Abstract

A Potato (Solanum tuberosum L.) is a major staple food consumed worldwide. Potato peel is an important constituent that is generally discarded and considered agricultural waste before processing or cooking. The present investigation is an attempt to utilize different contents of potato peels (PP) with potato flesh (PF) of processing cultivar (Kufri Chipsona 3) and table cultivar (Kufri Jyoti), which affect starch nutritional profile, glycemic response, and pasting properties. The combination of PP at different concentrations of 5, 10, and 15%, respectively, to PF showed a significant reduction (P < 0.05) in starch hydrolysis index (SHI), glycemic index (GI), and glycemic load (GL). Similarly, there was also a significant increase in the resistant starch content of the PP + PF combination. The maximum change in the predicted glycemic response was observed in the PP with 15%. A higher reduction in the in vitro glycemic response was observed in the Kufri Chipsona 3 as compared to Kufri Jyoti. The pasting properties of also showed significant changes with the addition of PP to the PF flour, which might be due to the change in intrinsic properties such as amylose and amylopectin content. The current investigation will help to provide an understanding of the use of PP in the processing industries to prepare low-GI food products.

Resumen

La papa (Solanum tuberosum L.) es uno de los principales alimentos básicos consumidos en todo el mundo. La cáscara de la papa es un componente importante que generalmente se desecha y se considera un residuo agrícola antes de procesarla o cocinarla. La presente investigación es un intento de utilizar diferentes contenidos de cáscaras de papa (PP) con pulpa (PF) de la variedad de procesamiento (Kufri Chipsona 3) y la variedad de mesa (Kufri Jyoti), que afectan el perfil nutricional del almidón, la respuesta glucémica y las propiedades de pegado. La combinación de PP a diferentes concentraciones de 5, 10 y 15%, respectivamente, a PF mostró una reducción significativa (P < 0.05) en el índice de hidrólisis del almidón (SHI), el índice glucémico (IG) y la carga glucémica (CG). Del mismo modo, también hubo un aumento significativo en el contenido de almidón resistente de la combinación PP+PF. El cambio máximo en la respuesta glucémica predicha se observó en el PP con un 15%. Se observó una mayor reducción de la respuesta glucémica in vitro en el Kufri Chipsona 3 en comparación con el Kufri Jyoti. Las propiedades de la pasta también mostraron cambios significativos con la adición de PP a la harina de PF, lo que podría deberse al cambio en las propiedades intrínsecas como el contenido de amilosa y amilopectina. La presente investigación ayudará a comprender el uso de PP en las industrias de procesamiento para preparar productos alimenticios de bajo índice glucémico.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Potato (Solanum tuberosum L.) is an important starchy solanaceous vegetable crop that is consumed worldwide after rice, wheat and maize (FAOSTAT 2019). It is the cheapest and most excellent source of energy, which can be considered in terms of nutrition and prevention of many chronic diseases (Visvanathan et al. 2016). The high calorific value and nutritional component have the potential to ensure food and nutritional security around the globe (Kolasa 1993). The major component of potato is carbohydrates, dietary fiber, and several important nutrients, including vitamin C, potassium, magnesium and phenolic compounds (Ru et al. 2019; Kumar et al. 2022). Compared to other staple crops, potatoes are more profitable in terms of nutrient-to-price ratio, for which it is considered a staple food around the globe (Drewnowski and Popkin 1997). Before the potato consumption, its peel is removed, resulting in abundant agricultural waste of no value (Singh et al. 2005a). It is estimated that the potato peel (PP) produced by various peeling techniques used in the processing industries and by consumers wastes between 15 and 40% of the biomass produced by the potato (Gebrechristos and Chen 2018). The enormous amounts of PP waste created are thought to contribute to environmental contamination and the loss of nutrients that can be used for the preparation of various food products (Pathak et al. 2017). The PP is a good source of pharmacologically important phenolic compounds, flavonoids, glycoalkaloids, and dietary fiber (Sánchez Maldonado et al. 2014). Transforming inexpensive PP waste into value-added products is the need of the hour that might have industrial demand.

The potato starch is comprised of around 65–85% and is mainly composed of amylose (α-1,4 glycosidic linkages) and amylopectin (α-1,4 and α-1,6 glycosidic linkages (Jansky and Fajardo 2016). The raw potato was reported to be high in resistant starch and also indigestible by different digestible enzymes. However, after cooking, the starch showed to have higher digestibility toward the hydrolyzing enzymes, which leads to an increase in the postprandial blood glucose response, measured in terms of the glycemic index (GI) and glycemic load (GL). The foods are categorized as high (> 70), medium (56–69) and low (< 55) GI based on the capacity for enhancement of postprandial blood glucose level (Wolever 2013; Lal et al. 2020). Potatoes are typically classified as high glycemic index (GI) foods because they are known to undergo rapid starch digestion when cooked. As a result, it is crucial to find ways to reduce the GI in potato-based products. Numerous studies have highlighted the presence of various compounds in PP, including phenolic compounds, starch, non-starch polysaccharides, suberin, lignin, and certain beneficial lipids (Pathak et al. 2017; Abdelraof et al. 2019). The beneficial and nutritive compounds present in PP have antioxidant, chemopreventive, antibacterial, apoptotic, anti-diabetic and anti-inflammatory properties (Vaitkevičienė 2019; Nawaz et al. 2020). An earlier report by Singh et al. (2005a) suggested that PP supplementation of 5% and 10% for four weeks in a diet of Streptozotocin (STZ)-induced diabetic male Wistar rats showed a significant reduction in blood glucose levels. The dietary fibers are reported to be beneficial in lowering postprandial blood glucose levels by interacting with the starch hydrolyzing component that leads to the slow release of glucose (Singh et al. 2005a). The enhanced dietary fiber is predominantly known as bulking again, which increases the mobility and hydration of human fecal material. Moreover, PP is suggested to have 43% phenolic compounds and about 10% glycoalkaloid, a higher amount of glycoalkaloid content reported in potato peel than PF (Ben Jeddou et al. 2017). Therefore, the incorporation of PP in food products mad from potatoes could be a naturaland most cost-effective strategy to provide dietary fiber and bioactive into the human body.

A plethora of reports on the addition of other food components in the potato on various glycemic response factors has been studied. However, the role of PP on GI, GL, RS and other pasting properties is lacking. The current study aimed to investigate the combinatorial effect of the addition of PP to PF of two popular cultivars of potatoes. The results from this study will help to understand the food scientist and nutritionists to prepare different food products with the combination of PF and PP.

Materials and Methods

Plant Material and Processing

Plant Material

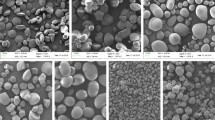

As the experimental material, Kufri Jyoti and Kufri Chipsona 3 potatoes were taken, which are mostly used for table and processing purposes, respectively. The potato tubers were procured from the ICAR-Central Potato Research Institute in Shimla, India. After the potato was peeled, it was ground into a paste and lyophilized (Scanvac Cool Safe, Labogene, Denmark). Potato peel (PP) of the same variety was used in combination of which potato flesh (PF) was used.

Processing of Food Material and Composition

In this experiment, potato peels (PP) and potato flesh (PF) were prepared for analysis in the following manner: First, the PP and PF were freeze-dried and subsequently ground to obtain a lyophilized powder. This lyophilized PP and PF powder was then sieved through a 100-mesh size sieve. To assess various parameters, we combined the lyophilized PF with the PP in different treatment combinations. These combinations included PF alone, PF + PP at 5%, PF + PP at 10%, and PF + PP at 15%. The parameters we analyzed included available starch, amylose and amylopectin content, starch hydrolysis index (SHI), carbohydrate content (ACHO), glycemic index (GI), glycemic load (GL), resistant starch (RS), and pasting properties, all of which are further described in the subsequent sections.

Starch Related Parameters

Starch Content

In accordance with Bjorck & Siljestrom, the total starch content of potato tuber and potato peel were analyzed (Björck and Siljeström 1992). Triplicate samples of total starch content from freeze-dried potato powder were used for analysis.

Amylose and Amylopectin Content

The amount of amylose in potatoes was measured using a modified version of the method developed by Juliano et al. (Juliano et al. 1981). Dry potato powder (0.1 g) was mixed with 1 mL of absolute ethanol and 9 mL of sodium hydroxide (1 N), and the tube was put in a boiling water bath (10 min). The volume was then brought up to 100 mL by adding double distilled water. In a volumetric flask, 5 mL of an aliquot was mixed with 1 mL of 1 N acetic acid and 2 mL of iodine solution (1 g of iodine and 10 g of KI in 500 mL of water). This solution was left in the dark for 20 min for colour development. The final volume was 100 mL, and the absorbance was measured to be 620 nm.

Amylopectin was calculated by the difference in total starch and amylose (Torruco-Uco et al. 2006) using the following formula:

Glycemic Response and Related Parameters

Available Carbohydrate Content (ACHO)

The Megazyme kit (Megazyme International, Ireland Ltd) was used to follow the manufacturer’s protocol to determine the available carbohydrate (ACHO) of a PF, PP and its mixture which was earlier standardized (Lal et al. 2022).

Starch Hydrolysis Index (SHI) and Predicted Glycemic Index (pGI)

Improved and standardised in vitro methods for estimating starch hydrolysis index (SHI) and GI were developed (Goñi et al. 1997). The digestive enzymes utilized in our study to hydrolyse starch were amyloglucosidase (3300 U/mL, Himedia Bioscience, India), α-amylase (10U/mg solid, porcine pancreatic, Sigma-Aldrich, USA), and pepsin (3000 U/mL, from porcine gastric mucosa, Sigma-Aldrich, USA). For the determination of SHI and GI of potato powder alone (200 mg) and potato flesh-potato peel powder combinations (PF, PF + PP 5%, PF + PP 10%, and PF + PP 15%) were used in the experiment. The samples were taken in triplicate for the analysis of SHI as per the improved protocol (Lal et al. 2020). For estimation of free glucose release and development of colour, glucose oxidase/ peroxidase (GOPOD) reagent (Megazyme International Ltd, Bray, Ireland) was used. The aliquots obtained were incubated with GOPOD reagent at 50 °C for 20 min in the water bath. The rate of starch digestion was expressed as the percentage of total starch hydrolyzed and collected at 30, 60, 90, 120 and 180 min. The mean values of glucose released from three replicates were used to plot curves (amount of glucose vs. time). The absorbance was measured at 510 nm using a spectrophotometer (Model-4001/ A, ThermoSpectronic, USA). The SHI was calculated by dividing the area under the curve (AUC) of the potato-vegetable samples by AUC of glucose (standard).

The estimated glycemic index (eGI) was calculated using the formula as given by Goni et al. (1997):

Determination of Predicted Glycemic Load (eGL)

The eGL for 100 g of potato sample was calculated using the formula

(http://www.glycemicindex.com/faqsList.php#1).

Estimation of Resistant Starch (RS)

The RS was determined according to Goñi et al. (1996), with the modification in the protocol (Kumar et al. 2018). The final colour was developed using Glucose oxidase/peroxidase reagent (GOPOD) and the final absorbance was measured at 450 nm using UV/Vis spectrophotometer.

Pasting Properties

The rheological measurement of pasting properties was made for potato flesh and potato peel powder with a Modular Compact Rheometer: MCR 302 (Anton Paar GmbH). The viscosity profiles of the potato samples were recorded with the standard 14% moisture content. All samples were done in triplicates to calculate mean values. About 1.5 g of dried potato flour was mixed with 15 mL of distilled water to study the pasting properties. The paste was first mixed at 950 rpm for 10 s and then at 150 rpm during the rest of the process. The temperature profile of the process was as follows: the paste was held at 50 °C for 60 s, heated to 95 °C for 3.7 min, and kept at 95 °C for 2.5 min. Then, it was cooled to 50 °C for 3.8 min and kept at 50 °C for 2 min. After the end of the test, the software provided data for pasting temperature, peak viscosity, setback viscosity, breakdown viscosity, and final viscosity.

Statistical Analysis

In the current study, various parameters for different combinations of potato cultivars viz., Kufri Jyoti and Kufri Chipsona 3 in four different treatments of PF, PF + PP 5%, PF + PP 10%, and PF + PP 15%. Each of these conditions was analyzed in triplicate (N = 3). The final data in the figures and tables were expressed as mean values ± standard error mean (SEM). The two-way analysis of variance (ANOVA), test of significance and comparison of mean test (Tukey’s multiple comparison test; P < 0.05) was performed using Microsoft Excel and Graph Pad Prism 6.01 software.

Results and Discussion

Effect of Potato Peel Addition on Starch, Amylose and Amylopectin of Potato

Starch is the major component of potato after water content in potato tuber. The earlier report suggests that potato peel (PP) is composed of non-starch polysaccharide (30%), starch (25%), protein (18%), lipids (1%), acid-soluble and acid-insoluble lignin (20%) and ash (about 6%) on a dry weight basis (Camire et al. 1997; Javed et al. 2019). Potato peel is an important protective layer that is present on the potato that prevents the potato flesh from being affected by soil, pests and diseases (Nema et al. 2008). In the present study, the effect of the addition of PP on the starch content of PF and PF + PP was studied (Tables S1 and S2). The addition of PP (5, 10 and 15% of the respective variety) to PF of Kufri Jyoti and KufriChipsona 3 was shown to have a significant increase in starch content (Fig. 1A). The starch content of Kufri Jyoti was reported to be 71.19% and the addition of 5, 10 and 15% of PP led to an increae in starch content by 1.5, 4, and6%, respectively. Similarly, adding about 15% of PP in the F of Kufri Chipsona 3 suggested a higher strch content of 71.3% as compared to only PF of Kufri Chipsona 4 (65.78%). Ourresults were concordant with the previous studies were the potato cultivars with peel, such as Lady Rosetta and Challenger, were reported to have the highest starch content on a dry weight basis as compared to those without the peel (Nawaz et al. 2019). The increase in starch content might be due to the contribution of the starch component from PP, where starch is predominantly present, along with the addition of PF.

Effect of the addition of potato peel (PP) to potato flesh (PF) on the (A) starch content (B) Amylose content (C) Amylopectin of Kufri Jyoti and Kufri Chipsona 3. The statistical significance of the mean differences across treatments. The bars signify the means and standard errors of three replicates. The asterisk shows P ≤ 0.05 as per Tukey’s multiple comparison test (Tables S1, S2, S3 and S4)

Amylose is an integral part of starch which is present in α(1–4) linear chain of glucose molecules. The amylose content in starchy crops is crucial for the transformation into resistant starch (Tian and Sun 2020). In our study, the addition of PP in both the cultivar viz., Kufri Jyoti and Kufri Chipsona 3 showed to have increased amylose content (Tables S1 and S3). The amylose content of Kufri Jyoti was reported to have increased highest by 15.02% in the PF + PP15%combination compred to only the PF of Kufri Jyoti (Fig. 1B). Similar results were obtained when PP of 15% was added to processing cultivar (Kufri Chipsona 3).

The amylose content of PP contributed to the already present of amylose content of PF (Thakur et al. 2021). Amylopectin is the branched polymer of the glucose chain in the starch granules. The PP also contains some amylose component. The subtraction of amylose content from total starch content calculates amylopectin. Therefore, the addition of PP in the PF of both cultivars showed a decrease in amylopectin content (Fig. 1C, Tables S1 and S4). However, the lowering of amylopectin was found to be significant when 15% of PP was added tothe PP of Kufri Jyoti. Similarly, the addition of PP 15% was found to reduce the amylopectin content only by 5% (Fig. 1C).

Addition of Potato Peel on Available Carbohydrate Content (ACHO) and Starch Hydrolysis Index (SHI) of Potato

The available carbohydrate (ACHO) is the amount of carbohydrate which is available for digestion by the hydrolytic enzymes (Pinhero et al. 2016). In our experiment, we studied the effect of the addition of potato peel on the available carbohydrate (ACHO) of potato combination (Fig. 2A). The ACHO was reported to be 13.21 and 12. 55 g/100 DW, respectively, in Kufri Jyoti and Kufri Chipsona 3 (Fig. 2A). The addition of potato peel (PP) to potato flesh (PF) showed a decrease in ACHO in all the treatments of PP + PF combination viz., 5%, 10% and 15% (P < 0.05) (Tables S1 and S5). The ACHO content due to the addition of PP 5, 10 and 15% were reported to be 12.29, 11.43 and 10.81 g/100 DW, respectively. A maximum significant lowering (18.17%) effect of about ACH was observed in PF + PP 15% combination as compared to other treatments (Fig. 2A and Table S5). Similarly, the lowering ACHO was observed at a maximum (35.88%) in the addition of P 15% to PF of Kufri Chipsna 3. The lowering of ACHO in both cultivars might be due to the different phenolics and flavonoid components present in the PP. Moreover, to our knowledge, there are no such direct reports of the combination of PP to PF on ACHO or any other starchy crops. The higher level of phenolics, glycoalkaloid and α-glucosidase inhibitors which might interact with the carbohydrate component of PP and, thereby reducing the ACHO of PF + PP combination (Arun et al. 2015).

Effect of the addition of potato peel (PP) to potato flesh (PF) on the (A) Available carbohydrate (B) Starch hydrolysis index of Kufri Jyoti and Kufri Chipsona 3. The statistical significance of the mean differences across treatments. The bars signify the means and standard errors of three replicates. The asterisk shows P ≤ 0.05 as per Tukey’s multiple comparison test (Tables S1, S5, and S6)

The degree of starch hydrolysis by different hydrolytic enzymes can be calculated by dividing the area under the curve (AUC) of starch hydrolysis (Lal et al. 2021a) of PF and PF-PP by the AUC of the reference food. The present study suggested that the addition of PP in PF showed a significant (P < 0.05, Table S6) lowering of SHI. The initial SHI of Kufri Jyoti and Kufri Chipsona 3 was reported to be 46.08 and 52.85, respectively (Fig. 2B). The addition of PP (5, 10 and 15%) suggested lowerig the SHI by 8.9, 15.7 and 21.1%, respectively in ufri Jyoti. Similarly, a higher reduction of SHI by 42% was observed by te addition of 15% PP to PF of KufriChipsona 3 (Fig. 2B). The aforementioned findings indicate that incorporating 15% PP into both cultivars of PF resulted in a more significant reduction in the Starch Hydrolysis Index (SHI) during the cooking process. Although there is no specific literature documenting the impact of PP on potato SHI, it is plausible that PP interacts with starch, resulting in a slower release of glucose. This interaction likely contributes to reduced carbohydrate digestibility and, subsequently, a lower SHI in the cooked potatoes.

The lowering of SHI due to the addition of PP with potato might be due to the phenolic and glycoalkaloid constituents present in the PP that delay and inhibit different enzymes involved in the digestion of starch (Arun et al. 2015). Moreover, the dietary fiber present in PP also interacts with the starch during the digestion process and acts as a mechanical barrier preventing starch’s enzymatic digestion (Camire 2016; Nawaz et al. 2019).

Effect of PP on Glycemic Response

The glycemic index (GI) indicates how the blood glucose level changes after eating a certain food that might contain carbohydrates in its component (Eyinla et al. 2021; Lal et al. 2021b, c). When eaten alone, starchy foods have a higher GI than when they are part of a mixed meal or eaten with other foods that are high in dietary fibre and other compounds that stop starch-breaking enzymes from working. Our results suggest that PP has a GI lowering effect when added with PF of both the cultivars compared to potato alone (Fig. 3A). The addition of 15% of PP to the PF leads to a significant maxmum lowering of GI from 76.21 to 68.80 and 81.65 to 73.53 in Kufri Jyoti and Kufri Chipsona 3, respectively (Fig. 3A). The lowering of GI was by 4.35, 7.37, and 10.24% due to the addition of PP 5, 10 and 15%, espectively in the Kufri Jyoti cultivar Fig. 3A). Similar results were obtained when 15% PP was added to Kufri Chipsona 3. To our kowledge, there are no such direct studies on the effect of the addition of PP to the potato on GI and related parameters. Our results were concordant with the earlier in vitro reports where the PP was reported to alleviate oxidative stress and lower the blood glucose level (Kaur et al. 2009; Arun et al. 2015). Moreover, other reports also suggested that starchy food like rice, when mixed with leafy vegetables such as spinach and lettuce, which contains more cellulose and hemicellulose, have lowered the postprandial plasma glucose peak (Selvakumar et al. 2017). Moreover, our results were agreeable with previously studied rice, when blended with chickpea and fenugreek flour, which showed lower in vitro GI than rice alone (Shirani and Ganesharanee 2009).

Effect of the addition of potato peel (PP) to potato flesh (PF) on the (A) glycemic index (B) glycemic load (C) resistant starch of Kufri Jyoti and Kufri Chipsona 3. The statistical significance of the mean differences across treatments. The bars signify the means and standard errors of three replicates. The asterisk shows P ≤ 0.05 as per Tukey’s multiple comparison test (Tables S1, S7, S8 and S9)

It was interesting to know that GL was also significantly (P < 0.05) reduced by the addition of PP in both the cultivars i.e., Kufri Jyoti and Kufri Chipsona 3 (Tables S1 and S8) compared to their respective control. The maximum reduction in GL was observed in the treatment where the combination of 15% PP with PF. The addition of PP in PF of Kufri Jyoti showed a significant reduction in GL in all the treatments. However, a maximum reduction of about 26.5% was reported in 15% PP (Fig. 3B). In comparison, a similar trend of reduction in GL was observed in Kufri Chipsona 3. The GL was reduced by around 42.6% reduction by the addition of 15% PP with PF in Kufri Chipsona 3 (Fig. 3B). There is no direct report on the effect of the addition of PP on the GL of potato. However, earlier reports on okra, cauliflower, beets, asparagus, eggplant, turnips, green beans, and carrots are reported to have hypoglycemic effects under in vitro conditions (Kahlon et al. 2007; Wu et al. 2020). Similarly, the study by Ramdath et al. (2014) revealed that polyphenol content in potatoes showed to have a negative correlation with glycemic response (which includes GI and GL) in a diabetic and normal human. The underlying mechanism behind the lowering of GI might be due to starch-polyphenol interaction, which prevents the hydrolyzing enzymes such as α-amylase, β-amylase phosphorylase and protease to act on starch granules (Camire et al. 1997; Fujita et al. 2003; Singh et al. 2005b; Azizi et al. 2020).

The PP contributes significantly to the enhancement of resistant starch of the combination of PF with PP. The resistant starch content was enhanced in all treatments of PP of 5%, 10% and 15%, in both the cultivar viz., Kufri Jyoti and Kufri Chipsona 3. The highest increase in RS by 54% was observed in the Kufri Jyoti with the addition of 15% of PP (Fig. 3C). Similarly, the addition of 15% PP to the PF of Kufri Chipsona 3 was reported to be a higher increase in the resistant starch content by 63.3% as compared to other treatments. It has been established that the insoluble fiber derived from extruded steam peels, which produces a larger quantity of glucose, may cause resistant starch development (Javed et al. 2019). The PP contains a dietary fiber component, which leads to the binding of amylose molecules, thereby enhancing resistant starch content in a combination of PF with PP.

Pasting Properties of Potato-Potato Peel Combination

The modification of starch when it is gelatinized in the presence of heat and moisture can be illustrated by pasting properties. Starch gelatinization is when starch granules lose their inherent order and crystalline structure and become amorphous. The pasting property, the viscosity of starch paste, and the rheological characteristics of starch gel are all important rheological qualities of starch (Kaur et al. 2007; Won et al. 2017; Shevkani et al. 2021). The amylograph data, specifically the peak viscosity, provided insights into the molecular-level degradation of starch. The preservation of starch granule integrity is influenced by factors such as the intensity of heat treatment and the inclusion of various chemical agents during the gelatinization process. When examining the gelatinization properties of potato and the impact of incorporating PP into PF flour, rheometer analysis revealed statistically significant differences (P < 0.05). These differences underscore the distinct gelatinization characteristics associated with the PF and PP treatments.

The pasting properties of starch isolated from both the cultivars viz., Kufri Jyoti and Kufri Chipsona 3 and the effect of PP on the PF of aforementioned are illustrated in Table 1. The result suggested that there was a significant (P < 0.05, Tables S1, S10-14) difference in the PF of these cultivars and the addition of PP to PF (Tables S10-14). Peak viscosity is generally depicted as the highest viscosity during the process of gelatinization (swelling of starch in the presence of moisture and heat).

In the current study the peak viscosity was decreased significantly (P < 0.05, Table 1) in both cultivars when PP was added to PF. The highest increase of PV by 22 and 25% was observed in the 15% PP added to Kufri Jyoti and Kufri Chispsona 3, respectively. The reason behind the lowering of PV might be due to the addition of external material, as PP interacts with amylopectin and reduces its swelling power (Nawaz et al. 2019). Moreover, the difference in the chemical composition of starch present in different cultivars, as Kufri Jyoti is table purpose and Kufri Chipsona 3 is processing one. The setback viscosity is also an important parameter of pasting properties, which signifies the role of amylose in potato. Earlier reports suggest that setback viscosity is directly proportional to the amylose content (Azizi et al. 2020). Our study also revealed that the addition of PP in PF of Kufri Jyoti and Kufri Chipsona 3, the setback viscosity was reported to be increased by 14.8 and 15.9%, respectively (Table 1). The lower vaue of setback viscosity was observed on the addition of PP, indicating a lower rate of retrogradation of potato (Villanueva et al. 2018). The setback value has been shown to be related to the ability of starches to form a hard gel (semi-solid paste). Setback from peak causes gel micelle regions to grow, which increases the retrogradation index.

Final viscosity is also an important parameter that has a crucial role in the formation of the gel after heating the starch in the presence of moisture (Nawaz et al. 2020). The final viscosity of Kufri Chipsona 3 was higher (4370 cP) as compared to Kufri Jyoti (2355 cP). The addition of PP to both cultivars showed a significant lowering of final viscosity; a higher reduction was reported in 15% PP (Tables S1 and 14).

Correlation Between Starch Digestibility Factors and Related Parameters

Many factors, including starch, amylose, resistant starch and pasting properties, influence the physicochemical, starch digestibility, and predicted GI of potatoes. The earlier reports revealed that GI of starch crops such as potato, rice and wheat showed to have a negative correlation with RS content and positively correlated with amylose content (Cummings and Englyst 1995; Kumar et al. 2020; Lal et al. 2020). In this current study, we observed significant correlations between starch-related parameters, including starch, amylose, and amylopectin, and factors related to glycemic response and starch digestibility. When PP was added to PF, we found a positive correlation between starch content and both resistant starch (R = 0.97) and peak time (R = 0.42). These findings highlight the interplay between starch composition and key factors influencing glycemic response and starch digestibility in our investigation (Fig. 4).

Heat map showing Pearson’s correlation matrix for different parameters taken in the study. Abbreviation: ACHO: available carbohydrate; SHI: starch hydrolysis index; GI: glycemic index; GL: glycemic load; RS: resistant starch; ST: starch; AMY: amylose; AMP: amylopectin; PT: pasting temperature; PV: pasting viscosity; SV: Setback viscosity; BV: breakdown viscosity; FV: final viscosity

On the contrary, there was a negative correlation between the starch and starch hydrolysis index (R = -0.98), GI (R = -0.98), peak viscosity (R = -0.86), breakdown viscosity (R = -0.86) and final viscosity (R = -0.87). After the addition of PP to PF in both cultivars, the amylose content showed a negative correlation with GI and GL (Fig. 4). Similarly, in our study, in PF + PP combination, there was a positive correlation between GL and GI (R = 0.46), GL and SHI (0.85), GL and ACHO (R = 0.97). However, RS content was reported to be negatively correlated with GI (R = -0.97) and GL (-0.27). The GI of PF + PP combination showed a higher negative correlation with RS content which might be due to the formation of type III RS in the potato thereby enhancing RS content. The peak viscosity was suggested to have an inverse relation with amylose content and a positive correlation with amylopectin. Peak time was positively correlated with starch (R = 0.42), amylopectin (R = 0.93), and available carbohydrate (R = 0.85) (Fig. 4). Pasting temperature also depends on amylose and amylopectin but within cultivar, no significant difference was found compared to those isolated in only potato flesh.

Conclusions

Our study showed a pronounced effect of addition of PP with PF in the starch digestibility parameters viz., estimated GI, GL and SHI. A higher reduction in the in vitro glycemic response was observed in the Kufri Chipsona 3 as compared to Kufri Pukhraj. Our study suggests that adding PP to potatoes (also starchy crops) might be an effective strategy for managing the postprandial rise in blood glucose levels. The addition of PF to PP showed an increase in starch and amylose content, resulting from the intrinsic property of PP, which also contains starch and carbohydrate as a component. The SHI and ACHO were reported to be lowered due to addition of PP with PF. The lowering of starch hydrolysis might be due to the different components present in PP, which may be interacted and slow down the release of glucose over a period of time. Most interestingly to know that the glycemic response factor such as GI and GL was reported to be significantly reduced by the addition of PP with PF. The phenolics, glycoalkaloid and α-glucosidase inhibitor components present in the PP might have reduced the release of glucose from starch, thereby lowering the GI and GL of the PP and PF mixture. Our result suggested that powder absorbing high water under increasing temperature had high PV. The PV, BV and FV of processing cultivar i.e., Kufri Chipsona 3 was reported to be higher than Kufri Jyoti, a table cultivar. However, the addition of PP in both cultivars reduced PV, which might be due to an increased amylose content of the mixture. Long amylopectin branches and amylose contributed to high gelatinization temperatures and retrogradation rate as the starch with a higher proportion of amylopectin chains. The addition of PP to the PF affects the pasting properties of potato flour (PP + PF). The present study will provide an understanding for the use of PP which is a major waste product of the potato processing industries. Moreover, the product developed by mixing PP with PF and other starchy flour might be beneficial for diabetic person, as the glycemic response is lowered.

Data Availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

Abdelraof, M., M. S. Hasanin, and H. El-Saied. 2019. Ecofriendly green conversion of potato peel wastes to high productivity bacterial cellulose. Carbohydrate Polymers 211: 75–83.

Arun, K. B., J. Chandran, R. Dhanya, P. Krishna, P. Jayamurthy, and P. Nisha. 2015. A comparative evaluation of antioxidant and antidiabetic potential of peel from young and matured potato. Food Biosci 9: 36–46.

Azizi, A. F., S. Sethi, A. Joshi, A. M. Singh, P. Raigond, M. K. Singh, and R. K. Yadav. 2020. Biochemical and functional attributes of raw and boiled potato flesh and peel powders for suitability in food applications. Journal of Food Science and Technology 57: 3955–3965.

ben Jeddou, K., F. Bouaziz, S. Zouari-Ellouzi, F. Chaari, S. Ellouz-Chaabouni, R. Ellouz-Ghorbel, and O. Nouri-Ellouz. 2017. Improvement of texture and sensory properties of cakes by addition of potato peel powder with high level of dietary fiber and protein. Food Chemistry 217: 668–677.

Björck, I. M. E., and M. A. Siljeström. 1992. In-vivo and in-vitro digestibility of starch in autoclaved pea and potato products. Journal of the Science of Food and Agriculture 58: 541–553.

Camire, M.E. 2016. Chapter 23—Potatoes and human health. In Advances in potato chemistry and technology, 2nd ed., eds. J. Singh and L. Kaur, 685–704. Academic Press.

Camire, M. E., D. Violette, M. P. Dougherty, and M. A. McLaughlin. 1997. Potato Peel Dietary Fiber Composition: effects of Peeling and Extrusion cooking processes. Journal of Agriculture and Food Chemistry 45: 1404–1408.

Cummings, J.H., and H.N. Englyst. 1995. Gastrointestinal effects of food carbohydrate. American Journal of Clinical Nutrition 61: 938–945.

Drewnowski, A., and B.M. Popkin. 1997. The nutrition transition: New trends in the global diet. Nutrition Reviews 55: 31–43.

Eyinla, T. E., R. A. Sanusi, and B. Maziya-Dixon. 2021. Effect of processing and variety on starch digestibility and glycemic index of popular foods made from cassava (Manihot esculenta). Food Chemistry 356: 129664.

FAOSTAT. 2019. Statistical database of Food and Agriculture Organization of the United Nations [FAO]. 2019. Retrieved from http://www.fao.org/faostat/en/.

Fujita, H., T. Yamagami, and K. Ohshima. 2003. Long-term ingestion of Touchi-extract, an α-glucosidase inhibitor, by borderline and mild type-2 diabetic subjects is safe and significantly reduces blood glucose levels. Nutrition Research 23: 713–722.

Gebrechristos, H.Y., and W. Chen. 2018. Utilization of potato peel as eco-friendly products: A review. Food Science & Nutrition 6 (6): 1352–1356.

Goñi, I., L. García-Diz, E. Mañas, and F. Saura-Calixto. 1996. Analysis of resistant starch: a method for foods and food products. Food Chemistry 56: 445–449.

Goñi, I., A. Garcia-Alonso, and F. Saura-Calixto. 1997. A starch hydrolysis procedure to estimate glycemic index. Nutrition Research 17: 427–437.

Jansky, S., and D. Fajardo. 2016. Amylose content decreases during tuber development in potato. Journal of the Science of Food and Agriculture 96: 4560–4564.

Javed, A., A. Ahmad, A. Tahir, U. Shabbir, M. Nouman, A. Hameed, A. Javed, A. Ahmad, A. Tahir, U. Shabbir, M. Nouman, and A. Hameed. 2019. Potato peel waste-its nutraceutical, industrial and biotechnological applications. AIMS Agriculture and Food 4 (3): 807–823.

Juliano, B.O., C.M. Perez, A.B. Blakeney, T. Castillo, N. Kongseree, B. Laignelet, E.T. Lapis, V.V.S. Murty, C.M. Paule, and B.D. Webb. 1981. International cooperative testing on the amylose content of milled rice. Starch - Stärke 33: 157–162.

Kahlon, T.S., M.H. Chapman, and G.E. Smith. 2007. In vitro binding of bile acids by okra, beets, asparagus, eggplant, turnips, green beans, carrots, and cauliflower. Food Chemistry 103: 676–680.

Kaur, L., J. Singh, N. Singh, and R. Ezekiel. 2007. Textural and pasting properties of potatoes (Solanum tuberosum L.) as affected by storage temperature. Journal of the Science of Food and Agriculture 87: 520–526.

Kaur, A., N. Singh, R. Ezekiel, and N.S. Sodhi. 2009. Properties of starches separated from potatoes stored under different conditions. Food Chemistry 114 (4): 1396–1404.

Kolasa, K.M. 1993. The potato and human nutrition. American Potato Journal 70: 375–384.

Kumar, A., U. Sahoo, B. Baisakha, O.A. Okpani, U. Ngangkham, C. Parameswaran, N. Basak, G. Kumar, and S.G. Sharma. 2018. Resistant starch could be decisive in determining the glycemic index of rice cultivars. Journal of Cereal Science 79: 348–353.

Kumar, A., P. A. Panda, M. K. Lal, U. Ngangkham, C. Sahu, K. R. Soren, H. N. Subudhi, S. Samantaray, and S. Sharma. 2020. Addition of Pulses, Cooking Oils, and Vegetables Enhances Resistant Starch and Lowers the Glycemic Index of Rice (Oryza sativa L.). Starch/Staerke 1900081.

Kumar, D., M.K. Lal, S. Dutt, P. Raigond, S.S. Changan, R.K. Tiwari, K.N. Chourasia, V. Mangal, and B. Singh. 2022. Functional fermented probiotics, prebiotics, and synbiotics from non-dairy products: a perspective from nutraceutical. Molecular Nutrition & Food Research 66: 2101059.

Lal, M.K., A. Kumar, P. Raigond, S. Dutt, S.S. Changan, K.N. Chourasia, R.K. Tiwari, D. Kumar, S. Sharma, S.K. Chakrabarti, and B. Singh. 2020. Impact of starch storage condition on glycemic index and resistant starch of cooked potato (Solanum tuberosum) tubers. Starch - Stärke 73: 1900281.

Lal, M.K., B. Singh, S. Sharma, M.P. Singh, and A. Kumar. 2021a. Glycemic index of starchy crops and factors affecting its digestibility: a review. Trends in Food Science & Technology 111: 741–755.

Lal, M.K., A. Kumar, P. Raigond, S. Dutt, S.S. Changan, K.N. Chourasia, R.K. Tiwari, D. Kumar, S. Sharma, S.K. Chakrabarti, and B. Singh. 2021b. Impact of starch storage condition on glycemic index and resistant starch of cooked potato (Solanum tuberosum) tubers. Starch/Staerke 73: 1900281.

Lal, M.K., R.K. Tiwari, R. Kumar, K.C. Naga, A. Kumar, B. Singh, P. Raigond, S. Dutt, K.N. Chourasia, D. Kumar, V. Parmar, and S.S. Changan. 2021c. Effect of potato apical leaf curl disease on glycemic index and resistant starch of potato (Solanum tuberosum L.) tubers. Food Chemistry 359: 129939.

Lal, M.K., R.K. Tiwari, A. Jaiswal, S.K. Luthra, B. Singh, S. Kumar, S. Gopalakrishnan, K. Gaikwad, A. Kumar, V. Paul, and M.P. Singh. 2022. Combinatorial interactive effect of vegetable and condiments with potato on starch digestibility and estimated in vitro glycemic response. Journal of Food Measurement and Characterization 16:3: 2446–2458.

Nawaz, A., Z. Xiong, Q. Li, H. Xiong, J. Liu, L. Chen, P. Wang, N. Walayat, S. Irshad, and J.M. Regenstein. 2019. Effect of wheat flour replacement with potato powder on dough rheology, physiochemical and microstructural properties of instant noodles. Journal of Food Processing and Preservation 43: e13995.

Nawaz, A., S.W. Ali, S. Irshad, F. Irshad, A. Ahmed, Z. Sharmeen, and I. Khan. 2020. Effect of peeling and unpeeling on yield, chemical structure, morphology and pasting properties of starch extracted from three diverse potato cultivars of Pakistan. International Journal of Food Science & Technology 55: 2344–2351.

Nema, P.K., N. Ramayya, E. Duncan, and K. Niranjan. 2008. Potato glycoalkaloids: formation and strategies for mitigation. Journal of the Science of Food and Agriculture 88: 1869–1881.

Pathak, P.D., Mandavgane, S.A., Puranik, N.M., Jambhulkar, S.J., and Kulkarni, B.D., 2017. Valorization of potato peel: a biorefinery approach. 38: 218–230. https://doi.org/10.1080/07388551.2017.1331337.

Pinhero, R.G., R.N. Waduge, Q. Liu, J.A. Sullivan, R. Tsao, B. Bizimungu, and R.Y. Yada. 2016. Evaluation of nutritional profiles of starch and dry matter from early potato varieties and its estimated glycemic impact. Food Chemistry 203: 356–366.

Ramdath, D.D., E. Padhi, A. Hawke, T. Sivaramalingam, and R. Tsao. 2014. The glycemic index of pigmented potatoes is related to their polyphenol content. Food & Function 5: 909–915.

Ru, W., Y. Pang, Y. Gan, Q. Liu, and J. Bao. 2019. Phenolic compounds and antioxidant activities of potato cultivars with white, yellow, red and purple flesh. Antioxidants 2019 8: 419.

Sánchez Maldonado, A.F., E. Mudge, M.G. Gänzle, and A. Schieber. 2014. Extraction and fractionation of phenolic acids and glycoalkaloids from potato peels using acidified water/ethanol-based solvents. Food Research International 65: 27–34.

Selvakumar, G., G. Shathirapathiy, R. Jainraj, and P. Yuvaraj Paul. 2017. Immediate effect of bitter gourd, ash gourd, Knol-Khol juices on blood sugar levels of patients with type 2 diabetes mellitus: a pilot study. Journal of Traditional & Complementary Medicine 7: 526–531.

Shevkani, K., M. Kaur, and N. Singh. 2021. Composition, pasting, functional, and microstructural properties of flours from different split dehulled pulses (dhals). Journal of Food Processing and Preservation 45: e15485.

Shirani, G., and R. Ganesharanee. 2009. Extruded products with fenugreek (Trigonella foenum-graecium) chickpea and rice: physical properties, sensory acceptability and glycaemic index. Journal of Food Engineering 90: 44–52.

Singh, N., V. Kamath, and P.S. Rajini. 2005a. Protective effect of potato peel powder in ameliorating oxidative stress in Streptozotocin diabetic rats. Plant Foods for Human Nutrition 60:2: 49–54.

Singh, N., V. Kamath, and P.S. Rajini. 2005b. Attenuation of hyperglycemia and associated biochemical parameters in STZ-induced diabetic rats by dietary supplementation of potato peel powder. Clinica Chimica Acta 353: 165–175.

Thakur, M., A.K. Rai, B.B. Mishra, and S.P. Singh. 2021. Novel insight into valorization of potato peel biomass into type III resistant starch and maltooligosaccharide molecules. Environmental Technology and Innovation 24: 101827.

Tian, S., and Y. Sun. 2020. Influencing factor of resistant starch formation and application in cereal products: a review. International Journal of Biological Macromolecules 149: 424–431.

Torruco-Uco, J.G., L.A. Chel-Guerrero, and D. Betancur-Ancona. 2006. Isolation and molecular characterization of makal (Xanthosoma yucatanensis) starch. Starch/Staerke 58: 300–307.

Vaitkevičienė, N. 2019. A comparative study on proximate and mineral composition of coloured potato peel and flesh. Journal of the Science of Food and Agriculture 99: 6227–6233.

Villanueva, M., B. de Lamo, J. Harasym, and F. Ronda. 2018. Microwave radiation and protein addition modulate hydration, pasting and gel rheological characteristics of rice and potato starches. Carbohydrate Polymers 201: 374–381.

Visvanathan, R., C. Jayathilake, Chaminda Jayawardana, and R. Liyanage. 2016. Health-beneficial properties of potato and compounds of interest. Journal of the Science of Food and Agriculture 96: 4850–4860.

Wolever, T.M.S. 2013. Glycemic index claims on food labels: review of health Canada’s evaluation. European Journal of Clinical Nutrition 67: 1229.

Won, C., Y.I. Jin, D.C. Chang, M. Kim, Y. Lee, P. Ganesan, Y.K. Lee, and Y.H. Chang. 2017. Rheological, pasting, thermal and retrogradation properties of octenyl succinic anhydride modified potato starch. Food Science and Technology 37: 321–327.

Wu, L., M. Weng, H. Zheng, P. Lai, B. Tang, J. Chen, and Y. Li. 2020. Hypoglycemic effect of okra aqueous extract on streptozotocin-induced diabetic rat. Food Science and Technology 40: 972–978.

Acknowledgements

Authors would like to acknowledge the Director of ICAR-Central Potato Research Institute, Shimla for constant support and guidance.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This research received no external funding.

Author information

Authors and Affiliations

Contributions

Conceptualization and design, MKL, RKT and AK; Interpretation of data and original draft preparation, MKL, RKT, AK, JPD; Analysis and interpretation of data and writing, MKL, RK, and DK; Performed analysis, interpretation of data and resources, SSC, SD, JSG, revised draft manuscript and supervision, MPS and BS. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 54.7 KB)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lal, M.K., Tiwari, R.K., Kumar, A. et al. Methodological Breakdown of Potato Peel’s Influence on Starch Digestibility, In Vitro Glycemic Response and Pasting Properties of Potato. Am. J. Potato Res. 101, 65–75 (2024). https://doi.org/10.1007/s12230-024-09942-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12230-024-09942-w