Abstract

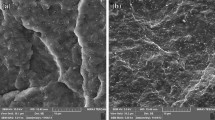

This study aimed to acquire a balance of mechanical properties comprising impact, tensile and flexural performances in PP based blend. In this respect, co-PP was employed as matrix because of its intrinsic high impact behavior. Hybrid nanocomposites based on co-PP and containing 10 wt % micron-sized short glass fibers (GF) and 2 to 8 wt % nano precipitated CaCO3 (NPCC) particles were produced by applying a two-step melt compounding method. Maleic anhydride grafted polypropylene (MAPP) was used as compatibilizer. Strong glass fiber-matrix adhesion and relatively uniform distribution of nano-CaCO3 particles were observed in SEM images. The maximum tensile strength was observed in co-PP hybrid nanocomposite containing 10 wt % glass fiber and 5 wt % nano-CaCO3 which was 58% more than that of neat co-PP. Flexural strength raised as much as 11% by adding glass fiber. The maximum flexural strength was obtained by incorporating 10 wt % glass fiber and 8 wt % nano-CaCO3 into co-PP matrix which was 24% higher than that of neat co-PP. The impact strength decreased upon addition of 10 wt % glass fiber and 5 and 8 wt % nano-CaCO3, this was attributed to the inherent high impact behavior of co-PP as well as strong interfacial interaction between dispersed phases and polymeric matrix.

Similar content being viewed by others

References

D. Tripathi, Practical Guide to Polypropylene (Rapra Technology, Shrewsbury, 2002).

R. Hartle, G. Riding, and T. Washburn, Proprietary Engineering Resins as Additives to Polypropylene (GE Advanced Materials, Las Vegas, Nevada, 2005).

H. Karian, Handbook of Polypropylene and Polypropylene Composites, Revised and Expanded (CRC, 2003).

L. Hollaway, Handbook of Polymer Composites for Engineers (Elsevier, Cambridge, 1994).

J. G. Drobny, Handbook of Thermoplastic Elastomers (William Andrew, Norwich, 2007).

W. Zuiderduin, C. Westzaan, J. Huetink, and R. Gaymans, Polymer 44, 261 (2003).

K. Yang, Q. Yang, G. Li, Y. Sun, and D. Feng, Mater. Lett. 60, 805 (2006).

C. G. Ma, Y. L. Mai, M. Z. Rong, W. H. Ruan, and M. Q. Zhang, Compos. Sci. Technol. 67, 2997 (2007).

S.-Y. Fu, X.-Q. Feng, B. Lauke, and Y.-W. Mai, Compos. Part B: Eng. 39, 933 (2008).

H. Hanim, R. Zurina, M. Ahmad Fuad, and A. Hassan, Malays. Polym. J. 3, 38 (2008).

E. T. Thostenson, C. Li, and T.-W. Chou, Compos. Sci. Technol. 65, 491 (2005).

S. Sinha Ray and M. Okamoto, Prog. Polym. Sci. 28, 1539 (2003).

W. Chow, Z. Mohd Ishak, J. Karger-Kocsis, A. Apostolov, and U. Ishiaku, Polymer 44, 7427 (2003).

K. Shelesh-Nezhad, H. Orang, and M. Motallebi, J. Thermoplast. Compos. Mater. 26, 544 (2013).

I. Kemal, A. Whittle, R. Burford, T. Vodenitcharova, and M. Hoffman, J. Appl. Polym. Sci. 127, 2339 (2013).

D. Eiras and L. A. Pessan, Mater. Res. 12, 517 (2009).

N. A. Rahman, A. Hassan, R. Yahya, R. Lafia-Araga, and P. Hornsby, J. Reinf. Plast. Compos. 31, 1247 (2012).

C. Hopmann, W. Michaeli, and F. Puch, Polym. Compos. 33, 2228 (2012).

N. A. Rahman, A. Hassan, R. Yahya, R. A. Lafia-Araga, and P. R. Hornsby, J. Reinf. Plast. Compos. 31, 269 (2012).

T. Mohan and K. Kanny, J. Reinf. Plast. Compos. 30(2), 152 (2010).

J. Thomason, M. Vlug, G. Schipper, and H. Krikor, Compos, Part A 27, 1075, (1996).

P. Dave, D. Chundury, G. Baumer, and L. Overley, J. Vinyl. Addit. Techn. 2, 253 (1996).

C.-M. Chan, J. Wu, J.-X. Li, and Y.-K. Cheung, Polymer 43, 2981 (2002).

C. Chi-Ming, W. Jingshen, and L. Jian-Xiong, Group. 500, 414 (2002).

J. G. Gwon, S. Y. Lee, S. J. Chun, G. H. Doh, and J. H. Kim, Mater. Sci. Eng. A 41, 1491 (2010).

M. Avella, S. Cosco, M. Di Lorenzo, E. Di Pace, M. Errico, and G. Gentile, Eur. Polym. J. 42, 1548 (2006).

H. U. Zaman, P. D Hun, R. A. Khan, and K.-B. Yoon, J. Thermoplast. Compos. Mater. 31(5), 323 (2012).

B. J. Ash, R. W. Siegel, and L. S. Schadler, Macromolecules 37, 1358 (2004).

A. Hassan, N. A. Rahman, and R. Yahya, J. Reinf. Plast. Compos. 30(14), 1223 (2011).

A. Z. Zakaria and K. Shelesh-Nezhad, Nanomater. Nanotechnol. 4, 17 (2014).

S.-Y. Fu, X.-Q. Feng, B. Lauke, and Y.-W. Mai, Compos. Part B 39, 933 (2008).

C. Deshmane, Q. Yuan, and R. Misra, Mater. Sci. Eng. A 452, 592 (2007).

I. Dubnikova, S. Berezina, and A. Antonov, J. Appl. Polym. Sci. 94, 1917 (2004).

L. Sun, R. F. Gibson, F. Gordaninejad, and J. Suhr, Compos. Sci. Technol. 69, 2392 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Soudmand, B.H., Shelesh-Nezhad, K. Experimental investigation on the mechanical properties of Co-polypropylene/GF/CaCO3 hybrid nanocomposites. Polym. Sci. Ser. A 58, 454–463 (2016). https://doi.org/10.1134/S0965545X16030172

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965545X16030172