Abstract

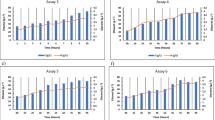

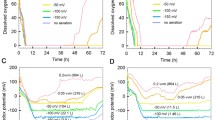

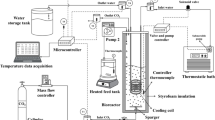

In this study, we investigated the effects of aeration on ethanol inhibition and glycerol production during fed-batch ethanol fermentation. When aeration was conducted at 0.13, 0.33, and 0.8 vvm, the ethanol productivity, specific ethanol production rate, and ethanol yield in the presence of greater than 100 g/L of ethanol were higher than when aeration was not conducted. In addition, estimation of the parameters (α and β) in a model equation of ethanol inhibition kinetics indicated that aeration alleviated ethanol inhibition against the specific growth rate and the specific ethanol production rate. Specifically, when aeration was conducted, the glycerol yield and specific glycerol production rate decreased approximately 50 and 70%, respectively. Finally, the results of this study indicated that aeration during fed-batch ethanol fermentation may improve the ethanol concentration in the final culture broth, as well as the ethanol productivity.

Similar content being viewed by others

References

Balata, M., H. Balata, and C. Őz (2008) Progress in bioethanol processing. Prog. Energy Combust. Sci. 34: 551–573.

Cardona, C. A. and Ó. J. Sánchez (2007) Fuel ethanol production: Process design trends and integration opportunities. Bioresour. Technol. 98: 2415–2457.

Demirbas, A (2007) Progress and recent trends in biofuels. Prog. Energy Combust. Sci. 33: 1–18.

Galbe, M., P. Sassner, A. Wingren, and G. Zacchi (2007) Process engineering economics of bioethanol production. Adv. Biochem. Engin/Biotechnol. 108: 303–327.

Hamelinck, C. N., G. van Hooijdonk, and A. P. C. Faaij (2005) Ethanol from lignocellulosic biomass: technoeconomic performance in short-, middle- and long-term. Biomass Bioenergy 28: 384–410.

Huanga, H. J., S. Ramaswamya, U. W. Tschirner, and B. V. Ramaraob (2008) A review of separation technologies in current and future biorefineries. Sep. Purif. Technol. 62: 1–21.

Sánchez, Ó. J. and C. A. Cardona (2008) Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour. Technol. 99: 5270–5295.

Sassner, P., M. Galbe, and G. Zacchi (2008) Technoeconomic evaluation of bioethanol production from three different lignocellulosic materials. Biomass Bioenergy 32: 422–430.

Jeon, B. Y., S. J. Kim, D. H. Kim, B. K. Na, D. H. Park, H. T. Tran, R. Zhang, and D. H. Ahn (2007) Development of a serial bioreactor system for direct ethanol production from starch using Aspergillus niger and Saccharomyces cerevisiae. Biotechnol. Bioprocess Eng. 12: 566–573.

Choi, G. Wook., H. W. Kang, Y. R. Kim, and B. W. Chung (2008) Ethanol production by Zymomonas mobilis CHZ2501 from industrial starch feedstocks. Biotechnol. Bioprocess Eng. 13: 765–771.

Bai, F. W., L. J. Chen, W. A. Anderson, and M. Moo-Young (2004) Parameter oscillations in very high gravity medium continuous ethanol fermentation and their attenuation on multi-stage packed column bioreactor system. Biotechnol. Bioeng. 88: 558–566.

Bai, F. W., L. J. Chen, Z. Zhang, W. A. Anderson, and M. Moo-Young (2004) Continuous ethanol production and evaluation of yeast cell lysis and viability loss under very high gravity medium conditions. J. Biotechnol. 110: 287–293.

Hayashida, S. and K. Ohta (1981) Formation of high concentrations of alcohol by various yeasts. J. Inst. Brew. 87: 42–44.

Krishnan, M. S., Y. Xia, G. T. Tsao, N. Kasthurikrishnan, N. Srinivasan, and R. G. Cook (1995) Process engineering of high-ethanol-tolerance yeast for the manufacture of ethanol. Appl. Biochem. Biotechnol. 51/52: 479–493.

Mota, M., J. M. Besie, P. Strehaiano, and G. Goma (1987) A simple device for fed-batch control in alcoholic fermentation. Biotechnol. Bioeng. 24: 775–777.

Thomas, K. C., S. H. Hynes, A. M. Jones, and W. M. Ingledew (1993) Production of fuel alcohol from wheat by VHG technology. Appl. Biochem. Biotechnol. 43: 211–226.

Thomas, K. C. and W. M. Ingledew (1990) Fuel alcohol production: effects of free amino nitrogen on fermentation of very-high-gravity wheat mash. Appl. Environ. Microbiol. 56: 2046–2050.

Thomas, K. C. and W. M. Ingledew (1992) Production of 21% (v/v) ethanol by fermentation of very high gravity (VHG) wheat mashes. J. Ind. Microbiol. 10: 61–68.

Wang, S., K. C. Thomas, K. Sosulski, and W. M. Ingledew (1999) Grain pearling and very high gravity (VHG) fermentation technologies for fuel alcohol production from rye and triticale. Process Biochem. 34: 421–428.

Loung, J. H. T. (1985) Kinetics of ethanol inhibition in alcohol fermentation. Biotechnol. Bioeng. 27: 280–285.

Marín, M. R. (1999) Alcoholic fermentation modeling: Current state and perspectives. Am. J. Enol. Vitic. 50: 166–178.

Bai, F. W., W. A. Anderson, and M. Moo-Young (2008) Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnol. Adv. 26: 89–105.

Alfenore, S., X. Cameleyre, L. Benbadis, C. Bideaux, J. L. Uribelarrea, G. Goma, C. Molina-Jouve, and S. E. Guillouet (2004) Aeration strategy: a need for very high ethanol performance in Saccharomyces cerevisiae fed-batch process. Appl. Microbiol. Biotechnol. 63: 537–542.

Alfenore, S., C. Molina-Jouve, S. E. Guillouet, J. -L. Uribelarrea, G. Goma, and L. Benbadis (2002) Improving ethanol production and viability of Saccharomyces cerevisiae by a vitamin feeding strategy during fed-batch process. Appl. Microbiol. Biotechnol. 60: 67–72.

Cot, M., M. O. Loret, J. François, and L. Benbadis (2007) Physiological behaviour of Saccharomyces cerevisiae in aerated fed-batch fermentation for high level production of bioethanol. FEMS Yeast Res. 7: 22–32.

Furukawa, K., E. Heinzle, and I. J. Dunn (1983) Influence of oxygen on growth of Saccharomyces cerevisiae in continuous culture. Biotechnol. Bioeng. 25: 2293–2317.

Hoppe, G. K. and G. S. Hansford (1984) The effect of micro-aerobic conditions on continuous ethanol production by Saccharomyces cerevisiae. Biotechnol. Lett. 6: 681–686.

Grosz, R. and G. Stephanopoulos (1990) Physiology, biochemical, and mathematical studies of micro-aerobic continuous ethanol fermentation by Saccharomyces cerevisiae. I: Hysteresis, oscillations, and maximum specific ethanol productivities in chemostat culture. Biotechnol. Bioeng. 36: 1006–1019.

Kirsop, B. H. (1981) Aeration in fermentation for ethanol production. Enzyme Microb. Technol. 3: 375–375.

Ryu, D. D. Y., Y. J. Kim, and J. H. Kim (1984) Effect of air supplement on the performance of continuous ethanol fermentation system. Biotechnol. Bioeng. 26: 12–16.

Sweere, A. P. J., J. R. Mesters, L. Janse, K. Ch. A. M. Luyben, and N. W. F. Kossen (1988) Experimental simulation of oxygen profiles and their influence on baker’s yeast production: I. One-fermentor system. Biotechnol. Bioeng. 31: 567–578.

Costenoble, R., H. Valadi, L. Gustafsson, C. Niklasson, and C. J. Franzén (2000) Microaerobic glycerol formation in Saccharomyces cerevisiae. Yeast 16: 1483–1495.

Franzen, C. J. (2003) Metabolic flux analysis in RQ-controlled microaerobic ethanol production by Saccharomyces cerevisiae. Yeast 20: 117–132.

Kuriyama, H. and H. Kobayashi (1993) Effects of oxygen supply on yeast growth and metabolism in continuous fermentation. J. Ferment. Bioeng. 75: 364–367.

Weusthuis, R. A., W. Visser, J. T. Pronk, W. A. Scheffers, and J. P. van Dijken (1994) Effects of oxygen limitation on sugar metabolism in yeasts: a continuous-culture study of the Klyuver effect. Microbiology 140: 703–715.

Seo, H. -B., S. S. Kim, H. -Y. Lee, and K. -H. Jung (2009) High-level production of ethanol during fed-batch ethanol fermentation with a controlled aeration rate and non-sterile glucose powder feeding of Saccharomyces cerevisiae. Biotechnol. Bioprocess Eng. 14: 591–598.

Bideaux, C., S. Alfenore, X. Cameleyre, C. Molina-Jouve, J. L. Uribelarrea, and S. E. Guillouet (2006) Minimization of glycerol production during the high-performance fedbatch ethanolic fermentation process in Saccharomyces cerevisiae, using a metabolic model as a prediction tool. Appl. Environ. Microbiol. 72: 2134–2140.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seo, HB., Yeon, JH., Jeong, M.H. et al. Aeration alleviates ethanol inhibition and glycerol production during fed-batch ethanol fermentation. Biotechnol Bioproc E 14, 599–605 (2009). https://doi.org/10.1007/s12257-009-0066-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-009-0066-3