Abstract

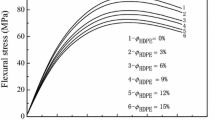

Improvement of both the tensile and impact strength of the same polymeric material has always been a great challenge for the plastic industry. The study focuses on the effect of incorporation of calcium carbonate nanoparticles (0.3 wt% to 15 wt%) into three polypropylene (PP) based matrices viz. PP homopolymer, propylene-ethylene (PP-PE) copolymer and the blend of PP:PP-PE (30:70) to improve their impact behavior without hampering the tensile strength much. A loss in both the tensile and impact properties was observed in PP based nanocomposite. However, PP-PE based nanocomposites showed a significant improvement in impact strength (47 %) at 10 wt% loading with a loss of tensile strength by 22 %. To minimize this loss a blend of PP:PP-PE (30:70) was explored as a matrix. At 10 wt% loading, this matrix showed an improvement of 30 % in impact strength whereas the tensile loss was minimized to 10 %. Further, silane coupling agent which promoted good interfacial adhesion was used for best compositions. The variation of crystalline morphology of the nanocomposites with various formulations was analyzed using differential scanning calorimetry and X-ray diffraction.

Similar content being viewed by others

References

J. Z. Liang, J. Appl. Polym. Sci., 83, 1547 (2002).

J. Z. Liang, Compos. Pt. A-Appl. Sci. Manuf., 38, 1502 (2007).

K. Yang, Q. Yang, G. Li, Y. Sun, and D. Feng, Mater. Lett., 60, 805 (2006).

J. Zhen, Y. F. Ding, and J. Q. Du, Plast. Proc. Appl., 23, 5 (2001).

J. W. Lim, A. Hassan, A. R. Rahmat, and M. U. Wahit, Plast. Rubber Compos., 35, 37 (2006).

M. Studzinski, R. Jeziórska, A. Szadkowska, and M. Zielecka, Polimery, 9, 625 (2014).

J. Karger-Kocsis, “Polypropylene: Structure, Blends and Composites”, p.194, Chapman and Hall, London, 1995.

A. Kiss, E. Fekete, and B. Pukánszky, Compos. Sci. Technol., 67, 1574 (2007).

Y. Lin, H. Chen, C. Chan, and J. Wu, J. Colloid Interface Sci., 354, 570 (2011).

S. Karamipour, H. Ebadi-Dehaghani, D. Ashouri, and S. Mousavian, Polym. Test., 30, 110 (2011).

T. D. Lam, T. V. Hoang, D. T. Quang, and J. S. Kim, Mater. Sci. Eng. A, 501, 87 (2009).

C. Chan, J. Wu, J. Li, and Y. Cheung, Polymer, 43, 2981 (2002).

G. M. Kim and G. H. Michler, Polymer, 39, 5689 (1998).

S. Wu, J. Appl. Polym. Sci., 35, 549 (1988).

O. K. Muratoglu, A. S. Argon, and R. E. Cohen, Polymer, 36, 921 (1995).

Z. Bartczak, A. S. Argon, R. E. Cohen, and M. Weinberg, Polymer, 40, 2347 (1999).

Y. D. Zhu, G. C. Allen, P. G. Jones, J. M. Adams, D. I. Gittins, P. J. Heard, and D. R. Skuse, Compos. Pt. A-Appl. Sci. Manuf., 60, 38 (2014).

Y. Lin, H. Chen, C. Chan, and J. Wu, Polymer, 51, 3277 (2010).

W. C. J. Zuiderduin, C. Westzaan, J. Huétink, and R. J Gaymans, Polymer, 44, 261 (2003).

Y. S. Thio, A. S. Argon, R. E. Cohen, and M. Weinberg, Polymer, 43, 3661 (2002).

J. Mócz, E. Fekete, K. Lászl, and B. Pukánszky, Macromol. Symp., 194, 111 (2003).

Y. Zare, Compos. Pt. A-Appl. Sci. Manuf., 84, 158 (2016).

G. Wang, X. Y. Chen, R. Huang, and L. Zhang, J. Mater. Sci. Lett., 21, 985 (2002).

C. G. Ma, M. Z. Rong, M. Q. Zang, and K. Friedrich, Polym. Eng. Sci., 45, 529 (2005).

N. Ranganathan, K. Oksman, S. K. Nayak, and M. Sain, J. Appl. Polym. Sci., 132, 41301 (2015).

M. Asgari and M. Masoomi, J. Thermoplast. Compos. Mater., 28, 357 (2015).

A. R. Kakrodi, S. Leduc, and D. Rodrigue, J. Appl. Polym. Sci., 124, 2494 (2012).

F. Ramsteiner, G. Kanig, W. Heckmann, and W. Gruber, Polymer, 24, 365 (1983).

M. Avella, S. Cosco, M. L. Di Lorenzo, E. Di Pace, M. E. Errico, and G. Gentile, Eur. Polym. J., 42, 1548 (2006).

W. Zhu, G. Zhang, J. Yu, and G. Dai, J. Appl. Polym. Sci., 91, 431 (2004).

M. Gahleitner, J. Wolfschwenger, C. Bachner, K. Bernreitner, and W. Neiβl, J. Appl. Polym. Sci, 61, 649 (1996).

R. Paukkeri and A. Lehtinen, Polymer, 34, 4075 (1993).

F. M. Mirabella, Polymer, 34, 1729 (1993).

I. Amer, A. Van Reenen, and T. Mokrani, Polímeros, 25, 556 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Joshi, M., Brahma, S., Roy, A. et al. Nano-calcium carbonate reinforced polypropylene and propylene-ethylene copolymer nanocomposites: Tensile vs. impact behavior. Fibers Polym 18, 2161–2169 (2017). https://doi.org/10.1007/s12221-017-7276-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-017-7276-7