Abstract

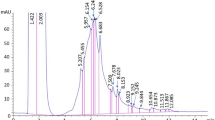

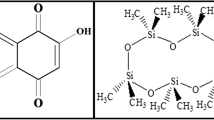

A large amount of wool with different characteristics is produced worldwide. The differences in wool structure due to the different habitats of sheep and goats and the corresponding environmental conditions have an impact on the dyeing properties of wool. In this paper, the mechanism of the shielding effects of wool fiber, which mainly originate from the cuticles and oil content (including the F-layer and lipoids in the wool) according to the significantly improved exhaustion and fixation rate of pretreated wool fiber, on dye during the dyeing process was studied. The surface morphology, integrity of the F-layer, oil content, and swelling of wool fiber were analyzed in this dyeing system, where decamethylcyclopentasiloxane was reported as a dyeing medium in the exhaustion wool dyeing method for the first time. For the investigated dye, the cuticles exhibited a severe shielding effect on the dyeing process, and the internal lipid substance exhibited the second-highest effect. All these results demonstrate that it is possible to apply this dyeing system to dye wool without cuticles and wool with a damaged cuticle surface. The analysis of the internal access effects in nonaqueous wool dyeing is of great significance for the rationalization of dyeing wool with cuticles in future commercial dyeing processes.

Similar content being viewed by others

Data availability

The data are available from the corresponding authors upon reasonable request.

References

J. Liu, P. Zhu, C. Zhao, S. Sui, Z. Dong, L. Zhang, Fibers Polym. 15, 1601 (2014)

M.Á. Pérez-Cabal, J.P. Gutiérrez, I. Cervantes, M.J. Alcalde, J. Anim. Breed. Genet. 518, 93 (2012)

X. Lv, L. Chen, S. He, C. Liu, B. Han, Z. Liu, M. Yusupu, H. Blair, P. Kenyon, S. Morris, W. Li, M. Liu, Annimals 10(6), 1058 (2020)

J. Lindberg, B. Philip, N. Gralen, Nature 162, 458 (1948)

M. Huson, D. Evans, J. Church, S. Hutchinson, J. Maxwell, G. Corino, J. Struct. Biol. 163, 127 (2008)

Y. Li, Text. Prog. 31(1–2), 1 (2001)

C. Canal, R. Molina, E. Bertran, P. Erra, J. Adhes. Sci. Technol. 18, 1077 (2004)

C. Canal, P. Erra, R. Molina, E. Bertran, Text. Res. J. 77, 559 (2007)

N. Zhang, P.H. Huang, P. Wang, Y.Y. Yu, M. Zhou, Q. Wang, Fibers Polym. 23, 985 (2022)

F.R. Oliveira, M. Fernandes, N. Carneiro, A.P. Souto, J. Appl. Polym. Sci. 128, 2638 (2013)

L. Coderch, O. Lopez, A.D.L. Maza, A.M. Manich, J.L. Parra, J. Cegarra, Text. Res. J. 67, 131 (1997)

Z. Jiang, Y. Zhang, N. Zhang, Q. Wang, P. Wang, Y. Yu, M. Zhou, Color. Technol. 138, 82 (2022)

K. Sakata, M. Imajo, Sen’i Gakkaishi 66, 74 (2010)

Z. Mengxing, J. Gao, F. Wang, L. Wang, H. Xue, Wool Text. J. 44, 32 (2016)

C.-K. Xu, H. Cheng, Z.-J. Liao, Pol. J. Environ. Stud. 27, 2325 (2018)

H. Zheng, Y. Xu, J. Zhang, X. Xiong, J. Yan, L. Zheng, J. Cleaner Prod. 143, 269 (2017)

L. Chen, B. Wang, J. Chen, X. Ruan, Y. Yang, Text. Res. J. 86, 533 (2016)

H. Zhang, C. Xu, J. Xin, M. Wu, Y. Zhang, Wool Text. J. 46, 20 (2018)

W. Cao, L. Pei, H. Zhang, J. Wang, Environ. Chem. Lett. 19, 737 (2021)

J. Wang, Y. Gao, L. Zhu, X. Gu, H. Dou, L. Pei, Polymers (Basel) 10, 1030 (2018)

W. Cheng, L. Pei, M.A. Saleem, L. Zhu, J. Wang, J. Cleaner Prod. 321, 128953 (2021)

H. Miao, C. Fu, Y. Li, R. Tao, J. Liu, Silk Sci. 38, 105 (2012)

Md.Y. Hossain, Y. Liang, Md.N. Pervez, X. Ye, X. Dong, M.M. Hassan, Y. Cai, Cellulose 28, 517 (2021)

W. Li, N. Zhang, Q. Wang, P. Wang, Y. Yu, M. Zhou, Fibers Polym. 22, 3045 (2021)

M.M. Hassa, M. Bhagvandas, A.C.S. Sustain, Chem. Eng. 5, 973 (2017)

Y. Luo, S. Zhai, L. Pei, J. Wang, Z. Cai, A.C.S. Sustain, Chem. Eng. 10, 3557 (2022)

S.D. Bringans, J.E. Plowman, J.M. Dyer, S. Clerens, J.A. Vernon, W.G. Bryson, Exp. Dermatol. 16, 951 (2010)

A.P. Fellows, M.T.L. Casford, P.B. Davies, Appl. Spectrosc. 74, 1540 (2020)

V. Totolin, M. Sarmadi, S.O. Manolache, F.S. Denes, J. Appl. Polym. Sci. 117, 281 (2010)

J. Gu, X. Chen, W. Zhu, J. D. Univ. 37, 317 (2011)

J. Liu, R.Y. Zhu, Y. Zhang, Wool Text. J. 41(5), 51 (2013)

M. van der Kraan, M.V.F. Cid, G.F. Woerlee, W.J.T. Veugelers, G.J. Witkamp, J. Supercrit. Fluids 40, 470 (2007)

M. Mori, M. Matsudaira, N. Inagaki, J. Text. Eng. 52, 19 (2006)

Acknowledgements

This work was supported by the Fundamental Research Funds for the Central Universities and Graduate Student Innovation Fund of Donghua University (CUSF-DH-D-2022062), the National Natural Science Foundation of China (22176031), the National Natural Science Foundation of China (22072089), Key Research and Development Program of Xinjiang Production and Construction Corps (2019AA001), Shanghai Sailing Program (21YF1416000), and Opening Project of Key Laboratory of Clean Dyeing and Finishing Technology of Zhejiang Province (QJRZ1901).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Luo, Y., Wang, J. & Cai, Z. Different Dyeing Properties in Nonaqueous Dyeing Systems for Various Wool Fibers. Fibers Polym 24, 2017–2025 (2023). https://doi.org/10.1007/s12221-023-00185-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00185-w