Abstract

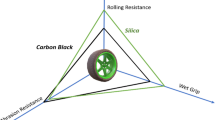

Silica dispersibility in a silica-rubber compound is an important factor determining the braking performance, wear resistance, and rolling resistance of an automobile tire tread. In this study, a poly(itaconic acid-co-acrylamide) (IA-co-AAM) dispersant was synthesized by the copolymerization of IA with AAM as a novel silica dispersant for a wet masterbatch (WMB) system. We confirmed the improved silica dispersibility in the silica-rubber compounds via a rubber process analyzer (RPA) and Mooney viscometer (MV). Based on the MV measurements, the values of MV for the silica-SBR compounds using the dispersant decreased by 30 % compared to those in the absence of the dispersant. This showed a positive effect on the rubber processing workability of the silica-SBR compounds. We also evaluated the dynamic viscoelastic properties of the compounds via a dynamic mechanical analyzer (DMA) and found that the rolling resistance of the compounds for the tire tread area also improved.

Similar content being viewed by others

References

S. Kobayashi, S. Plotkin, and S. K. Ribeiro, Energy Efficiency, 2, 125 (2009).

K. Holmberg, P. Andersson, and A. Erdemir, Tribol. Int., 47, 221 (2012).

K. Hwang, W. Kim, B. Ahn, H. Mun, E. Yu, D. Kim, G. Ryu, and W. Kim, Elastomers Compos., 53, 39 (2018).

A. Roberts, “The Physics of Tire Traction”, p.179, Springer, 1974.

R. Peterson, C. Eckert, and C. Carr, in “The Physics of Tire Traction”, p.223, Springer, 1974.

K. Grosch, Rubber Chem. Technol., 69, 495 (1996).

C. Yin, Q. Zhang, and D. Gong, Polym. Compos., 35, 1212 (2014).

J. Valentin, I. Mora-Barrantes, A. Rodriguez, L. Ibarra, and L. Gonzalez, J. Appl. Polym. Sci., 103, 1806 (2007).

T. Nakatsuka, H. Kawasaki, K. Itadani, and S. Yamashita, J. Appl. Polym. Sci., 27, 259 (1982).

M. Nasir, B. Poh, and P. Ng, Eur. Polym. J., 24, 961 (1988).

M. Nasir, B. Poh, and P. Ng, Eur. Polym. J., 25, 267 (1989).

J. Ten Brinke, S. Debnath, L. A. Reuvekamp, and J. W. Noordermeer, Compos. Sci. Technol., 63, 1165 (2003).

Y. Wang, L. Liao, J. Zhong, D. He, K. Xu, C. Yang, Y. Luo, and Z. Peng, J. Appl. Polym. Sci., 133, 43571 (2016).

J. W. Lightsey, D. J. Kneiling, and J. M. Long, Rubber World, 218, 35 (1998).

A. Koski, “Process for Hydrophobicizing Particles, and Their Use as Fillers in Polymer Masterbatches”, U.S. Patents, 2002.

W. Kim, B. Ahn, H. Mun, E. Yu, K. Hwang, and W. Kim, Elastomers Compos., 52, 242 (2017).

U. Goerl, A. Hunsche, A. Mueller, and H. Koban, Rubber Chem. Technol., 70, 608 (1997).

P. J. Wallen, G. C. Bowman, H. A. Colvin, C. J. Hardiman, and J. E. R. Reyna, U.S. Patents, 8357733B2 (2013).

Y. Gui, J. Zheng, X. Ye, D. Han, M. Xi, and L. Zhang, Compos. Part B-Eng., 85, 130 (2016).

R. G. Seaman, U.S. Patents, 1867633A (1932).

S. Xiao, Y. Tan, J. Xu, C. Xiong, X. Wang, and S. Su, Appl. Clay Sci., 97, 91 (2014).

J. Y. Lee, T. Lee, K. Kim, B. Kim, G. Kwag, J. Y. Kim, S. Ji, W. Kim, and H. J. Paik, Polym. Int., 63, 908 (2014).

I. Surya, H. Ismail, and A. Azura, Polym. Test., 32, 1313 (2013).

A. Nakayama, T. Kasai, M. Izuchi, and F. Nishiura, U.S. Patents, 20120108732A1 (2012).

F. Nishiura, Y. Kanda, and K. Someno, U.S. Patents, 9796819B2 (2017).

J. Kadlcak and L. B. Tunnicliffe, RubberCon, Manchester (2014).

X. B. Wang, C. S. Wang, and D. W. Zhang, In Adv. Mater. Res., 221, 684 (2011).

S. Rooj, A. Das, K. W. Stöckelhuber, N. Mukhopadhyay, A. R. Bhattacharyya, D. Jehnichen, and G. Heinrich, Appl. Clay Sci., 67, 50 (2012).

D. W. Kim, C. H. Kim, H. K. Jung, and Y. G. Kang, Elastomers Compos., 48, 114 (2013).

Acknowledgements

This work was supported by a grant from the Industrial Core Technology Development Program funded by Ministry of Trade, Industry and Energy (MOTIE), Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shin, W.S., Kwon, Y.R., Kim, J.S. et al. Improved Silica Dispersibility in Silica-rubber Compounds for a Tire Tread by Using an Itaconic Acid-based Polymeric Dispersant. Fibers Polym 22, 196–204 (2021). https://doi.org/10.1007/s12221-021-9355-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-021-9355-z