Abstract

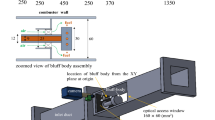

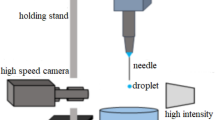

This study was performed to clarify criteria for cavitation inception and the relationship between flow conditions and cavitation flow patterns of diesel and biodiesel fuels. The goal was to analyze the effects of injection conditions and fuel properties on cavitating flow and disintegration phenomena of flow after fuel injection. To accomplish this goal, it was utilized a test nozzle with a cylindrical cross-sectional orifice and a flow visualization system composed of a fuel supply system and an image acquisition system. In order to analyze the rate of flow and injection pressure of the fuel, a flow rate meter and pressure gauge were installed at the entrance of the nozzle. A long distance microscope device equipped with a digital camera and a high resolution ICCD camera were used to acquire flow images of diesel and biodiesel, respectively. The effects of nozzle geometry on the cavitating flow were also investigated. Lastly, a detailed comparison of the nozzle cavitation characteristics of both fuel types was conducted under a variety of fuel injection parameters. The results of this analysis revealed that nozzle cavitation flow could be divided into four regimes: turbulent flow, beginning of cavitation, growth of cavitation, and hydraulic flip. The velocity coefficient of diesel fuel was greatly altered following an increase in flow rate, although for biodiesel, the variation of the velocity coefficient relative to the rate of flow was mostly constant. The cavitation number decreased gradually with an increase in the Reynolds number and Weber number, and the discharge coefficient was nearly equal to one, regardless of cavitation number. Lastly, it could not observe cavitation growth in the tapered nozzle despite an increase in fuel injection pressure.

Similar content being viewed by others

References

Badock, C., Wirth, R., Fath, A. and Leipertz, A. (1999). Investigation of cavitation in real size diesel injection nozzles. Int. J. Heat and Fluid Flow, 20, 538–544.

Chaves, H., Knapp, M. and Kubitzek, A. (1996). Experimental study of cavitation in a nozzle hole of diesel injectors using transparent nozzles. SAE Paper No. 962004.

Daikoku, M., Furudate, H., Noda, H. and Inamura, T. (2003). Effect of cavitation in the two-dimensional nozzle on liquid breakup process. Proc. 9th ICLASS 1, 1207.

Ganippa, L. C., Andersson, S. and Chomiak, J. (2000). Transient measurements of discharge coefficients of diesel nozzles. SAE Paper No. 2000-01-2788.

Inamura, T., Saito, H., Daikoku, M., Onodera, T., Sakamoto, H. and Kumakawa, A. (2005) Cavitating flow in rectangular nozzle with orifice. Proc. 10th ILASS-ASIA, 273–280.

Kato, M., Kano, H., Date, K., Oya, T. and Niizuma, K. (1997). Flow analysis in nozzle hole in consideration of cavitation. SAE Paper No. 970052.

Kim, J. H., Kim, H. D., Park, K. A., Matsuo, S. and Setoguchi, T. (2006). A fundamental study of a variable critical nozzle flow. Experiments in Fluids, 40, 127–134.

Koivula, T. S. and Ellman, A. U. (1998). Cavitation behaviour of hydraulic orifices and valves. SAE Paper No. 982038.

Payri, F., Bermudez, V., Rayri, R. and Salvador, F. J. (2004). The influence of cavitation on the internal flow and the spray characteristics in diesel injection nozzles. Fuel, 83, 419–431.

Payri, R., Garcia, J. M., Salvador, F. J. and Gimeno, J. (2005). Using spray momentum flux measurements to understand the influence of diesel nozzle geometry on spray characteristics. Fuel, 84, 551–561.

Petropoulou, S., Gavaises, M. and Theodorakakos, A. (2006). Adjoint method for controlled caviation inverse nozzle design. Int. J. Automotive Technology 7,3, 283–288.

Soteriou, C., Andrews, R. F and Smith, M. (1999). Further studies of cavitation and atomization in diesel injection. SAE Paper No. 1999-01-1486.

Schmidt, D. P., Rutland, C. J., Corradini, M. L., Roosen, P. and Genge, O. (1999). Cavitation in two-dimensional asymmetric nozzles. SAE Paper No. 1999-01-0518.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suh, H.K., Park, S.H. & Lee, C.S. Experimental investigation of nozzle cavitating flow characteristics for diesel and biodiesel fuels. Int.J Automot. Technol. 9, 217–224 (2008). https://doi.org/10.1007/s12239-008-0028-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-008-0028-3