Abstract

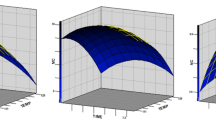

The purpose of this study was to optimize product yield and quality of the sweet potato chip manufacturing process in a pilot-scale industrial fryer using vacuum frying (VF) technology, response surface methodology (RSM), and artificial neural network (ANN) model. The variables, osmotic dehydration (OD) concentration, OD temperature, and VF temperature were designed to optimize the yield, oil content, and browning index (BI) of vacuum-fried sweet potato chips. Yield, oil content, and BI achieved optimal conditions for 52.46%, 10.65%, and 61.14 in RSM, and 53.52%, 11.58%, and 60.40 in ANN, respectively. Based on the statistical evaluation performance, the ANN model had a higher predictive performance than the RSM model. These findings highlight the high-quality pilot-scale manufacturing process along with a better statistical approach. Moreover, the optimized process can be used for the commercial production of vacuum-fried sweet potato chips.

Similar content being viewed by others

Change history

11 September 2023

An Erratum to this paper has been published: https://doi.org/10.1007/s12257-023-1061-9

References

Yolmeh, M. and S. M. Jafari (2017) Applications of response surface methodology in the food industry processes. Food Bioproc. Tech. 10: 413–433.

Bezerra, M. A., R. E. Santelli, E. P. Oliveira, L. S. Villar, and L. A. Escaleira (2008) Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76: 965–977.

Kim, D.-S., M. H. Choi, and H.-J. Shin (2021) Estimation of starch hydrolysis in sweet potato (Beni Haruka) based on storage period using nondestructive near-infrared spectrometry. Agriculture 11: 135.

Das, M., N. Rajan, P. Biswas, and R. Banerjee (2022) A novel approach for resistant starch production from green banana flour using amylopullulanase. LWT 153: 112391.

Okonkwo, C. E., O. I. Moses, C. Nwonuma, T. Abiola, B. O. Benjamin, J. O. Folorunsho, A. F. Olaniran, and Z. Pan (2022) Infrared and microwave as a dry blanching tool for Irish potato: product quality, cell integrity, and artificial neural networks (ANNs) modeling of enzyme inactivation kinetic. Innov. Food Sci. Emerg. Technol. 78: 103010.

Yang, Q.-Q., R.-Y. Gan, D. Zhang, Y.-Y. Ge, L.-Z. Cheng, and H. Corke (2019) Optimization of kidney bean antioxidants using RSM & ANN and characterization of antioxidant profile by UPLC-QTOF-MS. LWT 114: 108321.

Bhagya Raj, G. V. S. and K. K. Dash (2022) Comprehensive study on applications of artificial neural network in food process modeling. Crit. Rev. Food Sci. Nutr. 62: 2756–2783.

Tang, S. Y., J. S. Lee, S. P. Loh, and H. J. Tham (2017) Application of artificial neural network to predict colour change, shrinkage and texture of osmotically dehydrated pumpkin. IOP Conf. Ser.: Mater. Sci. Eng. 206: 012036.

Onu, C. E., P. K. Igbokwe, J. T. Nwabanne, C. O. Nwajinka, and P. E. Ohale (2020) Evaluation of optimization techniques in predicting optimum moisture content reduction in drying potato slices. Artif. Intell. Agr. 4: 39–47.

Zhang, Q., A. S. Saleh, J. Chen, and Q. Shen (2012) Chemical alterations taken place during deep-fat frying based on certain reaction products: a review. Chem. Phys. Lipids 165: 662–681.

Mariscal, M. and P. Bouchon (2008) Comparison between atmospheric and vacuum frying of apple slices. Food Chem. 107: 1561–1569.

Moreira, R. G. (2014) Vacuum frying versus conventional frying - An overview. Eur. J. Lipid Sci. Technol. 116: 723–734.

Da Silva, P. F. and R. G. Moreira (2008) Vacuum frying of high-quality fruit and vegetable-based snacks. LWT 41: 1758–1767.

Qiu, L., M. Zhang, Y. Wang, and B. Bhandari (2018) Effects of ultrasound pretreatments on the quality of fried sweet potato (Ipomea batatas) chips during microwave-assisted vacuum frying. J. Food Process Eng. 41: e12879.

Su, Y., M. Zhang, B. Bhandari, and W. Zhang (2018) Enhancement of water removing and the quality of fried purple-fleshed sweet potato in the vacuum frying by combined power ultrasound and microwave technology. Ultrason. Sonochem. 44: 368–379.

Ahmed, I., I. M. Qazi, and S. Jamal (2016) Developments in osmotic dehydration technique for the preservation of fruits and vegetables. Innov. Food Sci. Emerg. Technol. 34: 29–43.

Feumba Dibanda, R., E. Panyoo Akdowa, A. Rani P, Q. Metsatedem Tongwa, and C. M. Mbofung F (2020) Effect of microwave blanching on antioxidant activity, phenolic compounds and browning behaviour of some fruit peelings. Food Chem. 302: 125308.

Gramatikov, B. I. (2017) Detecting central fixation by means of artificial neural networks in a pediatric vision screener using retinal birefringence scanning. Biomed. Eng. Online 16: 52.

Thoai, D. N., C. Tongurai, K. Prasertsit, and A. Kumar (2018) Predictive capability evaluation of RSM and ANN in modeling and optimization of biodiesel production from palm (Elaeisguineensis) oil. Int. J. Appl. Eng. Res. 13: 7529–7540.

Ayustaningwarno, F., M. Dekker, V. Fogliano, and R. Verkerk (2018) Effect of vacuum frying on quality attributes of fruits. Food Eng. Rev. 10: 154–164.

Deng, L.-Z., A. S. Mujumdar, Q. Zhang, X.-H. Yang, J. Wang, Z.-A. Zheng, Z.-J. Gao, and H.-W. Xiao (2019) Chemical and physical pretreatments of fruits and vegetables: effects on drying characteristics and quality attributes–a comprehensive review. Crit. Rev. Food Sci. Nutr. 59: 1408–1432.

Dziki, D. (2020) Recent trends in pretreatment of food before freeze-drying. Processes 8: 1661.

Ren, A., S. Pan, W. Li, G. Chen, and X. Duan (2018) Effect of various pretreatments on quality attributes of vacuum-fried shiitake mushroom chips. J. Food Qual. 2018: 4510126.

del Valle, J. M., V. Aránguiz, and H. León (1998) Effects of blanching and calcium infiltration on PPO activity, texture, microstructure and kinetics of osmotic dehydration of apple tissue. Food Res. Int. 31: 557–569.

Rodríguez, Ó., P. J. Llabrés, S. Simal, A. Femenia, and C. Rosselló (2015) Intensification of predrying treatments by means of ultrasonic assistance: effects on water mobility, PPO activity, microstructure, and drying kinetics of apple. Food Bioproc. Tech. 8: 503–515.

Feng, Y., X. Yu, A. E. A. Yagoub, B. Xu, B. Wu, L. Zhang, and C. Zhou (2019) Vacuum pretreatment coupled to ultrasound assisted osmotic dehydration as a novel method for garlic slices dehydration. Ultrason. Sonochem. 50: 363–372.

Oladejo, A. O., H. Ma, W. Qu, C. Zhou, B. Wu, B. B. Uzoejinwa, D. I. Onwude, and X. Yang (2018) Application of pretreatment methods on agricultural products prior to frying: a review. J. Sci. Food Agric. 98: 456–466.

Cichowska, J., J. Żubernik, J. Czyżewski, H. Kowalska, and D. Witrowa-Rajchert (2018) Efficiency of osmotic dehydration of apples in polyols solutions. Molecules 23: 446.

Rahaman, A., X.-A. Zeng, A. Kumari, M. Rafiq, A. Siddeeg, M. F. Manzoor, Z. Baloch, and Z. Ahmed (2019) Influence of ultrasound-assisted osmotic dehydration on texture, bioactive compounds and metabolites analysis of plum. Ultrason. Sonochem. 58: 104643.

Dehghannya, J. and L. Abedpour (2018) Influence of a three stage hybrid ultrasound-osmotic-frying process on production of low fat fried potato strips. J. Sci. Food Agric. 98: 1485–1491.

Karizaki, V. M., S. Sahin, G. Sumnu, M. T. H. Mosavian, and A. Luca (2013) Effect of ultrasound-assisted osmotic dehydration as a pretreatment on deep fat frying of potatoes. Food Bioproc. Tech. 6: 3554–3563.

Krokida, M. K., V. Oreopoulou, Z. B. Maroulis, and D. Marinos-Kouris (2001) Effect of osmotic dedydration pretreatment on quality of french fries. J. Food Eng. 49: 339–345.

Nunes, Y. and R. G. Moreira (2009) Effect of osmotic dehydration and vacuum-frying parameters to produce high-quality mango chips. J. Food Sci. 74: E355–E362.

Oladejo, A. O., H. Ma, W. Qu, C. Zhou, B. Wu, X. Yang, and D. I. Onwude (2017) Effects of ultrasound pretreatments on the kinetics of moisture loss and oil uptake during deep fat frying of sweet potato (Ipomea batatas). Innov. Food Sci. Emerg. Technol. 43: 7–17.

Su, Y., M. Zhang, B. Chitrakar, and W. Zhang (2021) Reduction of oil uptake with osmotic dehydration and coating pre-treatment in microwave-assisted vacuum fried potato chips. Food Biosci. 39: 100825.

Tran, T. T. M., X. D. Chen, and C. Southern (2007) Reducing oil content of fried potato crisps considerably using a ‘sweet’ pretreatment technique. J. Food Eng. 80: 719–726.

Kim, D.-S. and H.-J. Shin (2021) Effect of pretreatment method on the physical properties of vacuum-fried sweet potato chips. Int. J. Adv. Eng. Tech. 14: 107–113.

Kim, T. and R. Moreira (2013) De-oiling and pretreatment for high-quality potato chips. J. Food Process Eng. 36: 267–275.

Moreira, R. G., X. Sun, and Y. Chen (1997) Factors affecting oil uptake in tortilla chips in deep-fat frying. J. Food Eng. 31: 485–498.

Gamble, M. H., P. Rice, and J. D. Selman (1987) Relationship between oil uptake and moisture loss during frying of potato slices from c. v. Record U.K. tubers. Int. J. Food Sci. Technol. 22: 233–241.

Ravli, Y., P. Da Sila, and R. G. Moreira (2013) Two-stage frying process for high-quality sweet-potato chips. J. Food Eng. 118: 31–40.

Sosa-Morales, M. E., A. P. Solares-Alvarado, S. P. Aguilera-Bocanegra, J. F. Muñoz-Roa, and G. A. Cardoso-Ugarte (2022) Reviewing the effects of vacuum frying on frying medium and fried foods properties. Int. J. Food Sci. Technol. 57: 3278–3291.

Devi, S., M. Zhang, R. Ju, and B. Bhandari (2021) Recent development of innovative methods for efficient frying technology. Crit. Rev. Food Sci. Nutr. 61: 3709–3724.

Selvakumar, R. and R. B. Tiwari (2018) Effect of osmotic treatments on weight reduction, water loss, solid gain, moisture, total solids, yield and drying ratio of carrot (Daucus carota L.) slices. Chem. Sci. Rev. Lett. 7: 959–965.

Krokida, M. K., V. T. Karathanos, and Z. B. Maroulis (2000) Effect of osmotic dehydration on color and sorption characteristics of apple and banana. Dry. Technol. 18: 937–950.

Serpen, A. and V. Gökmen (2007) Modeling of acrylamide formation and browning ratio in potato chips by artificial neural network. Mol. Nutr. Food Res. 51: 383–389.

Guiné, R. P. F. (2019) The use of artificial neural networks (ANN) in food process engineering. Int. J. Food Eng. 5: 15–21.

Said, F. M., J. Y. Gan, and J. Sulaiman (2020) Correlation between response surface methodology and artificial neural network in the prediction of bioactive compounds of unripe Musa acuminata peel. Eng. Sci. Technol. an Int. J. 23: 781–787.

Zikmund, W. G. (2000) Business Research Methods. 6th ed., p. 513. The Dryden Press.

Henseler, J., C. M. Ringle, and R. R. Sinkovics (2009) The use of partial least squares path modeling in international marketing. pp. 277–319. In: R. R. Sinkovics and P. N. Ghauri (eds.). New Challenges to International Marketing. Emerald Group Publishing Limited.

Bai, X.-L., T.-L. Yue, Y.-H. Yuan, and H.-W. Zhang (2010) Optimization of microwave-assisted extraction of polyphenols from apple pomace using response surface methodology and HPLC analysis. J. Sep. Sci. 33: 3751–3758.

Ciric, A., B. Krajnc, D. Heath, and N. Ogrinc (2020) Response surface methodology and artificial neural network approach for the optimization of ultrasound-assisted extraction of polyphenols from garlic. Food Chem. Toxicol. 135: 110976.

Aung, T., S.-J. Kim, and J.-B. Eun (2022) A hybrid RSM-ANN-GA approach on optimisation of extraction conditions for bioactive component-rich laver (Porphyra dentata) extract. Food Chem. 366: 130689.

Kashyap, P., C. S. Riar, and N. Jindal (2021) Optimization of ultrasound assisted extraction of polyphenols from Meghalayan cherry fruit (Prunus nepalensis) using response surface methodology (RSM) and artificial neural network (ANN) approach. J. Food Meas. Charact. 15: 119–133.

Kadiri, O., S. O. Gbadamosi, and C. T. Akanbi (2019) Extraction kinetics, modelling and optimization of phenolic antioxidants from sweet potato peel vis-a-vis RSM, ANN-GA and application in functional noodles. J. Food Meas. Charact. 13: 3267–3284.

Aliakbarian, B., F. C. Sampaio, J. T. de Faria, C. G. Pitangui, F. Lovaglio, A. A. Casazza, A. Converti, and P. Perego (2018) Optimization of spray drying microencapsulation of olive pomace polyphenols using response surface methodology and artificial neural network. LWT 93: 220–228.

Kramer, O. (2017) Genetic algorithms. pp. 11–19. In: O. Kramer (ed.). Genetic Algorithm Essentials. Springer.

Oladejo, A. O., H. Ma, W. Qu, C. Zhou, and B. Wu (2017) Effects of ultrasound on mass transfer kinetics, structure, carotenoid and vitamin C content of osmodehydrated sweet potato (Ipomea batatas). Food Bioproc. Tech. 10: 1162–1172.

Sobukola, O. P., V. Dueik, L. Munoz, and P. Bouchon (2013) Comparison of vacuum and atmospheric deep-fat frying of wheat starch and gluten based snacks. Food Sci. Biotechnol. 22: 177–182.

Pandiselvam, R., Y. Tak, E. Olum, O. J. Sujayasree, Y. Tekgül, G. Ç. Koç, M. Kaur, P. Nayi, A. Kothakota, and M. Kumar (2022) Advanced osmotic dehydration techniques combined with emerging drying methods for sustainable food production: impact on bioactive components, texture, color, and sensory properties of food. J. Texture Stud. 53: 737–762.

Núñez-Mancilla, Y., A. Vega-Gálvez, M. Pérez-Won, L. Zura, P. García-Segovia, and K. D. Scala (2014) Effect of osmotic dehydration under high hydrostatic pressure on microstructure, functional properties and bioactive compounds of strawberry (Fragaria vesca). Food Bioproc. Tech. 7: 516–524.

Wang, R., M. Zhang, and A. S. Mujumdar (2010) Effect of osmotic dehydration on microwave freeze-drying characteristics and quality of potato chips. Dry. Technol. 28: 798–806.

Acknowledgements

This study was financially supported by Chosun University (2022).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest.

Neither ethical approval nor informed consent was required for this study.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Kim, DS., Lee, J.H. & Shin, HJ. Optimization of Vacuum Frying Process for Sweet Potato Chip Manufacturing Using Response Surface Methodology and Artificial Neural Network Model. Biotechnol Bioproc E 28, 554–567 (2023). https://doi.org/10.1007/s12257-023-0061-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-023-0061-0