Abstract

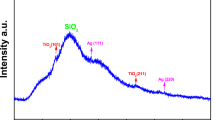

Leather finishing processes using toxic organic solvent based produce volatile organic compounds (VOC), chronic exposure to this chemicals effect on workers' health causing many diseases especially lung cancer. So, polyurethane waterbased was synthesized for application in leather finishing instead of organic solvent based because it’s economic and safety for industry and workers. Preparation of water-based polyurethane (PU) depends on the reaction of polyethylene glycol (PEG, 300) with isophorone diisocyanate (IPDI) and the reaction of IPDI-1,4-butanediol (BDO) together with dimethylolpropionic acid (DMPA), was synthesized by poly-addition polymerization reaction. PU was then modified with different amounts of silicon dioxide nanoparticles (1-5 % SiO2), used as a binder in leather finishing. Leather coated was characterized physically, chemically and thermally by FTIR, GPC, DLS, TEM, SEM and TGA. The results revel that, water vapor permeability (WVP) of leather coated with PU modified with SiO2 showed improvement due to the existence of SiO2 particles which increases the interspaces of the polyurethane coating. SEM showed that when the amount of SiO2 nanoparticles increases, there is uniform nanoparticles accumulated can be observed. EDX prove the presence of Si and O2 elements and the formation of SiO2 nanoparticles. Mechanical properties discussed that tensile strength; tear strength and elongation at break % increase with increase SiO2 concentration until 3 % SiO2 nanoparticles. TGA showed an improvement of thermal stability of coated leather modified with SiO2. Therefore, this study succeeded in preparation of safe, ecofriendly of water-based polyurethane binders which modified with SiO2 for using in leather finishing.

Similar content being viewed by others

References

T. C. Thorstensen, “Practical Leather Technology”, 4th ed. pp.300–320, New York, Shoe Trade Publishing, 1993.

K. T. Sarkar, “Modern Practice in Retanning, Dyeing and Finishing of Leather” (K. T. Sarkar Ed.), 1st ed., pp.70–90, Madras, India, 1996.

O. Mohamed, A. Moustafa, M. Mehawed, and N. El-Sayed, J. App.Polym. Sci., 111, 1488 (2009).

S. Yiding, W. Haihua, F. Guiqiang, and F. Xiaojing, J. Soc. Leath. Tech. Ch., 91, 108 (2006).

S. Sundar, N. Vijayalakshmi, S. Gupta, R. Rajaram, and G. Radhakrishnan, Prog. Polym. Sci., 56, 178 (2006).

L. Ollé, A. Bacardit, J. Morera, M. Bartoli, and J. Argelich, J. Soc. Leath. Tech. Ch., 92, 96 (2007).

L. Ollé, A. Shendryck, F. Combalia, J. Jorge, and A. Bacardit, J. Soc. Leath. Tech. Ch., 94, 111 (2009).

L. Ollé, M. Cobos, O. Olé, and A. Bacardit, J. Soc. Leath. Tech. Ch., 93, 222 (2009).

L. Peizhi, S. Yiding, Y. Xiaowu, and L. Lignghui, J. Soc. Leath. Tech. Ch., 94, 240 (2010).

S. Sudhahar, C. Sivaraj, and S. Gupta, J. Am. Leather. Chem. Assoc., 107, 249 (2012).

Y. Chen, H. Fan, and B. Shi, J. Am. Leather. Chem. Assoc., 106, 260 (2011).

T. Jeon, K. Jang, K. Kim, and H. Kim, Colloids. Surf. A: Physicochem. Eng. Asp., 302, 559 (2007).

M. Yeh, T. Yao, C. Hsieh, H. Yang, and C. Wu, Eur. Polym. J., 44, 2777 (2008).

X. Gao, Y. Zhu, X. Zhao, Z. Wang, D. An, Y. Ma, S. Guan, Y. Du, and B. Zhou, Appl. Surf. Sci., 257, 4719 (2011).

S. Ibrahim and H. Elsayed, Int. J. Chemtech Res., 9, 158, (2016).

M. Sangermano, H. ElSayed, and B. Voit, Polymer, 52, 2103 (2011).

I. Mihail, “Chemistry and Technology of Polyols for Polyurethanes”, Rapra Technology Limited, Shawbury, Shrewsbury, Shropshire, SY4 4NR, UK, 2005.

F. Coutinho, M. Delpech, and L. Alves, J. Appl. Polym. Sci., 80, 566 (2001).

S. Kim and K. Kim, J. Appl. Polym. Sci., 97, 1961 (2005).

P. Aruna and B. Rohini, J. Appl. Polym. Sci., 110, 2833 (2008).

S. Chai and Z. Zhang, J. Am. Leather. Chem. Assoc., 105, 41 (2010).

M. Hercule, Z. Yan, and M. Christophe, Inter. J. Chem., 3, 88 (2011).

J. Vincent and B. Natarajan, Open J. Organ. Polym. Mater., 4, 37 (2014).

I. Ugbaja, A. Ejila, A. Mamza, and N. Mbada, Sci. J. Chem., 4, 14 (2016).

O. Mohamed, N. Elsayed, A. Haroun, R. Attia, and A. Rabia, Egypt. J. Chem., 59, 759 (2016).

J. Ma, J. Hu, Z. Yang, and L. Liu, J. Sol-Gel Sci. Techn., 41, 209 (2007).

S. Sudhahar, C. Sivaraj, and S. Gupta, J. Am. Leather. Chem. Assoc., 107, 249 (2012).

ASTM E96/E96M-16, “Standard Test Methods for Water Vapor Transmission of Materials”, ASTM International, West Conshohocken, PA, 2016.

J. Hu, J. Ma, and W. Deng, Mater. Lett., 62, 2931 (2008).

J. Hu, J. Ma, and W. Deng, Eur. Polym. J., 44, 2695 (2008).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Elsayed, H., Attia, R., Mohamed, O. et al. Preparation of Polyurethane Silicon Oxide Nanomaterials as a Binder in Leather Finishing. Fibers Polym 19, 832–842 (2018). https://doi.org/10.1007/s12221-018-7979-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-018-7979-4