Abstract

Capturing CO2 from the atmosphere and converting it into fuels are an efficient strategy to stop the deteriorating greenhouse effect and alleviate the energy crisis. Among various CO2 conversion approaches, electrocatalytic CO2 reduction reaction (CO2RR) has received extensive attention because of its mild operating conditions. However, the high onset potential, low selectivity toward multi-carbon products and poor cruising ability of CO2RR impede its development. To regulate product distribution, previous studies performed electrocatalyst modification using several universal methods, including composition manipulation, morphology control, surface modification, and defect engineering. Recent studies have revealed that the cathode and electrolytes influence the selectivity of CO2RR via pH changes and ionic effects, or by directly participating in the reduction pathway as cocatalysts. This review summarizes the state-of-the-art optimization strategies to efficiently enhance CO2RR selectivity from two main aspects, namely the cathode electrocatalyst and the electrolyte.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Global warming caused by massive greenhouse gas emissions has brought many environmental challenges, including sea level rise, species extinction, and climate change [1, 2]. According to the State of the Climate in 2019, the average global temperature has increased by ca. 1.0 °C compared with the pre-industrial age because of the increased CO2 concentration in the atmosphere [3]. Two strategies have been proposed to decrease the CO2 concentration in the atmosphere: storing and utilizing CO2 [4, 5]. Compared with CO2 storage, CO2 utilization has received greater research attention in recent years because of its cost-effectiveness. CO2 utilization can be divided into two methods: direct application of CO2 and conversion of CO2 into other chemicals, such as fuels. The direct application of CO2 is employed on a small scale to improve oil recovery [6] and act as a supercritical liquid [7]. Therefore, the chemical conversion of CO2 accounts for the majority of CO2 utilization. Important chemical feedstocks, such as urea and salicylic acid, have been synthesized through thermal or catalytic processes using CO2 as the raw material [8, 9]. Moreover, renewable energy sources that are inherently hard to store, such as solar, wind, and geothermal, can be used to drive CO2 conversion, providing an ideal way of sustainable development. Among numerous CO2 conversion methods, electrocatalytic CO2 reduction is the most promising one because of its ambient reaction conditions and simple device fabrication. However, the advancement of electrocatalytic CO2 reduction reaction (CO2RR) still faces several challenges, including poor CO2 solubility, high activation energy, low energy efficiency, and low selectivity [10]. In addition, the deactivation of electrodes in less than 100 h largely restricts the practical use and technological commercialization of CO2RR [11]. The poor stability of CO2RR has several causes, depending on the type of cathode. For example, noble metals suffer from CO poison during the reduction process [12]; metallic chalcogenides are easily reduced at the reduction environment [13]; and agglomeration of catalysts with high dispersion decreases active site concentration [14]. The most problematic one is the low selectivity, which results in costly separation steps and energy consumption at downstream. In general, the CO2RR products that have been reported so far include C1 products (e.g., CO, HCOOH, CH3OH, HCHO, CH4), C2 products (e.g., C2H4, C2H6, C2H5OH, H2C2O4, CH3COOH), and C2+ products (e.g., n-propanol). The number of transferred electrons required to form these products and their corresponding standard redox potentials in acid and base electrolytes are listed in Table 1.

Although hydrocarbons and alcohols are thermodynamically favored, CO and HCOOH/HCOO− are kinetically preferred because they require fewer electron transfers to complete the reaction (2e− products) [11]. As a result, CO and formic acid, as the most common CO2RR products, usually show high selectivity using either metal or metal-free cathodes [15,16,17,18]. Meanwhile, products involving > 2e− transfer are prone to desorbing from the electrode surface before deep reductions occur, leading to low selectivity. For example, the simplest C2 product of C2H4 (12e−) has a maximum Faradic efficiency (FE) of 72% [19], whereas C3 products such as n-propanol (18e−) have an FE less than 20% [20]. Despite their low conversion efficiency, products with > 2e− transfer are still the preferred fuels owing to their higher energy density than CO and formic acid [21, 22]. Furthermore, due to the similar thermodynamic potentials, another competitive cathodic reaction for CO2RR in the presence of water, i.e., hydrogen evolution reaction (HER), concurrently occurs and affects the overall CO2RR selectivity [23]. The selectivity of CO2RR is influenced not only by the electrocatalysts but also by the electrolytes. The two factors interplay with each other. The most important factor dominating CO2RR activity and selectivity is the cathode material. Given the difficult activation of CO2, a suitable electrocatalyst can efficiently reduce the activation energy barrier and thus decrease the overpotential. As to the electrolyte, a suitable solvent presents high CO2 solubility; however, the ion species of the supporting electrolyte greatly decide the buffer capacity and solution pH. The cations adsorbed on the cathode–electrolyte interface via electrostatic interaction can modify the superficial environment and thus manipulate the adsorption affinity of CO2 and intermediates, leading to varied product distribution [24]. This review focuses on the two aforementioned factors and discusses their mechanism on the reaction pathways. Hopefully, our perspective could serve as a reference for the regulation of CO2RR selectivity and for the future design of advanced electrolysis systems for CO2RR.

Electrocatalyst

Cathode materials largely determine the activity and selectivity of an electrocatalytic cell. CO2RR electrochemical catalysts can be categorized according to various perspectives, such as homogeneous and heterogeneous catalysts or metallic and non-metallic catalysts. Widely used in mechanistic exploration, homogeneous catalysts can exclude environmental disturbance, including supporting electrolytes, temperature, pressure, and disclose the intrinsic reactivity of the electrocatalyst. However, most homogeneous catalysts can hardly overperform heterogeneous catalysts because of their sparse and discrete active sites, low stability, high synthesis cost, and toxicity. Therefore, this section focuses on the design strategies, including composition manipulation, morphology control, surface modification, and defect engineering, of high-performance heterogeneous catalysts.

Composition Manipulation

As early as 1985, Hori et al. [25] summarized the product preferences of electrocatalytic CO2RR on various metal electrodes. Four groups of metals were classified based on their dominant products [25, 26]:

-

(1)

formic acid on Pb, Hg, Tl, In, Sn, Cd, Bi;

-

(2)

CO on Au, Ag, Zn, Pd, Ga;

-

(3)

H2 on Ni, Fe, Pt, Ti;

-

(4)

C2(+) products on Cu.

Cu is the only pure metal that enables the formation of multi-electron reduction products, including CH4 (8e−), C2H4 (12e−), C2H5OH (12e−), and even n-propanol (18e−).

Compared with pure metals, alloys and composites undergo a more intricate catalytic process and show better catalytic properties. Bi- or multi-metal catalysts present a synergistic effect [27,28,29]. For instance, Au-deposited Cu displays a 100-fold enhanced catalytic activity for converting CO2 into C2+ products compared with bare Cu foils [30]. Benefiting from the bimetallic synergy, the catalytic process is divided into two regionalized steps, which greatly boost the reaction efficiency. First, CO2 is reduced into *CO at Au active sites. Then, the *CO species transfer to nearby Cu active sites and undergo further reduction into multi-carbon products, such as C2H5OH and n-propanol. In this work, Au and Cu were delicately integrated into a novel bimetal catalyst, and both components participated in the catalytic process, achieving a high catalytic performance. A similar tandem catalysis was also observed on the CuZn catalyst, in which *CO was stabilized on the catalyst surface and transferred from Zn atoms to adjacent Cu sites for further dimerization and protonation to yield C2H4, with FE up to 33.3% at − 1.1 V versus RHE [31]. Our group achieved a tunable CO2/H2 ratio of syngas (i.e., CO2 and H2) on partial Zn-substituted CdS-amine inorganic–organic hybrids at − 1.16 V versus RHE [32]. The amine provides the active sites for CO formation, whereas Zn substitution boosts HER. Therefore, different CO2/H2 ratios can be obtained by altering the Zn concentration.

Aside from the tandem catalytic effect, the introduction of a secondary component can also influence the surface electronic structure and thus change the binding strength of intermediates. Previous studies reported that the formation of C2H4 is more favored than that of C2H5OH on Cu. Intermediates of the C2H4 pathway, such as *CCH, possess higher π electron density than those of the C2H5OH pathway (*HCCHOH) at the synchronous step, which requires dense available binding sites (Fig. 1a). Hence, Li et al. [33] selected Ag, which has a weaker bonding ability, to combine with Cu to reduce the number of strong binding sites. The Ag/Cu catalyst can successfully switch the selectivity from C2H4 to ethanol, achieving a FE of 41% and a current density (j) up to 250 mA/cm2 at − 0.67 V versus RHE. Such synergy can also be observed in metal oxide compounds. For example, Schreier et al. [34] reported that CuO nanowires (NWs) coated with an atomic layer of SnO2 outperform pure CuO, showing a FE of ca. 90% toward CO. The enhanced selectivity is attributed to the decreased binding strength of *H and *CO: The former leads to the suppression of HER, and the latter promotes the fast release of *CO before further reduction.

In other cases, some components in a composite may not directly participate in the reaction but improve the physical or chemical properties of the active component to increase the overall reactivity. For example, carbon-based materials, as the most popular supporting materials, can improve the electrical conductivity, increase the specific surface area, enhance dispersity, and improve stability [35, 36]. As an example, Luc et al. [27] prepared a core@shell nanostructured catalyst, AgSn@SnOx, in which the bimetallic core improves the electrical conductivity of the electrocatalyst. Interestingly, the catalyst exhibits tunable FEs toward formic acid by varying the Ag/Sn ratio of the core, and a volcano-like relationship exists between Ag/Sn ratio and FEHCOOH. Two balance factors are responsible for the volcano-shaped correlation. On the one hand, the electrical conductivity of the electrocatalyst decreases with increasing Sn concentration, which reduces the overall catalytic activity. On the other hand, a lower Ag/Sn ratio means a thicker SnO surface layer availing the stabilization of *OCHO intermediates, resulting in a lower rate-determining step (RDS) (i.e., *CO2 to *OCHO) reaction barrier for the HCOOH pathway. However, for the CO pathway, the composition effect on key intermediates *CO2 and *COOH offsets with each other. Thus, the RDS energy barrier (i.e., *CO2 to *COOH) remains the same.

Heteroatoms with electron-donating or electron-withdrawing ability can create abundant positively and negatively charged sites. For example, Zhou et al. [37] utilized B dopants to alter the local electronic structure of Cu, stabilizing the surface Cuδ+ sites. A FE of ~ 79% toward C2 products and a durability of 40 h were obtained at − 1.1 V versus RHE. Moreover, as pure carbon materials have limited electrocatalytic CO2RR activity, heteroatoms, such as N, B, and S, are frequently used as dopants to optimize their surface electronic structure and achieve high catalytic properties. N-doped carbon (NC) has been extensively investigated as a material support and catalyst [23, 38,39,40]. Nitrogen in a carbon skeleton has three major forms, namely, pyridinic N, pyrrolic N, and graphitic N. The electrocatalytic CO2RR on NC greatly depends on the form and density of the N atoms. For example, Cui et al. [16] developed a steam etching method to partially wipe off pyridinic N and graphitic N but leave pyrrolic N on NC-wrapped CNT (CN-CNT). The as-prepared CN-CNT exhibits a FE of ca. 88% toward CO at − 0.5 V versus RHE with a ~ 20% increase compared with the untreated catalyst. Wu et al. [41] prepared N-doped graphene quantum dots, which exhibit a catalytic performance comparable to that of Cu with 45% C2 selectivity (including C2H4 and C2H5OH), instead of the CO selectivity of most non-metallic electrocatalysts [42,43,44]. The catalytic activity of the three N configurations can be arranged in the following order: pyridinic N > graphitic N > pyrrolic N [45,46,47]. Pyridinic N is the most active center. For instance, Liu et al. [43] synthesized a series of 3D N-doped graphene nanoribbon networks with different N site distributions. XPS spectra suggested that the FECO is linearly related to the content of pyridinic N. Furthermore, j shows a conspicuous decline when phosphate is used as a poison agent to selectively adsorb onto the pyridinic N sites. These observations, combined with density functional theory (DFT) calculations, indicate that the Lewis-acidic pyridinic N is mainly responsible for the high catalytic performance. Our group [48] also showed that the pyridinic N in the Ar-plasma-treated N-doped CNT arrays is the active site for CO formation on the basis of the correlation between structure variation and FECO. Similarly, various O defects on carbon materials were also investigated. Yang et al. [49] synthesized single-layer graphene nanodisks with different dominating types of O-containing surface groups, such as hydroxyl (–OH), epoxide (C–O–C), carbonyl (C=O), and carboxyl (–COOH). The catalytic performance was determined by the synergistic effects among all O-containing groups on the basis of their DFT computation. Therefore, unlike NC, in which each single N form alone can catalyze CO2RR, increasing the amount of O species as much as possible is more crucial. In addition, the reduced O-containing groups under reduction potentials can be easily regenerated by electrochemical in situ oxidation.

Morphology Control

The shape, size, and dimensionality of the nanostructures can easily change the intrinsic activity and selectivity of the catalyst toward CO2RR [50,51,52,53,54,55,56]. Many CO2RR catalysts show facet-dependent selectivity, i.e., the formation of target products can be controlled by synthesizing single crystals with specific exposed facets or by increasing the exposure of certain facets [57]. For example, the formation of C2H4 is more favored on the (100) facets of Cu, whereas that of CH4 is more favored on the (111) facets instead [58]. The Cu(711) facets, which consist of Cu(100) terraces and a small number of (111) steps, show the highest C2/C1 ratio in product distribution, even superior to that of Cu(100) [59]. In addition, the relationship between products and operating potential suggests that C2H4 forms at a lower overpotential than CH4 [60]. In DFT calculations, the *CO dimerization on the Cu(100) surface has a lower energy barrier than those on (111) and (110), and high *CO coverage is beneficial for reducing the energy barrier. The binding strength of key intermediates, such as *CO, over the Cu electrode, must be strong enough to facilitate the subsequent proton–electron transfer steps but not too strong to poison the active sites, creating an optimal adsorption and desorption environment for *CO [61]. To be more specific, Luo et al. [62] proposed two protonation pathways of *CO that lead to selectivity difference on Cu(111) and Cu(100) facets on the basis of DFT simulation. Hydrogenation on the Cu(111) facet occurs at the O end, forming *COH, whereas that on the Cu(100) facet occurs at the C atom instead, forming *CHO. Their proposal for the CH4 pathway on the Cu(111) facet has been adopted by other theoretical and experimental researchers [63, 64]. However, the reaction mechanism on Cu(100) is still under debate. As stated by Cheng et al. [65], two adjacent *CO will dimerize into *OCCO, which is the RDS of C2H4 formation, followed by a protonation process to form *OCCOH (Fig. 2). This mechanism was also verified by Koper et al. [66], who directly detected *OCCOH intermediates on the Cu(100) facet for the first time at low overpotentials ranging from + 0.1 V to − 0.15 V versus RHE using in situ Fourier-transform infrared spectroscopy. The facet dependency of Cu was also used to achieve exclusive C2 selectivity via tailoring surface morphology [54]. For instance, the nanoporous Cu prepared via the alloying–dealloying method can suppress CH4 generation to less than 1% and show 35% FEC2H4 at − 1.3 V versus RHE because of the extensive exposure of specific facets, especially (100) facets, together with the high concentration of catalytically active step and edge [67]. Nevertheless, further evidence is needed to attest current conjectures on the facet-dependent catalytic properties of Cu.

Lowest kinetic pathways for the eight-electron reduction of CO to ethylene (C2H4). Eley–Rideal (ER) (in black) and Langmuir–Hinshelwood (LH) mechanisms (in blue) are considered. H2O + e− (producing OH−) are the reactants in ER, whereas H* is the reactant in LH. The reaction free-energy barriers (ΔG‡) are provided. The slashed line shows the minor pathway for C2H4 formation through *C=C=O. Reproduced with permission from Ref. [65]. Copyright 2020 National Academy of Sciences

Ma et al. [68] found that the morphology differences can alter the local pH value near the electrode surface, thus changing product distribution based on their pH sensitivity, which will be discussed later. In their work, Cu NW arrays with diverse lengths and densities were prepared by simply controlling the reaction time. The longest and densest Cu NWs had the best C2H4 selectivity (Fig. 3a). According to the authors, the morphology-related catalytic performance stems from the sluggish superficial mass transfer with the increase in length and density, which impedes not only the entry of bicarbonate as a buffering agent but also suppresses the diffusion of OH− by-products, finally leading to a significant local pH rise to improve C2H4 selectivity (Fig. 3b). Developing materials with ultrahigh specific surface area can realize high reactivity because of the increased active sites, especially edges and steps. For example, Dutta et al. [69] synthesized a bifunctional Ag nanofoam cathode to selectively catalyze the formation of CO and CH4 at low and high overpotentials, respectively. Notably, this Cu-like selectivity at a high overpotential is different from the commonly observed CO selectivity on Ag electrodes. The abundant coordination-unsaturated sites in the nanofoam could enhance the CO binding strength, which greatly increases the surface coverage and the resident time of *CO intermediates, favoring the further reduction to CH4. Under proper morphology control, catalysts with similar compositions but different shapes and sizes present pronounced CO2RR activity and selectivity. For instance, Kortlever et al. [70] synthesized a two-dimensional PdAu catalyst with a Pd-excessive surface alloy structure. The unique surface structure of PdAu alloy enables the formation of C1 and C2 products and C3–C5 hydrocarbons and oxygenates at the onset potential of − 0.8 V versus RHE. Unfortunately, the detailed mechanism was not fully explored. By contrast, a different selectivity was observed on one-dimensional twisted PdAu NWs by Zhu et al. [53]. Results of transmission electron microscopy (TEM) and high-angle annular dark-field (HAADF) STEM (Fig. 4a–p) showed that the nanowires are metastable core–shell structures composed of pure Pd monolayer shell and PdAu core with abundant grain boundaries (GBs). Benefiting from the GB-rich surface, PdAu NWs present a FECO of ca. 94% at − 0.6 V versus RHE (Fig. 4q). In situ spectroscopic investigation and DFT calculations revealed that the sluggish activation of CO2 to *COOH is accelerated by the GBs, leading to a 0.23 eV decrease in the *COOH binding energy at the Pd/PdAu (110) facet compared with Pd(111). The weakened linear adsorption of *CO by incorporating Au into Pd also accounts for the high CO selectivity at a low overpotential (Fig. 4r).

a Faradaic efficiency for C2H4, C2H6, CO, HCOOH, ethanol, n-propanol, and H2 on Cu nanowire arrays with different lengths at − 1.1 V versus RHE in CO2-saturated 0.1 M KHCO3 electrolytes (0 μm nanowire represents Cu foil). b Schematic of the diffusion of electrolytes into Cu nanowire arrays. Reproduced with permission from Ref. [68]. Copyright 2016 Wiley–VCH

TEM images of synthesized a, d Pd, b, e Pd2.1Au, and c, f Pd0.8Au nanowires. g High-resolution STEM image of Pd nanowires. h HAADF-STEM image. XEDS maps of i Pd, j Au, and k combined elements of Pd0.8Au nanowire. l–o HAADF-STEM images. p Colored HAADF image of Pd0.8Au nanowires. q FE of CO measured on Pd/C and synthesized Pd-based nanowires. r COL to COB band intensity ratio. Reproduced with permission from Ref. [53]. Copyright 2018 Wiley–VCH

Downsizing the metal bulk to the atomic-level site is a promising approach for material optimization [71, 72]. As we mentioned before, bulk Zn was classified as a metal mainly yielding CO, while in the case of Zn single-atom catalyst, unexpectedly high CH4 selectivity with a FE of 85% and a jCH4 of − 31.8 mA/cm2 were achieved at − 1.8 V versus saturated calomel electrode [73]. The remarkable catalytic performance can be well maintained after undergoing a 35-h-long CO2 electrolysis. DFT simulations revealed that the first activation step is the formation of *OCHO (∆G 0.46 eV) rather than regular *COOH (∆G 1.2 eV) (the key intermediate of producing CO), where the O atom bonds to Zn instead of C atom. It was further confirmed by in situ attenuated total reflection surface-enhanced infrared absorption spectroscopy (ATR-SEIRAS), which detected *OCH3 and *OCH2 species. Atomically dispersed transition metals supported on NC have been exploited as promising non-precious electrocatalysts for converting CO2 to CO, in which nitrogen-coordinated single-atom metal (M − Nx) moieties serve as the active sites [35, 36, 74,75,76]. Zheng et al. [74] developed a facile method to prepare Ni SAC catalysts on commercial carbon black with FECO close to 100% and jCO above 100 mA/cm2. Pan et al. [75] reported that engineering the local support structure of SAC can significantly boost the catalytic performance. The Fe-N4 moieties supported at the holes of the graphene basal plane (edge-hosted Fe–N4) are more catalytic toward CO2-to-CO conversion than the pore-deficient graphene-supported counterparts (bulk-hosted Fe–N4). DFT and density-of-state studies suggested that the incorporation of pore edges can downshift the d-band center of Fe–N4 moieties, which will weaken the binding strength between Fe and *CO and thus facilitate CO desorption.

Surface Modification

The introduction of functional groups, such as organic ligands, to manipulate the catalytic reactivity is a common method for cathode design [77]. These surfactant-like functionalized species can tune the polarity and acidity of the interfacial environment, which is directly related to the adsorption affinity of Lewis-acidic CO2 reactants and intermediates. For example, Fang and Flake [78] reported that Au electrodes modified by three ligands exhibit disparate product distribution. In specific, the 4-pyridinylethanemercaptan (4-PEM)-modified Au electrode allows the formation of CO and H2. By contrast, the 2-mercaptopropionic acid (2-MPA)-modified Au electrode only yields H2. The high selectivity of 4-PEM-modified Au can be explained by a proton-induced desorption mechanism (Fig. 5a). First, a proton from the electrolyte is reduced to *H on the Au surface, which is attacked by CO2 to form *OCHO. Then, the protonated pyridine of 4-PEM donates a proton to the adjacent O of *HCO2, together with an electron delivered from the cathode to release the formic acid. Therefore, the acidity of the surface ligand, as an essential H donor in CO2 reduction, largely determines the catalytic performance, which is consistent with the pKa order of the three ligands, CYS > 4-PEM > 2-MPA. The moderate proton-donating ability of 4-PEM generates a delicate balance: The surface proton concentration is neither too high to favor the HER nor too low to affect the hydrogenation of *OCHO. Similarly, Wu et al. [79] reported the switchable production of CO and HCOO− at different potentials over cetyltrimethylammonium bromide (CTAB)-capped Au/SnO2. Interestingly, only H2 is generated on capping-free Au (CF-Au) and citrate-capped Au (Cit-Au). Comparing the \(\text{FE}_{\text{H}_2}\) on Au/SnO2 with the FEs measured on Au and SnO2 (Fig. 5b–g), CTAB-Au presents a more obvious deviation, indicating the existence of the strongest ligand–metal–oxide interactions to suppress HER.

Reproduced with permission from Ref. [79]. Copyright 2019 The Royal Society of Chemistry

a Proposed formate formation mechanism at the 4-pyridylethylmercaptan-modified Au surface. Reproduced with permission from Ref. [78]. Copyright 2017 American Chemical Society. Comparison of b, d, f jH2 and c, e, g \(\text{FE}_{\text{H}_2}\) between actual values and values calculated from the linear combination analysis for b and c CF-Au/SnO2, d and e CTAB-Au/SnO2, f and g Cit-Au/SnO2.

Cu electrodes can also be modified with polymer or organic molecules to manipulate CO2RR activity and selectivity. For example, Wei et al. [80] reported that the surface functionalization of Cu by polyaniline (PANI) can accelerate the reaction rate and substantially increase the C2+ hydrocarbon FE from ~ 15% to 60% at − 1.1 V versus RHE in the KHCO3 electrolyte and up to 80% C2+ hydrocarbon FE at − 1.2 V versus RHE, 40% of which comes from C2H4. Unlike the aforementioned CATB-Au/SnO2 [79], the PANI used in this work does not directly participate in CO2RR. According to earlier work from Zheng et al. [81], the N atoms in PANI show a strong Lewis acid–base interaction with CO2, which greatly enhances CO2 adsorption, improving the catalytic properties of Cu, Pd, and Pt. Wei et al. [80] further confirmed the role of PANI via ATR-SEIRAS. Their results showed that the PANI-modified Cu presents higher coverage of linear adsorbed CO species (COL) than pristine Cu foil, which is more prone to dimerize into *OCCO than bridge-adsorbed CO (COB). This modification strategy is also applicable for Cu nanoparticles, which not only enhances their reactivity but also prolongs their lifetime. Very recently, Li et al. [19] have conducted a systematic investigation on the surface modification of Cu with a series of functional organic molecules. A series of Cu electrodes coated with an organic film was prepared via electrodeposition of N-arylpyridinium precursors. Interestingly, the relationship between Bader charge (BC), which indicates the electron-donating capacity of tetrahydro-bipyridines, and \(\text{FE}_{\text{C}_{2}{\text{H}_4}}\) conforms to a volcano-shaped correlation (Fig. 6a). The \(\text{FE}_{\text{C}_{2}{\text{H}_4}}\) and COa/COb ratio (i.e., top-/bridge-adsorbed CO) also fit in the volcano relationship, which is consistent with the trend of BC-FE correlation (Fig. 6b). The two correlations suggest that organic additives with strong electron-donating ability have a high COa/COb ratio. According to DFT calculations, the dimerization of COa and COb to produce C2H4 has the lowest energy barrier of 0.72 eV, which is superior to that of a pair of COb and COa. Therefore, neither COb nor COa will lead to unfavored homogeneous coupling, rationalizing the existence of the optimal COa/COb ratio. Furthermore, the authors proposed that the tetrahydro-bipyridine film delivers its electron density to *CO to enhance CO adsorption and increase the possibility of dimerization. Such mechanism was verified by the excellent catalytic performance of N-aryl-dihydropyridine-based oligomer-modified Cu, which shows an unprecedented high FE of 72% toward C2H4 and a high j of 232 mA/cm2 at − 0.84 V versus RHE in KHCO3 solution.

a Trend for ethylene FE and calculated Bader charge for the nitrogen atom of the N-aryl-substituted tetrahydro-bipyridines. b Relationship between the ethylene FE and the ratio of atop CO to bridge CO on Cu–x electrodes. c Relationship between the ratio of atop CO to bridge CO on Cu–x and the Bader charge for the nitrogen atom of the N-aryl-substituted tetrahydro-bipyridine formed from additive x. Reproduced with permission from Ref. [19]. Copyright 2019 Springer Nature

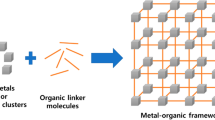

Aside from the organic ligands, some superficial inorganic small molecules are also efficient in boosting CO2 catalytic activity and selectivity. For instance, the pore surface of metal organic frameworks modified by hydroxyl presents a stronger adsorption affinity toward CO2 because of the electron–donor character of the oxygen atom [82]. As for the hydrophobic SiC quantum dot (SiC QD) cathode, surface hydroxylation (SiC–OH QDs) increases hydrophilicity, thereby promoting the superficial mass transfer [83]. Interestingly, DFT calculations showed that the surface hydroxyl on SiC–OH QDs directly participates in the CO2 initial activation via transferring its H atom to the C atom in CO2 forming *HCOO intermediates, instead of first generating CO2δ− on SiC QDs. The *HCOO pathway has a lower energy barrier than CO2δ−, contributing to the improvement in CO2 hydrogenation performance. Deng et al. [84] found that the *OH coverage on hydroxyl functionalized Sn branches (Sn–OH) is influential to CO2RR catalytic properties because excess *OH will occupy active sites and cause the reduction of Sn–OH to Sn. With careful manipulation, the best performed Sn–OH with optimal *OH concentration shows the highest FEHCOOH up to 82.5% at − 1.8 V versus Ag/AgCl. On the basis of in situ ATR-SEIRAS and DFT calculations, the enhanced CO2 adsorption forming H2CO3 in the presence of surface hydroxyls possibly originates from hydrogen bonds, accounting for the elevated CO2RR.

Defect Engineering

Vacancies

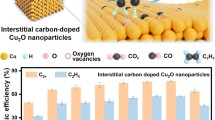

The introduction of vacancies can cause lattice deformation and thus alter surface electron density, contributing to the varied binding strength of intermediates which leads to different production preference. It was confirmed in the course of Zhao et al. [85], in which Bi cathode with abundant Bi atom vacancies (V-Bi) presented p states closer to the Fermi level than the vacancy-free counterpart owing to the electron-rich surface. The V-Bi cathode therefore delivered accelerated initial activation from CO2 to CO2·− and increased stability of *OCHO intermediate via p orbitals hybridization between O atoms, giving a FEHCOOH of 90% at an overpotential of 420 mV and remarkable longevity over 100 h. Similar optimization strategy toward metals was also applied to promoted the CO2-to-CO conversion on AuCu alloys [86]. DFT results indicated that the construction of vacancies enhanced the *COOH adsorption and slightly weaken the *CO binding strength, accounting for the elevated CO yields and lower onset potential. Ji et al. [87] implemented a theoretical investigation on the effects of anion vacancies on the catalytic property of transition metal dichalcogenides (Fig. 7). With the increase in vacancy concentration, the binding free energy of *COOH and *CHO got lower. Notably, excessive vacancies can result in the poison of active sites by intermediates or *H and *OH due to ultra-strong binding, suggesting the existence of optimal vacancy density. Constructing oxygen vacancies (OV) has been suggested as an efficient method to boost the catalytic performance of metal oxides. The enriched electrons derived by OV serve as Lewis base sites and increase CO2 adsorption affinity. Gu and coworkers [88] developed a partially reduced cooper oxide with numerous OV (CuOx-Vo), which exhibited ethylene FE up to 63% at − 1.4 V versus RHE, outperforming that of OV-free and OV-deficient counterparts. Further mechanistic exploration showed that the OV can not only stabilize *CO and *CHO intermediates, but also facilitate the *CH2 adsorption and thus promote the dimerization of *CH2 to produce C2H4. Similarly, the Bi2WO6 nanosheets delivered 11% higher maximal FECO and higher j after introducing OV into the structure [89, 90]. The significance of OV was even more pronounced in amorphous metal oxide. Han et al. [91] recently reported that OV enriched amorphous MnOx was capable of converting CO2 to CO with a FE of 94.8% and j of 10.4 mA/cm2 at an overpotential of 520 mV, consistent with the boosted CO2-to-HCOOH conversion on OV enriched amorphous InOx [92].

a, b Scaling relations of group X TMDs with various densities of basal plane vacancies. The labels show the number of vacancies removed in 4 × 4 cells. c Change in the binding free energies of H and OH with the density of vacancies. Reproduced with permission from Ref. [87]. Copyright 2019 American Chemical Society

Interfaces and Boundaries

In most cases, defects are not uniformly distributed in the catalyst. Simulations showed that defects in pure metal and composites near the interfaces have low migration energy barriers. Such results agree with the experimental observations that interfaces are rich in defects [93]. On the one hand, defects can stabilize the interface; on the other hand, the interfacial environment favors the formation of defects. Gao et al. [94] reported that Au–CeOx with numerous interfaces displays greater CO FE than Au alone. The hydroxyl groups dissociated from water and interface can recover the Ce3+ ions that were oxidized after bonding with CO2, thus enhancing CO2 adsorption. The binding strength of the key intermediate of the RDS, *COOH, is reinforced by the reduced Ce sites due to the interaction between Ce3+ and terminal oxygen atom in *COOH. Subsequently, the decomposition of *COOH to *CO and the desorption of *CO are also facilitated at the interface. In other words, the holistic promoting effects of the interface, including activation, adsorption, and desorption, basically come from the Ce3+ stabilized at the Au–CeOx interface, which can be applied to the optimization of materials other than Au. The application of the transferable method was further expanded in the Ag–CeOx/C catalyst, which presents a geometric jCO over four times that of Ag/C at − 0.89 V versus RHE and a FECO of 92.6%. In a previous work of our group, In/In2O3−x catalyst with an abundant interface was prepared by the in situ reduction of In2O3 [95]. The In/In2O3−x shows a FE of ca. 89.2% toward formate, outperforming that of In or indium oxide alone (ca. 67.5%). The high performance can be well interpreted by the fast electron transfer near the heterostructure interface owing to the Schottky effects.

The fabrication of boundaries is another way to improve cathode performance. For instance, Chen et al. [96] prepared a high-performance monometallic Cu electrode with rich GBs via electrodeposition and found that the electrode presents up to 70% selectivity toward C2H4 and C2H5OH at potentials ranging from − 1 to − 1.3 V versus RHE. In situ ATR-SEIRAS and DFT indicated that the GBs avail the *CO adsorption and increase the possibility of C–C coupling, thus increasing C2 yields. Feng et al. [97] disclosed a linear correlation between CO selectivity and GB density in Au/CNTs, indicating that the GBs are responsible for the high catalytic properties of Au/CNTs. DFT simulations were then conducted by Kim et al. [98] to gain mechanistic insights on this quantitative correlation. As revealed, the broken local spatial symmetry at the GB can tune the adsorbate-to-metal σ-bonding and metal-to-adsorbate π-back bonding strengths. The adsorption of key intermediates *COOH is therefore enhanced, which switched the RDS from the *COOH formation to the subsequent proton-coupled electron transfer (PCET) step. Likewise, Liu et al. [99] developed sub-2 nm SnO2 quantum wires (QWs) with numerous GBs. GB-rich SnO2 QWs present higher j than SnO2 nanoparticles, with a FEHCOOH of more than 80% and an energy efficiency of over 50% in a wide potential window, further verifying the feasibility and flexibility of introducing GBs to boost CO2RR activity.

The emerging oxide-derived Cu (OD-Cu) catalysts, synthesized via incomplete reduction of copper oxides or O2 plasma treatment of Cu, display overpotentials lower than 400 mV and high selectivity toward C2 products with a greater proportion of C2H5OH than regular Cu catalysts. At high overpotentials, the catalytic activity of OD-Cu toward C2H4 exceeds that of CH4, whereas more CO is generated at low overpotentials [100]. The origins of the improved catalytic activity remain elusive. GBs were proposed to be one of the active sites [101]. Other oxide/sulfide-derived metals also show notable CO2RR catalytic performance, making it a common material design routine. For instance, the bulk Co and bulk cobalt oxide are almost catalytically inert for CO2RR with a jHCOOH lower than − 0.5 mA/cm2. However, the four-atom-thick pure Co and OD-Co prepared by Gao et al. [102] enable the CO2-to-formate conversion, and the latter delivers higher activity (as low as 240 mV over potential) and selectivity (ca. 90%) than the former. This work turns inactive composition into active CO2RR catalysts, highlighting the significance of morphology and defects. Similarly, owing to the lattice vacancies created after the release of S, the sulfide-derived Bi (SD-Bi) obtained from the electrochemical reduction of BiS3 shows a HCOO− selectivity of ca. 40%, which is higher than that of Bi foil, further confirming that OD/SD-metal is a suitable candidate for CO2RR electrocatalysts [103].

Twin boundaries (TBs) are stable and well-defined defects in most metallic CO2RR catalysts, such as Au and Cu [104]. Tang et al. [104] reported a transferable routine to synthesize metal electrodes with quantitative TBs (TB-M) and measured the CO2 catalytic performances of a series of TM-Cu with TM densities ranging from 0 to 1015 cm−1. The CH4 FE continuously increases with increasing TM content and reaches a maximum of 59% at − 1.6 V versus RHE. Comparing CO reduction (COR) with CO2R, the *CO protonation on TB atoms is 104 faster than that on plane atoms, indicating the ultrahigh catalytic activity of TB sites. A similar precise investigation was also conducted in TB-rich Ag nanostructure [105]. The atom-specific activity, namely average current generated from one atom, of TB edges (TBEs) on Ag (~ 16 × 10−18 A/atom) is much higher than that of Ag(111) facets (~ 0.1 × 10−18 A/atom), indicating the spectacular intrinsic CO2 reduction activity of TBEs. DFT calculation suggested that the unique bridge-type adsorption configuration of *COOH on TBEs is thermodynamically favored, which decreases the energy barrier of RDS (protonation of CO2 to form *COOH), accounting for the high catalytic activity.

Electrolyte

In an electrolysis system, the electrolyte conducts current by the directional movement of the charged ions within the bulk phase and by the transfer of protons and electrons at the electrode surface. Notably, the type and the ionic concentration of the electrolyte can influence the catalytic activity and selectivity. The electrolytes used in CO2RR studies can be classified into four categories: aqueous, organic, ionic liquids (ILs), and molten ionic compounds. Aqueous electrolytes are preferred when the syngas is the target product because of the HER at the cathode. However, organic electrolytes and ILs with high CO2 solubilities are also frequently used because of the poor dissolution performance of CO2 in water. ILs are molten organic salts consisting of organic cations and inorganic anions, with a melting temperature below 100 °C, sometimes even as low as room temperature [106]. Unlike the volatile and flammable organic solvents, ILs are chemically and thermally stable and non-toxic; thus, they are deemed as the most promising alternatives for conventional CO2RR electrolytes [107]. However, given their high viscosity and the need of protons for CO2 hydrogenation, ILs are usually mixed with water or organic solvents to enhance mass transfer. Meanwhile, molten ionic compounds usually require high operating temperatures, which limit their application. In this section, we will introduce electrolyte-related factors affecting the activity and selectivity of CO2RR.

pH and Buffer Capacity

For an aqueous electrolyte, the pH effects on CO2RR are fairly complex. First, based on the pH dependence of the CO2 hydrolysis equilibrium, CO2 molecules dissolved in aqueous electrolytes can appear in many phases, such as carbonate, bicarbonate, and carbonic acid. In specific, bicarbonate dominates at pH 6–10.3, whereas carbonic acid and carbonate dominate in a more acidic and more alkaline environment, respectively. Increasing CO2 pressure can construct a CO32−/HCO3− buffer system that benefits CO2 solubility and pH stability. Notably, CO32− and HCO3− are not the actual reactants of CO2RR [108]. The competitive HER at the cathode has two well-established pathways: proton reduction (i.e., H+ + 2e− → H2) and water reduction (i.e., H2O + 2e− → H2 + 2OH−). The proton reduction pathway shows strong pH sensitivity, leading to a boosted hydrogen evolution rate at a high proton concentration. By contrast, the pH exerts minimal on the water reduction pathway. Therefore, under alkaline conditions, the water reduction pathway is more favorable than the proton reduction pathway because of the suppression of the latter [109, 110]. Owing to the mass transfer limitation, the available protons around the cathode are gradually depleted, leading to a shift of the HER pathway from the proton reduction to the water reduction even in electrolytes with bulk pH 2.5 [109]. In specific, the proton consumption and the OH− generation from water electrolysis lead to a conspicuous pH rise in the vicinity of the cathode, forming a huge pH gradient between the local and bulk phases. In an electrochemical flow cell, the forced mass transfer effect by high flow rates can reduce the thickness of the Nernst diffusion layer and thus mitigate the pH gradient [111]. The pH level is a significant factor that affects the selectivity of CO2RR. For instance, consistent with the observations in the flow cell, the generation of C2H4 and alcohols (ethanol and n-propanol) over Cu is promoted in non-buffering solutions with high local pH contrary to the CH4, which prevailed over other dominant products in buffer solutions, such as KHCO3 [59, 112,113,114]. Agreed with the Cu cathode, a similar pH dependency of the above-mentioned products was also found on other materials [111, 115]. Whether a reaction is pH-dependent lies on the reaction path it takes. Reaction pathways with PCET as their RDS are sensitive to pH variation, and a relatively low pH is more favorable for such reactions to proceed. Other pathways with decoupled proton–electron transfer (DPET) as their RDS are usually immune to pH changes [116, 117].

Considering the unique catalytic property of copper, the pH effects on Cu cathode have attracted considerable attention [118]. Given that surface-adsorbed *CO is easy to form on copper, COR was studied as an analog of CO2RR to obtain mechanistic insights [64, 119, 120]. On the basis of the modeling and experimental results of Liu et al. [121], the desired C2 reduction products can be selectively formed on Cu(211) facets by exploiting the differences in pH sensitivity between the C1 and C2(+) pathways (Fig. 8). In general, both of them begin with the formation of *CO intermediates. For the C1 pathway at pH 13, the initial *CO species undergo two steps of proton–electron transfer to form *CHOH. For the C2(+) pathway, the initial *CO species undergo a dimerization of *COCO and then protonate at the O atom (not C) to produce *COCOH. The RDS of C1 production at a low overpotential is the second proton–electron transfer from *CHO to *CHOH, whereas that of C2(+) production is the protonation of *COCO. At a high overpotential, the RDS of the C1 path is the first protonation of *CO, whereas the generation of C2(+) is largely limited by the declining *CO coverage due to the sluggish formation of *CO. This discrepancy in RDS explains the different pH dependencies of C1 and C2+ products. When switching the pH from 7 to 13, an overpotential decrease of ca. 360 mV occurs for the generation of C2(+) products, together with a significant selectivity enhancement of 1–2 orders of magnitude over the generation of C1 products.

Reaction schemes of major pathways considered for CO reduction toward C1 and C2(+) products. Green path denotes C2 production via OC–CHO coupling; blue and red paths represent C2 production via protonation of OCCO to form OCCHO and OCCOH, respectively; yellow path represents C2 production via OC–CHOH coupling. Black path denotes C1 production via CHOH and the dashed CH2O. Reproduced with permission from Ref. [121]. Copyright 2019 Springer Nature

Ion Effects

Alkali metal cations with anions, such as HCO3− and Cl−, are the most common aqueous electrolyte in an electrochemical CO2 reduction cell. The nature of these ions can affect CO2RR reactivity. For instance, large alkaline cations are conducive to the formation of C2 products [26, 122]. Thorson et al. [123] reported the hindering effects of large cations, such as Cs+ and Rb+, to HER on Ag electrodes, leading to a high CO FE. They attributed the high CO FE to the size-induced differences in cation hydration degree and adsorption ability. The enhanced adsorption of large cations means higher outer Helmholtz plane (OHP) potential, which will increase the kinetic overpotential of HER and thereby vary the reaction preference [124, 125]. When Cu is used as the cathode, electrolytes with large cations accelerate the generation of HCOO− and C2 products, such as C2H4 and C2H5OH, but exert negligible effects on the formation of H2, CO, and CH4 [126,127,128]. The selectivity can be well explained by the field stabilization effect. The dipole field created by the hydrated cations in OHP can stabilize adsorbed intermediates with large dipole moments, such as *CO2 and C–C coupling moieties [127, 128]. However, Singh et al. [126] deemed that the elevated activity and the shifted product distribution result from the preferential hydrolysis of cations with different radii near the cathode surface. Large cations possess low pKa [126]. Owing to the polarization of the solvated water molecules between the positive charges of cations and negative charges on the cathode, the pKa of interfacial cations further decreases. When it falls below the local pH, the solvated water dissociates a proton. The hydrolysis becomes more arresting as the cation moves toward the cathode, and the electrostatic interaction becomes stronger. This phenomenon was experimentally verified via in situ ATR-SEIRAS combined with the accurate measurement of interfacial pH by a rotating ring–disk electrode. The buffer ability can be arranged in the following order: Cs+ > K+ > Na+ > Li+ [126]. The formation of CO is immune to the cation effects [129]. Ringe et al. [130] used a combined ab initio/continuum model to simulate cation and electric double layer field and concluded that CO2RR is easily affected by the cation-induced interface charge density and electric field. This theoretical model matches the prior experimental observation that the selectivity varies with increasing cation radius on Ag, Cu, Pt, and Au(111) single-crystal electrodes.

Sato et al. [131] reported a synergistic mechanism between the cations and the electrocatalysts. In their work, surface-adsorbed K+ cations and multi-walled carbon nanotubes (MWCNTs) support the catalytically inert Mn complex into a highly efficient CO2-to-CO electrocatalyst (Fig. 9a). The absence of either K+ or WMCNTs would not produce such catalytic activity. DFT calculation revealed that the surface-enriched electrons on the MWCNTs attract K+ via electrostatic attraction, thereby enhancing the CO2 adsorption and decreasing the activation energy of the formation of complex-CO2 adducts (Fig. 9b). This synergy is also efficacious in modifying the inert Co and Re complexes. For inorganic anions, aside from the pH and buffering effect described above, the specific adsorption of anions on the cathode surface is also an important factor for CO2RR selectivity. Ogura et al. [132] proposed that the halide anions in electrolytes are prone to bind with Cu, forming Cu–X species, which was also later demonstrated by another theoretical study [133]. In the presence of strong Cu–X bonds, the binding strengths of proton and reaction intermediates change, leading to the suppression of HER and differences in activity and selectivity. Varela et al. [134] conducted an in-depth investigation about the halide effects and found that the presence of Cl− and Br− increases the CO FEs and that I− shows a sixfold enhancement of CH4 selectivity compared with the counterpart without halides. The surface-bonded halides donate negative charges to the Cu and modify the surface electronic environment, which enhances the interaction between the electrode and the intermediates with positively charged carbon atoms and thus increase the possibility of protonation (Fig. 10f). The electron-donating capability of the three halide anions can be arranged in the following order: I− > Br− > Cl−. In addition to the effect on the surface electronic structure, the halide anions also affect the morphology of cathode materials. For example, Br− and I− induce the formation of nanocubes on Cu, whereas Cl− does not (Fig. 10a–e) [134]. Furthermore, the surface-adsorbed Cl− helps stabilize the Cu+ active sites in Cu2O/Cu electrodes, leading to a long-term stability toward C2+ production [135].

a Results of DFT calculations and summarized experimental results. Free energy changes are shown for catalytic cycle reaction steps from dissociation of the monodentate ligand complex to CO2 addition for the Mn-complex catalyst. b Schematic of [Mn-MeCN]/MWCNT electrode during electrocatalytic CO2 reduction. Reproduced with permission from Ref. [131]. Copyright 2018 American Chemical Society

SEM images of a as-prepared Cu foil (after mechanical polishing), b after reaction in 0.1 M KHCO3, c after reaction in 0.3 M KCl + 0.1 M KHCO3, d after reaction in 0.3 M KBr + 0.1 M KHCO3, and e after reaction in 0.3 M KI + 0.1 M KHCO3. f Schematic illustrating how I– affects the net charge of Cu, making it more negative and facilitating the charge transfer for CO reduction. Reproduced with permission from Ref. [134]. Copyright 2016 American Chemical Society

Ionic Liquids

ILs have been widely used as the electrolyte for electrochemical CO2RR because of their superior CO2 solubility, high intrinsic ionic conductivity, and wide potential window. ILs can directly participate in CO2RR as a cocatalyst. For instance, Rosen et al. [136, 137] reported that the surface-adsorbed cations of 1-ethyl-3-methylimidazolium tetrafluoroborate (EMIM+) act as a cocatalyst toward CO2RR via complexing with CO2 molecules, forming EMIM-CO2 to lower the initial activation barrier and thereby boost the yield of CO on the Ag electrode. This result was verified in the study by Sun et al. [107], in which the carboxylate group covalently binds to the C2-site of the imidazolium ring in EMIM+ cations as confirmed by nuclear magnetic resonance and electrospray ionization mass spectroscopy (EI-MS) on the Pb electrode. On the one hand, the EMIM+ adsorbate layer traps CO2 and decreases the overpotential at Pb by 0.18 V; on the other hand, it serves as a surfactant and restrains the CO2·− dimerization yielding oxalate, thus increasing the CO FE. DFT simulations and sum frequency generation experiments conducted by Wang et al. [138] revealed an exhaustive mechanism of imidazolium: CO2 is first hydrogenated at the C2-site of the imidazolium ring, forming the key intermediate [EMIM-COOH]−, followed by sequential proton–electron transfer (SPET) steps to yield CO (via C–O breakage) or formic acid (via C–C breakage). Kemna et al. [139] provided spectroscopic evidence of the existence of imidazolium carboxylic acid species and the SPET mechanism. Recent studies have found that the overpotential diminution of ILs stems from the stability effects of electrostatic interaction between IL cations and negatively charged intermediates of the re-centered molecular catalyst Re(bpy)-(CO)3Cl (where bpy is 2,2′-bipyridine) [140]. In addition, imidazolium-based ILs prevail over pyrrolidinium-based ILs, presenting higher activity and selectivity. The authors ascribed this finding to the unique π-π stacking interaction between imidazolium cations and bpy− p orbitals. The impressive catalytic performance inherently abided by the optimization strategy of “solid ionic liquid layer” firstly proposed in the field of heterogeneous catalysis [141]. Inspired by this concept, Zhang et al. [142] prepared an IL-modified Cu catalyst (Cu-IL) via immobilized bis(trifluoromethylsulfonyl)imide (BMIm-NTf2) onto Cu foam. After the modification, the formation of ethylene, ethanol, and n-propanol on Cu-IL is completely blocked with the FE and j unchanged. This result can be ascribed to the fact that the suppressed products share a mutual intermediate, carbene (pathway I), which can be quenched by the IL cations, whereas those products formed via CO dimerization (pathway II) are immune to the IL effects. On the basis of this phenomenon, the elusive reduction pathways of various products are clarified as follows (Fig. 11): (1) The formation of ethylene, ethanol, and n-propanol on Cu-IL undergoes pathway I instead of pathway II; (2) The formation of glycol is slightly suppressed by IL, suggesting that it occurs via the dimerization of two adjacent *CO2·− species separated by surface-adsorbed IL cations, accounting for the decline in FE; (3) ethane is immune to IL and is produced through pathway II involving ethoxy intermediates instead of the re-adsorption and reduction of pre-formed ethylene (otherwise ethane will present IL-dependent FE); and (4) methane is formed through *CO hydrogenation to *CHO. This unprecedented mechanistic investigation method via IL modification exhibits the possibility of analyzing complicated CO2RR pathways without the need to identify surface intermediates.

Zhan et al. [143] fabricated an imidazolium-Pt catalytic system and found that CO2RR in ILs is affected by temperature (Fig. 12). The amount of formed CO2·− increases with increasing temperature. At subzero temperatures, the formation of imidazolium carboxylate (EMIM+–CO2−) is dominant. At 0 °C, CO2·− radicals couple with EMIM radicals, forming EMIM–CO2−. Some EMIM radicals can receive an electron and be reduced to EMIM carbene, which consequently bonds with CO2 to form EMIM+–CO2−. At 40 °C, sufficient CO2·− bonds to almost all EMIM radicals. This work disclosed a new parameter influencing catalytic performance for further research on IL-metal catalyst systems.

Low Bronsted and Lewis acidities of imidazolium-based electrolytes, especially aprotic non-aqueous solvents such as acetonitrile (AN), weaken the intermolecular forces, thus reducing reaction activity [144, 145]. Based on this, Atifi et al. [146] introduced aprotic IL based on hydrogenated N-heterocycle 1,8-diazabicyclo [5.4.0] undec-7-ene cations ([DBU-H]+) to cocatalyze CO2RR on Bi electrode in AN. Interestingly, the Bi/IL synergetic CO2 reduction system presents switchable product selectivity between CO (imidazolium-based IL, BMIM+) and HCOOH ([DBU-H]+) via simply modulating the electrolyte composition. In the presence of H2O, [DBU-H]+ can be generated in situ via directly extracting protons from water molecules, thereby saving ex situ operation and enhancing overall j. H2O serves as a H donor for CO2 hydrogenation in ILs; thus, its concentration should be determined. Ratschmeier et al. [147] reported that the onset potential of CO formation shifts as the water concentration increases on the Pt electrode. In a 0.1 M tetraethylammonium H2O/AN mixture electrolyte over the Pt cathode, oxalic acid is the dominant product at low H2O concentrations, whereas formic acid and H2 are the main products at high H2O concentrations [148].

Summary and Outlook

Capturing CO2 from the atmosphere and converting it into value-added chemicals, such as fuels, by using electrochemical methods not only mitigate the greenhouse effect but also relieve the global energy crisis. Although promising, the development of electrochemical CO2RR systems still faces several obstacles, among which the most pivotal one is the limited selectivity, especially toward multi-carbon hydrocarbon and oxygenates. To solve this issue, previous studies have developed several optimization strategies for the electrolysis system, including cathode materials modification and electrolytes regulation. The catalyst composition largely determines catalytic performance. Except for physical properties, such as conductivity, adsorption strength toward reactants and intermediates can be adjusted by constructing composite materials, thereby presenting controllable products preference. Increasing the specific area or altering the shape to introduce more active sites, downsizing particles into a single atom to motivate performance, and selectively inducing the formation of exclusive facets to obtain facet-dependent high selectivity are efficient methods to optimize electrocatalysts morphologically. Suitable surface modification with organic ligands or inorganic groups can affect the superficial electronic environment and modulate the acidity, thus changing the binding affinity. Catalytic activity and selectivity can increase after fabricating abundant defects, which are usually active centers in CO2RR. As to the electrolyte effects, ILs and organic solvents avail the solubility of CO2 molecules, which facilitate the reduction rate. Anions often present buffer capacity and influence the pH near the cathode. Reduction products involving PCET, such as formic acid and by-products H2, are sensitive to the proton concentration, based on which their production can be controlled via simply tuning interfacial pH. Electrolyte cations, such as imidazolium, adsorbed onto the catalyst surface via electrostatic interaction serve as surfactants altering the superficial environment or as H donors directly participating in CO2 hydrogenation. In brief, the cathode–electrolyte interface bears the mass transfer and provides the reaction platform, making it the core of future investigations on CO2RR mechanism. However, most CO2RR electrocatalysts reported by now still suffer from poor stability, which is far from the industrial standard. How to improve the lifetime of electrocatalysts without changing the catalytic performance will be a major task in the future design of cathode materials. Furthermore, our current understanding of the reaction mechanism requires deeper exploration, calling for further in-depth studies to establish a clear guidance toward future research on CO2RR. In terms of methodologies, theoretical calculations are highly needed to verify the mechanism hypothesis, and the in situ characteristic techniques are important to track the variations in the electronic structure of active sites and detect the metastable intermediates during the reactions. Therefore, future research on electrocatalytic CO2RR should not be limited to the development of excellent electrocatalysts but also focus on the entire electrolysis system and study the synergy among various factors.

Change history

21 April 2021

A Correction to this paper has been published: https://doi.org/10.1007/s12209-021-00286-8

References

Solomon S, Plattner GK, Knutti R et al (2009) Irreversible climate change due to carbon dioxide emissions. PNAS 106(6):1704–1709

Li JS, Tian Y, Zhou YN et al (2020) Abiotic-biological hybrid systems for CO2 conversion to value-added chemicals and fuels. Trans Tianjin Univ 26(4):237–247

Blunden J, Arndt D, Johnson GC et al (2020) State of the Climate in 2019. Bull Am Meteorol Soc 101(8):S1–S429

Nugent P, Belmabkhout Y, Burd SD et al (2013) Porous materials with optimal adsorption thermodynamics and kinetics for CO2 separation. Nature 495(7439):80–84

Qiu CH, Bai S, Cao WJ et al (2020) Tunable syngas synthesis from photocatalytic CO2 reduction under visible-light irradiation by interfacial engineering. Trans Tianjin Univ 26(5):352–361

Zhou X, Yuan QW, Peng XL et al (2018) A critical review of the CO2 huff ‘n’ puff process for enhanced heavy oil recovery. Fuel 215:813–824

Beckman EJ (2004) Supercritical and near-critical CO2 in green chemical synthesis and processing. J Supercrit Fluids 28(2–3):121–191

Alper E, Orhan OY (2017) CO2 utilization: developments in conversion processes. Petroleum 3(1):109–126

Aresta M, Dibenedetto A, Angelini A (2014) Catalysis for the valorization of exhaust carbon: from CO2 to chemicals, materials, and fuels: technological use of CO2. Chem Rev 114(3):1709–1742

Birdja YY, Pérez-Gallent E, Figueiredo MC et al (2019) Advances and challenges in understanding the electrocatalytic conversion of carbon dioxide to fuels. Nat Energy 4(9):732–745

Sun ZY, Ma T, Tao HC et al (2017) Fundamentals and challenges of electrochemical CO2 reduction using two-dimensional materials. Chem 3(4):560–587

Zhou Y, Zhou R, Zhu XR et al (2020) Mesoporous PdAg nanospheres for stable electrochemical CO2 reduction to formate. Adv Mater 32(30):2000992

Tan X, Yu C, Zhao C et al (2019) Restructuring of Cu2O to Cu2O@Cu-metal-organic frameworks for selective electrochemical reduction of CO2. ACS Appl Mater Interfaces 11(10):9904–9910

Fan MM, Jimenez JD, Shirodkar SN et al (2019) Atomic Ru immobilized on porous h-BN through simple vacuum filtration for highly active and selective CO2 methanation. ACS Catal 9(11):10077–10086

Cave ER, Montoya JH, Kuhl KP et al (2017) Electrochemical CO2 reduction on Au surfaces: mechanistic aspects regarding the formation of major and minor products. Phys Chem Chem Phys 19(24):15856–15863

Cui XQ, Pan ZY, Zhang LJ et al (2017) Selective etching of nitrogen-doped carbon by steam for enhanced electrochemical CO2 reduction. Adv Energy Mater 7(22):1701456

Ma W, Xie S, Zhang XG et al (2019) Promoting electrocatalytic CO2 reduction to formate via sulfur-boosting water activation on indium surfaces. Nat Commun 10(1):892

Shi Y, Ji Y, Long J et al (2020) Unveiling hydrocerussite as an electrochemically stable active phase for efficient carbon dioxide electroreduction to formate. Nat Commun 11(1):3415

Li FW, Thevenon A, Rosas-Hernández A et al (2020) Molecular tuning of CO2-to-ethylene conversion. Nature 577(7791):509–513

Li J, Che FL, Pang YJ et al (2018) Copper adparticle enabled selective electrosynthesis of n-propanol. Nat Commun 9(1):4614

Whipple DT, Kenis PJA (2010) Prospects of CO2 utilization via direct heterogeneous electrochemical reduction. J Phys Chem Lett 1(24):3451–3458

Gao DF, Cai F, Wang GX et al (2017) Nanostructured heterogeneous catalysts for electrochemical reduction of CO2. Curr Opin Green Sustain Chem 3:39–44

Duan XC, Xu JT, Wei ZX et al (2017) Metal-free carbon materials for CO2 electrochemical reduction. Adv Mater 29(41):1701784

Gao DF, Arán-Ais RM, Jeon HS et al (2019) Rational catalyst and electrolyte design for CO2 electroreduction towards multicarbon products. Nat Catal 2(3):198–210

Hori Y, Kikuchi K, Suzuki S (1985) Production of CO and CH4 in electrochemical reduction of CO2 at metal electrodes in aqueous hydrogencarbonate solution. Chem Lett 14(11):1695–1698

Hori Y, Suzuki S (1982) Electrolytic reduction of carbon dioxide at mercury electrode in aqueous solution. Bull Chem Soc Jpn 55(3):660–665

Luc W, Collins C, Wang S et al (2017) Ag-Sn bimetallic catalyst with a core-shell structure for CO2 reduction. J Am Chem Soc 139(5):1885–1893

Ma M, Hansen HA, Valenti M et al (2017) Electrochemical reduction of CO2 on compositionally variant Au-Pt bimetallic thin films. Nano Energy 42:51–57

Kotsiras A, Kalaitzidou I, Grigoriou D et al (2018) Electrochemical promotion of nanodispersed Ru-Co catalysts for the hydrogenation of CO2. Appl Catal B Environ 232:60–68

Morales-Guio CG, Cave ER, Nitopi SA et al (2018) Improved CO2 reduction activity towards C2+ alcohols on a tandem gold on copper electrocatalyst. Nat Catal 1(10):764–771

Feng Y, Li Z, Liu H et al (2018) Laser-prepared CuZn alloy catalyst for selective electrochemical reduction of CO2 to ethylene. Langmuir 34(45):13544–13549

Meng NN, Liu CB, Liu Y et al (2019) Efficient electrosynthesis of syngas with tunable CO/H2 ratios over ZnxCd1–xS-amine inorganic–organic hybrids. Angew Chem 58(52):18908–18912

Li YC, Wang Z, Yuan T et al (2019) Binding site diversity promotes CO2 electroreduction to ethanol. J Am Chem Soc 141(21):8584–8591

Schreier M, Héroguel F, Steier L et al (2017) Solar conversion of CO2 to CO using earth-abundant electrocatalysts prepared by atomic layer modification of CuO. Nat Energy 2:17087

Hou Y, Liang YL, Shi PC et al (2020) Atomically dispersed Ni species on N-doped carbon nanotubes for electroreduction of CO2 with nearly 100% CO selectivity. Appl Catal B: Environ 271:118929

Liu W, Yu L, Yin R et al (2020) Non-3d metal modulation of a 2D Ni-Co heterostructure array as multifunctional electrocatalyst for portable overall water splitting. Small 16(10):e1906775

Zhou Y, Che F, Liu M et al (2018) Dopant-induced electron localization drives CO2 reduction to C2 hydrocarbons. Nat Chem 10(9):974–980

Vasileff A, Zheng Y, Qiao SZ (2017) Carbon solving carbon’s problems: recent progress of nanostructured carbon-based catalysts for the electrochemical reduction of CO2. Adv Energy Mater 7(21):1700759

Meng NN, Zhou W, Yu YF et al (2019) Superficial hydroxyl and amino groups synergistically active polymeric carbon nitride for CO2 electroreduction. ACS Catal 9(12):10983–10989

Zhang BS, Xu WW, Lu ZY et al (2020) Recent progress on carbonaceous material engineering for electrochemical hydrogen peroxide generation. Trans Tianjin Univ 26(3):188–196

Wu J, Ma S, Sun J et al (2016) A metal-free electrocatalyst for carbon dioxide reduction to multi-carbon hydrocarbons and oxygenates. Nat Commun 7:13869

Wang R, Sun X, Ould-Chikh S et al (2018) Metal-organic-framework-mediated nitrogen-doped carbon for CO2 electrochemical reduction. ACS Appl Mater Interfaces 10(17):14751–14758

Liu S, Yang HB, Huang X et al (2018) Identifying active sites of nitrogen-doped carbon materials for the CO2 reduction reaction. Adv Funct Mater 28(21):1800499

He C, Zhang Y, Zhang YF et al (2020) Molecular evidence for metallic cobalt boosting CO2 electroreduction on pyridinic nitrogen. Angew Chem 59(12):4914–4919

Wu J, Liu M, Sharma PP et al (2016) Incorporation of nitrogen defects for efficient reduction of CO2 via two-electron pathway on three-dimensional graphene foam. Nano Lett 16(1):466–470

Xu J, Kan Y, Huang R et al (2016) Revealing the origin of activity in nitrogen-doped nanocarbons towards electrocatalytic reduction of carbon dioxide. Chemsuschem 9(10):1085–1089

Ma C, Hou PF, Wang XP et al (2019) Carbon nanotubes with rich pyridinic nitrogen for gas phase CO2 electroreduction. Appl Catal B: Environ 250:347–354

Ji Y, Shi YM, Liu CB et al (2020) Plasma-regulated N-doped carbon nanotube arrays for efficient electrosynthesis of syngas with a wide CO/H2 ratio. Sci China Mater 63(11):2351–2357

Yang F, Ma XY, Cai WB et al (2019) Nature of oxygen-containing groups on carbon for high-efficiency electrocatalytic CO2 reduction reaction. J Am Chem Soc 141(51):20451–20459

Loiudice A, Lobaccaro P, Kamali EA et al (2016) Tailoring copper nanocrystals towards C2 products in electrochemical CO2 reduction. Angew Chem 55(19):5789–5792

Lee S, Park G, Lee J (2017) Importance of Ag-Cu biphasic boundaries for selective electrochemical reduction of CO2 to ethanol. ACS Catal 7(12):8594–8604

Jeon HS, Kunze S, Scholten F et al (2018) Prism-shaped Cu nanocatalysts for electrochemical CO2 reduction to ethylene. ACS Catal 8(1):531–535

Zhu SQ, Wang Q, Qin XP et al (2018) Tuning structural and compositional effects in Pd-Au nanowires for highly selective and active CO2 electrochemical reduction reaction. Adv Energy Mater 8(32):1802238

Wang Y, Shen H, Livi KJT et al (2019) Copper nanocubes for CO2 reduction in gas diffusion electrodes. Nano Lett 19(12):8461–8468

Liu W, Yin R, Xu X et al (2019) Structural engineering of low-dimensional metal-organic frameworks: synthesis, properties, and applications. Adv Sci 6(12):1802373

Liu WX, Zheng D, Zhang L et al (2021) Bioinspired interfacial engineering of a CoSe2 decorated carbon framework cathode towards temperature-tolerant and flexible Zn–air batteries. Nanoscale. https://doi.org/10.1039/D0NR08365H

Won DH, Shin H, Koh J et al (2016) Highly efficient, selective, and stable CO2 electroreduction on a hexagonal Zn catalyst. Angew Chem 55(32):9297–9300

Hori Y, Takahashi I, Koga O et al (2002) Selective formation of C2 compounds from electrochemical reduction of CO2 at a series of copper single crystal electrodes. J Phys Chem B 106(1):15–17

Hori Y, Takahashi I, Koga O et al (2003) Electrochemical reduction of carbon dioxide at various series of copper single crystal electrodes. J Mol Catal A Chem 199(1–2):39–47

Huang Y, Handoko AD, Hirunsit P et al (2017) Electrochemical reduction of CO2 using copper single-crystal surfaces: effects of CO* coverage on the selective formation of ethylene. ACS Catal 7(3):1749–1756

Garza AJ, Bell AT, Head-Gordon M (2018) Mechanism of CO2 reduction at copper surfaces: pathways to C2 products. ACS Catal 8(2):1490–1499

Luo WJ, Nie XW, Janik MJ et al (2016) Facet dependence of CO2 reduction paths on Cu electrodes. ACS Catal 6(1):219–229

Cheng T, Xiao H, Goddard WAIII (2015) Free-energy barriers and reaction mechanisms for the electrochemical reduction of CO on the Cu(100) surface, including multiple layers of explicit solvent at pH 0. J Phys Chem Lett 6(23):4767–4773

Liu X, Xiao J, Peng H et al (2017) Understanding trends in electrochemical carbon dioxide reduction rates. Nat Commun 8:15438

Cheng T, Xiao H, Goddard WAIII (2017) Full atomistic reaction mechanism with kinetics for CO reduction on Cu(100) from ab initio molecular dynamics free-energy calculations at 298 K. PNAS 114(8):1795–1800

Pérez-Gallent E, Figueiredo MC, Calle-Vallejo F et al (2017) Spectroscopic observation of a hydrogenated CO dimer intermediate during CO reduction on Cu(100) electrodes. Angew Chem 56(13):3621–3624

Peng Y, Wu T, Sun L et al (2017) Selective electrochemical reduction of CO2 to ethylene on nanopores-modified copper electrodes in aqueous solution. ACS Appl Mater Inter 9(38):32782–32789

Ma M, Djanashvili K, Smith WA (2016) Controllable hydrocarbon formation from the electrochemical reduction of CO2 over Cu nanowire arrays. Angew Chem 55(23):6680–6684

Dutta A, Morstein CE, Rahaman M et al (2018) Beyond copper in CO2 electrolysis: effective hydrocarbon production on silver-nanofoam catalysts. ACS Catal 8(9):8357–8368

Kortlever R, Peters I, Balemans C et al (2016) Palladium-gold catalyst for the electrochemical reduction of CO2 to C1–C5 hydrocarbons. Chem Commun 52(67):10229–10232

Su X, Yang XF, Huang YQ et al (2019) Single-atom catalysis toward efficient CO2 conversion to CO and formate products. Acc Chem Res 52(3):656–664

Li M, Wang H, Luo W et al (2020) Heterogeneous single-atom catalysts for electrochemical CO2 reduction reaction. Adv Mater 32(34):e2001848

Han LL, Song SJ, Liu MJ et al (2020) Stable and efficient single-atom Zn catalyst for CO2 reduction to CH4. J Am Chem Soc 142:12563–12567

Zheng TT, Jiang K, Ta N et al (2019) Large-scale and highly selective CO2 electrocatalytic reduction on nickel single-atom catalyst. Joule 3(1):265–278

Pan FP, Li BY, Sarnello E et al (2020) Pore-edge tailoring of single-atom iron-nitrogen sites on graphene for enhanced CO2 reduction. ACS Catal 10(19):10803–10811

Li CC, Wang T, Gong JL (2020) Alternative strategies toward sustainable ammonia synthesis. Trans Tianjin Univ 26(2):67–91

Nam DH, De Luna P, Rosas-Hemandez A et al (2020) Molecular enhancement of heterogeneous CO2 reduction. Nat Mater 19:266–276

Fang YX, Flake JC (2017) Electrochemical reduction of CO2 at functionalized Au electrodes. J Am Chem Soc 139(9):3399–3405

Wu YS, Yuan XL, Tao ZX et al (2019) Bifunctional electrocatalysis for CO2 reduction via surface capping-dependent metal-oxide interactions. Chem Commun 55(60):8864–8867

Wei X, Yin ZL, Lyu KJ et al (2020) Highly selective reduction of CO2 to C2+ hydrocarbons at copper/polyaniline interfaces. ACS Catal 10(7):4103–4111

Zheng W, Nayak S, Yuan W et al (2016) A tunable metal-polyaniline interface for efficient carbon dioxide electro-reduction to formic acid and methanol in aqueous solution. Chem Commun 52(96):13901–13904

Yang J, Yan X, Xue T et al (2016) Enhanced CO2 adsorption on Al-MIL-53 by introducing hydroxyl groups into the framework. RSC Adv 6(60):55266–55271

Peng YH, Wang LB, Luo QQ et al (2018) Molecular-level insight into how hydroxyl groups boost catalytic activity in CO2 hydrogenation into methanol. Chem 4(3):613–625

Pan FP, Li BY, Xiang XM et al (2019) Efficient CO2 electroreduction by highly dense and active pyridinic nitrogen on holey carbon layers with fluorine engineering. ACS Catal 9(3):2124–2133

Zhao MM, Gu YL, Gao WC et al (2020) Atom vacancies induced electron-rich surface of ultrathin Bi nanosheet for efficient electrochemical CO2 reduction. Appl Catal B Environ 266:118625

Zhu WJ, Zhang L, Yang PP et al (2018) Formation of enriched vacancies for enhanced CO2 electrocatalytic reduction over AuCu alloys. ACS Energy Lett 3(9):2144–2149

Ji YF, Nørskov JK, Chan KR (2019) Scaling relations on basal plane vacancies of transition metal dichalcogenides for CO2 reduction. J Phys Chem C 123(7):4256–4261

Gu ZX, Yang N, Han P et al (2019) Oxygen vacancy tuning toward efficient electrocatalytic CO2 reduction to C2H4. Small Methods 3(2):1800449

Chu MG, Chen CJ, Guo WW et al (2019) Enhancing electroreduction of CO2 over Bi2WO6 nanosheets by oxygen vacancies. Green Chem 21(10):2589–2593

Ji LY, Peng XF, Wang Z (2020) Oxygen vacancy-enriched FeOx nanoparticle electrocatalyst for the oxygen reduction reaction. Trans Tianjin Univ 26(5):373–381

Han H, Jin S, Park S et al (2021) Plasma-induced oxygen vacancies in amorphous MnOx boost catalytic performance for electrochemical CO2 reduction. Nano Energy 79:105492

Zhang JB, Yin RG, Shao Q et al (2019) Oxygen vacancies in amorphous InOx nanoribbons enhance CO2 adsorption and activation for CO2 electroreduction. Angew Chem 58(17):5609–5613

Beyerlein IJ, Demkowicz MJ, Misra A et al (2015) Defect-interface interactions. Prog Mater Sci 74:125–210

Gao D, Zhang Y, Zhou Z et al (2017) Enhancing CO2 electroreduction with the metal-oxide interface. J Am Chem Soc 139(16):5652–5655

Liang Y, Zhou W, Shi YM et al (2020) Unveiling in situ evolved In/In2O3−x heterostructure as the active phase of In2O3 toward efficient electroreduction of CO2 to formate. Sci Bull 65(18):1547–1554

Chen ZQ, Wang T, Liu B et al (2020) Grain-boundary-rich copper for efficient solar-driven electrochemical CO2 reduction to ethylene and ethanol. J Am Chem Soc 142(15):6878–6883

Feng XF, Jiang KL, Fan SS et al (2015) Grain-boundary-dependent CO2 electroreduction activity. J Am Chem Soc 137(14):4606–4609

Kim KS, Kim WJ, Lim HK et al (2016) Tuned chemical bonding ability of Au at grain boundaries for enhanced electrochemical CO2 reduction. ACS Catal 6(7):4443–4448

Liu SB, Xiao J, Lu XF et al (2019) Efficient electrochemical reduction of CO2 to HCOOH over sub-2 nm SnO2 quantum wires with exposed grain boundaries. Angew Chem 58(25):8499–8503

Kas R, Kortlever R, Milbrat A et al (2014) Electrochemical CO2 reduction on Cu2O-derived copper nanoparticles: controlling the catalytic selectivity of hydrocarbons. Phys Chem Chem Phys 16(24):12194–12201

Verdaguer-Casadevall A, Li CW, Johansson TP et al (2015) Probing the active surface sites for CO reduction on oxide-derived copper electrocatalysts. J Am Chem Soc 137(31):9808–9811

Gao S, Lin Y, Jiao X et al (2016) Partially oxidized atomic cobalt layers for carbon dioxide electroreduction to liquid fuel. Nature 529(7584):68–71

Yang XX, Deng PL, Liu DY et al (2020) Partial sulfuration-induced defect and interface tailoring on bismuth oxide for promoting electrocatalytic CO2 reduction. J Mater Chem A 8(5):2472–2480

Tang C, Shi JJ, Bai XW et al (2020) CO2 reduction on copper’s twin boundary. ACS Catal 10(3):2026–2032

Hu F, Abeyweera SC, Yu J et al (2020) Quantifying electrocatalytic reduction of CO2 on twin boundaries. Chem 6(11):3007–3021

Brennecke JF, Maginn EJ (2001) Ionic liquids: innovative fluids for chemical processing. AIChE J 47(11):2384–2389

Sun L, Ramesha GK, Kamat PV et al (2014) Switching the reaction course of electrochemical CO2 reduction with ionic liquids. Langmuir 30(21):6302–6308

Gupta N, Gattrell M, MacDougall B (2006) Calculation for the cathode surface concentrations in the electrochemical reduction of CO2 in KHCO3 solutions. J Appl Electrochem 36(2):161–172

Ooka H, Figueiredo MC, Koper MTM (2017) Competition between hydrogen evolution and carbon dioxide reduction on copper electrodes in mildly acidic media. Langmuir 33(37):9307–9313

Han SM, Yun QB, Tu SY et al (2019) Metallic ruthenium-based nanomaterials for electrocatalytic and photocatalytic hydrogen evolution. J Mater Chem A 7(43):24691–24714

Billy JT, Co AC (2017) Experimental parameters influencing hydrocarbon selectivity during the electrochemical conversion of CO2. ACS Catal 7(12):8467–8479

Hori Y, Murata A, Takahashi R et al (1987) Electroreduction of carbon monoxide to methane and ethylene at a copper electrode in aqueous solutions at ambient temperature and pressure. J Am Chem Soc 109(16):5022–5023

Hori Y, Murata A, Takahashi R et al (1988) Enhanced formation of ethylene and alcohols at ambient temperature and pressure in electrochemical reduction of carbon dioxide at a copper electrode. J Chem Soc Chem Commun 1:17

Hori Y, Murata A, Takahashi R (1989) Formation of hydrocarbons in the electrochemical reduction of carbon dioxide at a copper electrode in aqueous solution. J Chem Soc Faraday Trans 85(8):2309