Abstract

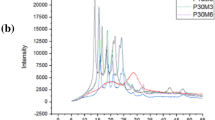

Natural fibre-based composites have been investigated as a viable ecological alternative to conventional materials, combining low-cost and sustainable features to engineering products. In tropical countries, such as Brazil, there are many lignocellulosic residues that are discarded in nature, polluting the environment, such as the Tucumã fruit, which generates about 50 tonnes/month of solid waste only in the city of Manaus (State of Amazonas). This work investigates a novel wood-plastic composite (WPC) made from recycled polypropylene (PP) and Tucumã endocarp powder (TEP) without coupling agents that encompasses social and environmental issues. WPCs are composed of 10, 20, 30, 40 and 50 wt% of TEP combined with PP by injection moulding, being characterised by SEM, FTIR, flammability, water absorption, ageing, tensile, compressive, three-point bending, impact and scratch tests. TEP does not react to the matrix phase, presenting 49.4 % and 37.4 % of cellulose and lignin, respectively. In general, the incorporation of TEP not only increases the elastic modulus and the dynamic friction coefficient, but also reduces the strength and the burning rate of WPCs. WPC preserves its physical integrity after ageing, absorbing up to 1.6 % of water. Composites made with 20 wt% of TEP can be considered promising materials to be used as wood plastic for sustainable engineering applications.

Similar content being viewed by others

References

K. A. N. Matos, D. P. Lima, A. P. P. Barbosa, A. Z. Mercadante, and R. C. Chisté, Food Chem., 272, 216 (2019).

F. O. J. Oboh, Int. J. Biomed. Heal. Sci., 5, 57 (2009).

S. L. F. Ramos, G. Dequigiovanni, A. M. Sebbenn, M. T. G. Lopes, P. Y. Kageyama, J. L. V. de Macêdo, M. Kirst, and E. A. Veasey, BMC Genet., 17, 63 (2016).

A. C. Kieling, G. P. Santana, M. C. dos Santos, S. S. da Silva, C. L. S. Amorin, and J. R. Pontes, Scientia Amazonia, 8, 2 (2019).

L. Manzato, L. C. A. Rabelo, S. M. Souza, C. G. Silva, E. A. Sanches, D. Rabelo, L. A. M. Mariuba, and J. Simonsen, J. Mol. Struct., 1143, 229 (2017).

P. Nygård, B. S. Tanem, T. Karlsen, P. Brachet, and B. Leinsvang, Compos. Sci. Technol., 68, 3418 (2008).

Y. Yu, Y. Yang, M. Murakami, M. Nomura, and H. Hamada, Adv. Compos. Mater., 22, 425 (2013).

A. Nourbakhsh and A. Ashori, Polym. Compos., 29, 569 (2008).

G. Brokamp, N. Valderrama, M. Mittelbach, C. A. R. Grandez, A. S. Barfod, and M. Weigend, Bot. Rev., 77, 571 (2011).

Y. T. G. Gowda, M. R. Sanjay, K. S. Bhat, P. Madhu, P. Senthamaraikannan, and B. Yogesha, Cogent. Eng., 5, 1446667 (2018).

J. Wu, D. Yu, C. M. Chan, J. Kim, and Y. W. Mai, J. Appl. Polym. Sci., 76, 1000 (2000).

T. W. Kim, S. Y. Lee, S. J. Chun, G. H. Doh, and K. H. Paik, J. Compos. Mater., 45, 1595 (2010).

H. S. Katz in “Non-Silane Coupling Agents” (I. Skeist Ed.), Handbook of Adhesives. Springer, Boston, MA, 1990.

P. J. Van Soest, J. B. Robertson, and B. A. Lewi, J. Dairy Sci., 74, 3583 (1991).

O. Väntsi and T. Kärki, J. Reinf. Plast. Compos., 34, 879 (2015).

ASTM E1252-98, “Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis”, ASTM International, West Conshohocken, PA, 2013.

ASTM D3418-03, “Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry”, ASTM International, West Conshohocken, PA, 2003.

ASTM E2809-13, “Standard Guide for Using Scanning Electron Microscopy/X-ray Spectrometry in Forensic Paint Examinations”, ASTM International, West Conshohocken, PA, 2013.

ASTM D638-14, “Standard Test Method for Tensile Properties of Plastics”, ASTM International, West Conshohocken, PA, 2014.

ASTM D695-15, “Standard Test Method for Compressive Properties of Rigid Plastics”, ASTM International, West Conshohocken, PA, 2015.

ASTM D790-03, “Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials”, ASTM International, West Conshohocken, PA, 2003.

ASTM D256-04, “Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics”, ASTM International, West Conshohocken, PA, 2004.

ASTM D570-98, “Standard Test Method for Water Absorption of Plastics”, ASTM International, West Conshohocken, PA, 2018.

ASTM G171-03, “Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus”, ASTM International, West Conshohocken, PA, 2003.

ASTM D635-03, “Standard Test Method for Rate of Burning and/or Extent and Time of Burning of Plastics in a Horizontal Position”, ASTM International, West Conshohocken, PA, 2003.

BS EN 60068-2-38:2009, “Environmental Testing Tests”, Test Z/AD: Composite Temperature/Humidity Cyclic Test, ISBN 978 0 580 52986 3, 2019.

P. R. Rodrigues, M. F. L. Araújo, T. L. Rocha, R. V. S. Veloso, L. A. Pantoja, and A. S. Santos, PeerJ, 6, e5275 (2018).

F. Xu, J. Yu, T. Tesso, F. Dowell, and D. Wang, Appl. Energy, 104, 801 (2013).

H. Yang, R. Yan, H. Chen, D. H. Lee, and C. Zheng, Fuel, 86, 1781 (2007).

O. Derkacheva and D. Sukhov, Macromol. Symp., 265, 61 (2008).

Y. Liu, T. Hu, Z. Wu, G. Zeng, D. Huang, Y. Shen, X. He, M. Lai, and Y. He, Environ. Sci. Pollut. Res., 21, 14004 (2014).

R. A. Díaz, “Thermal Analysis. Fundamentals and Applications to Material Characterization”, In: Proceedings of the International Seminar: Thermal Analysis and Rheology, Ferrol, 30 June-4 July, 2003, pp.121–140, Universidad da Coruña, 2005.

M. S. Mat-Shayuti, M. Z. Abdullah and P. S. M. Megat-Yusoff, MATEC Web Conf., 69, 03001 (2016).

A. M. P. Silva, D. E. Margalho, and D. S. C. Correia Junior, Rev. Mater., 25, https://doi.org/10.1590/S1517-707620200003.1131 (2020).

A. B. L. Melo, L. F. L. Paiva, J. C. Santos, T. H. Panzera, and R. T. S. Freire, J. Res. Updat. Polym. Sci., 5, 108 (2016).

J. C. Santos, T. H. Panzera, A. L. Christoforo, K. O. Vieira, M. A. Schiavon, and F. A. R. Lahr, J. Test. Eval., 44, 1535 (2016).

A. C. Kieling and G. P. Santana, Scientia Amazonia, 6, 24 (2017).

A. Saltelli, M. Ratto, T. Andres, F. Campolongo, J. Cariboni, D. Gatelli, M. Saisana, and S. Tarantola, “Global Sensitivity Analysis: The Primer”, John Wiley & Sons, 2008.

S. K. Najafi, Waste Manag., 33, 1898 (2013).

I. Naghmouchi, P. Mutjé, and S. Boufi, Ind. Crops Prod., 72, 183 (2014).

P. Y. Kuo, S. Y. Wang, J. H. Chen, H. C. Hsueh, and M. J. Tsai, Mater. Des., 30, 3489 (2009).

H. Bouafif, A. Koubaa, P. Perré, and A. Cloutier, Compos. Part A Appl. Sci. Manuf., 40, 1975 (2009).

ABNT NBR 13818:1997, “Placas cerâmicas para revestimento — especificação e métodos de ensaio”, Associação Brasileira de Normas Técnicas, 1997.

Y. Arao, S. Nakamura, Y. Tomita, K. Takakuwa, T. Umemura, and T. Tanaka, Polym. Degrad. Stab., 100, 79 (2014).

L. A. Lowden and T. R. Hull, Fire Sci. Rev., 2, 4 (2013).

G. Guo, C. B. Park, Y. H. Lee, Y. S. Kim, and M. Sain, Polym. Eng. Sci., 47, 330 (2007).

Acknowledgements

The authors would like to thank the Universidade Federal do Amazonas (UFAM), Universidade do Estado do Amazonas (UEA), Institute Nacional de Pesquisas da Amazônia (iNPA), Universidade de São Paulo (USP), Instituto de Desenvolvimento Tecnológco (INDT) and Tutiplast Company for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kieling, A.C., Santana, G.P., Santos, M.C.D. et al. Wood-plastic Composite Based on Recycled Polypropylene and Amazonian Tucumã (Astrocaryum aculeatum) Endocarp Waste. Fibers Polym 22, 2834–2845 (2021). https://doi.org/10.1007/s12221-021-0421-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-021-0421-3