Abstract

Astaxanthin additions to animal diets predominantly serve as colorization aid to satisfy consumer expectations and desire for a consistent product with familiar coloration, e.g. the characteristic pink colorization of the flesh of species being produced by aquaculture. The heterobasidiomycetous yeast Phaffia rhodozyma (Xanthophyllomyces dendrorhous) can be used as natural feed source of astaxanthin. However, currently, the majority of astaxanthin used for the feed market is produced by chemical synthesis. We present a further step in direction of a competitive production of natural astaxanthin in an optimized bioprocess with non-genetically modified Phaffia rhodozyma. After medium optimization AXJ-20, a mutant strain of P. rhodozyma wild-type strain ATCC 96594, was able to grow to a cell dry weight concentration of over 114 g per kg of culture broth in a fed-batch process. In this bioprocess, where pH was lowered from 5.5 to 3.5 during the maturation phase, AXJ-20 produced the highest value reported for astaxanthin production with P. rhodozyma up to now: 0.7 g astaxanthin per kg of culture broth with a space-time-yield of 3.3 mg astaxanthin per kg of culture broth per hour. Lowering the pH during the bioprocess and increasing trace element and vitamin concentrations prevented loss of cell dry weight concentration in the maturation phase and proved to be critical for astaxanthin concentration and purity.

Similar content being viewed by others

References

Food and Agriculture Organization of the United Nations, The State of World Fisheries and Aquaculture -Opportunities and challenges. http://www.fao.org/3/a-i3720e.pdf

Storebakken, T., P. Foss, K. Schiedt, E. Austreng, S. Liaaen-Jensen, and U. Manz (1987) Carotenoids in diets for salmonids: IV. Pigmentation of Atlantic salmon with astaxanthin, astaxanthin dipalmitate and canthaxanthin. Aquacult. 65: 279–292.

BCC Research LLC, The Global Market for Carotenoids (FOD025C) http://www.bccresearch.com/market-research/foodand-beverage/carotenoids-market-fod025c.html

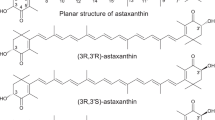

Higuera-Ciapara, I., L. Felix-Valenzuela, and F. Goycoolea (2006) Astaxanthin: A review of its chemistry and applications. Cr. Rev. Food Sci. 46: 185–196.

Phaff, H., M. Miller, M. Yoneyama, and M. Soneda (1972) A comparative study of the yeast florae associated with trees on the Japanese Islands and in the west coast of North America. pp. 759–774. In: G. Terui (ed.). Fourth International Fermentation Symposum Proceedings: Fermentation Technology Today. Society of Fermentation Technology, Osaka, Japan.

Miller, M., M. Yoneyama, and M. Soneda (1976) Phaffia, a new yeast genus in the Deuteromycotina (Blastomycetes). Int. J. Syst. Bacteriol. 26: 286–291.

Golubev, W. (1995) Perfect state of Rhodomyces dendrorhous (Phaffia rhodozyma). Yeast 11: 101–110.

Andrewes, A. G., H. J. Phaff, and M. P. Starr (1976) Carotenoids of Phaffia rhodozyma, a red-pigmented fermenting yeast. Phytochem. 15: 1003–1007.

Schroeder, W. A. and E. A. Johnson (1993) Antioxidant role of carotenoids in Phaffia rhodozyma. J. Gen. Microbiol. 139: 907–912.

Schroeder, W. A. and E. A. Johnson (1995) Carotenoids protect Phaffia rhodozyma against singlet oxygen damage. J. Ind. Microbiol. Biotechnol. 14: 502–507.

Ramirez, J., H. Gutierrez, and A. Gschaedler (2001) Optimization of astaxanthin production by Phaffia rhodozyma through factorial design and response surface methodology. J. Biotechnol. 88: 259–268.

Schmidt, I., H. Schewe, S. Gassel, C. Jin, J. Buckingham, M. Hümbelin, G. Sandmann, and J. Schrader (2011) Biotechno logical production of astaxanthin with Phaffia rhodozyma/Xanthophyllomyces dendrorhous. Appl. Microbiol. Biotechnol. 89: 555–571.

Bjerkeng, B., M. Peisker, K. von Schwartzenberg, T. Ytrestøyl, and T. Åsgård (2007) Digestibility and muscle retention of astaxanthin in Atlantic salmon, Salmo salar, fed diets with the red yeast Phaffia rhodozyma in comparison with synthetic formulated astaxanthin. Aquacult. 269: 476–489.

Whyte, J. N. C. and K. L. Sherry (2001) Pigmentation and composition of flesh of Atlantic salmon fed diets supplemented with the yeast Phaffia rhodozyma. North Am. J. Aquacult. 63: 52–57.

Jacobson, G. K., S. O. Jolly, J. J. Sedmak, T. J. Skatrud, and J. M. Wasileski (1999) Astaxanthin over-producing strains of Phaffia rhodozyma, methods for their cultivation, and their use in animal feeds. US Patent 6,413,736.

de la Fuente, J. L., E. Peiro, B. Diez, A. T. Marcos, C. Schleissner, M. Rodriguez Saiz, C. Rodriguez Otero, W. Cabri, and J. L. Barredo (2005) Method of production of astaxanthin by fermenting selected strains of Xanthophyllomyces dendrorhous. US Patent 2005/0124032 A1.

Hoshino, T., Y. Setoguchi, and Y. Takagi (2008) Astaxanthin production using fed-batch fermentation process by Phaffia rhodozyma. US Patent 7,432,076.

Frengova, G. I. and D. M. Beshkova (2009) Carotenoids from Rhodotorula and Phaffia: Yeasts of biotechnological importance. J. Ind. Microbiol. Biotechnol. 36: 163–180.

Rodriguez-Saiz, M., J. L. de la Fuente, and J. L. Barredo (2010) Xanthophyllomyces dendrorhous for the industrial production of astaxanthin. Appl. Microbiol. Biotechnol. 88: 645–658.

De Boer, L., B. Van Hell, and A. J. J. Krouwer (1997) Strains of Phaffia rhodozyma containing high levels of astaxanthin and low levels of 3-hydroxy-3´,4´-didehydro-b, Y-caroten-4-one (HDCO). US Patent 5,648,261.

Visser, H., G. Sandmann, and J. C. Verdoes (2005) Xanthophylls in fungi: Metabolic engineering of the astaxanthin biosynthetic pathway in Xantophyllomyces dendrorhous. pp. 257–272. In: J. Barredo (ed.). Microbial Processes and Products. Humana Press, Totowa, New Jersey, USA.

Gassel, S., H. Schewe, J. Schrader, and G. Sandmann (2013) Multiple improvement of astaxanthin biosynthesis in Xanthophyllomyces dendrorhous by a combination of conventional mutagenesis and metabolic pathway engineering. Biotechnol. Lett. 35: 565–569.

An, G. H., B. G. Jang, and M. H. Cho (2001) Cultivation of the carotenoid-hyperproducing mutant 2A2N of the red yeast Xanthophyllomyces dendrorhous (Phaffia rhodozyma) with molasses. J. Biosci. Bioeng. 92: 121–125.

Hu, Z. -C., Y. -G. Zheng, Z. Wang, and Y. -C. Shen (2006) pH control strategy in astaxanthin fermentation bioprocess by Xanthophyllomyces dendrorhous. Enz. Microb. Technol. 39: 586–590.

Hu, Z. -C., Y. G. Zheng, Z. Wang, and Y. C. Shen (2007) Production of Astaxanthin by Xanthophyllomyces dendrorhous ZJUT46 with Fed-Batch Fermentation in 2.0 M3 Fermentor. Food Technol. Biotechnol. 45: 209–212.

An, G. H., D. B. Schuman, and E. A. Johnson (1989) Isolation of Phaffia rhodozyma mutants with increased astaxanthin content. Appl. Environ. Microbiol. 55: 116–124.

Johnson, E. A. and G. -H. An (1991) Astaxanthin from microbial sources. Crit. Rev. Biotechnol. 11: 297–326.

Meyer, P. S., J. C. du Preez, and S. G. Kilian (1993) Selection and evaluation of astaxanthin-overproducing mutants of Phaffia rhodozyma. World J. Microbiol. Biotechnol. 9: 514–520.

Acheampong, E. A. and A. M. Martin (1995) Kinetic studies on the yeast Phaffia rhodozyma. J. Basic Microb. 35: 147–155.

Kusdiyantini, E., P. Gaudin, G. Goma, and P. J. Blanc (1998) Growth kinetics and astaxanthin production of Phaffia rhodozyma on glycerol as a carbon source during batch fermentation. Biotechnol. Lett. 20: 929–934.

Flores-Cotera, L. B., R. Martin, and S. Sanchez (2001) Citrate, a possible precursor of astaxanthin in Phaffia rhodozyma: Influence of varying levels of ammonium, phosphate and citrate in a chemically defined medium. Appl. Microbiol. Biotechnol. 55: 341–347.

Ni, H., Q. H. Chen, H. Ruan, Y. F. Yang, L. J. Li, G. B. Wu, Y. Hu, and G. Q. He (2007) Studies on optimization of nitrogen sources for astaxanthin production by Phaffia rhodozyma. J. Zhejiang Univ. Sci. B. 8: 365–370.

Liu, Y. S. and J. Y. Wu (2008) Modeling of Xanthophyllomyces dendrorhous growth on glucose and overflow metabolism in batch and fed-batch cultures for astaxanthin production. Biotechnol. Bioeng. 101: 996–1004.

Wang, W. and L. Yu (2009) Effects of oxygen supply on growth and carotenoids accumulation by Xanthophyllomyces dendrorhous. Z. Naturforsch. C. 64: 853–858.

de la Fuente, J. L., M. Rodríguez-Sáiz, C. Schleissner, B. Díez, E. Peiro, and J. L. Barredo (2010) High-titer production of astaxanthin by the semi-industrial fermentation of Xanthophyllomyces dendrorhous. J. Biotechnol. 148: 144–146.

Gassel, S., J. Breitenbach, and G. Sandmann (2014) Genetic engineering of the complete carotenoid pathway towards enhanced astaxanthin formation in Xanthophyllomyces dendrorhous starting from a high-yield mutant. Appl. Microbiol. Biotechnol. 98: 345–350.

Ojima, K., J. Breitenbach, H. Visser, Y. Setoguchi, K. Tabata, T. Hoshino, J. van den Berg, and G. Sandmann (2006) Cloning of the astaxanthin synthase gene from Xanthophyllomyces dendrorhous (Phaffia rhodozyma) and its assignment as a beta-carotene 3-hydroxylase/4-ketolase. Mol. Genet. Genom. 275: 148–158.

Liu, Y. -S., J. -Y. Wu, and K. -P. Ho (2006) Characterization of oxygen transfer conditions and their effects on Phaffia rhodozyma growth and carotenoid production in shake-flask cultures. Biochem. Eng. J. 27: 331–335.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schewe, H., Kreutzer, A., Schmidt, I. et al. High concentrations of biotechnologically produced astaxanthin by lowering pH in a Phaffia rhodozyma bioprocess. Biotechnol Bioproc E 22, 319–326 (2017). https://doi.org/10.1007/s12257-016-0349-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-016-0349-4