Abstract

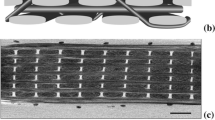

Nowadays, technical woven fabrics are broadly utilized as reinforcement of composites. Resin capacity of woven fabric is one of the main challenges in laminate fabrication. Resin diffusion during fabrication of the composite is extremely depended on fabric micro-morphology. The geometry of weave unit cell and its pore are fundamental factors in evaluating resin capacity and resin diffusion within fabrics. The main attempt of this study was obtaining an approach to evaluate resin capacity of a woven fabric via simulating pore shape and pore volume. For this purpose, four basic unit cells for all kind of weaves were simulated with the two shapes of tow cross-section: lens and racetrack. Afterwards, 3D shape and volume of their pores were simulated using this approach. The proposed approach is established on the base of initial data of fabric such as tow setts, tow titers, planar density and thickness of a technical fabric. To assess the simulation, three types of woven fabrics namely, plain, twill and satin were impregnated by epoxy resin using vacuum infusion process. The volume fractions of the matrix and fibers of real composites were compared with simulated ones. It was demonstrated that the approach with racetrack assumption led to high degree of convergence with experimental results. The maximum relative error of pioneered method to evaluate volume of the pore in this condition exceeded up to 1.43 %. Suitable correlation between volume fractions of the pore and void was observed in experimental data. It is experimentally demonstrated that the void volume fraction of composite will be increased with decrease of pore volume due to difficulty of wetting. In this paper, it is illustrated that the resin capacity of a woven fabric is a function of vacuum level in vacuum infusion process. For instance, resin capacity of a certain plain fabric could be reduced up to 10 % under 60 kPa (0.6 bar) of vacuum in contrast with steady state of fabric at room atmosphere.

Similar content being viewed by others

References

A. Ragab, A. Fouda, H. El-Deeb, and H. Abou-Taleb, J. Text. Sci. Eng., 7, 1 (2017).

X. Xueliang, Ph. D. Dissertation, University of Nottingham, 2012.

S. Backer, Text. Res. J., 21, 248 (1951).

E. H. Glaessgen, C. M. Pastore, O. H. Griffin, and A. Birger, Compos. Part B-Eng., 27, 43 (1996).

P. Dubrovski, J. Text. Inst., 92, 288 (2001).

P. D. Dubrovski, Text. Res. J., 70, 915 (2000).

E. Elnashar, AUTEX Res. J., 5, 207 (2005).

R. T. Ogulata, J. Text. Apparel, Technol. Manag., 5, 1 (2006).

J. Kastner, B. Plank, D. Salaberger, and J. Sekelja, “Defect and Porosity Determination of Fibre Reinforced Polymers by X-ray Computed Tomography”, 2nd International Symposium on NDT in Aerospace, 2010.

S. Rief, E. Glatt, E. Laourine, D. Aibibu, C. Cherif, and A. Wiegmann, AUTEX Res. J., 11, 78 (2011).

R. Angelova, Open Eng., 2, 129 (2012).

R. B. Turan and A. Okur, J. Text. Inst., 103, 875 (2012).

P. Kumar, S. Sinha, and S. Ghosh, Fiber. Polym., 17, 1489 (2016).

A. Endruweit, X. Zeng, M. Matveev, and A. C. Long, Compos. Part A-Appl. Sci. Manuf., 104, 139 (2018).

X. Chen, J. Inf. Comput. Sci., 5, 71 (2010).

S. Afrashteh, A. A. Merati, and A. A. Jeddi, Indian J. Fiber Text. Res., 38, 126 (2013).

X. Xiao, A. Long, and X. Zeng, J. Mater. Sci., 49, 7563 (2014).

J. Hu, “Structure and Mechanics of Woven Fabrics”, Elsevier, 2004.

Acknowledgement

We would like to thank Dr. Abolfazl Zare Shah Abadi (Assistant professor of mechanic engineering in Islamic Azad university-Yazd branch) for his contribution during the simulations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharafat, H.R., Dolatabadi, M.K. & Jeddi, A.A.A. Resin Capacity of Technical Woven Fabrics: Pore Volume and Pore Shape Simulation. Fibers Polym 21, 2664–2674 (2020). https://doi.org/10.1007/s12221-020-9485-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9485-8