Abstract

Pertactin (PRN), a non-fimbrial outer membrane protein of Bordetella pertussis, is the limiting component of the acellular pertussis vaccine because of its low concentration. This study aimed to develop a large-scale urea-based process for PRN extraction from B. pertussis. Cell pellet processing conditions, including freezing and thawing, were found to substantially affect PRN yield. A single cycle of rapid freezing of the cell pellet at − 30 °C with slow thawing at 5 ± 3 °C resulted in up to fivefold higher PRN yield than condition without freezing and thawing. The search for urea treatment conditions was also conducted, and 5 M urea treatment for 2 h was the optimal condition. The developed urea-based process was applied to 50 L culture scale, and residual impurities were removed by sequential anion exchange, hydrophobic interaction and gel filtration chromatography and resulted in PRN with a purity of over 95% at a yield of 33.2%. From 50 L culture broth, the final yield of PRN per cell pellet was 0.23 mg/g (wet weight). Thus, a large-scale production process for high-quality PRN from B. pertussis was developed based on urea extraction process. The results may serve as a reference for production of other membrane proteins.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Pertussis, also known as whooping cough, is a highly contagious respiratory disease transmitted directly between humans [1, 2]. Pertussis is caused by the bacterium Bordetella pertussis and can affect people of all ages, with serious or even deadly outcomes for babies under one year of age [2,3,4,5]. The whole-cell pertussis (wP) vaccine developed in the late 1940s protected against pertussis and rapidly reduced incidence [6]. However, adverse reactions were observed at a high frequency after administration of the wP vaccine [7,8,9], underlining the need for a safer pertussis vaccine [5].

Acellular pertussis (aP) vaccine comprising several components including such as pertussis toxin (PT), filamentous hemagglutinin (FHA) and pertactin (PRN) from B. pertussis is safer and less reactogenic than the wP vaccine [9, 10]. Among the components of aP vaccine, PRN, a non-fimbrial outer membrane, represents a limiting factor in the large-scale production of aP vaccine because of its very low concentration, less than 1% of the total cellular protein [11,12,13,14].

PRN, also known as P.69, has an apparent molecular weight of 69 kDa in gel electrophoresis and is an autotransporter protein initially synthesized as a 93 kDa precursor [15]. Following cleavage, PRN remains loosely associated with the cell surface in a non-covalent manner and can be released by heat treatment [16] or by chaotropic compounds such as urea [17]. However, because of low abundance of PRN, it is challenging to purify protein in the presence of impurities from both the cell pellet and remaining culture medium while maintaining structural and functional integrity.

Heat treatment of Gram-negative bacteria increases the hydrophobicity of the cell surface, causing the release of outer membrane proteins through partial disruption of the outer membrane [18]. Although heat treatment is relatively easy to perform, it can only be used for extraction of heat-resistant outer membrane proteins as it can induce irreversible protein denaturation and aggregation [19]. In contrast, chemical treatment using chaotropic compounds disrupts hydrogen bonds and hydrophobic interactions and can release outer membrane proteins from Gram-negative bacteria [20, 21]. Urea is the chaotrope most commonly used for membrane protein extraction because urea-based denaturation maintains solubility and exhibits good reversibility [22].

Chemical treatment with concentrations of urea below 8 M leads to relatively weak and reversible structural changes and is fairly easy to carry out at scale [23]. Although an additional step is required for urea removal, we believe that urea treatment represents a better method for extracting PRN from B. pertussis than other methods as it has a better chance of maintaining the intact PRN structure that is a prerequisite for retaining immunogenicity in a vaccine context. Although urea has been used for PRN extraction (Jackson, G., Fahim, R., Tan, L., Chong, P., Vose, J. and Klein, EP0527753 B2, 2003), studies on the conditions affecting the PRN yield have not been fully substantiated.

In this study, we aimed to optimize a urea-based process, including cell pellet processing, for PRN extraction from B. pertussis and scaled it up to a 50 L bioreactor as a model for large-scale production of this element of the aP vaccine.

2 Materials and methods

2.1 Microorganism

B. pertussis Tohama Phase I strain was isolated from a case of pertussis in Japan in the 1950s and widely used as vaccine strain. B. pertussis Tohama Phase I strain was used for all experiments and was acquired from Korea National Institute of Health.

2.2 Culture medium and culture conditions

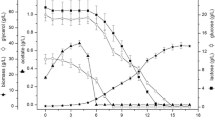

Modified Stainer-Scholte medium was used for the starter culture and large-scale fermentation. Its composition was (g/L): sodium L-glutamate, 10.0; NaCl, 2.0; casamino acids, 2.5; KH2PO4, 0.5; L-proline, 0.2; KCl, 0.2; MgCl2‧6H2O, 0.1; CaCl2‧2H2O, 0.026; Trizma base, 3.0; soluble starch, 0.5; and heptakis, 0.5. The pH was adjusted to 7.4 with 38% (w/w) HCl. For the starter, cells were inoculated at 0.4% (v/v) into 250-mL Erlenmeyer flasks containing 50 mL media and cultured at 35 °C and 130 rpm for 23 h. For bioreactor fermentation, bioreactors were inoculated at 10% (v/v) with starter cultures. Bioreactor fermentations were run for 25 h in a Bioflo 115 (Eppendorf) with a working volume of 2 L or a Biostat D-DCU (Sartorius) with a working volume of 50 L or 200 L. Operating conditions were 0.2 vvm, 35 °C and 130 rpm, and the pH was automatically controlled at 7.4.

2.3 Cell harvesting

For 2 L or 50 L cultures, cell pellets were obtained by high-speed centrifugation at 12,230 g for 50 min at 5 ± 3 °C using an Avanti JXN-26 centrifuge (Beckman Coulter). The cell pellets were stored at − 30 °C or lower and used for chemical treatment experiments. For 200 L culture, a sequential centrifugation method was used to obtain cell pellets. The culture supernatant was separated from the slurry by continuous centrifugation using a self-cleaning disk centrifuge (MBPX 404 SGP-31; Alfa Laval) at room temperature (RT) for 2 h at a flow rate of 100 L/h and 9,500 rpm. The separated slurry was then subjected to high-speed centrifugation at 12,230 g for 50 min at 5 ± 3 °C to prepare cell pellets. The pellets were stored at − 30 °C or lower.

2.4 Extraction of PRN associated with the cell surface

For PRN extraction, unless otherwise specified, cell pellets thawed at RT were resuspended in 4.0–6.0 M urea containing four times the cell pellet weight of urea. The cell suspension was stirred at 280 rpm for 1.5–3.0 h at RT using a magnetic stirrer and then centrifuged at 12,230 g for 1.5 h at 5 ± 3 °C to remove cell debris. Supernatants collected after centrifugation were filtered through a 0.22 µm filter and stored at 5 ± 3 °C.

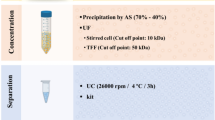

2.5 PRN purification

PRN in filtered supernatant was sequentially purified using anion exchange chromatography (AEC), hydrophobic interaction chromatography (HIC) and gel filtration chromatography (GFC) using Q Sepharose XL, Butyl Sepharose 4 FF and Sephacryl S-100 HR resins (Cytiva), respectively. Column chromatographic purification was carried out using an AKTA Explorer and Pilot (Cytiva) with UNICORN software (Cytiva). Purified PRN antigen was treated with formalin to abrogate residual toxicity.

2.6 Sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS–PAGE)

SDS–PAGE used on a Novex 4–20% Tris-glycine gel (Thermo Fisher Scientific). Molecular weights were estimated by comparison with standard proteins (Seeblue Plus 2 pre-stained standard; Invitrogen).

2.7 Lowry assay

Protein concentrations were determined using a Modified Lowry Protein Assay Kit (Thermo Fisher Scientific) according to the manufacturer’s instructions.

2.8 Enzyme-linked immunosorbent assay (ELISA)

ELISA was used to determine PRN concentrations. Flat-bottomed polystyrene microtiter plates were coated with 2 µg/mL in-house anti-PRN antibody. The wells were washed, and diluted test samples and reference in-house PRN protein were added and incubated for 1.5 h at 37 °C. After washing, the plates were incubated for 1.5 h with biotin-labeled anti-PRN antibody (1:2,000). Next, 100 µL of streptavidin–horseradish peroxidase (Thermo Fisher Scientific, 1:400) was added to each well and the plates were incubated 1.0 h at 37 °C. After washing, 3,3′,5,5′-tetramethylbenzidine solution (Thermo Fisher Scientific) was added to each well and the plate was incubated for 10 min at RT. Then, the plate was read at 450 nm using a Micro ELISA autoreader (Spectramax; molecular devices).

2.9 Statistical analysis

Statistical analyses were performed using Prism 9.5 (GraphPad). To determine statistically significant differences between groups, either the ordinary ANOVA test or two-way ANOVA was used, depending on the data type. Significant differences are indicated by *p < 0.05, **p < 0.01, ***p < 0.001, and ****p < 0.0001. ns indicates no significant difference.

3 Results and discussion

As illustrated in Fig. 1, the three antigenic components of aP vaccine from wild-type B. pertussis are PT, FHA, and PRN. Among them PT and FHA are abundant in culture supernatant and can be obtained relatively easily using a purification process. In contrast, PRN, an outer membrane protein is expressed at very low levels and is present both in culture supernatant and in cell membrane.

When purifying PRN from culture supernatant as opposed to cell membrane, cross-contamination with PT may occur, requiring an additional detoxification step to ensure vaccine safety. This detoxification process can affect the efficacy of a vaccine by affecting the structure of the PRN antigen. It has been reported that a sufficient amount of PRN can be obtained from cell membrane [13]. Therefore, in this study, only PRN from cell membrane was used for further studies.

3.1 Membrane protein extraction using heat and chemical treatment

Outer membrane proteins, including PRN, can be extracted from cell pellets by breaking electrostatic and/or hydrogen bonds using relatively mild techniques. The two most widely used methods for extracting membrane proteins are heat and chemical extraction. When outer membrane proteins were extracted from cell pellets using heat treatment under various conditions as previously described [13], the total protein recovery determined was 23.5–49.6 mg per approximately 20 g wet weight (Table S1). In contrast, the total protein extracted from cell pellets using treatment with 4.0 M urea treatment for 2 h at RT was 80.1 mg per approximately 20 g wet weight (Table S1). Outer membrane proteins, including PRN, were extracted from B. pertussis using 4.0–6.0 M urea, but when urea concentrations of higher than 6.0 M were used, cell debris could not be adequately removed on centrifugation due to elevated viscosity.

3.2 Effect of cell pellet preparation and storage conditions on PRN extraction

To attempt PRN production on a manufacturing scale, a large volume of culture broth was processed by continuous-flow centrifugation with cells obtained in the form of a slurry. Cell pellets were obtained from the slurry by ultracentrifugation at 12,230 g for 50 min at 5 ± 3 °C (Fig. 1).

If the cell slurry can be stored for several days without loss of PRN activity, this provides more flexibility in downstream processing. Cell pellet preparation and storage conditions, which are expected to induce structural changes in the cell membrane, may affect PRN extraction [24].

To determine optimal conditions for cell pellet preparation, storage and thawing, approximately 16 g wet weight of cell pellets was prepared from 2 L portions of culture broth from the same lot under various conditions (summarized in Table 1 for T1–T22). PRN was extracted from the cell pellets using 64 mL 4.5 M urea. To evaluate the effect of cell slurry storage on PRN extraction, T1–T11 were not stored under slurry conditions prior to ultracentrifugation, whereas T12–T22 were stored at 5 ± 3 °C for 3 days.

In preliminary work, we found that freezing of cell pellets had a substantial effect on PRN extraction. To test this further, cell pellets (T2, T4, T5, T13, T15 and T16) were stored at –70 °C for 20 min, as a cold shock. Cold-shocked cell pellets were thawed at two different temperatures (RT or 5 ± 3 °C) for 24 h or 3 days. Cell pellets not subjected to cold shock (T3, T6, T7, T14, T17 and T18) were stored at the listed temperature for 1 or 3 days. As controls, samples T1 and T12 were used directly for PRN extraction with neither cold shock nor additional storage. To determine whether the time required to thaw cell pellets could be shortened, cell pellets frozen at − 30 or − 70 °C for 1 or 3 days (T8–T11 and T19–-T22) were treated directly with 4.5 M urea. The amount of PRN extracted from cell pellets prepared under various conditions was determined using SDS-PAGE and ELISA. The band at 69 kDa on the SDS-PAGE gel represents PRN (Fig. 2A).

Effect of cell pellet preparation and storage conditions on pertactin (PRN) extraction. A Sodium dodecyl sulfate polyacrylamide gel electrophoresis analysis of PRN using Coomassie blue staining (PRN molecular weight 69 kDa). C cell pellet stored at − 70 °C for 1 d without slurry storage, M molecular marker. B Enzyme-linked immunosorbent assay analysis of PRN. Cell pellets were treated with 4 times the cell pellet weight of urea as a 4.5 M solution for 2 h. ****p < 0.0001 (triplicate runs)

As shown in Fig. 2, SDS-PAGE and ELISA gave the similar results. Slurry storage at 5 ± 3 °C for 3 days did not significantly affect PRN extraction from cell pellets, but cold shock did. Cold-shocked cell pellets (T2, T4, T5, T13, T15 and T16) yielded two–fivefold higher amounts of PRN, compared to non-cold-shocked cell pellets (T1, T3, T6, T7, T12, T14, T17 and T18), which strongly supports the hypothesis that the freezing step for extraction of outer membrane PRN in higher yields. Further, thawing conditions for frozen cell pellets affected PRN extraction. Cold-shocked cell pellets thawed and stored at 5 ± 3 °C yielded higher amounts of PRN than did those thawed and stored at RT (T2, T13, T4 and T15). The highest amounts of PRN (270–286 µg/mL of urea) were obtained from cold-shocked cells thawed and stored at 5 ± 3 °C (T4, T5 and T15). When frozen cell pellets were directly treated with urea without an additional thawing step (T10–T11 and T21–T22), the amount of PRN extracted was less than half that obtained from cold-shocked cell pellets subjected to an additional thawing step, regardless of the thawing temperature (T2, T4, T5, T13, T15 and T16). The results indicate that both cell pellet freezing and thawing processes meaningfully affect PRN extraction (Fig. 2B).

The rate of freeze thawing for Gram-negative bacteria is known to affect membrane structure and protein release [24]. Cells that have been frozen and thawed have a damaged outer membrane structure, which makes it easier to extract outer membrane proteins when treated with urea. When urea is applied directly to the cells without thawing, the thawing process occurs more rapidly. Rapid thawing could affect membrane structure, leading to differential extraction of membrane proteins.

The extracted solution was yellowish, probably because of the pigment components of the membrane [25]. The extraction solution from cold-shocked cell pellets (T2, T4, T5, T13, T15 and T16) was a darker yellow, whereas that from the other samples was paler yellow, indicating that the extent of outer membrane extraction can be determined based on the color of the extracted solution. Pigment-bearing components were removed using column chromatography, and the final purified PRN solution was colorless and transparent.

The cell pellet freezing and thawing conditions, which have a significant impact on PRN extraction, were further optimized with regard to duration of the storage of the frozen cell pellet, the thawing temperature and time, and the number of freeze–thaw cycles. As shown in Fig. 3A, the amount of PRN extracted tended to decrease slightly with longer storage at − 30 °C. Independent of the duration of storage of frozen cell pellets at − 30 °C (up to 10 days), the amount of PRN extracted from frozen cell pellets by direct urea treatment without a thawing step was less than 40% of that of frozen cell pellets thawed at 37 °C prior to urea treatment, confirming the importance of the thawing step. When subject to direct urea treatment, cell pellets frozen at − 30 °C thawed completely in less than 10 min.

Effect of cell pellet thawing conditions on pertactin (PRN) extraction. A Frozen cell pellets stored at − 30 °C for 1 (F/S 1 d), 3 (F/S 3 d) or 10 d (F/S 10 d) without thawing. Frozen cell pellet stored at − 30 °C for 10 d was thawed at 37 °C for 15 min (F/T). B Frozen pellets thawed under different conditions, 37 °C for 15 min (37 °C/15 min), RT for 1 h (RT/1 h) or 5 ± 3 °C for 2 d (5 ± 3 °C/2 d). C Effect of freeze–thaw cycles on PRN productivity. One cycle consists of freezing (− 30 °C, 1 d) and thawing (5 ± 3 °C, 2 d). Cell pellets were treated with four times the cell pellet weight of urea as a 5.0 M solution for 2 h. **p < 0.01, ***p < 0.001, and ****p < 0.0001 (triplicate runs)

As shown in Fig. 3B, thawing conditions also had a significant effect on PRN extraction. The extraction process was performed after the pellets were thawed, and the time taken to thaw the pellets depended on the thawing temperature. It took 15 min in a 37 °C water bath, 1 h at RT and 2 days at 5 ± 3 °C. The highest PRN concentrations (293.6 ± 31.8 µg/mL of urea) were obtained from frozen cell pellets thawed at 5 ± 3 °C for 2 days, a result that was 2.1- and 1.3-fold higher, respectively, than those obtained by thawing at 37 °C for 15 min or at RT for 1 h. The amount of PRN extracted from cell pellets frozen at − 30 °C was similar to that from pellets frozen at − 70 °C (Fig. 2B). Thawing conditions may affect the membrane structure and affect release of PRN, although a clear mechanism relating thawing conditions and PRN productivity has yet to be determined.

Application of multiple freeze–thaw cycles (freezing for 1 day at − 30 °C and thawing at 5 ± 3 °C for 2 days) did not increase PRN extraction (Fig. 3C); in fact, three freeze–thaw cycles decreased PRN extraction yield to 56% of that obtained after one cycle. Repeated freeze–thaw cycles can induce cell lysis and the release of proteases from cells that can degrade PRN. Thus, one freeze–thaw cycle was suitable for extraction of PRN from cell pellets.

3.3 Effect of urea treatment conditions on PRN extraction

It was expected that a higher urea concentration and longer urea treatment time would increase the viscosity of the urea solution containing the cell mass. Harsh extraction conditions, such as urea concentrations higher than 6 M, can disrupt the inner membrane and/or the nucleus, releasing large amounts of viscous materials, including chromosomal DNA into the supernatant, and high solution viscosity makes it difficult to separate the cell mass by centrifugation, lowering PRN yield. To increase the amount of PRN extracted from thawed cell pellets, urea treatment conditions were optimized for urea concentration (4.5–6.0 M) and treatment time (1.5–3 h).

Of the urea concentrations tested, 5.0 M resulted in the highest PRN yield (Fig. 4). A further increase in the urea concentration from 5.0 to 6.0 M decreased PRN yield. We found that 2 h treatment with 5.0 M urea was sufficient to extract PRN from thawed cell pellets (Fig. 4). The concentration of extracted PRN under the optimized conditions was 276.8 ± 6.8 µg/mL of urea, while that after 3 h treatment was 249.0 ± 21.3 µg/mL of urea.

Effect of urea treatment conditions on pertactin (PRN) extraction. Frozen cell pellets were thawed at 5 ± 3 °C for 2 d. Thawed cell pellets were treated with 4.5, 5.0 or 6.0 M urea for 1.5, 2.0, 2.5 or 3.0 h. *p < 0.05, ***p < 0.001, and ****p < 0.0001 (triplicate runs). ns indicates no significant differences

3.4 Scale-up of PRN production

Large-scale production of high-quality PRN is critical for commercialization of new aP vaccines. We attempted a 25-fold scale-up of PRN extraction using 5.0 M urea with cell pellets harvested from broth of a 50 L culture of B. pertussis. As a control, PRN was extracted from cell pellets harvested from broth of a 2 L culture by treatment with 5.0 M urea for 2 h. Prior to urea treatment, cell pellets were subjected to one freeze–thaw cycle. Cell pellets were then treated with four times the cell pellet weight of urea as a 5.0 M solution.

For 2 L culture, the yield of PRN was 208.2 ± 6.5 µg/mL of urea, while at a 50 L scale, the yield was 140.0 ± 4.2 µg/mL of urea (Fig. 5A). As the cell pellet weight from the larger culture was higher, more time was needed to completely dissolve the cell pellet and extract PRN from the cell membrane. When the urea treatment time was increased to 3 h, the PRN yield obtained from the 50 L culture was 220.3 ± 5.2 µg/mL of urea, comparable to that obtained for the 2 L culture.

Scale-up of pertactin (PRN) production process to 50 L. A Enzyme-linked immunosorbent assay of PRN. C cell pellet prepared from 2 L culture broth were treated with 5.0 M urea for 2 h, followed by one cycle of freezing (− 30 °C, 1 d) and thawing (5 ± 3 °C, 2 d). Cell pellets were treated with four times the cell pellet weight of urea as a 5.0 M solution for 1.5, 2.0, 2.5 or 3.0 h. ****p < 0.0001. ns indicates no significant differences. B Sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE) with Coomassie staining (PRN molecular weight 69 kDa). PRN extracted from the cell pellet in 5.0 M urea was subjected to three sequential of chromatographic steps, and the final PRN product was obtained after concentration and buffer exchange. After each step, PRN purity was assessed by SDS-PAGE. Lane 1: urea-treated sample, lane 2: anion exchange chromatography, lane 3: hydrophobic interaction chromatography, lane 4: gel filtration chromatography, lane 5: final PRN product after concentration and buffer exchange, M molecular marker

PRN extracted from cell pellets in 5.0 M urea contained impurities, largely in the form of host-cell-derived proteins. PRN extracted from 50 L of culture broth was subjected to AEC, HIC and GFC to remove impurities. After each chromatographic step, PRN purity was analyzed using SDS-PAGE and Coomassie blue staining (Fig. 5B). The chromatograms of each step are shown in Fig. S1. After three steps, PRN impurities were successfully removed, and the final PRN product was obtained using concentration and buffer exchange (Fig. 5B). A total of 124 mg purified PRN was obtained from 50 L culture broth, with a yield of 33.2%. The PRN antigen used in a single dose of commercially available adult Tdap vaccine is 2.5 μg, and a productivity of 124 mg is sufficient to produce approximately 50,000 doses in a 50 L culture scale. The final PRN yield per cell pellet (wet weight) was 0.23 mg/g and the final purity was > 95%, suitable for vaccine use (Table S2). Large-scale production of high-quality PRN was thus successfully achieved. An aP vaccine manufactured using the process developed in this study is now in phase II clinical trials in Korea [26, 27].

4 Conclusion

Cell pellet processing conditions including freezing and thawing were found to dramatically affect PRN yield. A large-scale production process was developed successfully based on optimized urea extraction of PRN, a non-fimbrial outer membrane protein of B. pertussis, which is the limiting component of aP vaccines. The production process developed in this study may also serve as a reference for manufacture of other membrane proteins.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

de Greeff SC, Mooi FR, Westerhof A et al (2010) Pertussis disease burden in the household: how to protect young infants. Clin Infect Dis 50:1339–1345. https://doi.org/10.1086/652281

Paddock CD, Sanden GN, Cherry JD et al (2008) Pathology and pathogenesis of fatal Bordetella pertussis infection in infants. Clin Infect Dis 47:328–338. https://doi.org/10.1086/589753

Bordet J, Gengou O (1906) Le microbe de la coqueluche. Ann Inst Pasteur (Paris) 20:731–741

Goodnow RA (1980) Biology of Bordetella bronchiseptica. Microbiol Rev 44:722–738. https://doi.org/10.1128/mr.44.4.722-738.1980

Miller DL, Ross EM, Alderslade R et al (1981) Pertussis immunisation and serious acute neurological illness in children. Br Med J (Clin Res Ed) 282:1595–1599. https://doi.org/10.1136/bmj.282.6276.1595

Whooping Cough Immunization Committee (1959) Vaccination against whooping-cough; the final report to the Whooping-Cough Immunization Committee of the Medical Research Council and to the medical officers of health for Battersea and Wandsworth, Bradford, Liverpool, and Newcastle. Br Med J 1:994–1000

Barkin RM, Pichichero ME (1979) Diphtheria-pertussis-tetanus vaccine: reactogenicity of commercial products. Pediatrics 63:256–260

Centers for Disease Control (CDC) (1982) Pertussis-England and Wales. MMWR Morb Mortal Wkly Rep 31:629–632

Jadhav SS, Gairola S (1999) Composition of acellular pertussis and combination vaccines: a general review. Biologicals 27:105–110. https://doi.org/10.1006/biol.1999.0191

Isomura S, Suzuki S, Sato Y (1985) Clinical efficacy of the Japanese acellular pertussis vaccine after intrafamiliar exposure to pertussis patients. Dev Biol Stand 61:531–537

Charles IG, Dougan G, Pickard D et al (1989) Molecular cloning and characterization of protective outer membrane protein P.69 from Bordetella pertussis. Proc Natl Acad Sci U S A 86:3554–3558. https://doi.org/10.1073/pnas.86.10.3554

Hellwig SM, Rodriguez ME, Berbers GA et al (2003) Crucial role of antibodies to pertactin in Bordetella pertussis immunity. J Infect Dis 188:738–742. https://doi.org/10.1086/377283

Li Z, Zhang Y, Wang Q et al (2016) Purification design and practice for pertactin, the third component of acellular pertussis vaccine, from Bordetella pertussis. Vaccine 34:4032–4039. https://doi.org/10.1016/j.vaccine.2016.06.029

Montaraz JA, Novotny P, Ivanyi J (1985) Identification of a 68-kilodalton protective protein antigen from Bordetella bronchiseptica. Infect Immun 47:744–751. https://doi.org/10.1128/iai.47.3.744-751.1985

Leininger E, Roberts M, Kenimer JG et al (1991) Pertactin, an Arg-Gly-Asp-containing Bordetella pertussis surface protein that promotes adherence of mammalian cells. Proc Natl Acad Sci U S A 88:345–349. https://doi.org/10.1073/pnas.88.2.345

Gould-Kostka JL, Burns DL, Brennan MJ et al (1990) Purification and analysis of the antigenicity of a 69,000 Da protein from Bordetella pertussis. FEMS Microbiol Lett 55:285–289. https://doi.org/10.1016/0378-1097(90)90010-n

Almarza J, Rincon L, Bahsas A et al (2009) Molecular mechanism for the denaturation of proteins by urea. Biochemistry 48:7608–7613. https://doi.org/10.1021/bi9007116

Tsuchido T, Katsui N, Takeuchi A et al (1985) Destruction of the outer membrane permeability barrier of Escherichia coli by heat treatment. Appl Environ Microbiol 50:298–303. https://doi.org/10.1128/aem.50.2.298-303.1985

Kishore D, Kundu S, Kayastha AM (2012) Thermal, chemical and pH induced denaturation of a multimeric β-galactosidase reveals multiple unfolding pathways. PLoS ONE 7:e50380. https://doi.org/10.1371/journal.pone.0050380

Kielkopf CL, Bauer W, Urbatsch IL (2021) Considerations for membrane protein purification. Cold Spring Harb Protoc. https://doi.org/10.1101/pdb.top102285

Smith SM (2017) Strategies for the purification of membrane proteins. Methods Mol Biol 1485:389–400. https://doi.org/10.1007/978-1-4939-6412-3_21

Nilsson S, Angeletti D, Wahlgren M et al (2012) Plasmodium falciparum antigen 332 is a resident peripheral membrane protein of Maurer’s clefts. PLoS ONE 7:e46980. https://doi.org/10.1371/journal.pone.0046980

Soloaga A, Ramírez JM, Goñi FM (1998) Reversible denaturation, self-aggregation, and membrane activity of Escherichia coli alpha-hemolysin, a protein stable in 6 M urea. Biochemistry 37:6387–6393. https://doi.org/10.1021/bi9730994

Souzu H (1980) Studies on the damage to Escherichia coli cell membrane caused by different rates of freeze-thawing. Biochim Biophys Acta 603:13–26. https://doi.org/10.1016/0005-2736(80)90387-9

Odanaka K, Iwatsuki M, Satho T et al (2017) Identification and characterization of a brilliant yellow pigment produced by Bordetella pertussis. Microbiol Immunol 61:490–496. https://doi.org/10.1111/1348-0421.12541

Huh DH, Han SB, Shin HJ et al (2018) Immunogenicity and protective efficacy of a newly developed tri-component diphtheria, tetanus, and acellular pertussis vaccine in a murine model. J Microbiol Immunol Infect 51:732–739. https://doi.org/10.1016/j.jmii.2017.04.003

Kwon HJ, Han SB, Kim BR et al (2017) Assessment of safety and efficacy against Bordetella pertussis of a new tetanus-reduced dose diphtheria-acellular pertussis vaccine in a murine model. BMC Infect Dis 17:247. https://doi.org/10.1186/s12879-017-2369-x

Acknowledgements

This work was supported by GC Biopharma (project number: GC3111).

Funding

Open Access funding enabled and organized by KAIST.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

Neither ethical approval nor informed consent was required for this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Moon, J.H., Park, J.K., Park, B.Y. et al. Extraction of the outer membrane protein pertactin from Bordetella pertussis with urea for the production of acellular pertussis vaccine. Biotechnol Bioproc E (2024). https://doi.org/10.1007/s12257-024-00028-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12257-024-00028-2