Abstract

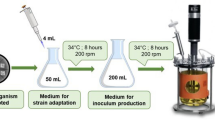

Bacillus pumilus, a bacterial strain was isolated from agricultural soil and used for xylanase enzyme (Xy) production under the submerged fermentation technique. The (Xy) enzyme had an optimum temperature at 50℃ (maximum activity from 45–60 °C) and was active at broad pH range (5.0–8.0) with an optimum pH at around 6.3 as evaluated from response surface methodology studies. This enzyme after purification (purification; 2.87 folds, specific activity; 64.3 U/mg) was immobilized onto MOFCu-BTC (a copper ion-based metal organic framework) and was used for clarification of freshly squeezed fruit juice (pineapple and pomegranate). The study revealed an improved catalytic efficiency (Vmax from 1.252.5 to 1.361 U/mL/mg of support) and greater half-life of the immobilized system (77–99 min). The activation energy decreased from that required for the free system (37.59–25.63 kJ/mol). The reusability of the enzyme improved after immobilization where 61% of the enzyme’s activity was retained after 21 cycles of usage. The MOFXy-Cu-BTC system showed improved clarification (47.58–57.97% for pineapple, and 15.34–18.3 for pomegranate) thereby showing its effectiveness in commercial juice clarification process.

Similar content being viewed by others

Data availability

Additional data is presented in the supplementary files. Any other data required can be provided.

References

Sharma N, Sharma N (2017) Microbial xylanases and their industrial applications as well as future perspectives: a review. Global J Biol Agric Health Sci 6:5–12. https://doi.org/10.24105/gjbahs.6.3.1702

Bai ZY, You S, Zhang F et al (2023) Efficient fermentable sugar production from mulberry branch based on a rational design of GH10 xylanase with improved thermal stability. Renew Energy 206:566–573

Shah K, Vishwa AP (2019) Microbial xylanase production and their industrial application in industry: a review. In: Saranraj P, Stephens PRS, Shah KR (eds) Microbiology and biotechnology in human life, 1st edn. JPS Scientific Publications, Tamil Nadu

Ulucay O, Gormez A, Ozic C (2022) For biotechnological applications: Purification and characterization of recombinant and nanoconjugated xylanase enzyme from thermophilic Bacillus subtilis. Biocatal Agric Biotechnol 44:102478

Chakdar H, Kumar M, Pandiyan K et al (2016) Bacterial xylanases: biology to biotechnology. 3Biotech 6:150. https://doi.org/10.1007/s13205-016-0457-z

Kaushal J, Khatri M, Singh G et al (2021) A multifaceted enzyme conspicuous in fruit juice clarification: an elaborate review on xylanase. Int J Biol Macromol 193:1350–1361. https://doi.org/10.1016/j.ijbiomac.2021.10.194

Bajaj BK, Manhas K (2012) Production and characterization of xylanase from Bacillus licheniformis P11(C) with potential for fruit juice and bakery industry. Biocatal Agric Biotechnol 1:330–337

Wang D, Lou J, Yuan J et al (2021) Laccase immobilization on core-shell magnetic metal-organic framework microspheres for alkylphenol ethoxylate compound removal. J Environ Chem Eng 9:105000

Ahmed IN, Yang XL, Dubale AA et al (2018) Hydrolysis of cellulose using cellulase physically immobilized on highly stable zirconium based metal-organic frameworks. Bioresour Technol 270:377–382. https://doi.org/10.1016/j.biortech.2018.09.077

Yadav P, Maharjan J, Korpole S et al (2018) Production, purification, and characterization of thermostable alkaline xylanase from Anoxybacillus kamchatkensis NASTPD13. Front Bioeng Biotechnol 6:65. https://doi.org/10.3389/fbioe.2018.00065

Raj A, Kumar S, Singh SK et al (2018) Production and purification of xylanase from alkaliphilic Bacillus licheniformis and its pretreatment of eucalyptus kraft pulp. Biocatal Agric Biotechnol 15:199–209

Waterborg JH (2009) The lowry method for protein quantitation. In: Walker JM (ed) The protein protocols handbook. Humana Press, Totowa

Kaushal J, Arya SK, Khatri M et al (2022) Efficacious bioconversion of waste walnut shells to xylotetrose and xylopentose by free xylanase (Xy) and MOF immobilized xylanase (Xy-Cu-BTC). Bioresour Technol 357:127374. https://doi.org/10.1016/j.biortech.2022.127374

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 23:257–270

Lu F, Lu M, Lu Z et al (2008) Purification and characterization of xylanase from Aspergillus ficuum AF-98. Bioresour Technol 99:5938–5941. https://doi.org/10.1016/j.biortech.2007.10.051

Kaushal J, Seema SG et al (2018) Immobilization of catalase onto chitosan and chitosan-bentonite complex: a comparative study. Biotechnol Rep (Amst) 18:e00258. https://doi.org/10.1016/j.btre.2018.e00258

Malhotra G, Chapadgaonkar SS (2022) Partial purification and characterization of a thermostable xylanase from Bacillus licheniformis isolated from hot water geyser. J Genet Eng Biotechnol 20:50. https://doi.org/10.1186/s43141-022-00333-4

Rodriguez JMG, Hux NP, Philips SJ et al (2019) Michaelis-Menten graphs, Lineweaver-Burk plots, and reaction schemes: investigating introductory biochemistry students’ conceptions of representations in enzyme kinetics. J Chem Educ 96:1833–1845

Glekas PD, Kalantzi S, Dalios A et al (2022) Biochemical and thermodynamic studies on a novel thermotolerant GH10 xylanase from Bacillus safensis. Biomolecules 12:790. https://doi.org/10.3390/biom12060790

Bhushan B, Pal A, Kumar S et al (2015) Biochemical characterization and kinetic comparison of encapsulated haze removing acidophilic xylanase with partially purified free xylanase isolated from Aspergillus flavus MTCC 9390. J Food Sci Technol 52:191–200

Nagar S, Mittal A, Gupta VK (2012) Enzymatic clarification of fruit juices (Apple, Pineapple, and Tomato) using purified Bacillus pumilus SV-85S xylanase. Biotechnol Bioprocess Eng 17:1165–1175

Kaushal J, Raina A, Singh G et al (2022) Methodical study implicating the effectiveness of microbial treatment over xylanase enzymatic treatment for pulp bio-bleaching. Environ Technol Innov 28:102731

Blanco A, Vidal T, Colom JF et al (1995) Purification and properties of xylanase a from alkali-tolerant Bacillus sp. strain BP-23. Appl Environ Microbiol 61:4468–4470. https://doi.org/10.1128/aem.61.12.4468-4470.1995

Korkmaz H, Hür H, Dinçer S (2004) Characterization of alkaline keratinase of Bacillus licheniformis strain HK-1 from poultry waste. Ann Microbiol 54:201–211

Hou M, Liang C, Fei Y et al (2023) Analysis of the effect of metal ions on the ability of Xylanase to hydrolyze wheat bran by molecular dynamics simulations. Front Bioeng Biotechnol 11:1142873. https://doi.org/10.3389/fbioe.2023.1142873

Bagewadi ZK, Mulla SI, Shouche Y et al (2016) Xylanase production from Penicillium citrinum isolate HZN13 using response surface methodology and characterization of immobilized xylanase on glutaraldehyde-activated calcium-alginate beads. 3Biotech 6:164. https://doi.org/10.1007/s13205-016-0484-9

Nagar S, Mittal A, Kumar D et al (2012) Immobilization of xylanase on glutaraldehyde activated aluminum oxide pellets for increasing digestibility of poultry feed. Process Biochem 47:1402–1410

Sen S, Ray L, Chattopadhyay P (2012) Production, purification, immobilization, and characterization of a thermostable β-galactosidase from Aspergillus alliaceus. Appl Biochem Biotechnol 167:1938–1953. https://doi.org/10.1007/s12010-012-9732-6

Tanriseven A, Doğan Ş (2002) A novel method for the immobilization of β-galactosidase. Process Biochem 38(1):27–30

Kharazmi S, Taheri-Kafrani A, Soozanipour A et al (2020) Xylanase immobilization onto trichlorotriazine-functionalized polyethylene glycol grafted magnetic nanoparticles: a thermostable and robust nanobiocatalyst for fruit juice clarification. Int J Biol Macromol 163:402–413. https://doi.org/10.1016/j.ijbiomac.2020.06.273

Singh RS, Singh T, Kennedy JF (2020) Purification, thermodynamics and kinetic characterization of fungal endoinulinase for the production of fructooligosaccharides from inulin. Int J Biol Macromol 164:3535–3545. https://doi.org/10.1016/j.ijbiomac.2020.09.001

Mehnati-Najafabadi V, Taheri-Kafrani A, Bordbar AK (2018) Xylanase immobilization on modified superparamagnetic graphene oxide nanocomposite: effect of PEGylation on activity and stability. Int J Biol Macromol 107:418–425. https://doi.org/10.1016/j.ijbiomac.2017.09.013

da Silva PO, de Alencar Guimarães NC, Serpa JDM et al (2019) Application of an endo-xylanase from Aspergillus japonicus in the fruit juice clarification and fruit peel waste hydrolysis. Biocatal Agric Biotechnol 21:101312

Alagöz D, Varan NE, Toprak A et al (2022) Immobilization of xylanase on differently functionalized silica gel supports for orange juice clarification. Process Biochem 113:270–280

Acknowledgements

This work is supported by WOS-A DST fellowship LS-2/2021 and DBT Builder Project (BT/INF/ 22/SP41295/2020) at University Institute of Engineering and Technology, Panjab University, India.

Author information

Authors and Affiliations

Contributions

SKA, MK and GS designed the concept; JK wrote the manuscript. All of the authors discussed, commented on, and revised the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

Neither ethical approval nor informed consent was required for this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaushal, J., Khatri, M., Singh, G. et al. Xylanase enzyme from novel strain and its immobilization onto metal organic framework MOF for fruit juice clarification. Biotechnol Bioproc E 29, 197–210 (2024). https://doi.org/10.1007/s12257-024-00007-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-024-00007-7