Abstract

Cotton fiber maturity has been reported as average maturity and maturity distribution in a sample, through measuring the fibers in the way of either an individual fiber cross-section or a longitude of several subsamples by cross-sectional image analysis (IA), advanced fiber information system (AFIS), and Cottonscope method. As a different approach, attenuated total reflection Fourier transform infrared (ATR FT-IR) spectroscopy was proposed to estimate fiber maturity (MIR) and maturity distribution at a bundle fiber level on the basis of three MIR (low-, mid-, and high) classifications. Although maturity distributions from IA, AFIS, or Cottonscope measurement are reported, they are not related with high-volume instrument (HVI) and AFIS qualities considerably. Novelty of this study examined the effect of individual three MIR indices and additional MIR differentials on HVI and AFIS qualities in commercial cotton fibers. There were statistically significant and moderate-to-strong correlations between the MIR indices and fiber maturity and fineness measurements, and also moderate correlations between the MIR indices and other fiber qualities (for example, HVI strength). In particular, there was a moderate correlation between MIR readings and one fiber length parameter [AFIS L(n)] or two short fiber content (SFC) properties [AFIS SFC(w) and AFIS SFC(n)]. Meanwhile, MIR differential (D3) was observed to be correlated with HVI strength significantly and strongly. The result indicated the capability of ATR FT-IR spectroscopy for monitoring fiber maturity distribution in commercial cotton fibers and further in understanding fiber quality measurement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cotton crop is one of the most important agricultural commodities in the world, primarily for its naturally produced textile fiber [1]. Cotton fiber quality plays a vital role in cotton production and sustainability. Cotton production is determined by at least three main factors (i.e., genotype, environment, and agricultural practices) and their interactions, which influence both yield and fiber quality potential and ultimately determine the growers and processors’ profitability [2].

Cotton fibers are developed from protodermal cells on the outer integument layer of cotton seeds, and take approximately 6–8 weeks for fiber reaching fully maturity. To meet the need of cotton fiber mechanical harvesting, chemical boll openers and leaf defoliants are used to increase cotton boll opening and reduce plant vegetative growth [3]. Cotton fiber quality is naturally variable within locules in a single boll, from the bottom to the top boll position in a plant, and from different areas in a grown field, leading to fiber-to-fiber quality variation within a sample [4,5,6,7]. High-volume instrumentation (HVI™) and advanced fiber information system (AFIS) are the most commonly used instruments of evaluating multiple cotton fiber qualities quickly for cotton industry, breeders, and researchers [8,9,10]. HVI reports the fiber micronaire (MIC), upper half mean length (UHML), length uniformity index (UI), strength, elongation, color (color grade, Rd, + b), short fiber content (SFC), trash, and maturity properties from testing a bundle of fibers, while AFIS provides 20 fiber quality parameters including a complete fiber length and distribution, trash content, nep content, fineness, and maturity from testing the individualized fibers. A brief description of reported HVI and AFIS qualities in a routine and standard fiber test is given in Appendix [9,10,11,12].

Major factor of cotton fiber as an industrial raw material is the cellulose deposition within the secondary cell wall (SCW). Fiber maturity, often represented by the term circularity (Ɵ), is defined as the cross-sectional area of the SCW relative to the area of a circle having the same perimeter [13,14,15]. Variability in cotton fiber maturity can have a negative impact on fiber breakage and entanglement (neps) during mechanical processing, dye uptake in yarn and fabric products, as well as yarn processing and textile performance [10, 16,17,18]. Besides AFIS method for fiber maturity measurement routinely [9, 19,20,21], traditional cross-sectional image analysis (IA) [13,14,15] and Cottonscope [20,21,22,23,24] are used in the laboratories to capture natural variability in cotton fiber maturity. The three methods are capable of analyzing fibers at a single fiber level from each of several subsamples in a sample, but it could be difficult to obtain a representative result if a sample is highly heterogeneous in fiber maturity and quality. As a different approach, attenuated total reflection Fourier transform infrared (ATR FT-IR) spectroscopy was proposed in 2011 [25], based on spectral intensity differences induced by relative cellulose amount of cotton fibers. In the concept, two algorithms were created from fibers in seed cottons to evaluate fiber infrared maturity (MIR) index, and further MIR was compared with AFIS maturity and IA maturity on diverse cotton fibers [25, 26]. One ATR FT-IR spectrum represents the information of fibers at a bundle fiber level, differing from the analysis of fibers at either an individual fiber cross-section level or a longitudinal level in which fibers were aligned or cut prior to IA, AFIS, and Cottonscope analysis. Hence, conventional ATR FT-IR measurement provides fiber maturity in a general manner, and a large number of FT-IR subsamples across a sample is necessary for its maturity distribution.

From the aspect of measuring procedures, IA, AFIS, and Cottonscope methods are relatively time-consuming and destructive, and also only represent the fiber maturity of several subsamples in a sample, which is acceptable when the sample either is homogenous after a well-blending process at a large scale or is available at a small amount during cotton breeding and genetic studies. In other words, it could be a challenge to have a reliable fiber maturity of naturally variable cotton fibers by measuring several subsamples. Nevertheless, IA, AFIS, and Cottonscope provide maturity distribution that characterizes the level of maturity variation in a sample. However, maturity distributions from three measurements are reported as immature fiber content (IFC), not fiber mid- and high-maturity contents. To our best knowledge, these maturity distributions have not been linked with HVI and AFIS qualities extensively. The barrier might be due to the availability of IA, AFIS, or Cottonscope instrument and its maturity distributional data. ATR FT-IR method might be an alternative and complementary option for investigating fiber maturity, since it enables to analyze as little as 0.5 mg fiber directly without the need of preparing fiber samples first (such as fiber alignment, cutting, and weighing), and also enables to scan individual subsample rapidly for less than 2 min. By analyzing fibers with many subsamples, it is possible to draw accurate FT-IR maturity distribution within an unblended sample. The main objective of this study was (1) to calculate, in addition to average MIR value from all subsamples for each sample, MIR,L, MIR,M, or MIR,H value representing the subsamples with MIR in the respective range of less than 0.58, 0.58 to 0.80, or greater than 0.80 [27], and (2) to correlate different MIR indices with HVI and AFIS qualities. Novelty of this study lies in utilizing three fiber maturity levels (MIR,L, MIR,M, and MIR,H) from ATR FT-IR method and establishing any relationships between each MIR distributional indices and HVI and AFIS qualities in unblended commercial cotton fibers, ultimately implementing this ATR FT-IR spectral technique as a non-destructive, rapid, and easy-use tool for optimizing fiber quality improvement for cotton fiber researchers and growers.

2 Experimental Details

2.1 Cotton Fiber Samples

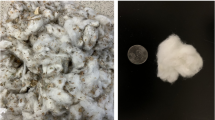

A total of 11 commercial Upland seed cotton samples from nine cultivars, grown in three U.S. states [Mississippi (MS), Missouri (MO), and New Mexico (NM)] and harvested in 2019 were used [27]. They were Americot NG3522 (NG3522), Deltapine 1646 (DP1646), Dyna-Gro 3385 (DG3385), Fiber Max 1830 (FM1830), Phytogen 350 (PHY350), Phytogen 430 (PHY430), Phytogen 444 (PHY444), Stoneville 4848 (ST4848), and Stoneville 5471 (ST5471). These samples were kept at laboratory environment and ~ 1 kg of each were ginned using a laboratory roller gin for fiber analysis.

2.2 Fiber HVI and AFIS Measurement

The samples were conditioned at 21 ± 1 °C temperature and 65 ± 2% relative humidity for 48 h prior to HVI and AFIS testing. HVI properties were determined by an HVI 1000 (USTER Technologies Inc., Knoxville, TN) with five replications per sample, and AFIS values were assessed by an AFIS Pro 2 (USTER Technologies Inc., Knoxville, TN) with three replications of 5000 fibers per measurement. All measurements were performed at the Southern Regional Research Center of USDA’s Agricultural Research Service (USDA-ARS-SRRC) routinely.

2.3 ATR FT-IR Collection and MIR Calculation

An FTS 3000MX FT-IR spectrometer (Varian Instruments, Randolph, MA) equipped with a ceramic source, KBr beam splitter, deuterated triglycine sulfate (DTGS) detector, and an ATR attachment was used to acquire the fiber spectra. ATR sampling device utilized a DuraSamplIR single-pass diamond-coated internal reflection accessory (Smiths Detection, Danbury, CT), and a consistent contact pressure was applied by the way of a stainless-steel rod and an electronic load display. Fifty subsamples were randomly taken across each sample and their ATR FT-IR spectra were collected over the range of 4000–600 cm−1 at 4 cm−1 resolution and 16 co-added scans in absorbance unit, with extreme attention to avoid the spectral interference of any non-lint materials (seed, trash, seed-coat, etc.) in a sample.

Fiber MIR values were calculated by executing simple algorithmic analyses of ATR FT-IR spectra as exampled in Fig. 1 with reported procedure [25]. Briefly, after the spectra were exported into Microsoft® Excel® for Office 365, R1 was calculated from the first algorithm R1

in which I1500, I1032, and I956 are each a 3-point intensity average at respective wavenumber. The wavenumber at 1032 cm−1 represented the large and positive intensity variation, while the one at 956 cm−1 characterized the large and negative intensity variation in the difference spectrum between immature and mature cottons. The wavenumber at 1500 cm−1 was used to offset two readings because of its minimum absorbance.

Next, the R1 value was converted to MIR by the second algorithm MIR

where R1, R1,lr, and R1,sm are the R1 values for the unknown sample, the largest R1, and the smallest R1, respectively. The R1,sm and R1,lr values were determined to be 0.14 and 0.59 [25].

There were 50 MIR values (or 50 subsamples) for each of 11 samples. Average MIR value from 50 MIR values was taken for each sample. After assigning the MIR in the range of 0.0–1.0 into 20 bins (bin width, 0.05) and counting the frequency number of each bin, MIR frequency distribution curve was obtained for each individual sample.

Separately, 50 subsamples were grouped into low-, mid-, or high-MIR class on the basis of the MIR in the respective range of less than 0.58, 0.58 to 0.80, or greater than 0.80 [27]. Then MIR,L, MIR,M, or MIR,H index were obtained by dividing the sum of MIR values with the total of MIR values for an individual low-, mid-, or high-MIR class in the following equations:

Furthermore, three MIR differentials (D1, D2, and D3) were calculated from the equations below

2.4 Statistical Analysis

Seven MIR indices (MIR, MIR,L, MIR,M, MIR,H, D1, D2, and D3) of each sample were correlated with HVI and AFIS qualities (Table 1), in which trash properties were not selected, because any non-lint materials were not included in ATR FT-IR spectral acquisition. Both correlation coefficient (r) and p value on any pair between fiber MIR indices and HVI or AFIS qualities at a confidence level of 95% (α = 0.05) were calculated using Regression function under Data Analysis in Microsoft® Excel® for Office 365. When |r| value is less than 0.3, between 0.3 and 0.7, or greater than 0.7, a weak, moderate, or strong (either positive or negative) linear correlation exists between the two variables [28]. The degree of statistically significant differences is expressed as significant*, very significant**, and very significant at p < 0.001***.

3 Results and Discussion

3.1 HVI and AFIS Fiber Quality Data

Table 1 shows a list of the descriptive statistics of selected HVI and AFIS properties as well as FT-IR maturity from a routine experimental report for 11 commercial cottons. Variations of these properties in Table 1 could represent the variability of targeted fiber quality in commercial cottons and cotton breeding programs. Some properties are more sensitive to fluctuations within different cotton cultivars than other properties, as shown by either a larger standard deviation (STDEV) or the coefficient of variation (CV%). For example, CV% varies greatly from the least of 2.02 for HVI MAT to the greatest of 64.3% for AFIS SCN.

HVI and AFIS provide the fiber maturity and fineness measurements, which include HVI MIC and MAT as well as AFIS MR, IFC, and Fineness. Both HVI MIC and MAT are positive correlated with either AFIS MR or Fineness but negative with AFIS IFC strongly (r > 0.80) and significantly (Table 2). Although HVI MAT and AFIS MR in Table 1 show a comparable mean maturity value (0.87 for HVI MAT and 0.88 for AFIS MR), HVI MAT has a smaller STDEV and CV% (0.02 and 2.02) than AFIS MR (0.04 and 4.65). Relative to mean HVI MAT (0.87) and AFIS MR (0.88), FT-IR MIR was a little less (0.78) (Table 1). Expectedly, FT-IR MIR has positive strong and significant relationships with HVI MIC, HVI MAT, and AFIS MR (r > 0.70) (Table 2).

HVI and AFIS generate the fiber length properties too. Fiber length measurements in Table 1 from one HVI parameter (UHML) and six AFIS readings [L(w), L(w) CV, UQL(w), L(n), L(n) CV, and L5%(n)] suggest the greatest mean value at 1.43 inches for AFIS L5%(n), whereas the lowest mean value at 0.81 inches for AFIS L(n). There are positive strong and statistically significant relationships between HVI UHML and three AFIS readings [L(w), UQL(w), and L5%(n)] in Table 2 (r > 0.80), but relatively there exists a positive moderate (r = 0.63) and significant correlation between HVI UHML and AFIS L(n). Meanwhile, HVI UHML shows a positive moderate correlation with AFIS L(n) CV and a positive weak correlation with AFIS L(w) CV insignificantly.

The two instruments also produce SFC result, with SFC measured by HVI on a beard of fibers while by AFIS based on fiber weight (SFC(w)) and number (SFC(n)). The mean SFC values differ quietly between HVI and AFIS method (Table 1), ranging from 4.07% as measured by HVI to 9.22% (SFC(w)) and 28.3% (SFC(n)) by AFIS. HVI SFC indicates a weak positive and statistically insignificant correlation with both AFIS SFC(w) and AFIS SFC(n) (Table 2). Likely, this is due to the difference in measuring techniques between the two methods, utilizing the weight or number of fibers in AFIS data integration against the beard fibers in HVI data integration that is not related to weight and number of fibers [29].

3.2 Variation of MIR Distribution

Cotton manifests a naturally variability in its qualities, including fiber maturity. Figure 2 compares MIR frequency between DP1646 and ST4848 cultivar fibers that share the same mean MIR value of 0.81. Both cultivars indicate a broad range of MIR variation and reveal a frequency pattern discrepancy; for instance, the ST4848 cultivar has more low-MIR fibers than the DP1646 fibers. This implies that cotton genotype and environment (weather, location, and agricultural practice) as well as their interactions greatly influence fiber MIR property.

After grouping individual subsample into one of 3-MIR (low-, mid-, and high) classification classes, MIR,L, MIR,M, and MIR,H values were estimated. Figure 3 shows the pattern of MIR,L, MIR,M, and MIR,H values along with an increasing MIR on 11 cotton samples. High MIR cotton cultivars tend to contain more MIR, H fibers, less MIR,M and MIR,L fibers than low-MIR cotton cultivars. With MIR raising, MIR,H value increases steadily, whereas MIR,M and MIR,L values reduce gradually.

Although AFIS MR is observed to be less sensitivity [21, 23], it offers maturity distribution that characterizes the level of single fiber maturity variation of ~ 15,000 fibers in a sample (5000 fibers per test × 3 fiber subsampling). MR is determined by measuring the shape and number of individualized fibers from two different angles and then indirectly calculated from the percentage of mature fiber content (ө ≥ 0.50; ө = MR × 0.577) and immature fiber content (IFC; ө < 0.25) [10]. Similar to 3-MIR (low-, mid-, and high) classes in Fig. 3, MRIF, MRTW, and MRR values were assessed by totaling the percentage of fibers in respective ө values of < 0.25, 0.25 to 0.50, and ≥ 0.5 for immature fibers (IF), thin-walled (TW) fibers, and mature fibers (R) [30]. In parallel with MIR values in Fig. 3, Fig. 4 indicates that great MR cotton cultivars have more MRR fibers, less MRTW and MRIF fibers than low MR cotton cultivars. Unlike MRTW and MRIF values decreasing, MRR value increases constantly with MR elevating.

Positive strong and significant relationship (r = 0.74) between AFIS MR and FT-IR MIR in Table 2 suggests the feasibility of linking MR value with MIR in unblended fiber samples. Tendency of MIR index in Fig. 3 resembles that in Fig. 4, but there exists a difference between Fig. 3 and Fig. 4. For example, CV% of MIR ranging from 20.56 to 76.86 for three classes in Fig. 3 are greater than those of MR stretching from 11.87 to 17.63 for three classes in Fig. 4, echoing the previous observation that AFIS maturity is not sensitive. In addition, these is a substantial difference in characterizing fiber maturity between two methods, MIR directly measures the amount of cellulose and therefore the maturity at bundle fiber level, while MR indirectly determines fiber maturity from the shape and number of individualized fibers at single fiber level.

3.3 Relationship of MIR Indices to HVI and AFIS Fiber Quality

Correlation analysis is useful to understand the relationships between fiber maturity distribution and either HVI or AFIS properties. Thus, the correlation coefficients of seven MIR indices against nine HVI and fifteen AFIS properties in Table 1 were calculated, and only the pairs with moderate-to-strong relationships (r ≥ 0.30) or statistically significant correlations (p value ≤ 0.05) were compiled in Table 3 for the analysis. In other words, the seven MIR readings were correlated with three HVI qualities (UHML, Rd, and SFC) and three AFIS properties [L(w), UQL(w), and L5%(n)] either weakly (r < 0.30) or insignificantly (p value > 0.05).

Among four MIR indices (MIR, MIR,L, MIR,M, and MIR,H), MIR has the similar pattern to MIR, H value for all properties listed in Table 3, and also both MIR and MIR,H values reveal a different tendency from MIR,M and MIR,L values. Notably, the trend of MIR,M values differs from that of MIR,L values for some properties. For example, HVI STR is correlated with MIR, M moderately (r = −0.59) but with MIR, L weakly (r = −0.01).

The four MIR readings show statistically significant and moderate-to-strong correlations with fiber maturity and fineness measurements known as HVI MIC, HVI MAT, AFIS MR, AFIS IFC, and AFIS Fineness, except for one pair of MIR,L vs. HVI MAT. Opposite to MIR,M and MIR,L values, both MIR and MIR,H values increase with HVI MIC, HVI MAT, AFIS MR, or AFIS Fineness increasing but expectedly with AFIS IFC decreasing.

There are statistically insignificant and moderate correlations between the four MIR values and four HVI properties (UI, STR, ELO, and + b) and three AFIS indices (Nep Size, Nep, and SCN), without the consideration of weak correlations between MIR,L and HVI STR, between MIR,L and HVI ELO, between MIR, L and AFIS SCN, as well as between mean MIR and AFIS SCN.

The four MIR readings have moderate correlations with three AFIS fiber length properties (L(w)CV, L(n), and L(n)CV). Both MIR and MIR, H value increase with AFIS L(n) value. Although being insignificant statistically, moderate correlations between the four MIR readings and AFIS L(n) might imply some degree of relationships between the two differing fiber characteristics, compared to only weak relationships between the four MIR readings and the other fiber length indices [HVI UHML, AFIS L(w), AFIS UQL(w), and AFIS L5%(n)] (not shown in Table 3). All but MIR,L values are statistically significant with AFIS L(w)CV, whereas only MIR,L is significant with AFIS L(n)CV.

Most of the four MIR values are significantly and moderately correlated with AFIS SFC(w) and AFIS SFC(n). Unlike MIR and MIR, H value, both MIR,M and MIR,L values increase with AFIS SFC(w) and AFIS SFC(n) arising, emphasizing a great impact of less mature fibers on AFIS SFC in a sample. Contradictorily, the four MIR readings exhibit weak and insignificant relationships with HVI SFC (not shown in Table 3).

To examine the effect of relative MIR difference between any combinations of three MIR indices (MIR,L, MIR,M, and MIR,H) in one sample on HVI and AFIS properties, three MIR differentials (D1, D2, and D3) were correlated with the properties and the results were inserted in Table 3 for connection. In general, D1 resembles D2 in the aspect of r and p values, and both are similar to MIR,H value but are different from D3 value. Interestingly and particularly, D3 value indicates a significant and strong correlation with HVI STR among seven different MIR indices in Table 3. This observation might unravel the importance of relative MIR differential (MIR,M–MIR,L) in a sample on HVI STR property, which increases with D3 value reduction.

4 Conclusion

This study presented an ATR FT-IR spectroscopy method for determining cotton fiber maturity distribution at a bundle fiber level on the basis of 3-MIR (low-, mid-, and high) classifications. While the result was from 50 subsamples in a sample, it represented an analysis of 50 different bundle fibers in naturally variable cotton samples. Contrarily, traditional IA, AFIS, and Cottonscope methods analyze several subsamples in a sample and report IFC only (or without mid- and high-maturity content). With MIR increasing, MIR,H index increases steadily, while MIR,M and MIR,L values reduce gradually. Correlation analysis of seven MIR indices with HVI and AFIS qualities revealed that the MIR values, in general, were statistically significant and moderately-to-strongly correlated with fiber maturity and fineness measurements as well as were moderately related to additional fiber qualities (for example, HVI STR). Notably, there was a moderate correlation between MIR value and AFIS L(n), rather than between MIR readings and other fiber length measurements [HVI UHML, AFIS L(w), AFIS UQL(w), and AFIS L5%(n)]. There were significant and moderate correlations between MIR and either AFIS SFC(w) or AFIS SFC(n), instead of between MIR and HVI SFC. Relative MIR differential (D3) was observed to have a significant and strong correlation with HVI STR. The result indicated the usefulness of ATR FT-IR approach as a non-destructive, rapid and easy-to-use tool in monitoring the fiber maturity distribution and further in understanding fiber quality measurements.

Data Availability

All data presented in this study are available upon request.

References

W.C. Robertson, B.A. Roberts, in Cotton: technology for the 21st century. ed. by P.J. Wakelyn, M.R. Chaudhry (International Cotton Advisory Committee, Washington DC, 2010), p.63

J. Bradow, G. Davidonis, J. Cotton Sci. 4, 34 (2000)

B.J. Brecke, J.C. Banks, J.T. Cothren, in Cotton harvest management: use and influence of harvest aids. ed. by J.R. Supak, C.E. Snipes (The Cotton Foundation, Memphis, TN, 2001), p.119

A.G. Ayele, B.R. Kelly, E.F. Hequet, Agron. J. (2018). https://doi.org/10.2134/agronj2017.06.0359

P.J. Bauer, J.A. Foulk, G.R. Gamble, E.J. Sadler, Crop. Sci. (2009). https://doi.org/10.2135/cropsci2008.06.0350

L. Feng, V.B. Bufon, C.I. Mills, E. Hequet, J.P. Bordovsky, W. Keeling, R. Boman, C.W. Bednarz, Agron. J. (2011). https://doi.org/10.2134/agronj2010.0185

C. Turner, H. Sari-Sarraf, E. Hequet, S. Vitha, Textile Res. J. 85, 867–883 (2015). https://doi.org/10.1177/0040517514551466

C.D. Delhom, J. Knowlton, V.B. Martin, C. Blake, J. Cotton Sci. 24, 189 (2020)

C. Kelly, E. Hequet, J. Dever, J. Cotton Sci. 16, 1 (2012)

B. Kelly, N. Abidi, D. Ethridge, E.F. Hequet, in Cotton, 2nd edn., ed. by D.D. Fang, R.G. Percy (American Society of Agronomy, Crop Science Society of America, and Soil Science Society of America, Madison, WI, 2015), p.665

Cotton Incorporated, The Classification of Cotton (Cotton Incorporated, Cary, NC, 2018), p.2018

C.D. Delhom, B. Kelly, V. Martin, in Cotton Fiber: Physics, Chemistry and Biology. ed. by D.D. Fang (Springer, Cham, Switzerland, 2018), p.41

E. Hequet, B. Wyatt, N. Abidi, D.P. Thibodeaux, Textile Res. J. (2006). https://doi.org/10.1177/0040517506064710

D.P. Thibodeaux, J.P. Evans, Textile Res. J. 56, 130 (1986)

B. Xu, B. Pourdeyhimi, Textile Res. J. 64, 330 (1994)

W.S. Anthony, W.R. Meredith, J.R. Williford, Textile Res. J. 58, 633 (1988)

S. Gordon, in Cotton: Science and Technology. ed. by S. Gordon, Y.-L. Hsieh (Woodhead Publishing Limited, Cambridge, UK, 2007), p.68

R.L. Long, C.D. Delhom, M.P. Bange, Textile Res. J. (2021). https://doi.org/10.1177/0040517521992769

J.M. Bradow, O. Hinojosa, L.H. Wartelle, G. Davidonis, G.F. Sassenrath-Cole, P.J. Bauer, Textile Res. J. 66, 545 (1996)

H.J. Kim, C.D. Delhom, D.C. Jones, B. Xu, J. Textile Ins. (2023). https://doi.org/10.1080/00405000.2023.2204460

D. Paudel, E. Hequet, N. Abidi, Ind. Crop Prod. (2013). https://doi.org/10.1016/j.indcrop.2012.12.041

H.J. Kim, C.D. Delhom, D.D. Fang, L. Zeng, J.N. Jenkins, J.C. McCarty, Crop. Sci. (2020). https://doi.org/10.1002/csc2.20197

J. Rodgers, C. Delhom, C. Fortier, D. Thibodeaux, Textile Res. J. (2012). https://doi.org/10.1177/0040517511431317

J. Rodgers, G.R.S. Naylor, X. Cui, C. Delhom, D. Hinchliffe, Textile Res. J. (2015). https://doi.org/10.1177/0040517514548809

Y. Liu, D. Thibodeaux, G. Gamble, Textile Res. J. (2011). https://doi.org/10.1177/0040517511410107

Y. Liu, H.J. Kim, C.D. Delhom, D.P. Thibodeaux, Cellulose (2019). https://doi.org/10.1007/s10570-019-02502-0

Y. Liu, C.D. Delhom, Textile Res. J. (2023). https://doi.org/10.1177/00405175221137096

B. Ratner, J. Target. Meas. Anal. Mark. (2009). https://doi.org/10.1057/jt.2009.5

M.H.J. van der Sluijs, C.D. Delhom, V.B. Martin, J. Textile Inst. (2021). https://doi.org/10.1080/00405000.2020.1816684

E. Lord, S.A. Heap, The Origin and Assessment of Cotton Fiber Maturity (International Institute for Cotton, 1981). https://www.cottontech.co.uk. Accessed 23 August 2023.

Acknowledgements

Authors wish to acknowledge Dr. C. Delhom in providing seed cotton samples, Ms. M. Schexnayder in cotton ginning, and Ms. H. King in fiber HVI and AFIS measurement. Mention of a product or specific equipment does not constitute a guarantee or warranty by the U.S. Department of Agriculture and does not imply its approval to the exclusion of other products that may also be suitable.

Funding

No funds, grants, or other support was received.

Author information

Authors and Affiliations

Contributions

YL was responsible for all fiber data. Both authors conceived the research, conducted data analysis, and prepared the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

Authors do not have conflict of interest.

Appendix

Appendix

System | Property | Description |

|---|---|---|

HVI | MIC | Micronaire (MIC), a measure of fiber fineness and maturity simultaneously |

MAT | Maturity (MAT), a measure of degree of secondary cell wall thickness | |

UHML, inch | Upper-half mean length (UHML), a measure of average length by number of the longer one half of the fibers by weight | |

UI, % | Length uniformity index (UI), as a ratio in percentage between the mean length and the UHML of the fibers | |

STR, cN/tex | Strength (STR), external force required to break a bundle of fibers | |

ELO, % | Elongation (ELO), a measure of how far the fibers will stretch before they break | |

Color Grade | Determined by the degree of reflectance (Rd) and yellowness (+ b) | |

Rd, % | An indication of how bright or dull in a sample | |

+ b | A characterization of the degree of pigmentation in a sample | |

SFC, % | Short fiber content, a measure of percentage (%) by weight of fibers shorter than 0.5 inches or 12.7 mm | |

Area % | A measure of the percentage of the surface area occupied by trash particles | |

Particle count | A measure of the number of trash particles visible | |

Leaf grade | A measure of the leaf content calculated from HVI Area % and HVI Particle Count | |

AFIS | L(w), inch | Average fiber length (inch or mm) of the fibers based on the fiber weight |

L(w) CV, % | A percentage (%) of standard deviation of fiber length by the average fiber length L(w) | |

UQL(w), inch | Upper quartile length (UQL), a measure of fiber length (inch or mm) that is the longer 25% of all fibers by weight | |

SFC(w), % | Short fiber content (SFC), a percentage (%) of fibers by weight that are below 0.5 inches or 12.7 mm | |

L(n), inch | Average fiber length (inch or mm) of the fiber based on the fiber number | |

L(n) CV, % | A percentage (%) of standard deviation of fiber length by the average fiber length L(n) | |

SFC(n), % | Short fiber content (SFC), a percentage (%) of fibers by number that are shorter than 0.5 inches or 12.7 mm | |

L5%(n), inch | A measure of fiber length (inch or mm) that is the longer 5% of all fibers by number | |

MR | Maturity ratio (MR), a measure of degree of secondary cell wall thickening | |

IFC, % | Immature fiber content (IFC), a percentage of fibers that have a cell wall thickness less than ө = 0.25 | |

Fineness, mTex | A measure of average fineness (mtex) of the fibers | |

Total Cnt, g | A total number of trash particles of all sizes per gram of sample | |

Trash size, µm | Mean size (µm) of all trash particles | |

Dust Cnt, g | A number of dust particles less than 500 µm per gram of sample | |

Trash Cnt, g | A number of particles greater than 500 µm per gram of sample | |

VFM, % | A percentage (%) of visible foreign matter (VFM) in a sample by weight | |

Nep size, µm | Mean size (µm) of neps due to fiber entanglement | |

Neps, Cnt/g | A number of neps per gram, including seed-coat neps (SCNs) | |

SCN size, µm | Average size (µm) of seed-coat neps (SCNs) | |

SCN, Cnt/g | A number of seed-coat neps (SCNs) per gram |

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, Y., Chang, S. Comprehensive Analysis of Cotton Fiber Infrared Maturity Distribution and Its Relation to Fiber HVI and AFIS Properties. Fibers Polym 25, 1127–1136 (2024). https://doi.org/10.1007/s12221-023-00448-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00448-6