, Y.; Qiu, S. L.; Zhao, D. Y.; Xiao, F. S. Strongly acidic and high-temperature hydrothermally stable mesoporous aluminosilicates with ordered hexagonal structure. Angew. Chem. Int. Edit. 2001, 40, 1258–1262.

Liu, J.; Shin, Y.; Nie, Z. M.; Chang, J. H.; Wang, L. Q.; Fryxell, G. E.; Samuels, W. D.; Exarhos, G. J. Molecular assembly in ordered mesoporosity: A new class of highly functional nanoscale materials. J. Phys. Chem. A 2000, 104, 8328–8339.

Margelefsky, E. L.; Zeidan, R. K.; Dufaud, V.; Davis, M. E. Organized surface functional groups: Cooperative catalysis via thiol/sulfonic acid pairing. J. Am. Chem. Soc. 2007, 129, 13691–13697.

Dufaud, V.; Davis, M. E. Design of heterogeneous catalysts via multiple active site positioning in organic-inorganic hybrid materials. J. Am. Chem. Soc. 2003, 125, 9403–9413.

Li, C.; Zhang, H. D.; Jiang, D. M.; Yang, Q. H. Chiral catalysis in nanopores of mesoporous materials. Chem. Commun. 2007, 547–558.

Raja, R.; Thomas, J. M.; Jones, M. D.; Johnson, B. F. G.; Vaughan, D. E. W. Constraining asymmetric organometallic catalysts within mesoporous supports boosts their enantioselectivity. J. Am. Chem. Soc. 2003, 125, 14982–14983.

Kaleta, W.; Nowinska, K. Immobilisation of heteropoly anions in Si-MCM-41 channels by means of chemical bonding to aminosilane groups. Chem. Commun. 2001, 535–536.

Chen, L. F.; Zhu, K.; Bi, L. H.; Suchopar, A.; Reicke, M.; Mathys, G.; Jaensch, H.; Kortz, U.; Richards, R. M. Solvent-free aerobic oxidation of n-alkane by iron(III)-substituted polyoxotungstates immobilized on SBA-15. Inorg. Chem. 2007, 46, 8457–8459.

Pope, M. T.; Muller, A. Polyoxometalate chemistry—An old field with new dimensions in several disciplines. Angew. Chem. Int. Ed. Engl. 1991, 30, 34–48.

Pope, M. T. Heteropoly and Isopoly Oxometalates; Springer-Verlag: Berlin, 1983.

Volkmer, D.; Du Chesne, A.; Kurth, D. G.; Schnablegger, H.; Lehmann, P.; Koop, M. J.; Muller, A. Toward nanodevices: Synthesis and characterization of the nanoporous surfactant-encapsulated Keplerate (DODA)40(NH4)2[(H2O)n⊂Mo132O372(CH3COO)30(H2O)72]. J. Am. Chem. Soc. 2000, 122, 1995–1998.

Fan, D. W.; Jia, X. F.; Tang, P. Q.; Hao, J. C.; Liu, T. B. Self-patterning of hydrophobic materials into highly ordered honeycomb nanostructures at the air/water interface. Angew. Chem. Int. Edit. 2007, 46, 3342–3345.

Neumann, R. Polyoxometallate complexes in organic oxidation chemistry. Prog. Inorg. Chem. 1998; 47, 317–370.

Kozhevnikov, I. V. Catalysis by heteropoly acids and multicomponent polyoxometalates in liquid-phase reactions. Chem. Rev. 1998, 98, 171–198.

Hill, C. L.; Prossermccartha, C. M. Homogeneous catalysis by transition-metal oxygen anion clusters. Coord. Chem. Rev. 1995, 143, 407–455.

Mizuno, N.; Misono, M. Heterogenous catalysis. Chem. Rev. 1998, 98, 199–217.

Mizuno, N.; Yamaguchi, K.; Kamata, K. Epoxidation of olefins with hydrogen peroxide catalyzed by polyoxometalates. Coord. Chem. Rev. 2005, 249, 1944–1956.

Liu, Y. Y.; Koyano, G.; Na, K.; Misono, M. Isomerizations of n-pentane and n-hexane over cesium hydrogen salt of 12-tungstophosphoric acid promoted by platinum. Appl. Catal. A-Gen. 1998, 166, L263–L265.

Misono, M. Heterogeneous catalysis by heteropoly compounds of molybdenum and tungsten. Catal. Rev.-Sci. Eng. 1987, 29, 269–321.

Yamada, T.; Yoshinaga, Y.; Okuhara, T. Synthesis and characterization of an ultramicroporous cesium hydrogen salt of 12-tungstophosphoric acid, Cs2.1H0.9PW12O40. Bull. Chem. Soc. Jpn. 1998, 71, 2727–2734.

Rhule, J. T.; Neiwert, W. A.; Hardcastle, K. I.; Do, B. T.; Hill, C. L. Ag5PV2Mo10O40, a heterogeneous catalyst for air-based selective oxidation at ambient temperature. J. Am. Chem. Soc. 2001, 123, 12101–12102.

Yamaguchi, K.; Mizuno, N. Heterogeneously catalyzed liquid-phase oxidation of alkanes and alcohols with molecular oxygen. New J. Chem. 2002, 26, 972–974.

Xi, Z. W.; Zhou, N.; Sun, Y.; Li, K. L. Reaction-controlled phase-transfer catalysis for propylene epoxidation to propylene oxide. Science 2001, 292, 1139–1141.

Xi, Z. W.; Wang, H. P.; Sun, Y.; Zhou, N.; Cao, G. Y.; Li, M. Direct epoxidation of olefins catalyzed by heteropolyoxometalates with molecular oxygen and recyclable reductant. J. Mol. Catal. A-Chem. 2001, 168, 299–301.

Uchida, S.; Hashimoto, M.; Mizuno, N. A breathing ionic crystal displaying selective binding of small alcohols and nitriles: K3[Cr3O(OOCH)6(H2O)3][alpha-SiW12O40]·16H2O. Angew. Chem. Int. Edit. 2002, 41, 2814–2817.

Uchida, S.; Mizuno, N. Zeotype ionic crystal of Cs5[Cr3O(OOCH)6(H2O)3][(alpha-CoW12O40]·7.5H2O with shape-selective adsorption of water. J. Am. Chem. Soc. 2004, 126, 1602–1603.

Uchida, S.; Mizuno, N. Unique guest-inclusion properties of a breathing ionic crystal of K3[Cr3O(OOCH)6(H2O)3][alpha-SiW12O40]·16H2O. Chem.-Eur. J. 2003, 9, 5850–5857.

Uchida, S.; Kawamoto, R.; Mizuno, N. Recognition of small polar molecules with an ionic crystal of alpha-Keggin-type polyoxometalate with a macrocation. Inorg. Chem. 2006, 45, 5136–5144.

Kawamoto, R.; Uchida, S.; Mizuno, N. Amphiphilic guest sorption of K2[Cr3O(OOCC2H5)6(H2O)3]2[alpha-SiW12O40] ionic crystal. J. Am. Chem. Soc. 2005, 127, 10560–10567.

Uchida, S.; Kawamoto, R.; Akatsuka, T.; Hikichi, S.; Mizuno, N. Structures and sorption properties of ionic crystals of macrocation-Dawson-type polyoxometalates with different charges. Chem. Mater. 2005, 17, 1367–1375.

Uchida, S.; Mizuno, N. Design and syntheses of nano-structured ionic crystals with selective sorption properties. Coord. Chem. Rev. 2007, 251, 2537–2546.

Okun, N. M.; Anderson, T. M.; Hill, C. L. [(Fe-III(OH2)2)3(A-alpha-PW9O34)2]9− on cationic silica nanoparticles, a new type of material and efficient heterogeneous catalyst for aerobic oxidations. J. Am. Chem. Soc. 2003, 125, 3194–3195.

Okun, N. M.; Ritorto, M. D.; Anderson, T. M.; Apkarian, R. P.; Hill, C. L. Polyoxometalates on cationic silica nanoparticles. Physicochemical properties of an electrostatically bound multi-iron catalyst. Chem. Mater. 2004, 16, 2551–2558.

Okun, N. M.; Anderson, T. M.; Hill, C. L. Polyoxometalates on cationic silica—Highly selective and efficient O2/air-based oxidation of 2-chloroethyl ethyl sulfide at ambient temperature. J. Mol. Catal. A-Chem. 2003, 197, 283–290.

Kwon, T.; Tsigdinos, G. A.; Pinnavaia, T. J. Pillaring of layered double hydroxides (LDHs) by polyoxometalate anions. J. Am. Chem. Soc. 1988, 110, 3653–3654.

Rives, V.; Ulibarri, M. A. Layered double hydroxides (LDH) intercalated with metal coordination compounds and oxometalates. Coord. Chem. Rev. 1999, 181, 61–120.

Liu, P.; Wang, H.; Feng, Z. C.; Ying, P. L.; Li, C. Direct immobilization of self-assembled polyoxometalate catalyst in layered double hydroxide for heterogeneous epoxidation of olefins. J. Catal. 2008, 256, 345–348.

Centi, G.; Perathoner, S. Catalysis by layered materials: A review. Micropor. Mesopor. Mat. 2008, 107, 3–15.

Jana, S. K.; Kubota, Y.; Tatsumi, T. Cobalt-substituted polyoxometalate pillared hydrotalcite: Synthesis and catalysis in liquid-phase oxidation of cyclohexanol with molecular oxygen. J. Catal. 2008, 255, 40–47.

Liu, Y. Y.; Murata, K.; Hanaoka, T.; Inaba, M.; Sakanishi, K. Syntheses of new peroxo-polyoxometalates intercalated layered double hydroxides for propene epoxidation by molecular oxygen in methanol. J. Catal. 2007, 248, 277–287.

Kwon, T.; Pinnavaia, T. J. Synthesis and properties of anionic clays pillared by [XM12O40]n-Keggin ions. J. Mol. Catal. 1992, 74, 23–33.

Kwon, T.; Pinnavaia, T. J. Pillaring of a layered double hydroxide by polyoxometalates with Keggin-ion structures. Chem. Mater. 1989, 1, 381–383.

Tomalia, D. A.; Naylor, A. M.; Goddard, W. A. Starburst dendrimers-molecular-level control of size, shape, surface-chemistry, topology, and flexibility from atoms to macroscopic matter. Angew. Chem. Int. Edit. Engl. 1990, 29, 138–175.

Astruc, D.; Chardac, F. Dendritic catalysts and dendrimers in catalysis. Chem. Rev. 2001, 101, 2991–3023.

Twyman, L. J.; King, A. S. H.; Martin, I. K. Catalysis inside dendrimers. Chem. Soc. Rev. 2002, 31, 69–82.

Scott, R. W. J.; Wilson, O. M.; Oh, S. K.; Kenik, E. A.; Crooks, R. M. Bimetallic palladium-gold dendrimerencapsulated catalysts. J. Am. Chem. Soc. 2004, 126, 15583–15591.

Brunner, H. Dendrizymes-expanded ligands for enantioselective catalysis. J. Organomet. Chem. 1995, 500, 39–46.

Niu, Y. H.; Yeung, L. K.; Crooks, R. M. Size-selective hydrogenation of olefins by dendrimer-encapsulated palladium nanoparticles. J. Am. Chem. Soc. 2001, 123, 6840–6846.

Balogh, L.; Tomalia, D. A. Poly(amidoamine) dendrimertemplated nanocomposites. 1. Synthesis of zerovalent copper nanoclusters. J. Am. Chem. Soc. 1998, 120, 7355–7356.

Scott, R. W. J.; Wilson, O. M.; Crooks, R. M. Synthesis, characterization, and applications of dendrimerencapsulated nanoparticles. J. Phys. Chem. B 2005, 109, 692–704.

Wilson, O. M.; Scott, R. W. J.; Garcia-Martinez, J. C.; Crooks, R. M. Synthesis, characterization, and structure-selective extraction of 1–3-nm diameter AuAg dendrimer-encapsulated bimetallic nanoparticles. J. Am. Chem. Soc. 2005, 127, 1015–1024.

Wang, G. Y.; Liu, X. Y.; Zhao, G. Synthesis of dendrimer-supported prolinols and their application in enantioselective reduction of ketones. Synlett 2006, 1150–1154.

Chung, Y. M.; Rhee, H. K. Design of silica-supported dendritic chiral catalysts for the improvement of enantio selective addition of diethylzinc to benzaldehyde. Catal. Lett. 2002, 82, 249–253.

Chung, Y. M.; Rhee, H. K. Dendritic chiral auxiliaries on silica: A new heterogeneous catalyst for enantioselective addition of diethylzinc to benzaldehyde. Chem. Commun. 2002, 238–239.

Scott, R. W. J.; Sivadinarayana, C.; Wilson, O. M.; Yan, Z.; Goodman, D. W.; Crooks, R. M. Titania-supported PdAu bimetallic catalysts prepared from dendrimerencapsulated nanoparticle precursors. J. Am. Chem. Soc. 2005, 127, 1380–1381.

Zeng, H. D.; Newkome, G. R.; Hill, C. L. Poly(polyoxometalate) dendrimers: Molecular prototypes of new catalytic materials. Angew. Chem. Int. Edit. 2000, 39, 1771–1774.

Kasuga, T.; Hiramatsu, M.; Hoson, A.; Sekino, T.; Niihara, K. Formation of titanium oxide nanotube. Langmuir 1998, 14, 3160–3163.

Sun, X. M.; Li, Y. D. Synthesis and characterization of ion-exchangeable titanate nanotubes. Chem. -Eur. J. 2003, 9, 2229–2238.

Bavykin, D. V.; Lapkin, A. A.; Plucinski, P. K.; Friedrich, J. M.; Walsh, F. C. TiO2 nanotube-supported ruthenium(III) hydrated oxide: A highly active catalyst for selective oxidation of alcohols by oxygen. J. Catal. 2005, 235, 10–17.

Bavykin, D. V.; Lapkin, A. A.; Plucinski, P. K.; Torrente-Murciano, L.; Friedrich, J. M.; Walsh, F. C. Deposition of Pt, Pd, Ru, and Au on the surfaces of titanate nanotubes. Top. Catal. 2006, 39, 151–160.

Xu, J. C.; Lu, M.; Guo, X. Y.; Li, H. L. Zinc ions surface-doped titanium dioxide nanotubes and its photocatalysis activity for degradation of methyl orange in water. J. Mol. Catal. A-Chem. 2005, 226, 123–127.

Huang, P. X.; Wu, F.; Zhu, B. L.; Gao, X. P.; Zhu, H. Y.; Yan, T. Y.; Huang, W. P.; Wu, S. H.; Song, D. Y. CeO2 nanorods and gold nanocrystals supported on CeO2 nanorods as catalyst. J. Phys. Chem. B 2005, 109, 19169–19174.

Wu, J. J.; Tseng, C. H. Photocatalytic properties of nc-Au/ZnO nanorod composites. Appl. Catal. B-Environ. 2006, 66, 51–57.

Tasker, P. W. The stability of ionic-crystal surfaces. J. Phys. C-Solid State Phys. 1979, 12, 4977–4984.

Arita, R.; Tanida, Y.; Entani, S.; Kiguchi, M.; Saiki, K.; Aoki, H. Polar surface engineering in ultrathin MgO(111)/Ag(111): Possibility of a metal-insulator transition and magnetism. Phys. Rev. B 2004, 69, 235423–235423.

Plass, R.; Egan, K.; Collazo-Davila, C.; Grozea, D.; Landree, E.; Marks, L. D.; Gajdardziska-Josifovska, M. Cyclic ozone identified in magnesium oxide (111) surface reconstructions. Phys. Rev. Lett. 1998, 81, 4891–4894.

Itoh, H.; Utamapanya, S.; Stark, J. V.; Klabunde, K. J.; Schlup, J. R. Nanoscale metal-oxide particles as chemical reagents-intrinsic effects of particle-size on hydroxyl content and on reactivity and acid-base properties of ultrafine magnesium oxide. Chem. Mater. 1993, 5, 71–77.

Stankic, S.; Muller, M.; Diwald, O.; Sterrer, M.; Knozinger, E.; Bernardi, J. Size-dependent optical properties of MgO nanocubes. Angew. Chem. Int. Edit. 2005, 44, 4917–4920.

Zhu, K. K.; Hu, J. C.; Kubel, C.; Richards, R. Efficient preparation and catalytic activity of MgO(111) nanosheets. Angew. Chem. Int. Edit. 2006, 45, 7277–7281.

Hu, J. C.; Zhu, K.; Chen, L. F.; Kubel, C.; Richards, R. MgO(111) nanosheets with unusual surface activity. J. Phys. Chem. C 2007, 111, 12038–12044.

Niederberger, M.; Garnweitner, G.; Pinna, N.; Antonietti, M. Nonaqueous and halide-free route to crystalline BaTiO3, SrTiO3, and (Ba,Sr)TiO3 nanoparticles via a mechanism involving C-C bond formation. J. Am. Chem. Soc. 2004, 126, 9120–9126.

Niederberger, M.; Bard, M. H.; Stucky, G. D. Benzyl alcohol and transition metal chlorides as a versatile reaction system for the nonaqueous and lowtemperature synthesis of crystalline nano-objects with controlled dimensionality. J. Am. Chem. Soc. 2002, 124, 13642–13643.

Hu, J. C.; Zhu, K. K.; Chen, L. F.; Yang, H. J.; Li, Z.; Suchopar, A.; Richards, R. Preparation and surface activity of single-crystalline NiO(111) nanosheets with hexagonal holes: A semiconductor nanospanner. Adv. Mater. 2008, 20, 267–271.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License ( https://creativecommons.org/licenses/by-nc/2.0 ), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Zhu, K., Wang, D. & Liu, J. Self-assembled materials for catalysis. Nano Res. 2, 1–29 (2009). https://doi.org/10.1007/s12274-009-9002-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-009-9002-2