Abstract

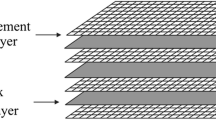

An investigation of nanosilica (SiO2), influencing the mechanical and thermal attributes of carbon fiber (CF)/polycarbonate (PC) laminates, is described in this study. Polycarbonates with four different weight percentages of SiO2 (PC-SiO2, 0.1, 0.3, 0.6 and 1.0 wt%) were prepared using a melt-blending technique. The PC-SiO2 nanocomposites were then used to fabricate planar CF/PC laminates through a hot hydraulic press machine. The prepared laminates were characterized by a number of different techniques; namely, tensile tests, dynamic mechanical thermal analysis (DMTA), differential scanning calorimetry (DSC), thermal gravimetric analysis (TGA) and scanning electron microscopy (SEM). The tensile test findings revealed that when 0.6 wt% of SiO2 was added to the laminate layers, the maximum tensile modulus and yield stress were achieved. The mechanical properties obtained by DMTA supported the tensile test results. It should be noted that the 0.6 wt% of SiO2 had the highest mechanical properties. The DMTA and DSC analyses were used to measure the glass transition temperatures (Tg) of laminates. We found that with the addition 0.6 wt% of SiO2 the Tg increased to approximately 1°C compared to 0 °C for the neat CF/PC laminate, meaning that by adding up 0.1 to 0.6 nanosilica to the polymer, the value Tg first increased and then decreased. To characterize the mass loss, the thermal degradation of polycarbonate influenced by nitrogen was investigated through TGA. According to our TGA results, the highest thermal stability was achieved by adding 0.6 wt% of SiO2 to the PC.

Similar content being viewed by others

References

Z. Shen, S. Bateman, D. Y. Wu, P. McMahon, M. D. Olio, and J. Gotama, Compos. Sci. Technol., 69, 239 (2009).

W. Albouy, B. Vieille, and L. Taleb, Compos. Part A-Appl., 67, 22 (2014).

A. Margossian, S. Bel, and R. Hinterhoelzl, Compos. Part A-Appl., 77, 154 (2015).

T. Yokozeki, Y. Iwahori, S. Ishiwata, and K. Enomoto, Compos. Part A-Appl., 38, 2121 (2007).

B. Vieille and W. Albouy, Int. J. Fatigue, 80, 1 (2015).

N. Oya and H. Hamada, Compos. Part A-Appl., 28, 823 (1997).

F. Ning, W. Cong, J. Qiu, J. Wei, and S. Wang, Compos. Part B-Eng., 80, 369 (2015).

G. Schinner, J. Brandt, and H. Richter, J. Thermoplast. Compos. Mater, 3, 239 (1996).

F. Rezaeia, R. Yunus, and N. A. Ibrahim, Mater. Des., 30, 260 (2009).

C. Martin-Barrera and P. I. Gonzalez-Chi, Polym. Test., 31, 1053 (2012).

A. Yapici, N. Tarakcioglu, A. Akdem, and A. Avci, J. Thermoplast. Compos. Mater., 14, 146 (2001).

M. Hou, K. Friedrich, and R. Scherer, Compos. Struct., 27, 157 (1994).

A. Fereidoon, M. Ghorbanzadeh-Ahangari, S. Saedodin, and T. Macromol, Sci. Part B; Phys., 48, 25 (2009).

B. Ashrafi, A. M. Díez-Pascual, L. Johnson, M. Genest, S. Hind, Y. Martinez-Rubi, J. M. González-Domínguez, M. T. Martínez, B. Simard, M. A. Gómez-Fatou, and A. Johnston, Compos. Part A-Appl., 43, 1267 (2012).

N. L. Batista, M. L. Costa, K. Iha, and E. C. Botelho, J. Thermoplast. Compos. Mater., 28, 265 (2015).

M. M. Thawre, K. K. Verma, N. Jagannathan, D. R. Peshwe, R. K. Paretkar, and C. M. Manjunatha, Compos. Part B-Eng, 86, 120 (2016).

Y. Rostamiyan and A. Ferasat, Damage. Mech., 26, 1 (2016).

Y. Rostamiyan, A. Fereidoon, A. G. Ghalebahman, A. H. Mashhadzadeh, and A. Salmankhani, Mater. Des., 65, 1236 (2015).

M. Hemmati, A. Narimani, H. Shariatpanahi, A. Fereidoon, and M. G. Ahangari, Inter. J. Polym. Mater, 60, 384 (2011).

Y. Rostamiyan and A. B. Fereidoon, Strength. Mater., 45, 619 (2013).

M. H. Gabr, W. Okumura, H. Ueda, W. Kuriyama, K. Uzawa, and I. Kimpara, Compos. Part B-Eng., 69, 94 (2015).

Y. Rostamiyan, A. Fereidoon, M. Rezaeiashtiyani, A. Hamed Mashhadzadeh, and A. Salmankhani, Mater. Des., 69, 96 (2014).

Y. Rostamiyan and R. Azadi, Adv. Mech. Eng., 8, 1 (2016).

A. S. Luyt, M. D. Dramićanin, Ž. Antić, and V. Djoković, Test., 28, 348 (2009).

S. Kang, S. I. Hong, C. R. Choe, M. Park, S. Rim, and J. Kim, Polymer, 42, 879 (2001).

H. Behniafar and S. Azadeh, Int. J. Polym. Mater., 64, 1 (2015).

S. Sprenger, M. H. Kothmann, and V. Altstaedt, Compos. Sci. Technol., 105, 86 (2014).

Y. T. Sung, C. K. Kum, H. S. Lee, N. S. Byon, H. G. Yoon, and W. N. Kim, Polymer, 46, 5656 (2005).

K. N. E. Verghese, R. E. Jensen, J. J. Lesko, and T. C. Ward, Polymer, 42, 1633 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fathalian, M., Ghorbanzadeh Ahangari, M. & Fereidoon, A. Effect of Nanosilica on the Mechanical and Thermal Properties of Carbon Fiber/Polycarbonate Laminates. Fibers Polym 20, 1684–1689 (2019). https://doi.org/10.1007/s12221-019-1158-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-019-1158-0