Abstract

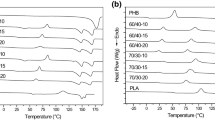

In order to explore an alternative method instead of plasticization for improving the toughness, flexibility and processability of PLA based packaging films, two different kinds of modified polyethylene based elastomers, such as glycidyl methacrylate or maleic anhydride functionalized ethylene-acrylate based elastomers, were melt blended with PLA. Their properties were compared with conventional PEG plasticized PLA. The chemical interaction between end groups of PLA and epoxide or maleic anhydride functional groups of elastomers was shown by FTIR. Scanning electron microscopy showed that up to 20 % PEG loading, one phase morphology was achieved, however beyond this point, a phase separation was observed for plasticized PLA. For PLA/elastomer blends, a two-phase morphology was obtained as a result of immiscible nature of PLA and elastomers. Tensile and dynamic mechanical properties indicated that elastomer based blends were better than plasticized PLA independently from elastomer type. Differential scanning calorimeter (DSC) analysis exhibited that the T g value was remarkably lowered in the plasticized PLA; however, it did not change in the case of elastomers. In terms of oxygen permeability and biodegradability, plasticized PLA was found to be better than elastomer based blends.

Similar content being viewed by others

References

S. Jacobsen and H. G. Fritz, Polym. Eng. Sci., 39, 1303 (1999).

Y. Hua, M. Rogunovaa, V. Topolkaraevb, A. Hiltnera, and E. Baer, Polymer, 44, 5701 (2003).

A. Sorrentino, G. Gorrosi, and V. Vittoria, Sci. Technol., 18, 85 (2007).

G. H. Koo and J. Jang, Fiber. Polym., 9, 674 (2008).

S. Solarski, M. Ferreira, and E. Devaux, Polymer, 46, 11187 (2005).

L. Petersson, I. Kvien, and K. Oksman, Compos. Sci. Technol., 67, 2535 (2007).

I. Pillin, N. Montrelay, and Y. Grohens, Polymer, 47, 4676 (2006).

N. Ljungberg, T. Andersson, and B. Wesslen, J. Appl. Polym. Sci., 88, 3239 (2003).

E. Foldes and A. Szigeti-Erdei, J. Vinyl Addit. Techn., 3, 220 (1997).

N. Ljungberg and B. Wesslen, J. Appl. Polym. Sci., 86, 1227 (2002).

Y. Hu, M. Rogunova, V. Topolkaraev, A. Hiltner, and E. Baer, Polymer, 44, 5701 (2003).

G. Zhang, J. Zhang, S. Wang, and D. Shen, J. Polym. Sci. Pol. Phys., 41, 23 (2003).

Z. Jia, J. Tan, C. Han, Y. Yang, and L. Dong, J. Appl. Polym. Sci., 114, 1105 (2009).

H. Tsuji, A. Mizuno, and Y. Ikada, J. Appl. Polym. Sci., 70, 2259 (1998).

M. Baiardo, G. Frisoni, M. Scandola, M. Rimelen, D. Lips, K. Ruffieux, and E. Wintermantel, J. Appl. Polym. Sci., 90, 1731 (2003).

G. X. Chen, H. S. Kim, E. S. Kim, and J. S. Yoon, Polymer, 46, 11829 (2005).

T. Yokohara and M. Yamaguchi, Eur. Polym. J., 44, 677 (2008).

M. Shibata, Y. Inoue, and M. Miyoshi, Polymer, 47, 3557 (2006).

S. Sun, M. Zhang, H. Zhang, and X. Zhang, J. Appl. Polym. Sci., 122, 2992 (2011).

A. K. Mohanty, L. T. Drzal, B. P. Rook, and M. Misra, Michigan State University, US Patent, 7256223 B2 (2007).

J. R. Randall, C. M. Ryan, J. Lunt, M. H. Hartman, E. S. Hall, and J. J. Kolstad, US Patent, 6495631 (2002).

L. T. Lima, R. Aurasb, and M. Rubino, Prog. Polym. Sci., 33, 820 (2008).

H. T. Oyama, Polymer, 50, 747 (2009).

Z. Su, Q. Li, Y. Liu, G. Hu, and C. Wu, Eur. Polym. J., 45, 2428 (2009).

H. Durgun and G. Bayram, J. Adhes. Sci. Technol., 19, 407 (2005).

M. Sclavons, M. Laurent, J. Devaux, and V. Carlier, Polymer, 46, 8062 (2005).

H. T. Chiu and Y. K. Hsiao, J. Polym. Res., 13, 153 (2006).

G. Ozkoc, G. Bayram, and M. Quaedflieg, J. Appl. Polym. Sci., 107, 3058 (2008).

P. Pan, B. Zhu, and Y. Inoue, Macromolecules, 40, 9664 (2007).

S. Gumus, A. Aytac, and G. Ozkoc, J. Appl. Polym. Sci., 123, 2837 (2012).

M. Sheth, R. A. Kumar, V. Dave, R. A. Gross, and S. P. McCarthy, J. Appl. Polym. Sci., 66, 1495 (1997).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dogan, S.K., Gumus, S., Aytac, A. et al. Properties of modified ethylene terpolymer/poly(lactic acid) blends based films. Fibers Polym 14, 1422–1431 (2013). https://doi.org/10.1007/s12221-013-1422-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-013-1422-7