Abstract

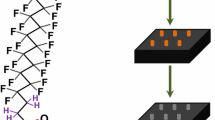

GaAs wafers have been decorated with Ag nanoplates through direct galvanic reaction between aqueous AgNO3 solutions and GaAs, resulting in Ag nanoplate/GaAs composite surfaces with varying hydrophobocity after the Ag nanoplates are coated with self-assembled monolayers of alkyl thiol molecules. By carefully controlling the reaction conditions, such as growth time and concentration of the AgNO3 solution, the size, thickness, and surface roughness of the individual Ag nanoplates can be tuned in order to produce different topographic structures and roughness of the composite surfaces, which in turn infl uences the hydrophobicity of the surfaces. The as-synthesized composite surfaces have been found to exhibit various levels of hydrophobicity and different wetting states such as the Wenzel wetting state, Cassie impregnating wetting state, and Cassie nonwetting state. The relationship between surface structure and hydrophobic state is also discussed.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Yuan, J.; Liu, X.; Akbulut, O.; Hu, J.; Suib, S. L.; Kong, J.; Stellacci, F. Superwetting nanowire membranes for selective absorption. Nat. Nanotechnol. 2008, 3, 332–336.

Lahann, J. Nanomaterials clean up. Nat. Nanotechnol. 2008, 3, 320–321.

Sethi, S.; Ge, L.; Ci, L.; Ajayan, P. M.; Dhinojwala, A. Gecko-inspired carbon nanotube-based self-cleaning adhesives. Nano Lett. 2008, 8, 822–825.

Sun, T.; Feng, L.; Gao, X.; Jiang, L. Bioinspired surfaces with special wettability. Acc. Chem. Res. 2005, 38, 644–652.

Feng, X.; Jiang, L. Design and creation of superwetting/antiwetting surfaces. Adv. Mater. 2006, 18, 3063–3078.

Nosonovsky, M.; Bhushan, B. Biologically inspired surfaces: Broadening the scope of roughness. Adv. Funct. Mater. 2008, 18, 1–13.

Roach, P.; Shirtcliffe, N. J.; Newton, M. I. Progress in superhydrophobic surface development. Soft Matter 2008, 4, 224–240.

Li, X.-M.; Reinhoudt, D.; Crego-Calama, M. What do we need for a superhydrophobic surface? A review on the recent progress in the preparation of superhydrophobic surfaces. Chem. Soc. Rev. 2007, 36, 1350–1368.

Zhang, X.; Shi, F.; Niu, J.; Jiang, Y.; Wang, Z. Superhydrophobic surfaces: From structural control to functional application. J. Mater. Chem. 2008, 18, 621–633.

Ma, M.; Hill, R. M. Superhydrophobic surfaces. Curr. Opin. Colloid Interface Sci. 2006, 11, 193–202.

Ou, J.; Perot, B.; Rothstein, J. P. Laminar drag reduction in microchannels using ultrahydrophobic surfaces. Phys. Fluids 2004, 16, 4635–4643.

Patankar, N. A. Transition between superhydrophobic states on rough surfaces. Langmuir 2004, 20, 7097–7102.

Patankar, N. A. On the modeling of hydrophobic contact angles on rough surfaces. Langmuir 2003, 19, 1249–1253.

Patankar, N. A. Mimicking the lotus effect: Influence of double roughness structures and slender pillars. Langmuir 2004, 20, 8209–8213.

Feng, L.; Zhang, Y.; Xi, J.; Zhu, Y.; Wang, N.; Xia, F.; Jiang, L. Petal effect: A superhydrophobic state with high adhesive force. Langmuir 2008, 24, 4114–4119.

Wenzel, R. N. Resistance of solid surfaces to wetting by water. J. Ind. Eng. Chem. 1936, 28, 988–994.

Cassie, B. D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551.

Nosonovsky, M.; Bhushan, B. Biominetic superhydrophobic surfaces: Multiscale approach. Nano Lett. 2007, 7, 2633–2637.

Cho, W. K.; Choi, I. S. Fabrication of hairy polymeric films inspired by Geckos: Wetting and high adhesion properties. Adv. Funct. Mater. 2008, 18, 1089–1096.

Cao, L.; Hu, H.-H.; Gao, D. Design and fabrication of micro-textures for inducing a superhydrophobic behavior on hydrophilic materials. Langmuir 2007, 23, 4310–4313.

Wang, M.-F.; Raghunathan, N.; Ziaie, B. A nonlithographic top-down electrochemical approach for creating hierarchical (micro-nano) superhydrophobic silicon surfaces. Langmuir 2007, 23, 2300–2303.

Winkleman, A.; Gotesman, G.; Yoffe, A.; Naaman, R. Immobilizing a drop of water: Fabricating highly hydrophobic surfaces that pin water droplets. Nano Lett. 2008, 8, 1241–1245.

Love, J. C.; Gates, B. D.; Wolfe, D. B.; Paul, K. E.; Whitesides, G. M. Fabrication and wetting properties of metallic half-shells with submicron diameters. Nano Lett. 2002, 2, 891–894.

Larmour, I. A.; Bell, S. E. J.; Saunders, G. C. Remarkably simple fabrication of superhydrophobic surfaces using electroless galvanic deposition. Angew. Chem. Int. Ed. 2007, 46, 1710–1712.

Li, Y.; Li, C.; Cho, S. O.; Duan, G.; Cai, W. Silver hierarchical bowl-like array: Synthesis, superhydrophobicity, and optical properties. Langmuir 2007, 23, 9802–9807.

Zhao, Y.; Lu, Q.; Chen, D.; Wei, Y. Superhydrophobic modification of polyimide films based on gold-coated porous silver nanostructures and self-assembled monolayers. J. Mater. Chem. 2006, 16, 4504–4509.

Zhao, N.; Shi, F.; Wang, Z.; Zhang, X. Combining layer-by-layer assembly with electrodeposition of silver aggregates for fabricating superhydrophobic surfaces. Langmuir 2005, 21, 4713–4716.

Jiang, Y.; Wang, Z.; Yu, X.; Shi, F.; Xu, H.; Zhang, X. Self-assembled monolayers of dendron thiols for electrodeposition of gold nanostructures: Toward fabrication of superhydrophobic/superhydrophilic surfaces and pH-responsive surfaces. Langmuir 2005, 21, 1986–1990.

Wang, S.; Feng, L.; Liu, H.; Sun, T.; Zhang, X.; Jiang, L.; Zhu, D. Manipulation of surface wettability between superhydrophobicity and superhydrophilicity on copper films. ChemPhysChem 2005, 6, 1475–1478.

Mundo, R. D.; Palumbo, F.; d’Agostino, R. Nanotexturing of polystyrene surface in fluorocarbon plasmas: From sticky to slippery superhydrophobicity. Langmuir 2008, 24, 5044–5051.

Gao, L.; McCarthy, T. J. A commercially available perfectly hydrophobic material. Langmuir 2007, 23, 9125–9127.

Xie, Q.; Fan, G.; Zhao, N.; Guo, X.; Xu, J.; Dong, J.; Zhang, L.; Zhang, Y.; Han, C. C. Facile creation of a bionic super-hydrophobic block copolymer surface. Adv. Mater. 2004, 16, 1830–1833.

Balu, B.; Breedveld, V.; Hess, D. W. Fabrication of “rolloff” and “sticky” superhydrophobic cellulose surfaces via plasma processing. Langmuir 2008, 24, 4785–4790.

Jin, M.; Feng, X.; Feng, L.; Sun, T.; Zhai, J.; Li, T.; Jiang, L. Superhydrophobic aligned polystyrene nanotube fi lms with high adhesive force. Adv. Mater. 2005, 17, 1977–1981.

Zhai, L.; Cebeci, F. C.; Cohen, R. E.; Rubner, M. F. Stable superhydrophobic coating from polyelectrolyte multilayers. Nano Lett. 2004, 4, 1349–1353.

Namavar, F.; Cheung, C. L.; Sabirianov, R. F.; Mei, W.-N.; Zeng, X. C.; Wang, G.; Haider, H.; Garvin, K. L. Lotus effect in engineered zirconia. Nano Lett. 2008, 8, 988–996.

Coffinier, Y.; Janel, S.; Addad, A.; Blossey, R.; Gengembre, L.; Payen, E.; Boukherroub, R. Preparation of superhydrophobic silicon oxide nanowire surfaces. Langmuir 2007, 23, 1608–1611.

Ming, W.; Wu, D.; van Benthem, R.; de With, G. Superhydrophobic films from raspberry-like particles. Nano Lett. 2005, 5, 2298–2301.

Nakajima, A.; Hashimoto, K.; Watanabe, T. Transparent superhydrophobic thin fi lms with self-cleaning properties. Langmuir 2000, 16, 7044–7047.

Pastine, S. J.; Okawa, D.; Kessler, B.; Rolandi, M.; Llorente, M.; Zettl, A.; Frechet, J. M. J. A facile and patternable method for the superface modification of carbon nanotube forests using perfl uoroarylazides. J. Am. Chem. Soc. 2008, 130, 4238–4239.

Zhu, L.; Xiu, Y.; Xu, J.; Tamirisa, P. A.; Hess, D. W.; Wong, C. P. Superhydrophobicity on two-tier rough surfaces fabricated by controlled growth of aligned carbon nanotube arrays coated with fluorocarbon. Langmuir 2005, 21, 11208–11212.

Lau, K. K. S.; Bico, J.; Teo, K. B. K.; Chhowalla, M.; Amaratunga, G. A. J.; Milne, W. I.; McKinley, G. H.; Gleason, K. K. Superhydrophobic carbon nanotube forests. Nano Lett. 2003, 3, 1701–1705.

Wang, S.; Jiang, L. Definition of superhydrophobic states. Adv. Mater. 2007, 19, 3423–3424.

Lafuma, A.; Quere, D. Superhydrophobic states. Nat. Mater. 2003, 2, 457–460.

Bormashenko, E.; Pogreb, R.; Stein, T.; Whyman, G.; Erlich, M.; Musin, A.; Machavariani, V.; Aurbach, D. Characterization of rough surfaces with vibrated drops. Phys. Chem. Chem. Phys. 2008, 10, 4056–4061.

McHale, G. Cassie and Wenzel: were they really so wrong? Langmuir 2007, 23, 8200–8205.

Marmur, A. Soft contact: measurement and interpretation of contact angles. Soft Matter 2006, 2, 12–17.

Sun, Y.; Wiederrecht, G. P. Surfactantless synthesis of silver nanoplates and their application in SERS. Small 2007, 3, 1964–1975.

Sun, Y. Direct growth of dense, pristine metal nanoplates with well-controlled dimensions on semiconductor substrates. Chem. Mater. 2007, 19, 5845–5847.

Sun, Y.; Yan, H.; Wu, X. Effects of visible and synchrotron X-ray radiation on the growth of silver nanoplates on n-GaAs wafers: A comparative study. Appl. Phys. Lett. 2008, 92, 183109.

Sun, Y.; Yan, H.; Wiederrecht, G. P. Comparative study on the growth of silver nanoplates on GaAs substrates by electron microscopy, synchrotron X-ray diffraction, and optical spectroscopy. J. Phys. Chem. C 2008, 112, 8928–8938.

Hong, X.; Gao, X.; Jiang, L. Application of superhydrophobic surface with high adhesive force in no lost transport of superparamagnetic microdroplet. J. Am. Chem. Soc. 2007, 129, 1478–1479.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Electronic supplementary material

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License ( https://creativecommons.org/licenses/by-nc/2.0 ), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Sun, Y., Qiao, R. Facile tuning of superhydrophobic states with Ag nanoplates. Nano Res. 1, 292–302 (2008). https://doi.org/10.1007/s12274-008-8030-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-008-8030-7