Abstract

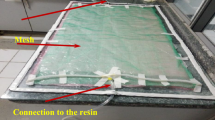

In this study, the vacuum-bag-only (VBO) process was used to fabricate composite laminates by employing interleaved unidirectional fully impregnated prepreg and dry fiber. The mechanical test results show that the flexure strength, compression after impact (CAI) strength and compression before impact (CBI) strength of the carbon fiber composite laminate produced by this process are about 84%, 72% and 83% of the autoclave composite laminate, respectively. The CAI strength with impact energy of 8.5 J retained about 85.4% and 96.4% of the original strength, respectively, for the components fabricated by the interleaved layup VBO and conventional autoclave processes. Ultrasonic scanning was performed for the 50 × 50 cm2 unidirectional carbon fiber composite to identify the void distribution. The results show that the composites fabricated by interleaved layup VBO process have good quality and low porosity. In the case of glass fiber composites, the hybrid laminate of this process was used to fabricate composite laminate in which unidirectional glass fiber prepregs and bidirectional dry woven glass fiber fabric are interleaved layup. The ultrasonic test results show that the internal pores of this composite laminate are very few, and the quality is good. The feasibility of applying the process to different materials or woven materials was demonstrated.

Similar content being viewed by others

Data availability statement

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

F. C. Campbell Jr, Manufacturing technology for aerospace structural materials, Elsevier, (2011)

L. Grunenfelder, T. Centea, P. Hubert, S. Nutt, Compos. A Appl. Sci. Manuf. 45, 119 (2013)

T. Centea, S. Hughes, S. Payette, J. Kratz, and P. Hubert, in "53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA"Ed.^Eds.), 1568, Year of Converence.

T. Centea, L.K. Grunenfelder, S.R. Nutt, Compos. A Appl. Sci. Manuf. 70, 132 (2015)

R. Harshe, J. Indian Inst. Sci. 95, 207 (2015)

S.Y. Park, C.H. Choi, W.J. Choi, S.S. Hwang, Appl. Compos. Mater. 26, 187 (2019)

S. M. Hughes and P. Hubert, SAMPE Tech, (2013).

Y.-H. Yang, W.-B. Young, Fibers Polym. 22, 460 (2021)

M. S. Moreno, A. R. Gutierrez, and J. M. Vicente, in "IOP Conference Series: Materials Science and Engineering"Ed.^Eds.), 012047, Year of Converence.

I. ASTM, ASTM D790-07, (2007).

M. Richardson, M. Wisheart, Compos. A Appl. Sci. Manuf. 27, 1123 (1996)

A. Amaro, P. Reis, M. De Moura, Strain 47, 203 (2011)

S. Sanchez-Saez, E. Barbero, R. Zaera, C. Navarro, Compos. Sci. Technol. 65, 1911 (2005)

A. International, "Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event", ASTM International, (2007)

A. Standard, ASTM D7137/D7137M (American Society for Testing and Materials, West Conshohocken, 2007)

A. Stamopoulos, K. Tserpes, P. Prucha, D. Vavrik, J. Compos. Mater. 50, 2087 (2016)

Y. Mujahid, N. Sallih, M.Z. Abdullah, M. Mustapha, Polym. Compos. 42, 567 (2021)

M. Pishvar, M. Amirkhosravi, M.C. Altan, Polym. Compos. 40, 159 (2019)

S. H. Rueda, Curing, defects and mechanical performance of fiber-reinforced composites, Universidad Politécnica de Madrid, (2013)

S. Rivallant, C. Bouvet, E. Abi Abdallah, B. Broll, and J.-J. Barrau, Composite Structures, 111, 147 (2014)

P. Hubert, T. Centea, L. Grunefelder, S. Nutt, J. Kratz, and A. Lévy, 2.4 Out-of-Autoclave Prepreg Processing, Elsevier, (2018)

Acknowledgements

The authors would like to thank the financial support from Ministry of Science and Technology in Taiwan under the contract number of MOST 109-2221-E-006-030. In addition, the authors would like to thank the assistance from the Aeronautical Systems Research Division of National Chung-Shan Institute of Science and Technology (NCSIST) in Taiwan, for the successful completion of the ultrasonic detection part of this paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chang, YY., Young, WB. Study on the Characteristics of Vacuum-Bag-Only Processed Composites by Prepreg/Fiber Interleaved Layup. Fibers Polym 24, 653–670 (2023). https://doi.org/10.1007/s12221-023-00026-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00026-w