Abstract

Liquid metal gallium has been widely used in numerous fields, from nuclear engineering, catalysts, and energy storage to electronics owing to its remarkable thermal and electrical properties along with low viscosity and nontoxicity. Compared with high-temperature liquid metals, room-temperature liquid metals, such as gallium (Ga), are emerging as promising alternatives for fabricating advanced energy storage devices, such as phase change materials, by harvesting the advantageous properties of their liquid state maintained without external energy input. However, the thermal and electrical properties of liquid metals at the phase transition are rather poorly studied, limiting their practical applications. In this study, we reported on the physical properties of the solid–liquid phase transition of Ga using a custom-designed, solid–liquid electrical and thermal measurement system. We observed that the electrical conductivity of Ga progressively decreases with an increase in temperature. However, the Seebeck coefficient of Ga increases from 0.2 to 2.1 µV/K, and thermal conductivity from 7.6 to 33 W/(K∙m). These electrical and thermal properties of Ga at solid–liquid phase transition would be useful for practical applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In 1871, the Russian chemist Dmitri Mendeleev [1], who first formulated the Periodic Law and created the farsighted version of the periodic table of elements, predicted the existence of gallium (Ga) and named it “eka-aluminum” in the periodic table. In the position of Ga in the periodic table, he predicted several physical properties, such as density, melting point, oxide character, and bonding in chloride [2]. Four years later, the French chemist Paul Emile Lecoq de Boisbaudran [3] first observed in a sample of sphalerite the emission spectroscopy of Ga with two characteristic violet lines. He then obtained elemental Ga using electrolysis of Ga hydroxide in potassium hydroxide solution [4]. He also measured the density of Ga to be 4.7 g/cm3, which did not match the value of Mendeleev’s predictions. However, after calibration, the correct density value was determined to be 5.9 g/cm3, which perfectly matched Mendeleev’s estimate [2]. Subsequently, Ga as a room-temperature liquid metal has received considerable attention [5]. One of the distinctive features of Ga, which belongs to the same group as Al in the periodic table, is its melting point of 302.9146 K (29.7646 °C, 85.5763 °F) (slightly above room temperature) [6], and water-like bulk viscosity (viscosity: 1.99 cps (1 cps = 1 mPa∙s), close to that of water: 1.00 cps) [7]. Züger et al. [8] believed that the low melting point of Ga is related to the mixed covalent and metallic bonding in its solid state, hence affecting the phase behavior with a dimeric species of Ga. Ga readily alloys with most metals, such as In, Sn, Zn, Cd, and Pb, to form low melting point alloys. The melting point of the Ga–In–Sn eutectic alloy is the lowest; its trade name is Galinstan (“-stan” refers to tin, which is called stannum in Latin) and has a low freezing point of − 19 °C (− 2.2 °F) [9]. Because the mechanical and thermal properties of Ga considerably change during its phase changing at the solid–liquid state, this liquid metal can be used to fabricate several flexible and stretchable devices on account of its integrated mechanical, thermal, and electrical features. Examples of such applications include soft robotics [10], flexible and wearable electronics [11, 12], and renewable energy for waste heat recovery [13]. In addition to the unique physical properties of Ga, its electronic property is mainly focused on its eutectics or compounds. For example, gallium arsenide makes up 95% of the annual global Ga consumption for semiconductor applications, 53% of which is ascribed to cell phones, 27% to wireless communications, and the remaining to automobiles, consumers, fiber optics, and military uses [14]. Despite having been listed in the periodic table for more than a century, only recently, the research and development of Ga has attracted widespread interest. Liquid metals, which have for a long time piqued scientific curiosities, drew renewed attention these years with novel applications. For example, the American Chemical Society recognized Ga as one of the top research stories of the year in 2016 [15], showcasing the potential of Ga for various new applications [16], such as biomedicine [17], energy storage systems [18], 3D printing [19], and pattern printing. They used the liquid metal to fabricate stretchable devices that contain stacked layers of LEDs and sensors embedded in gloves that can track the subtle motions of fingers [20]. Over the last decade, the literature on liquid metals, including Ga, has substantially grown with an annual increase of approximately 21% [21].

Unfortunately, owing to the lack of appropriate research models and equipment, the measurement of the physical and electrical properties of liquid metals, such as Ga, at room temperature has been limited only to the solid or liquid state. A few studies, however, have been conducted on the physical plasticity or mutability of these liquid metals during phase change, focusing on features such as density, crystal structure, and electrical and thermal properties. The shortcoming is largely ascribed to the lack of appropriate characterization techniques during solid–liquid phase transition.

The physical and chemical properties of liquid metals are highly important in various fields of science and engineering. An important property of liquid metals is their low viscosity, which allows them to flow easily and rapidly. This property is particularly useful in metallurgy for the casting and shaping of metal parts. Another important property of liquid metals is their remarkable electrical conductivity, making them valuable in electronic devices such as thermometers, switches, and sensors. In this study, some interesting physical properties of Ga during the phase transition process from the solid-to-liquid state have been studied. We observed that the density in the liquid phase was higher than that in the solid phase, the electrical conductivity decreased while transforming from the α-Ga crystal phase to the I4 space group, and the thermal conductivity showed an anomaly at the melting point.

Materials and Experimental

To conduct low-temperature characterization on a physical property measurement system (PPMS), pellets of solid Ga (99.99%, Sigma-Aldrich) were cut into a 5 mm × 5 mm × 1 mm sheet. A larger Ga sheet measuring 20 mm × 10 mm × 0.5 mm was produced for use at temperatures of 290–480 K. This was achieved by dropping the liquid metal into a glass channel of the same size at 50 °C. For thermal conductivity measurement using NanoTR, a thin sheet of Ga was coated onto a glass substrate by applying a blade to the surface of the sheet on a hot plate at 50 °C. Glass substrates were washed and sonicated in an acetone bath, followed by isopropanol and deionized water for 15 min. Finally, the surface was treated with ultraviolet ozone at 398 K for 10 min.

The electrical conductivity, thermal conductivity, and Seebeck coefficient of the bulk Ga sample were measured on the PPMS (Quantum Design, USA) using a thermal transport option in the low-temperature region of 20–270 K. The electrical conductivity and Seebeck coefficient of the solid and liquid states of Ga were simultaneously measured on homemade copper contacts and thermocouples at 290–480 K (Fig. 1). The heat capacity of Ga at a temperature ranging from room temperature (298 K) to 773 K was measured on a differential scanning calorimetry system. The out-of-plane κ of the thin films was measured using the pulsed laser heating thermoreflectance method with a rear heating and front detection configuration (NanoTR, NETZSCH) at 290–480 K (Fig. 2). X-ray diffraction (XRD) experiments were conducted on a Bruker AXS (D8 ADVANCE GADDS) X-ray diffractometer with Cu K-\(\alpha \) radiation (λ = 1.54 Å); the beam diameter for this instrument can range from 0.05 to 0.8 mm. The volume density of a thin film was estimated using the mass and volume of the films. In all the experiments, we performed heating from low temperature to above solid–liquid phase transition temperature to avoid the effect of supercooling on the phase transition delay.

Results and Discussion

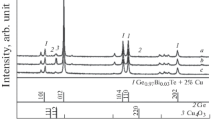

Figure 3 shows the in situ broad XRD patterns under the controlled temperature patterns of Ga metal coated on a glass substrate at 294 K (solid state) and 323 K (liquid state), respectively.

Based on the XRD data, this α-Ga metallic molecular crystal with a = 4.522 Å, b = 7.849 Å, and c = 4.519 Å, as shown in Fig. 4 (top), has the lowest energy, which is approximately consistent with the theoretical values of the Ga crystal structure with a = 4.38 Å, b = 7.43 Å, and c = 4.39 Å. According to the XRD crystal parameters, the calculated theoretical density of the solid-state α-Ga crystal is 5.774 g/cm3, which is similar to the reported density of 5.9 g/cm3 [2]. In general, the metallic crystalline phase will expand and lead to a decrease in the total molar mass during the process of metal melting. Therefore, a sufficient free volume allows melting to result in the rearrangement of Ga atoms. This local metal atomic arrangement is also related to its crystal form to some extent. However, the XRD spectra of liquid Ga at 50 °C (Fig. 3, bottom) show a prominent peak and broad shoulder at 2θ ≈ 35° and 2θ ≈ 45°, respectively, revealing that the Ga atomic distance decreases and, consequently, the density of Ga in the liquid state increases when Ga changes from a solid state to a liquid state.

Based on an ab initio study of Ga lattice at 21 °C, the molecular character and metallic conduction coexist in an α phase of Ga [22]. This stable α-Ga metallic molecular crystal at ambient pressure is in the space group Cmca, indicating the base-centered orthorhombic with eight atoms in the cubic unit cell state (Fig. 4). Upon changing Ga to its liquid state, the liquid Ga phase assumes the space group I4 with crystal lattice parameters of a = b = 2.809 Å and c = 4.534 Å at ambient pressure. The calculated theoretic density is 6.470 g/cm3, which is higher than those obtained from simulation and experimental values, 6.097–6.539 g/cm3 [23, 24].

In short, liquid-state Ga has a higher density than solid-state Ga, which is not as the general metals but as the ice–water situation. The unit cell of the crystalline phase α-Ga comprises eight atoms, a little further away at 2.7–2.8 Å, with an average coordination number of ~ 7. Figure 4 shows that certain quantities of free volume are located between locally denser motifs in the solid and liquid states, respectively. The dimer-like α-Ga units largely disappear in the liquid state with an increase in temperature because thermodynamically, all Ga atoms are similar in the disordered state, although the second peaks at around 65° in Fig. 3 (bottom) may suggest some residual, dimer-like units remaining. Hence, upon melting, the topological structure of the α-Ga crystal breaks up and then reconstructs. The local atomic arrangements of liquid metals cannot be truly random but meet both topological and chemical requirements [21], leading to high density and high packing efficiency. Therefore, the question is whether the Ga metallic molecular crystal and density variations enable to induce possible alteration in electrical and thermal properties, implying that Ga behaves differently from other nonliquid metals.

The thermoelectric properties were measured in both solid and liquid states of the pure Ga bulks that were diced in pellets and filled in a glass channel using the PPMS system (20–270 K) and homemade system (290–480 K), respectively (Fig. 5). The Seebeck coefficient and electrical conductivity of Ga were measured on the PPMS and homemade systems, respectively. As shown in Fig. 5, the highest electrical conductivity of 7880 S/cm of the α-Ga crystal pellet was observed at 11 K, followed by a steady decline to 3580 S/cm at 260 K (solid) in the PPMS system. In the customized set up system, the conductivity of Ga decreased from 3560 to 3230 ± 300 S/cm at its melting point of 303 K, with a slow drop during and after liquefaction. This means that metallic Ga does not change its electrical conductivity during the liquefaction process, probably due to the considerable phase change of the lattice.

As shown in Fig. 5, metallic Ga clearly displays a continuous decline in electrical conductivity at 10–480 K. However, the trend of the Seebeck coefficient is more complex during temperature increase and during phase transition. First, the ultralow Seebeck coefficient at 11 K was observed approximately to be 0.2 ± 0.1 µV/K, which is consistent with the reported lowest value of 0.3 µV/K [21]. Subsequently, the Seebeck coefficient steeply increases to approximately 1.0 µV/K, remains steady at 90–200 K, and increases to nearly 2 µV/K with an increase in the temperature to room temperature. In the phase-changing characterization system, as shown in Fig. 5, the Seebeck coefficient slowly increases from 1.7 to 2.3 µV/K without any significant change at the melting point of 303 K. Noteworthily, this phenomenon shows that Ga has satisfactory electrical and thermoelectric plasticity at solid–liquid phase transition, and this may be important for the liquid metal to retain consistent properties during applications.

It is widely known that all phase changes are accompanied by an enthalpy change in a system. For example, phase changes from a more-ordered state to a less-ordered state (such as solid to liquid or gas) are endothermic. As shown in Fig. 6a, the heat capacity of Ga increases from 0.57 to 7.13 J/g K at 303 K, at which solid Ga converts into liquid. The heat capacity of Ga is further reduced to 0.59 J/g K after fully melting at over 304 K. The heat transfer coefficient is also known as thermal admittance in the sense that the material may be seen as admitting heat to flow. Finally, thermal conductivity ƙ combines thermal diffusivity α with density ρ and specific heat Cp [22]. (Eq. (1))

Same as that for the measurement of electrical conductivity, we use the PPMS system to measure the thermal conductivity at a low-temperature range (20–270 K) and use the NanoTR system at a high-temperature range (300–480 K). The thermal conductivity of Ga exhibits a similar trend to that of the Seebeck coefficient in the temperature range of 20–270 K (Fig. 6b). The lowest thermal conductivity of 8.1 W/(K∙m) at 11 K was observed, and it continued to increase to approximately 33 W/(K∙m) at 270 K. Using the NanoTR system, a rapid drop to 11.3 W/(K∙m) at the melting point was observed, then quickly increasing to 32 W/(K∙m), and then stabilizing at approximately 30 W/(K∙m) during 350–480 K. Obviously, most heat is absorbed to break down the α-Ga crystal structure and reconstruct to the liquid phase with little heat transfer. Hence, the endothermic change at 303 K considerably reduces the thermal transfer in liquid metal during the phase change of melting.

Additionally, we noted the supercooling effect of Ga upon lowering the temperature from high temperature to the phase change temperature, enabling Ga to remain in the liquid state at room temperature or lower, despite its melting point of 303 K. We did not observe considerable changes in electrical conductivity and Seebeck coefficient, thereby confirming that the conductivity and thermoelectric properties remain stable during phase transition.

Conclusion

The electrical and thermal properties and Seebeck coefficient of Ga were studied in the solid and liquid states with a particular focus on phase transition. Ga exhibited an ultralow Seebeck coefficient of ~ 0.2 ± 0.1 µV/K and the highest electrical conductivity of 7880 S/cm at 11 K. At the melting point of 303 K, liquid Ga has a higher density than its crystal metal, as confirmed by the XRD results. The electrical conductivity of Ga in the solid state decreased with an increase in temperature, whereas the overall Seebeck coefficient roughly increased with an increase in temperature. However, at the point of phase transition, the electrical conductivity and Seebeck coefficient were maintained at approximately 3200 S/cm and 2 µV/K, respectively. Additionally, we observed a considerable drop in thermal conductivity at the point of phase transition, followed by a rapid return to the previous value. These electrical and thermal properties of metallic Ga before and after liquefaction may find some interesting applications in electrodes and electrical conductors. This study might trigger further investigations of liquid metals and other phase-changing materials with plasticity features at the phase transition.

References

Ball P (2002) The Ingredients: a Guided tour of the elements. Oxford University Press

Greenwood NN, Earnshaw A (1997) Chemistry of the Elements, 2nd edn. ScienceDirect (Elsevier) press

Lecoq de Boisbaudran PÉ (1875) Caractères chimiques et spectroscopiques d’un nouveau métal, le gallium, découvert dans une blende de la mine de Pierrefitte, vallée d’Argelès (Pyrénées). C R Hebd Seances Acad Sci 81:493–495

Weeks ME (1932) The discovery of the elements. XV. Some elements predicted by Mendeleeff. J Chem Educ 9(9):1605

Tang SY, Tabor C, Kalantar-Zadeh K et al (2021) Gallium liquid metal: the devil’s elixir. Annu Rev Mater Res 51:381–408

Preston-Thomas H (1990) The international temperature scale of 1990 (ITS-90). Metrologia 27(1):3–10

Spells KE (1936) The determination of the viscosity of liquid gallium over an extended range of temperature. Proc Phys Soc 48(2):299–311

Züger O, Dürig U (1992) Atomic structure of the α-Ga(001) surface investigated by scanning tunneling microscopy: direct evidence for the existence of Ga2 molecules in solid gallium. Phys Rev B 46(11):7319–7321

Surmann P, Zeyat H (2005) Voltammetric analysis using a self-renewable non-mercury electrode. Anal Bioanal Chem 383(6):1009–1013

Tonazzini A, Mintchev S, Schubert B et al (2016) Variable stiffness fiber with self-healing capability. Adv Mater 28(46):10142–10148

Ilyas N, Cook A, Tabor CE (2017) Designing liquid metal interfaces to enable next generation flexible and reconfigurable electronics. Adv Mater Interfaces 4(15):1700141

Liu S, Yuen MC, White EL et al (2018) Laser sintering of liquid metal nanoparticles for scalable manufacturing of soft and flexible electronics. ACS Appl Mater Interfaces 10(33):28232–28241

Dai D, Zhou YX, Liu J (2011) Liquid metal based thermoelectric generation system for waste heat recovery. Renew Energy 36(12):3530–3536

Moskalyk RR (2003) Gallium: the backbone of the electronics industry. Miner Eng 16(10):921–929

Jacoby M (2016) Liquid metals went to work. C&EN Glob Enterp 94(49):26

Woo M (2020) Core concept: liquid metal renaissance points to wearables, soft robots, and new materials. P Natl Acad Sci USA 117(10):5088–5091

Yan J, Lu Y, Chen G et al (2018) Advances in liquid metals for biomedical applications. Chem Soc Rev 47(8):2518–2533

Guo X, Zhang L, Ding Y et al (2019) Room-temperature liquid metal and alloy systems for energy storage applications. Energ Environ SCI 12(9):2605–2619

Ladd C, So JH, Muth J et al (2013) 3D Printing of free standing liquid metal microstructures. Adv Mater 25(36):5081–5085

Hirsch A, Michaud HO, Gerratt AP et al (2016) Intrinsically stretchable biphasic (solid–liquid) thin metal films. Adv Mater 28:4507–4512

Dickey MD (2020) EML webinar overview: liquid metals at the extreme. Extreme Mech Lett 40:100863

Gong XG, Chiarotti GL, Parrinello M (1991) α-gallium: a metallic molecular crystal. Phys Rev B 43(17):14277–14280

Hoather WH (1936) The density and coefficient of expansion of liquid gallium over a wide range of temperature. Proc Phys Soc 48(5):699–707

Li R, Wang L, Li L et al (2017) Local structure of liquid gallium under pressure. Sci Rep 7(1):5666

Acknowledgements

The authors would like to acknowledge the support provided by A*STAR and the Industry Alignment Fund through the Pharos “Hybrid thermoelectric materials for ambient applications” Program (No. 1527200021). The authors would also like to thank Dr. Fengxia Wei for her valuable comments and suggestions.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare that there is no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, X., Repaka, D.V.M., Suwardi, A. et al. Thermal and Electrical Properties of Liquid Metal Gallium During Phase Transition. Trans. Tianjin Univ. 29, 209–215 (2023). https://doi.org/10.1007/s12209-023-00357-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-023-00357-y