Abstract

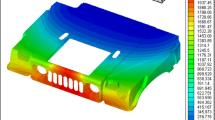

In this paper, the flow characteristics of resin in vacuum-assisted forming (VARI) process were studied by experiments and numerical simulation. The position and time of resin flow front were recorded by high-speed camera and timer. The viscosity of resin, porosity and permeability of composites were tested. Based on Darcy’s law, the resin permeability model in composite molding was derived, and the permeability was obtained by nonlinear fitting. The unit cell model of plain fabric was established and the flow characteristics of four kinds of viscosity resins were simulated by finite volume method. The flow profile and filling time were compared between experimental and numerical simulation, and the error between the model and the experiment is less than 12%, which verifies the accuracy of the model and shows that the model can be used to predict the flow behavior of resin with different viscosities in composite molding.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

J.A. Delicano, Compos. Interface. 25, 1039 (2018)

D.K. Rajak, D.D. Pagar, P.L. Menezes, E. Linul, Polymer 11, 1667 (2019)

S.O. Amiandamhen, M. Meincken, L. Tyhoda, Fiber. Polym. 21, 677 (2020)

S. Lu, X. Yang, L. Zhang, J. Ma, S. Wang, H. Tang, K. Ma, X. Wang, Mater. Res. Express. 6, 115628 (2019)

C. Xia, S.Q. Shi, L. Cai, Compos. Part B Eng. 78, 138 (2015)

J. Chen, X. Gao, K. Zhao, W. Wu, Fiber Polym. 23, 3126 (2022)

A. Debabrata, G. Suhasini, H. Santosh, Compos. Part A Appl. Sci. and Manuf. 151, 106641 (2021)

K.D. Shokrollahi, D. Toghraie, M. Hashemian, Fiber Polym. 21, 571 (2020)

O. Ahmed, M.E. Hassan, E. Jamal, J. Compos. Mater. 56, 3221 (2022)

F. Rubino, P. Carlone, Polymer 11, 20 (2018)

S. Shevtsov, I. Zhilyaev, S.H. Chang, J.K. Wu, N. Snezhina, J.P. Huang, Compos. Struct. 259, 113437 (2021)

G. Zaynab, C.L. Bruno, B. Rachid, C. Philippe, B. Salim, P. Henri, T. Francois, Polym. Compos. 43, 3560 (2022)

C.D. Fratta, F. Klunker, P. Ermanni, Compos. Part A Appl. Sci. Manuf. 47, 1 (2013)

C. Arulappan, A. Duraisamy, D. Adhikari, S. Gururaja, J. Reinf. Plast. Comp. 34, 3 (2015)

E. Andreas, M. Mikhail, T. Michael, Polym. Compos. 43, 8308 (2022)

Y. Yu, X. Cui, Z. Liang, X. Qing, W. Yan, 229. Compos. Sci. Technol. 229, 109712 (2022)

H. Darcy, Les fontaines publiques de la Ville de Dijon (Dalmont, Paris, 1856)

M. Carmona, E. Perez, M. Palacio, Appl. Therm. Eng. 150, 456 (2019)

G.K. Marri, C. Balaji, Int. J. Heat Mass Transf. 164, 120454 (2021)

Acknowledgements

The authors acknowledge the financial supports from the Natural Science Foundation of Inner Mongolia (Grant no. 2021MS01010), Basic Research Program Foundation of Institutions of Higher Education of Inner Mongolia (Grant no. JY20220119) and the National Natural Science Foundation of China (Grant no. 51765051, 12272189).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

You, G., Gao, X., Chen, J. et al. Experimental and Numerical Simulation of Resin Flowing in VARI Process. Fibers Polym 24, 2673–2681 (2023). https://doi.org/10.1007/s12221-023-00261-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00261-1