Abstract

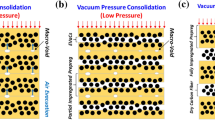

The present study addressed the fabrication of carbon fiber-reinforced polymer (CFRP) composites using two different techniques: manual layup and vacuum bagging molding. The purpose was to compare their unique properties. CFRP composites employ woven roving mat carbon fiber as a reinforcing material, combined with an epoxy matrix consisting of Araldite and hardener. The resin to fiber ratio has been maintained at a 1:1 ratio, while the resin to hardener ratio has been maintained at a 10:1 ratio by weight. Various stacking sequences of carbon/epoxy composites (0/90) were made using both approaches. Optimization of several process parameters was carried out to enhance the mechanical properties of the polymer composites. Every laminate was composed of four to eight layers. Various carbon/epoxy composite orientations were subjected to testing until failure using a universal testing machine, in accordance with the relevant applicable standards (ASTM-D3039), in order to determine the ultimate tensile strength, % elongation (or ductility), and elastic constant. Furthermore, the adhesion intensity between the fiber and resin was assessed by conducting microstructural studies using a scanning electron microscope. The results demonstrated that the samples fabricated using the vacuum bagging mold technique exhibited superior tensile strength compared to the samples fabricated using the hand layup approach.

Similar content being viewed by others

References

J. Bauer, S. Hengsbach, I. Tesari, R. Schwaiger, O. Kraft, High-strength cellular ceramic composites with 3d microarchitecture. Proc Natl Acad. Sci. Unit. States Am. 111, 2453e58 (2014). https://doi.org/10.1073/pnas.1315147111

C. Yang, Y. Kim, S. Ryu, G.X. Gu, Prediction of composite microstructure stress strain curves using convolutional neural networks. Mater. Des. 189, 9 (2020). https://doi.org/10.1016/j.matdes.2020.108509

G.X. Gu, M. Takaffoli, M.J. Buehler, Hierarchically enhanced impact resistance of bioinspired composites. Adv. Mater. (2017). https://doi.org/10.1002/adma.201700060

J.W.C. Dunlop, P. Fratzl, Biological composites. Annu. Rev. Mater. Res. 40, 1e24 (2010). https://doi.org/10.1146/annurev-matsci-070909-104421

C. Chen, G.X. Gu, Generative deep neural networks for inverse materials design using backpropagation and active learning. Adv. Sci. (2020). https://doi.org/10.1002/advs.201902607

F.C. Campbell Jr., Manufacturing processes for advanced composites (Elsevier, The Netherlands, 2003)

P.K. Mallick, Fiber-reinforced composites: materials, manufacturing, and design (CRC Press, Boca Raton, 2007)

N. Forintos, T. Czigany, Multifunctional application of carbon fiber reinforced polymer composites: electrical properties of the reinforcing carbon fibers–a short review. Compos. B Eng. 162, 331–343 (2019). https://doi.org/10.1016/j.compositesb.2018.10.098

A. Toldy, G. Szebenyi, K. Molnar et al., The effect of multilevel carbon reinforcements on the fire performance, conductivity, and mechanical properties of epoxy composites. Polymers 11(2), 303 (2019). https://doi.org/10.3390/polym11020303

S. Hegde, B. Satish Shenoy, K.N. Chethan, Review on carbon fiber reinforced polymer (CFRP) and their mechanical performance. Mater. Today: Proc. 19, 658–662 (2019). https://doi.org/10.1016/j.matpr.2019.07.749

Altin Karatas¸ M, Gokkaya H., A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 14(4), 318–326 (2018). https://doi.org/10.1016/j.dt.2018.02.001

M.-S. Scholz, J.P. Blanchfield, L.D. Bloom et al., The use of composite materials in modern orthopaedic medicine and prosthetic devices: a review. Compos. Sci. Technol. 71(16), 1791–1803 (2011). https://doi.org/10.1016/j.compscitech.2011.08.017

A.P. Kumar, Analysis of carbon fiber reinforced polymer composite hip prosthesis based on static and dynamic loading. Int. J. Appl. Eng. Res. 10, 574–579 (2015)

N. Forintos, T. Czigany, Reinforcing carbon fibers as sensors: the effect of temperature and humidity. Compos. Appl. Sci. Manuf. 131, 105819 (2020). https://doi.org/10.1016/j.compositesa.2020.105819

F.S. Shahar, M.T. Hameed Sultan, S.H. Lee et al., A review on the orthotics and prosthetics and the potential of kenaf composites as alternative materials for ankle-foot orthosis. J. Mech. Behav. Biomed. Mater. 99, 169–185 (2019). https://doi.org/10.1016/j.jmbbm.2019.07.020

F. Cucinott, E. Guglielmino, F. Sfravara, Life cycle assessment in yacht industry: a case study of comparison between hand lay-up and vacuum infusion. J. Clean. Prod. 142, 3822–3833 (2017)

P. Meshram, S. Sahu et al., Study on mechanical properties of epoxy and nylon/epoxy composite. Mater. Today: Proc. 5, 5925–5932 (2017)

B. Muralidhara, S.P. Kumaresh Babu, B. Suresha, Utilizing vacuum bagging process to prepare carbon fiber/epoxy composites with improved mechanical properties. Mater. Today: Proc. 27, 2022–2028 (2020)

S.Y. Kim, C.S. Shim, C. Sturtevant, H. Song, C Mechanical properties and production quality of hand-layup and vacuum infusion processed hybrid composite materials for GFRP marine structures. Int. J. Nav. Archit. Ocean Eng. 6, 723–736 (2014)

K. Karthik, V. Ramesh, S. Kolappan, K. Arunkumar, J. Udayaprakash, R. Rameshkumar, Experimental investigation on hybrid fibre reinforced polymer epoxy LY556 composites by vacuum bag molding. Mater. Today: Proc. 62, 714–720 (2022)

D. Bharath, B. Sandhya Rani, V. Saritha, P. Irshadh Khan, Tensile and erosion behaviour of medium calcined alumina microparticles on GFRP composites fabricated with vacuum bagging process. Mater. Today: Proc. 46, 11–12 (2021)

L. Amorim, A. Santos, J.P. Nunes, G. Dias, J.C. Viana, Quasi static mechanical study of vacuum bag infused bouligand inspired composites. Polym. Test. 100, 107261 (2021)

H.B. Vinay, H.K. Govindaraju, P. Banakar, Evaluation of glass/carbon reinforced polymer composites. Polym. Polym. Compos. 24(7), 469–472 (2016)

G. Francucci, S. Palmer, W. Hall, External compaction pressure over vacuum-bagged composite parts: effect on the quality of flax fiber/epoxy laminates. J. Compos. Mater. 52(1), 3–15 (2018)

S.Y. Nayak, R.C. Composites et al., Tensile and Flexural properties of chopped strand E-glass fibre mat tensile and flexural properties of chopped strand E-glass fibre mat reinforced CNSL- epoxy composites. Web Conf (2018). https://doi.org/10.1051/matecconf/201714402025

F. Correiaa, A.C. Robitaillea, C.D. Longa, P. Rudda, S.G. Sima, Analysis of the vacuum infusion I.A. moulding process: analytical formulation. Compos. Part A 36, 1645–1656 (2005)

Abdurohman K et al (2017) Effect of mesh-peel ply variation in vacuum infusion process to mechanical properties of glass composite. In: IOP Journal of Physics: Conference Series-5th International Seminar on Aerospace Science and Technology 2017.

K. Abdurohman, A. Marta dan, An experimental study of polyester composite tensile properties reinforced unidirectional carbon fiber manufactured by vacuum infusion for LSU material. Jurnal Teknologi Dirgantara 14(1), 61–72 (2016)

F. Cucinotta, E. Guglielmino, F. Sfravara, Life cycle assessment in yacht industry: a case study of comparison between hand lay-up and vacuum infusion. J. Clean. Prod. 142, 3822–3833 (2017). https://doi.org/10.1016/j.jclepro.2016.10.080

P. Meshram et al., Study on mechanical properties of epoxy and nylon/epoxy composite. Mater. Today: Proc. 5(2), 5925–5932 (2018). https://doi.org/10.1016/j.matpr.2017.12.192

Yu. Chen, Influence of multipass friction stir processing on microstructure and mechanical properties of Al5083 alloy. Mater. Sci. Eng. A 650, 281–289 (2016)

M.V.N.V. Satyanarayana, A. Kumar, Effect of microstructure and precipitate formation on mechanical and corrosion behavior of friction stir processed AA6061 alloy using different cooling media. Met. Mater. Int. (2021). https://doi.org/10.1177/14644207211005790

M.V.N.V. Satyanarayana, K. Adepu, K. Chauhan, Effect of overlapping friction stir processing on microstructure, mechanical properties and corrosion behavior of AA6061 alloy. Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00757-y

Marukurthi VNV, Satyanarayana KA Microstructure evolution, mechanical and corrosion behavior of AA2014 alloy processed through cryogenic friction stir processing. Advanced Engineering Materials (SCI, IF-3.9) (2020)

K. Abdurohman, T. Satrio, N.L. Muzayadah, A comparison process between hand lay-up, vacuum infusion and vacuum bagging method toward e-glass EW 185/lycal composites. IOP Conf. Ser.: J. Phys. 1130, 012018 (2018). https://doi.org/10.1088/1742-6596/1130/1/012018

M. Farooq, N. Banthia, An innovative FRP fibre for concrete reinforcement: Production of fibre, micromechanics, and durability. Constr. Build. Mater. 172, 406–421 (2018)

M.A. Faizal, Y.K. Beng, K.N. Dalimin, Tensile properties of hand lay-up plain weave woven E-glass/polyester composite: curing pressure and ply arrangement effect. Borneo Sci. J. Sci. Technol. 19, 27–34 (2011)

S. Mahale, D. Rajamani, A. Revathi et al., Hot-wet property characterisation of a high-temperature cured glass–epoxy composite in immersion environment. J. Reinf. Plast. Compos. 23(17), 1883–1892 (2004)

A. Behera, P. Dupare, M.M. Thawre et al., Effects of hygrothermal aging and fiber orientations on constant amplitude fatigue properties of CFRP multidirectional composite laminates. Int. J. Fatigue 136, 105590 (2020)

R.B.A. Ouled Ahmed, S. Chatti, D.H. Ben, Modeling of hygrothermal damage of composite materials. Mech. Adv. Compos. Struct. 3, 137–144 (2016)

Y. Wang, T.H. Hahn, AFM characterization of the interfacial properties of carbon fiber reinforced polymer composites subjected to hygrothermal treatments. Compos. Sci. Technol. 67, 92–101 (2007)

U. Gaur, C.T. Chou, B. Miller, Effect of hydrothermal ageing on bond strength. Composites 25, 609–612 (1994)

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Amar, T.A., Kumar, A. & Yadav, D.K. A Comparative Study on the Properties of Carbon Fiber-Reinforced Polymer Composites Developed by Hand Layup and Vacuum Bagging Molding Techniques. J. Inst. Eng. India Ser. D (2024). https://doi.org/10.1007/s40033-023-00631-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-023-00631-2