Abstract

The demands for high-performance and low-cost batteries make K-ion batteries (KIBs) considered as promising supplements or alternatives for Li-ion batteries (LIBs). Nevertheless, there are only a small amount of conventional inorganic electrode materials that can be used in KIBs, due to the large radius of K+ ions. Differently, organic electrode materials (OEMs) generally own sufficiently interstitial space and good structure flexibility, which can maintain superior performance in K-ion systems. Therefore, in recent years, more and more investigations have been focused on OEMs for KIBs. This review will comprehensively cover the researches on OEMs in KIBs in order to accelerate the research and development of KIBs. The reaction mechanism, electrochemical behavior, etc., of OEMs will all be summarized in detail and deeply. Emphasis is placed to overview the performance improvement strategies of OEMs and the characteristic superiority of OEMs in KIBs compared with LIBs and Na-ion batteries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the past several decades, the technologies and markets of Li-ion batteries (LIBs) have gradually matured. Given their outstanding energy density and long cycling life, LIBs are widely used in portable electronic equipment, electric vehicles, and large-scale energy storage [1]. However, with the rapidly increasing market demand, the low abundance of lithium resources drives researchers to focus on batteries consisting of earth-abundant elements, such as sodium [2, 3], potassium [4, 5], and aluminum [6, 7]. K-ion batteries (KIBs) have attracted remarkable attention owing to their unique advantages, which make them promising supplements or alternatives for LIBs compared with other metal-ion batteries.

Potassium (18400 ppm) is the seventh most abundant element in the earth’s crust; it is orders of magnitude more abundant than lithium (18 ppm) [8]. In addition, although the standard electrode potential of K+/K (−2.936 V vs. SHE) in water is higher than that of Li+/Li (−3.040 V vs. SHE) (but lower than that of Na+/Na (−2.714 V vs. SHE)), the K+/K couple can exhibit the lowest standard potential in specific organic solvents [9, 10]. For example, the redox potential of potassium (−3.002 V vs. SCE) is lower than that of Li+/Li (−2.906 V vs. SCE) and Na+/Na (−2.691 V vs. SCE) in propylene carbonate (PC) [10], which is beneficial for enhancing the energy density and safety of batteries. Similar to Na-ion batteries (NIBs), K ions do not alloy with Al when using low-cost Al foil as the negative-electrode current collector, which is another advantage of KIBs compared with LIBs [11]. In addition, K ions can form stage 1 graphite intercalation compound (KC8) with a high theory capacity of 279 mA·h/g [12, 13]. Therefore, the commercial graphite industry of LIBs can be potentially compatible with futuristic KIBs and superior to NIBs [14]. More importantly, K+ can exhibit considerably weaker Lewis acidity and smaller Stokes radius in organic solvents compared with Li+ and Na+ [15]. Hence, K+ demonstrates a low desolvation energy and high ionic conductivity, which are beneficial for the ionic mobility across the electrolyte/electrode interface and bulk electrolyte [16]. Therefore, K-ion-based systems can easily achieve high-power densities.

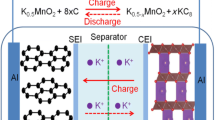

KIBs have a similar rock-chair principle to LIBs. During the charge/discharge process, K+ commutes between the anode and cathode, together with the insertion/desertion of K+ into/from electrodes. Thereby, the natures of electrode materials are significant for the performance and safety of KIBs. Cathode materials can be generally categorized into Prussian blue and its analogs (PBAs) [17, 18], polyanionic compounds [19, 20], layered metal oxides [21, 22], and organic materials [23,24,25]. Anode materials commonly include carbonaceous [26,27,28], K-alloying [29, 30], conversion-type [31, 32], and organic materials [33]. Given that K+ (1.38 Å) has a larger radius than Li+ (0.76 Å) and Na+ (1.02 Å) [34], using conventional inorganic electrode materials for KIBs usually cause severe structure deformation, incurring low capacity and rapid capacity fading of batteries [35]. On the contrary, organic electrode materials (OEMs) are assembled on the basis of van der Waals force rather than covalent/ionic bonding. Hence, a large interlayer spacing and flexible structure can be achieved in OEMs [36]. Therefore, OEMs that have been extensively researched for use in LIBs and NIBs may be also suitable for KIBs.

Except for ion universality, OEMs have other attractive advantages:

-

1.

Low cost and high sustainability. A large number of OEMs are ubiquitous and can be refined from biomass. Most of the OEMs consist of C, H, O, N, and S and lack resource-scarcity metals (such as Co) [37].

-

2.

Abundant variety and wide potential range. In general, OEMs can be classified into three types based on their electrochemically active groups [38, 39]: (a) p-type materials, such as conductive polymers, that undergo oxidation reaction first, accepting anions such as PF6− and ClO4− to maintain neutralization; (b) n-type materials, such as carbonyl compounds and imines, that can be reduced to negatively charged states. Thus, cations, including Li+ and K+, are necessary to neutralize the negatively charged states; (c) bipolar-type materials, such as nitroxyl radical compounds, that have the properties of n- and p-type materials, undergo either oxidation or reduction reaction first [40]. As a result, the diverse redox mechanisms and chemical environments cause OEMs to exhibit a wide potential range. In general, p-type materials have a high redox potential (> 3 V vs. Li+/Li) than n-type materials (< 3 V vs. Li+/Li) [41,42,43]. Hence, n-type materials can be used as an anode or cathode, whereas p-type materials are only suitable for the cathode.

-

3.

High energy and power density. Most of n-type materials have high capacities because of their multiple-electron transfer reactions and low molecular mass, which can offset the relatively low potential to achieve a competitive energy density. Li2C6O6 can show a reversible capacity of 580 mA·h/g with a high energy density of 1300 W·h/kg [44]. Except for organodisulfide and thioether, in which the S–S or S=O bonds break/forming need high activation energy, all other organic compounds have fast kinetics [38, 40, 45]. Meanwhile, nitroxide derivatives have rate constants that are approximately as high as 10−1 cm/s [46]. More importantly, KIBs assembled by fast kinetics OEMs and high-conductivity K+ electrolytes have a huge potential to achieve super-high-rate capability.

A large number of OEMs with remarkable performance in KIBs have been investigated in recent years due to their great advantages [45, 47]. Herein, we summarize the recent progress in the research and development of OEMs for non-aqueous KIBs. As shown in Scheme 1, depending on the redox mechanism, organic cathode materials mainly include carbonyl, imine, and anion insertion compounds. Meanwhile, anode materials can be categorized into four types, including carbonyl, azo, and unsaturated C=C compounds and covalent organic frameworks/metal organic frameworks (COFs/MOFs). The reaction mechanisms, electrochemical performances, existing issues, optimizing methods, and next challenges of OEMs are discussed in detail and thoroughly. This review also provides the half-cell/full battery performances of all the organic materials we mentioned.

Organic Cathode Materials

Compared with anode materials that usually have high capacities (> 250 mA·h/g) [48,49,50], the relatively low capacity of cathode materials (generally < 150 mA·h/g) restricts the energy density of K-ion full batteries [51,52,53]. In this case, organic cathode materials with high capacity and potential are essential for KIBs and have become an important topic in the current research. The commonly used cathode materials include organic carbonyl, imine, and anion insertion compounds. In this section, we will provide an overview of the reaction mechanisms, electrochemical performance, and improvement strategies of organic cathode materials used in KIBs.

Organic Carbonyl Compounds

Organic carbonyl compounds, such as 9,10-anthraquinone (AQ) [54] and polyimides (PIs) [55], are important for various OEMs due to their attractive benefits of high capacity, wide potential range, and low cost. Almost all organic carbonyl materials belong to n-type materials. The reaction mechanisms of carbonyl materials depend on the changes in the charge states of oxygen and carbon atoms within the carbonyl groups. During the reduction process, the C=O group accepts an electron and a metal cation, forming the C–O–M compound. Meanwhile, the redistribution of electrons in the conjugated organic framework can stabilize the reduction state of OEMs. The reoxidation process is a reversible process, during which the C–O–M compound reverts to the C=O group with the dissociation of metal cations. In general, organic carbonyl materials can be classified into three different groups based on the stabilization mechanism (Fig. 1) [56]:

-

(I)

Group I compounds, such as organic ketones, possess vicinal carbonyls that can be reduced to a stable enolate structure.

-

(II)

Group II consists of a series of compounds, such as organic anhydrides and terephthalate, whose carbonyl groups are directly connected to the aromatic core. In this case, the negative charges can be easily delocalized to the aromatic core, forming a stabilized reduction state.

-

(III)

Group III compounds are quinone compounds that can form additional aromatic systems after reduction.

Although a small number of carbonyl compounds owning relatively low potential, such as terephthalate, can be used as anode materials in KIBs, most of the carbonyl compounds are applied as cathode materials. Therefore, in the subsequent discussion, we will review different kinds of carbonyl compounds used as cathode materials in KIBs.

Organic Anhydrides

Chen et al. [57] reported 3,4,9,10-perylene-tetracarboxylicacid-dianhydride (PTCDA, Fig. 2a, No. 1, Table 1) in 2015. Based on the reaction mechanism, PTCDA belongs to group II of carbonyl compounds. PTCDA electrodes exhibit specific capacities of 130 and 73 mA·h/g at the current densities of 10 and 500 mA/g, respectively, at which approximately two K+ can insert into one PTCDA molecule (Fig. 2b, c). PTCDA also exhibits a decent cycle stability with a capacity decay of 0.12% per cycle. These advantages of PTCDA prove the feasibility of organic anhydrides in KIBs; to date, more studies have been devoted to the research of organic anhydrides. Xing et al. [58] investigated the variation in the crystal structure and chemical bond of PTCDA at different states of charge (SOCs) in the first cycle through ex situ X-ray diffraction (XRD) and ex situ infrared (IR) spectra. As shown in Fig. 2d, e, the crystal structure of PTCDA gradually transformed through amorphization during the potassiation process (points 1–4). However, in the depotassiation process, after being recharged to point 6, the ordered structure only can be partially recovered. This incompletely structural recovery in the first cycle was likely responsible for the difference in the discharge curves between the first and post-first cycles (Fig. 2b, c). From point 6 to point 7, the structure of PTCDA underwent amorphization again, and this condition might be attributed to the insertion of PF6− under the high voltage. In the IR spectra shown in Fig. 2f, the peak of C=O at ~ 1788 cm−1 shifted to 1773 cm−1 after potassiation, indicating that the C=O bonds on reduced PTCDA molecule weakened. At the same time, a new peak which was assigned to the C–O–K appeared at ~ 1824 cm−1, indicating that carbonyl is the reactive site of PTCDA.

a Reaction mechanisms of PTCDA. b–c Galvanostatic charge/discharge profiles of the PTCDA electrodes at 10 mA/g. Reproduced with permission [57]. Copyright 2015, Elsevier. d Galvanostatic charge/discharge profile of PTCDA in the first cycle at 20 mA/g. e Ex situ XRD patterns collected at different states of charge corresponding to d. f Ex situ IR patterns collected at different states of charge corresponding to d. Reproduced with permission [58]. Copyright 2015, Elsevier

Except for conducting polymers, almost all OEMs are electrical insulators or semiconductors [92]. Therefore, the electrodes of OEMs usually contain a large amount of conductive carbon (30%–60%), reducing the practical energy density of batteries [93]. To improve the conductivity of PTCDA, Fan et al. [59] introduced a novel and effective method of annealing PTCDA at 450 °C (PTCDA@450°C, No. 2). After annealing, the peak value of C=O bond reduced, whereas that of C–O bond increased, indicating that the annealing process can promote the polymerization of PTCDA (Fig. 3a, b). In addition, after annealing, the binding energy of O1s increased, indicating that O atoms were electron-deficient (Fig. 3b), that is, the aromatic C atoms were electron-rich. The electron-rich feature of aromatic C atoms can significantly increase the capability of electron transport in the bulk phase of materials. As expected, the conductivity of PTCDA@450°C reached up to 5.32 × 10−6 S/m, whereas that of pristine PTCDA was less than 10−10 S/m. Hence, the rate capacity and cycling stability of the KIBs significantly improved when PTCDA@450°C was used as the cathode (Fig. 3c, d).

Comparison between PTCDA@450°C and pristine PTCDA in a high-resolution C1s X-ray photoelectron spectroscopy (XPS) patterns, b high-resolution O1s XPS patterns, c cycling stability, and d rate performance. Reproduced with permission [59]. Copyright 2018, Wiley–VCH

Quinones

Quinones, a class of typical representations of OEMs, have been widely investigated in LIBs [94, 95], NIBs [96, 97], and flow batteries [98, 99]. The high mass fraction of carbonyl groups renders quinones with a high theory capacity [100, 101]. However, quinones with low molecular mass generally exhibit high solubility in organic electrolytes because of their similar polarity, thus resulting in the rapid capacity fading of batteries. One feasible method to solve this problem is to employ metalorganic salts [102, 103]. Functional groups, such as metal enolate (–O−–Li+), metal sulfonate (–SO3−–Na+), and metal carboxylate (–COO−–Li+) can significantly increase the polarity of organic salts, inhibiting the solution of quinones in aprotic electrolytes [63, 104]. Polymerization is another effective way because the corresponding polymer can not only reduce the solubility of small molecules but also retain the redox-active sites of the monomer. To the best of our knowledge, all the quinones used in KIBs are quinone-based organic salt or quinone-based polymers.

Quinone-Based Organic Salts

Anthraquinone-1,5-disulfonic acid sodium (AQDS, Fig. 4a, No. 3) has been widely investigated in KIBs [60, 105, 106]. A recent study [60] showed that AQDS can deliver a reversible discharge capability of ~ 97 mA·h/g with two potential plateaus at ~ 2.0 and ~ 1.6 V vs. K+/K (Fig. 4b). Notably, AQDS can achieve a higher rate capability and cycling stability in dimethoxyethane (DME) electrolyte compared with ethylene carbonate/diethyl carbonate (EC/DEC) electrolyte (Fig. 4c, d). Furthermore, the electrode/electrolyte interfacial resistance (Rf) and the thickness of the solid–electrolyte interface (SEI) film increase more quickly in EC/DEC electrolyte compared with DME electrolyte. Based on the molecular orbital computation, in DME electrolyte, the prior reduction of KFSI will form an impermeable inorganic-rich inner layer, which significantly mitigates the decomposition of DME. However, in EC/DEC electrolyte, the almost simultaneous decomposition of EC, DEC, and KFSI leads to a random distribution of inorganic-rich layer, inducing the permeation of electrolyte and the rapid growth of the SEI film. From the simulation and experiment data, the stability of SEI film can significantly influence the reaction kinetics and transfer resistance, thus further proving the battery performance. Li et al. [105] then employed AQDS as the cathode, coupled with reduced state graphite (KC8) as the anode. The full KIBs delivered an average capacity of ~ 105 mA·h/g (calculated by the cathode mass) for 250 cycles at 100 mA/g with a discharge potential of 1.8 V. In addition, para-disodium-2,5-dihydroxy-1,4-benzoquinone (p-Na2C6H2O6, Fig. 4a, No. 4) [61] has been used in KIBs, delivering a capacity of 190.6 mA·h/g at 0.1 C (Fig. 4e). The prepared battery maintained a capacity of 90.1 mA·h/g after 50 cycles with a capacity retention of 46% (Fig. 4f).

a Schematic of AQDS and the synthesis route of p-Na2C6H2O6. Reproduced with permission [61, 106]. Copyright 2018/2019, Elsevier. b Galvanostatic charge/discharge profiles of AQDS electrodes at 0.1 C in DME electrolyte. c Rate and d cycling performance of AQDS electrodes in different electrolytes. Reproduced with permission [60]. Copyright 2018, Wiley–VCH. e Galvanostatic charge/discharge profiles and f cycling performance of p-Na2C6H2O6 electrodes at 0.1 C. Reproduced with permission [61]. Copyright 2019, Elsevier

Based on the multiple-electron transfer reaction, quinones can be used to assemble all-OEM full batteries. Zhao et al. [63] introduced an oxocarbon (K2C6O6, No. 6) material for KIBs. K2C6O6 demonstrated two pairs of peaks at 2.4 V/2.8 V and 1.2 V/1.3 V (Fig. 5a), indicating a two-electron transfer reaction and corresponding to a high capacity of 212 mA·h/g (Fig. 5b). Based on the large voltage interval between the first and the second K+ insertion process (Fig. 5c, d), the K-ion full battery assembled with K2C6O6 and K4C6O6 demonstrated an energy density of 35 W·h/kg with an operating voltage of 1.1 V.

a Cyclic voltammetry curves of K2C6O6 electrodes at different scan rates. b Galvanostatic charge/discharge profiles of K2C6O6 at 0.2 C. c–d Galvanostatic charge/discharge profiles of the c anode (K4C6O6) and d cathode (K2C6O6) regions of the K-ion full battery at 25 mA/g. Reproduced with permission [63]. Copyright 2016, Wiley–VCH

Quinone-Based Polymers

Jian et al. [64] introduced an easily synthesized poly(anthraquinonyl sulfide) (PAQS, No. 7) as the cathode for KIBs. The PAQS exhibited a high reversible capacity of 200 mA·h/g with two slopes at 2.1 and 1.6 V versus K+/K (Fig. 6a). As shown in Fig. 6b, PAQS showed a capacity retention of 75% after 50 cycles at a current density of 20 mA/g. Tang et al. [65] synthesized another kind of quinone, PPTS (Fig. 6c, No. 8), through the structure of sulfide. PPTS delivered a capacity of 250 mA·h/g at a current rate of 0.1 A/g, with the energy density increasing to 450 W·h/kg (Fig. 6d). Benefiting from the low charge-transfer resistance and high ion diffusion coefficient, PPTS exhibited a super-high rate capability, with a reversible capacity of 163 mA·h/g at a current rate of 10 A/g (Fig. 6e). Most importantly, with the help of FEC additive and Joule heating under a high current density, which can suppress the parasitic reaction and heal potassium dendrites, K metal/PPTS batteries exhibited a high cycling stability with a capacity retention of 74% after 3000 cycles at the current rate of 5 A/g (Fig. 6f). Notably, the average discharge voltage of all the quinones mentioned above is below 2 V. One feasible method to enhance the redox potentials is the introduction of electron-withdrawing groups [107, 108]. Zhou et al. [66] developed three kinds of polydiaminoanthraquinones (PQ-1,5; PQ-1,4; PQ-CN) linked by polyaniline skeleton as novel cathode materials for KIBs. Benefiting from the electron-withdrawing groups of -CN, PQ-CN (No. 9) exhibited a lower lowest-unoccupied molecular orbital (LUMO) energy level (−3.53 eV) and smaller highest-occupied molecular orbital–LUMO gaps (Eg) (2.29 eV) compared with PQ-1,5 and PQ-1,4 (Fig. 6g). PQ-CN delivered the highest specific capacity of 184 mA·h/g with the median discharge voltage increasing to 2.0 V (Fig. 6h).

a Galvanostatic charge/discharge profiles of PAQS electrodes at 20 mA/g. The inset shows the structure of PAQS. b Cycling performance of PAQS at 20 mA/g. Reproduced with permission [64]. Copyright 2016, Elsevier. c Reaction mechanism of PPTS. d Galvanostatic charge/discharge profiles of PPTS electrodes at 0.1 A/g. e Rate capability of PPTS electrodes. f Cycling performance of PPTS electrodes. Reproduced with permission [65]. Copyright 2019, The Royal Society of Chemistry. g Band structures by density functional theory calculations and h galvanostatic charge/discharge profiles of PQ-1,5; PQ-1,4; PQ-CN at 50 mA/g. Reproduced with permission [66]. Copyright 2019, The Royal Society of Chemistry

Aromatic Imides

Small Aromatic Imide Molecules

3,4,9,10-perylene-tetracarboxylic diimide (PTCDI, No. 10), which has a very similar molecular structure (Fig. 7a) with PTCDA (as mentioned in Section of Organic Anhydrides), can also be used as an organic cathode material for KIBs. Xiong et al. [67] observed that high-concentration electrolyte can effectively inhibit the dissolution of PTCDI. Therefore, by using the electrolyte containing 5 M KFSI, PTCDI delivered a reversible capacity of 137 mA·h/g, which was the same as its theoretical capacity. Meanwhile, the cycling stability of PTCDI was significantly enhanced in the 5 M KFSI electrolyte, with a capacity retention of 92% after 50 cycles at 50 mA/g (Fig. 7a).

a Cycling performance of PTCDI in electrolytes with different concentrations at 50 mA/g. Reproduced with permission [67]. Copyright 2019, The Royal Society of Chemistry. b Rate capability of PTCDA and PTCDA-0, -2, -3, and -4C. Reproduced with permission [68]. Copyright 2019, Wiley–VCH. c Galvanostatic charge/discharge profiles of PI@G electrodes at 100 mA/g. d Cycling stability of PI-based electrodes at 100 mA/g. Reproduced with permission [69]. Copyright 2019, American Chemical Society. e Molecular structure of PI, and PI-CMP. f Molecular structure and cycling stability of PQI at 50 mA/g. g Cycling stability of PI-CMP at 50 mA/g. Reproduced with permission [70]. Copyright 2019, The Royal Society of Chemistry

PIs

PIs are a series of polymers synthesized by the polycondensation reaction of imide monomers, and they have been widely applied in engineering plastic because of their high heat resistance and excellent mechanical strength. PIs contain redox-active aromatic imide monomers that can be used as cathode materials in KIBs. Tong et al. [68] have shown that the electrochemical properties of PTCDA-based PIs can be easily tuned via changing the length of -(CH2)k- segment (Fig. 7b). PTCDA-2C (No. 11) exhibited the highest rate capability with a reversible capacity of 118 mA·h/g at 0.37 C and 91 mA·h/g at 14.7 C (Fig. 7b). Notably, at 147.06 C (35.2 kW/kg), PTCDA-2C electrodes can still maintain a record-high energy density of 113 W·h/kg. This superior rate performance of PTCDA-2C electrodes was attributed to the increased capacitive contribution and the decreased K-ion uptake energy barriers. Additionally, PTCDA-2C demonstrated a superior cycling stability with a capacity retention of 94% after 1000 cycles at 2.21 C. Hu et al. [69] reported another kind of PI synthesized with 1,4,5,8-naphthalenetetracarboxylic dianhydride and ethylenediamine (Fig. 7c). Graphite nanosheets were added to PIs (PI@G, No. 12) during polymerization to increase the electrical conductivity and suppress the aggregation of PIs. PI@G can deliver an increased discharge capacity of 142 mA·h/g at 100 mA/g (Fig. 7c). Meanwhile, as shown in Fig. 7d, PI@G exhibited the maximum capacity retention of 96% after 100 cycles, which was considerably better than that of PI@Acetylene black and PI@Single-wall nanotubes. Tian et al. [70] also introduced three kinds of PIs, namely, one-dimensional (1D) polymers (PI (No. 13) and PQI (No. 14)) and 2D conjugated microporous polymer (PI-CMP (No. 15)) for KIBs (Fig. 7e, f). PQI delivered the highest initial capacity of 186 mA·h/g because of the highest mass fraction of carbonyl groups (Fig. 7f). Nevertheless, the tight distribution of the potassiated carbonyl group can result in a rapid capacity fading for PQI (Fig. 7f). Moreover, given the extended π-conjugation structure, PI-CMP exhibited the highest capacity retention of 60.2% after 200 cycles (Fig. 7g).

Organic Imine Compounds

The imine reaction is based on the reversible reaction between nitrogens in the imine group (C=N) and potassium ions; this process can be further stabilized by the conjugated structure. Kapaev et al. [72] reported a hexaazatriphenylene-based polymer for KIBs (Fig. 8a). For convenience, the polymer consisting of the structure of 5,6,11,12,17,18-hexaazatrinaphthylene is named as PHATNA (No. 17) in this review [109]. In the electrolyte of 1 M KPF6 in DME, PHATNA electrodes delivered a specific capacity of 245 mA·h/g, indicating that PHATNA can undergo a three-electron reversible reaction based on the imine, and to some extent undergo the fourth-electron reaction based on metalation. At a high current density of 10 A/g, PHATNA electrodes can maintain the capacity retention of ~ 75% compared with that at the current rate of 0.05 A/g (Fig. 8b). Moreover, PHATNA electrodes showed an excellent cycling performance. No considerable capacity decay can be observed over thousands of cycles at 10 A/g (Fig. 8c). Slesarenko et al. [73] introduced a tetraazapentacene-based organic material-octahydroxytetraazapentacene (OHTAP, Fig. 8d, No. 18) for KIBs. The pyrazine rings and hydroxyls of OHTAP are redox-active groups, delivering a reversible capacity of ~ 330 mA·h/g at the second cycle. Meanwhile, the relatively stable capacity of ~ 220 mA·h/g can be maintained after 8–10 cycles. However, the OHTAP electrodes suffered from severe capacity decay, which was mainly due to the dissolution of OHTAP in the electrolytes (Fig. 8e).

a Reaction mechanism of PHATNA electrodes. b Galvanostatic charge/discharge profiles of PHATNA electrodes at the current density range from 0.05 to 10 A/g. c Cycling stability of PHATNA electrodes at the current density of 10 A/g. Reproduced with permission [72]. Copyright 2019, The Royal Society of Chemistry. d Schematic of OHTAP. e Cycling stability of OHTAP electrodes at 0.1 C. Reproduced with permission [73]. Copyright 2019, Elsevier

Anion Insertion Compounds

The redox potential of organic carbonyl and imine compounds are generally low (< 3 V vs. K+/K), which is not favorable for the improvement of the energy density of batteries. Moreover, most of the organic cathode materials cannot provide potassium sources, preventing the assembly of full batteries. Hence, OEMs based on the anion insertion reaction provide a special alternative for building high-energy K-ion full batteries. During the oxidation process, electrons can be removed from the functional groups of anion insertion compounds at a relatively high potential, accompanied by the insertion of anions, such as TFSI−, PF6−, and ClO4−, into positively charged functional groups. The reduction progress includes the recovery of their functional groups to electric neutrality and the desertion of anions [110]. In general, the anion insertion reaction is usually based on nitroxide free radicals, amino groups, and heteroatoms [111,112,113]. The redox potentials of anion insertion compounds are generally above 3 V (vs. K+/K). Given that cathodes undergo the insertion of anions rather than K+ during the redox reaction, the batteries matched with K-ion insertion anodes and anion insertion cathodes should be classified as dual-ion batteries (DIBs). The studies of anion insertion compounds in KIBs mostly focus on polymerized aromatic amines, which are based on the redox reactions of amine groups/N-atoms. Fan et al. [74] investigated the K-ion-based DIBs (PDIBs) assembled with a polytriphenylamine (PTPAn, No. 19) cathode and graphite anode in a KPF6-based electrolyte. These PDIBs delivered a reversible capacity of 60 mA·h/g with the average discharge voltage of 3.23 V at the current density of 50 mA/g (Fig. 9a). Moreover, PDIBs exhibited superior cycling stability with a capacity retention of 75.5% after 500 cycles at the current density of 100 mA/g. Afterward, poly(N,N′-diphenyl-p-phenylenediamine) (PDPPD, No. 20) was introduced as the cathode in potassium half-cells. PDPPD can deliver a capacity of 63 mA·h/g in the KPF6-based electrolyte at 1 C (Fig. 9b), whereas the corresponding capacity in lithium and sodium half-cells were 97 and 94 mA·h/g, respectively [75]. Another kind of polyarylamine-type cathode, poly(N-phenyl-5,10-dihydrophenazine) (p-DPPZ, No. 21), can achieve a practical specific capacity of 162 mA·h/g at the current density of 200 mA/g [76]. Notably, with the help of the optimized electrolyte containing high-concentration KPF6, p-DPPZ exhibited an excellent rate capability with a capacity retention of ~ 80% when the current density increased from 200 mA/g to 10 A/g (Fig. 9c). Li et al. [77] introduced poly(N-vinylcarbazole) (PVK, No. 22) for PDIBs, which exhibited a capacity of 117 mA·h/g with a high average operation potential of 4.05 V vs. K+/K (Fig. 9d). However, the battery suffered from a low Coulombic efficiency (CE) in the first cycle because of the irreversible electrolyte decomposition. Conductive polymers, such as polyaniline (No. 23), can also act as cathode materials in PDIBs (Fig. 9e). In the PDIBs assembled with K foil and polyaniline, Gao et al. [78] replaced the organic–liquid electrolyte with cross-linked poly(methyl methacrylate) (PMMA). Polyaniline-based PDIBs can deliver the same reversible capacity of ~ 137 mA·h/g in liquid and polymer-gel electrolytes. However, given the low interfacial resistance and stable electrode/electrolyte interface, the PDIBs with PMMA electrolyte demonstrated an increased rate and cycling performance (Fig. 9f, g). Hence, the combination of polymer electrolytes with conductive polymer is a low-cost and promising way to build a high-performance potassium battery for practical application.

The reaction mechanism and galvanostatic charge/discharge profiles of a PTPAn/graphite-based dual-ion batteries, reproduced with permission [74]. Copyright 2017, American Chemical Society, b PDPPD electrodes, reproduced with permission [75]. Copyright 2019, The Royal Society of Chemistry, c p-DPPZ electrodes, reproduced with permission [76]. Copyright 2019, American Chemical Society, and d PVK electrodes [77], reproduced with permission. Copyright 2018, Elsevier. e Reaction mechanism of polyaniline electrodes; f Rate capability and g cycling stability of polyaniline electrodes in polymer electrolyte and liquid electrolyte at 50 mA/g, reproduced with permission [78]. Copyright 2018, Wiley–VCH

Organic Anode Materials

Organic Carbonyl Compounds

Quinones

Vitamin K (VK), a 2-methyl-1,4-naphthoquinone derivative and an essential element for the human body, can be used as an anode material for KIBs because of its low potential [79]. Graphene nanotubes (GNTs) were mixed with VK to form VK@GNT (Fig. 10a, No. 24) to increase the electronic conductivity and inhibit the dissolution of VK. The π–π interaction between the GNTs and VK was successfully established after hybridization. Hence, the VK@GNT electrodes demonstrated a significantly decreased charge-transfer resistance and high stability. As a result, VK@GNT electrodes delivered an increased reversible capability of 338.9 mA·h/g and enhanced capacity retention of 66% after 100 cycles at a current density of 100 mA/g (Fig. 10b, c). Furthermore, ex situ XPS analysis demonstrated the reversible evolution between the C=O and C–O–K of VK@GNT during the charge/discharge process, indicating that the C=O groups are the redox sites of VK.

a Reaction mechanism of Vitamin K and the synthetic route of Vitamin K@ graphene nanotubes (VK@GNK). b Galvanostatic charge/discharge profiles of VK@GNT at 100 mA/g. c Cycling stability of VK and VK@GNT at 100 mA/g. Reproduced with permission [79]. Copyright 2018, Royal Society of Chemistry

Organic Conjugated Carboxylic Acids/Salts

Organic conjugated carboxylic acids/salts belong to group II of organic carbonyl compounds (Section of Organic Carbonyl Compounds). They generally exhibit a low redox potential due to the loss of resonance or aromaticity in the core of the molecules [56]. Wang et al. [80] introduced terephthalic acid (H2TP, No. 25) as an anode material for KIBs. The reaction process of H2TP included two steps (Fig. 11a). In Step I, H2TP transformed into potassium hydrogen terephthalate (KHTP) through an irreversible potassiation process at the irreversible discharge plateau of ~ 1.8 V, accompanied by the conversion of the active H+ into H2 gas. In Step II, KHTP underwent a reversible two-electron redox reaction, delivering a specific capacity of 280 mA·h/g (including 61 mA·h/g derived from super P) with a charge plateau at ~ 0.8 V. Moreover, after 150 cycles at a current density of 50 mA/g, the H2TP electrodes can still deliver a stable capacity of ~ 240 mA·h/g with a capacity retention of 86%. However, H2TP suffered from several issues, such as the generation of H2 gas and the dissolution of active materials, which can be circumvented by starting with potassium salts as the anode [114, 115]. Deng et al. [81] introduced potassium terephthalate (K2TP, No. 26) and potassium 2,5-pyridinedicarboxylate (K2PC, No. 27) as anode materials for KIBs. K2TP and K2PC were nanosized to a size of 50–500 nm by ball-milling with super P to increase the electronic conductivity of potassium salt. K2TP and K2PC can deliver reversible capacities of 270 and 245 mA·h/g, respectively. However, the CE of K2TP and K2PC were 46% and 44%, respectively, which may be attributed to the formation of the SEI and other side reactions. K2TP and K2PC can maintain satisfactory capacities of 158 and 176 mA·h/g at the 100th cycle (Fig. 11b). Li et al. [82] introduced potassium 1,1′-biphenyl-4,4′-dicarboxylate (K2BPDC, No. 28) and potassium 4,4′-E-stilbenedicarboxylate (K2SBDC, No. 29) to KIBs. However, compared with terephthalate, the structure of biphenyl in K2BPDC and K2SBDC had increased molecular mass. Hence, K2BPDC and K2SBDC can achieve stable capacities of 144 and 132 mA·h/g, respectively. Wang et al. [83] synthesized potassium perylene-3,4,9,10-tetracarboxylate (K4PTC) by using the precursor of PTCDA (No. 1). However, although K4PTC contained four carboxylate groups (Fig. 11c), it can only undergo a two-electron transfer reaction rather than the expected four-electron transfer reaction. In addition, the multiple K–O bonds with strong ionic character and high molecular mass significantly alleviated the dissolution of active materials. After in situ compositing with carbon nanotubes, K4PTC@CNT (No. 30) can achieve enhanced capacities of 107, 99, and 78 mA·h/g at the current densities of 100, 200, and 500 mA/g, respectively (Fig. 11d). Meanwhile, K4PTC@CNT electrodes also delivered a good cycling performance with a reversible capacity of 97 mA·h/g after 500 cycles under 50 mA/g.

a Reaction mechanism of H2TP. Reproduced with permission [80]. Copyright 2018, Elsevier. b Reaction mechanism and cycling stability of K2TP and K2PC at 0.2 C. Reproduced with permission [81]. Copyright 2017, Elsevier. c Synthetic route and proton nuclear magnetic resonance spectrum of K4PTC. d Rate performance of K4PTC@CNT. Reproduced with permission [83]. Copyright 2019, The Royal Society of Chemistry

Organic Azo Compounds

Azo compounds are a class of promising anode materials for KIBs because of their low potential and high reversibility; they have been widely investigated in LIBs and NIBs [116, 117]. During the reduction process, each nitrogen atom can accept one electron and one cation, whereas the double bond of N=N converts into single bonds. Reversibly, the N=N double bond can be recovered during the oxidation reaction. Liang et al. [85] introduced azobenzene-4,4′-dicarboxylic acid potassium salt (ADAPTS, No. 32, Fig. 12a) as an anode for KIBs. The high-resolution transmission electron microscopy (HRTEM) image in Fig. 12b exhibits that ADAPTS has a high crystallinity, indicating the strong π–π interaction in the ADAPTS crystal. The extended π-conjugated structure renders ADAPTS with high stability and fast kinetics. At ambient temperature, ADAPTS showed reversible capacities of 134 and 66 mA·h/g at 0.1 and 10 C, respectively (Fig. 12c), and the capacity can be maintained at 109 mA·h/g after 100 cycles at 0.1 C (Fig. 12d). Meanwhile, during the operation at a high temperature of 60 °C, the ADAPTS electrodes can retain a high stability with a capacity retention of 81% after 80 cycles at 2 C (Fig. 12e).

a Reaction mechanism of ADAPTS. b High-resolution transmission electron microscopy image of ADAPTS. c Rate performance and d galvanostatic charge/discharge profiles of ADAPTS at ambient temperature. e Cycling stability of ADAPTS at 2 C at the temperature of 60 °C. Reproduced with permission [85]. Copyright 2018, Wiley–VCH

Organic Unsaturated C=C Compounds

In several conjugated hydrocarbon compounds, unsaturated C=C bonds can be reversibly reduced to saturated C–C bonds under a low potential. Therefore, organic unsaturated C=C compounds can be used as anode materials for KIBs. As mentioned in Section of Organic Anhydrides, PTCDA [57] can undergo a two-electron transfer reaction based on the carbonyl groups at voltages above 1.5 V versus K+/K. When the voltage was further decreased in the initial discharge process, the other two carbonyl groups of K2PTCDA can accept extra two electrons and K+ at the voltage range of 1.5–0.64 V, transforming into K4PTCDA (Fig. 13a). Moreover, when the voltage further decreased below 0.64 V, K4PTCDA can still deliver a high capacity of ~ 620 mA·h/g with a seven-electron transfer reaction. The capacity delivered below 0.64 V can be attributed to the reaction of unsaturated carbons with K ions. As shown in Fig. 13b, at the voltage range between 0.01 and 3 V, although the initial discharge capacity can reach as high as 890 mA·h/g, the reversible charge capacity was 413 mA·h/g, gradual stabilizing in the subsequent cycles (Fig. 13c). Additionally, Bai et al. [86] reported PTCDI as an anode material in KIBs; this compound can exhibit a reversible capacity of 320 mA·h/g with a six-electron transfer reaction based on carbonyl and unsaturated carbons (Fig. 13d, e). Benefiting from the fast K-ion diffusion coefficient (1 × 10−8 cm2/s) and the low charge-transfer resistance (93 Ohm), PTCDI showed a remarkable rate capability with capacities of 320, 290, 246, and 208 mA·h/g at the current densities of 0.5, 1, 2, and 5 A/g, respectively (Fig. 13f). Meanwhile, the capacity can be maintained at ~ 235 mA·h/g after 100 cycles under 0.5 A/g.

a Reaction mechanism of PTCDA as an anode. b–c Galvanostatic charge/discharge profiles of PTCDA at 10 mA/g. Reproduced with permission [57]. Copyright 2015, Elsevier. d Reaction mechanism of PTCDI as an anode. e Galvanostatic charge/discharge profiles at 0.5 A/g and f rate capability of PTCDI. Reproduced with permission [86]. Copyright 2019, The Royal Society of Chemistry

COFs and MOFs

COFs

COFs are 2D or 3D compounds with high crystallinity and porosity and linked by strong covalent bonds [118]. The COFs containing electrochemically active organic groups can serve as electrode materials. Moreover, the robust framework construction can prevent the dissolution of COFs; the open channels are beneficial for ion diffusion, rendering COFs as promising electrode materials for KIBs. Chen et al. [87] successfully prepared COF-10@CNT (No. 33) by in situ growing of COF-10 on the exterior surface of the CNT (Fig. 14a, b). This method exposed more sites on COF-10@CNT and enabled the fast transport of K+/electrons. Hence, COF-10@CNT demonstrated an outstanding performance with reversible capacities of 330 and 68 mA·h/g at the current densities of 25 and 5000 mA/g, respectively, which were substantially higher than the capacity of COF-10 (203 and 12 mA·h/g) at the same current densities. COF-10@CNT can also retain a reversible capacity of 288 mA·h/g after 500 cycles at 100 mA/g (Fig. 14a). In addition, XPS results proved that the reaction of COF-10@CNT was based on the reversible interaction between the π-electron clouds of benzene rings with K+. Two homologous covalent triazine frameworks (CTFs) with similar chemical compositions and topological structures were developed to investigate the effect of pore size on the electrochemical performance of COFs (Fig. 14c) [88]. CTF-0 (No. 34) with a small pore size delivered high reversible capacities of 152 and 63 mA·h/g at the current densities of 0.05 and 1 A/g, respectively. However, CTF-1 (No. 35) with a high pore size exhibited capacities of 73 and 31 mA·h/g at the corresponding currents densities (Fig. 14d). The low resistance of the SEI film (RSEI) and high ion diffusion coefficient (Dapp) of CTF-0 possibly contributed to its superior electrochemical performance. Ex situ XPS spectra demonstrated that the C=C peak disappeared when discharged to 0.01 V and recovered when charged to 3 V, implying that the reaction of CTF was based on the C=C groups (Fig. 14e). Hence, CTFs and COF-10 can be classified as OEMs based on unsaturated C=C bonds (Section of Organic Unsaturated C=C Compounds).

a Illustration for the formation of COF-10@CNT and cycling stability of COF-10@CNT and COF-10 electrodes at 100 mA/g. b High-resolution transmission electron microscopy images of COF-10@CNT. Reproduced with permission [87]. Copyright 2019, American Chemical Society. c Illustration for the formation of CTFs and their potassiation/depotassiation process. d Rate capability of CTF-0 and CTF-1. e C1s XPS spectra of CTF-0. Reproduced with permission [88]. Copyright 2019, The Royal Society of Chemistry

MOFs

Various MOFs have also been investigated as anode materials for KIBs. The reactions of MOFs can be based on their redox-active metal centers and redox-active ligands [119]. Given the high reversible redox activity and strong coordination with metal ions, terephthalate anion (C8H4O42−) is a classic ligand for building MOFs that can be applied as anode materials [120,121,122]. Interestingly, the electrochemical behavior of small-molecule ligands in MOFs can be enhanced under the influence of transition-metal cations [123]. For example, cobalt terephthalate (CoTP, No. 36) can deliver an abnormally high reversible capacity of up to 700 mA·h/g after 100 cycles in LIBs, whereas the specific capacity of terephthalate is 300 mA·h/g [124, 125]. The enhanced capacity can be attributed to two possible reasons: the reversible redox reaction of Co2+/Co0 and the reaction of unsaturated C=C bonds is activated in the presence of transition-metal cations. Nevertheless, in KIBs, CoTP can only exhibit a normal electrochemical behavior with a reversible capacity of ~ 242 mA·h/g and a low initial CE of 38% (Fig. 15a) [89]. The reaction mechanism of CoTP has been further investigated (Fig. 15b). In the initial discharging process (Step I), Co2+ and TP were reduced to Co and K4TP, respectively, accepting 4 electrons and 4 K+. However, reduced Co cannot be oxidized again. Only the reversible two-electron reaction between K2TP and K4TP can be realized in the sequential process (Step II). The abnormally enhanced capacity of CoTP cannot be successfully realized in KIBs. The acceptable rate performance (66 mA·h/g at 240 mA/g) and cycling stability (112 mA·h/g at 200th cycle) of CoTP electrodes can be achieved with the addition of 10wt% super P. In addition, other TP-based MOFs, such as MIL-125(Ti) (No. 37) and MOF-235(Fe)/MCNTs (No. 38), have also been developed as anode materials for KIBs [90, 91]. Both MOFs exhibited good crystallinity, high surface areas, and large pore volumes. The reaction of these MOFs was based on the reversible reaction of organic terephthalate moiety without the direct engagement of Ti or Fe ions, delivering similar capacities of 153 and 157 mA·h/g for MIL-125(Ti) and MOF-235(Fe)/MCNTs, respectively (Fig. 15c, d). Notably, the two MOFs showed excellent cycling stability. At the current density of 50 mA/g, MIL-125(Ti) demonstrated no capacity decay after 200 cycles (Fig. 15c), whereas MOF-235(Fe)/MCNTs maintained the capacity retention of 92% after 50 cycles.

a Galvanostatic charge/discharge profiles of CoTP at 60 mA/g. b Reaction mechanism of CoTP. Reproduced with permission [89]. Copyright 2017, Elsevier. c Galvanostatic charge/discharge profiles of MIL-125(Ti) at different cycles under 50 mA/g. Reproduced with permission [90]. Copyright 2017, The Royal Society of Chemistry. d Galvanostatic charge/discharge profiles of MOF-235(Fe)/MCNTs at different current densities. Reproduced with permission [91]. Copyright 2020, Elsevier

Summary and Perspective

Although LIBs, NIBs, and KIBs have similar rock-chair principles, the unique properties of K+ render KIBs with outstanding advantages that increase the attractiveness of KIBs as a potential complement for LIBs. However, the insertion of large K ions usually causes severe strain and distortion of the structure of inorganic compounds. Oppositely, the large interstitial space and good structural flexibility of organic materials can promote the diffusion of K+, which can further enable the full use of the characteristic superiority of K-ion systems. As promising materials for KIBs, a variety of OEMs have been researched and developed in recent years, and they have been summarized in this review. In theory, OEMs that have been applied in LIBs can also be used in KIBs. Therefore, most of the studies on OEMs in KIBs were built on the top of the research on OEMs in LIBs, thus significantly reducing research cost. Although OEMs have numerous evident advantages, two major shortages hinder their application in KIBs: (1) high solubility in organic electrolytes and (2) low electronic conductivity. Thus, various measures were utilized to alleviate these drawbacks, including the following: (1) polymerizing small organic molecules and synthesizing organic salt to inhibit the dissolution of OEMs; (2) building π–π conjugated interaction with CNTs/graphene or enhancing π–π conjugated behavior inside the organic molecules to facilitate electron conduction and prevent dissolution; (3) using solid-state or high-concentration electrolytes to inhibit the dissolution of OEMs.

Notably, when using OEMs as cathode materials in KIBs, the redox potential of most carbonyl and imine compounds are lower than that of their inorganic counterparts, such as layered metal oxides and PBAs. In addition, although OEMs based on anion insertion reactions can achieve a high voltage, their specific capacities are relatively low, which also decreases the energy density of full batteries. Hence, future works should focus on improving the potential of K-ion insertion organic compounds and increasing the capacity of anion insertion compounds by molecular engineering. First, in principle, the introduction of electron-withdrawing groups (e.g., –SO3−, –NO2, and –CN)/electron-donating groups (e.g., –OH, –Me, and –OMe) can effectively increase/decrease the redox potential, which is an effective way to increase the energy density of cathode/anode materials, respectively [126]. Second, tuning the position of organic groups is another means to adjust the potential of OEMs. For example, (2,3-dilithium-oxy)-terephthalate (Li4-o-DHT) can demonstrate a significant redox potential gain of 300 mV compared with its para-regioisomer [127]. However, the relation between the configuration and redox potential needs to be further investigated. Third, given that the theoretical capacity of OEMs depends on the number of transferred electrons and the molecular mass of each unit, the molecular structure with less inactive groups is favorable. For example, given its low molecular mass, PTEO can demonstrate the highest theoretical capacity of 147 mA·h/g among cyclic nitroxide compounds [128]. Another serious challenge for carbonyl and imine compounds is the lack of potassium source in pristine state. Given that potassiated carbonyl compounds are air and moisture sensitive, the use of potassiated anode materials is a feasible method. Compared with LiC6, KC8 (potassiated graphite) anode can be easily prepared by multiple methods, such as thermal treatment or solution intercalation; hence, KIBs are attractive for the use of cation-free organic cathodes [14, 129].

For anode materials, most of the organic materials are incomparable with commercial graphite when considering their cost, capacity, operating potential, and stability. However, graphite is inadequate for practical application in KIBs. During insertion, K+ suffers from severe volume charges, which is almost six times greater than the volume expansion during the insertion of Li+ [36]. Meanwhile, alloying and conversion-type anodes suffer from serious volume expansion, causing the pulverization of materials [130, 131]. Hence, these challenges of traditional materials bring huge opportunities for organic anode materials. However, the studies on organic anode materials in KIBs are scarce compared with those on cathode materials. Thus far, the small-molecule K2TP with low cost and low potential, together with several high-stability COFs/MOFs, are promising candidates as organic anode materials for KIBs. However, the low initial CE is a common issue for almost all organic anode materials, and it can be attributed to the irreversible side reactions, such as the formation of SEI or other irreversible reactions. The low initial CE can be alleviated through pretreating electrodes or optimizing electrolytes, such as pre-potassiation [132], optimizing the type/concentration of electrolytes [133], and introducing electrolyte additives [134]. Nevertheless, to date, the studies on the improvement of the initial CE and SEI of organic anode materials in KIBs are scarce and must be given more attention in future research.

In future research, given that the reported OEMs do not fully meet practical requirements, the exploration of new reaction mechanism and novel OEMs should be important research fields. In this process, theoretical chemical calculation and machine learning should be widely used to forecast the properties of OEMs, which can effectively reduce the research cost. Furthermore, the current studies OEMs were tested under laboratory conditions; such condition is far from practical application situation. For practical applications, the low electronic conductivity can not only cause inferior power density but also limit mass loading. More studies should focus on developing new methods to increase electronic conductivities. Moreover, the bulk densities of reported OEMs are usually low (1–2 g/cm3 [40]; that of LiFePO4 is 3.6 g/cm3 [135]), which will reduce the volumetric energy density of practical batteries, further restricting the application in portable devices. Moreover, OEMs have unique advantages in other fields, such as flexibility [136], biodegradability [137], low-temperature operation [138], and high-power batteries [139], which should be given more attention. The affordable cost of organic materials, minimal electrolyte usage, pre-potassiation, etc. should also be considered in future commercialization practices. In general, although OEMs and KIBs are still in their infant stages, and considerable works need to be fulfilled to achieve their satisfactory performance. The development of OEMs still provides a huge opportunity for KIBs, that is, KIBs based on OEMs can be perceived as promising choices in targeted applications.

References

Yang ZG, Zhang JL, Kintner-Meyer MCW et al (2011) Electrochemical energy storage for green grid. Chem Rev 111(5):3577–3613

Lv Z, Ling MX, Yi HM et al (2020) Electrode design for high-performance sodium-ion batteries: coupling nanorod-assembled Na3V2(PO4)3@C microspheres with a 3D conductive charge transport network. ACS Appl Mater Interfaces 12(12):13869–13877

Yi HM, Lin L, Ling MX et al (2019) Scalable and economic synthesis of high-performance Na3V2(PO4)2F3 by a solvothermal–ball-milling method. ACS Energy Lett 4(7):1565–1571

Ji BF, Yao WJ, Zheng YP et al (2020) A fluoroxalate cathode material for potassium-ion batteries with ultra-long cyclability. Nat Commun 11:1225

Zhang WC, Liu YJ, Guo ZP (2019) Approaching high-performance potassium-ion batteries via advanced design strategies and engineering. Sci Adv 5(5):eaav7412

Debnath S, Phan C, Searles DJ et al (2020) Graphdiyne and hydrogen-substituted graphdiyne as potential cathode materials for high-capacity aluminum-ion batteries. ACS Appl Energy Mater 3(8):7404–7415

Cai Y, Kumar S, Chua R et al (2020) Bronze-type vanadium dioxide holey nanobelts as high performing cathode material for aqueous aluminium-ion batteries. J Mater Chem A 8(25):12716–12722

Greenwood NN, Earnshaw A (2012) Chemistry of the elements. Elsevier, Amsterdam

Marcus Y (1985) Thermodynamic functions of transfer of single ions from water to nonaqueous and mixed solvents: part 3: standard potentials of selected electrodes. Pure Appl Chem 57(8):1129–1132

Matsuura N, Umemoto K, Takeuchi Z (1974) ChemInform abstract: standard potentials of alkali metals, silver, and thallium metal/ion couples in N,N’-dimethylformamide, dimethyl sulfoxide, and propylene carbonate. Chemischer Informationsdienst. https://doi.org/10.1002/chin.197426026

Wu XY, Leonard DP, Ji XL (2017) Emerging non-aqueous potassium-ion batteries: challenges and opportunities. Chem Mater 29(12):5031–5042

Fan L, Ma RF, Zhang QF et al (2019) Graphite anode for a potassium-ion battery with unprecedented performance. Angew Chem Int Ed 58(31):10500–10505

Wang ZH, Selbach SM, Grande T (2014) Van der Waals density functional study of the energetics of alkali metal intercalation in graphite. RSC Adv 4(8):3973–3983

Eftekhari A, Jian ZL, Ji XL (2017) Potassium secondary batteries. ACS Appl Mater Interfaces 9(5):4404–4419

Okoshi M, Yamada Y, Komaba S et al (2017) Theoretical analysis of interactions between potassium ions and organic electrolyte solvents: a comparison with lithium, sodium, and magnesium ions. J Electrochem Soc 164(2):A54–A60

Hosaka T, Kubota K, Hameed AS et al (2020) Research development on K-ion batteries. Chem Rev 120(14):6358–6466

Xue LG, Li YT, Gao HC et al (2017) Low-cost high-energy potassium cathode. J Am Chem Soc 139(6):2164–2167

Zhang CL, Xu Y, Zhou M et al (2017) Batteries: potassium Prussian blue nanoparticles: a low-cost cathode material for potassium-ion batteries. Adv Funct Mater. https://doi.org/10.1002/adfm.201770024

Han J, Li GN, Liu F et al (2017) Investigation of K3V2(PO4)3/C nanocomposites as high-potential cathode materials for potassium-ion batteries. Chem Commun 53(11):1805–1808

Liao JY, Hu Q, He XD et al (2020) A long lifespan potassium-ion full battery based on KVPO4F cathode and VPO4 anode. J Power Sources 451:227739

Jo JH, Choi JU, Park YJ et al (2020) P2-K0.75[Ni1/3Mn2/3]O2 cathode material for high power and long life potassium-ion batteries. Adv Energy Mater 10(7):1903605

Kim H, Kim JC, Bo SH et al (2017) K-ion batteries based on a P2-type K0.6CoO2 cathode. Adv Energy Mater 7(17):1700098

Sun T, Li ZJ, Yang X et al (2019) Imine-rich poly(o-phenylenediamine) as high-capacity trifunctional organic electrode for alkali-ion batteries. CCS Chem 1(4):365–372

Fei HF, Liu YN, An YL et al (2018) Stable all-solid-state potassium battery operating at room temperature with a composite polymer electrolyte and a sustainable organic cathode. J Power Sour 399:294–298

Lv S, Yuan JJ, Chen Z et al (2020) Copper porphyrin as a stable cathode for high-performance rechargeable potassium organic batteries. Chemsuschem 13(9):2286–2294

Liu Y, Lu YX, Xu YS et al (2020) Pitch-derived soft carbon as stable anode material for potassium ion batteries. Adv Mater 32(17):2000505

Chang XQ, Zhou XL, Ou XW et al (2019) Ultrahigh nitrogen doping of carbon nanosheets for high capacity and long cycling potassium ion storage. Adv Energy Mater 9(47):1902672

Ji BF, Zhang F, Wu NZ et al (2017) A dual-carbon battery based on potassium-ion electrolyte. Adv Energy Mater 7(20):1700920

Ding HB, Wang J, Fan L et al (2020) Sn-Sb compounds with novel structure for stable potassium storage. Chem Eng J 395:125147

Huang HW, Wang JW, Yang XF et al (2020) Inside back cover: unveiling the advances of nanostructure design for alloy-type potassium-ion battery anodes via in situ TEM. Angew Chem Int Ed 59(34):14693

Jo CH, Jo JH, Choi JU et al (2020) Oxalate-based high-capacity conversion anode for potassium storage. ACS Sustain Chem Eng 8(9):3743–3750

Huang HW, Cui J, Liu GX et al (2019) Carbon-coated MoSe2/MXene hybrid nanosheets for superior potassium storage. ACS Nano 13(3):3448–3456

Deng QJ, Tian CC, Luo ZB (2020) Atomic layer deposition of Al2O3 on organic potassium terephthalate with enhanced K-storage behavior for K-ion batteries. Ionics 26(4):1805–1812

Inamuddin Boddula R, Asiri AM (2020) Potassium-Ion batteries. Wiley, Hoboken

Sha M, Liu L, Zhao HP et al (2020) Review on recent advances of cathode materials for potassium-ion batteries. Energy Environ Mater 3(1):56–66

Rajagopalan R, Tang YG, Ji XB et al (2020) Advancements and challenges in potassium ion batteries: a comprehensive review. Adv Funct Mater 30(12):1909486

Yin XP, Sarkar S, Shi SS et al (2020) Sodium-ion batteries: recent progress in advanced organic electrode materials for sodium-ion batteries: synthesis, mechanisms, challenges and perspectives. Adv Funct Mater 30(11):2070071

Song ZP, Zhou HS (2013) Towards sustainable and versatile energy storage devices: an overview of organic electrode materials. Energy Environ Sci 6(8):2280

Xu Y, Zhou M, Lei Y (2018) Organic materials for rechargeable sodium-ion batteries. Mater Today 21(1):60–78

Lu Y, Chen J (2020) Prospects of organic electrode materials for practical lithium batteries. Nat Rev Chem 4(3):127–142

Zhang YD, An YF, Yin B et al (2019) A novel aqueous ammonium dual-ion battery based on organic polymers. J Mater Chem A 7(18):11314–11320

Yao ZY, Tang W, Wang XX et al (2020) Synthesis of 1,4-benzoquinone dimer as a high-capacity (501 mAh g−1) and high-energy-density (> 1000 Wh kg−1) organic cathode for organic Li-ion full batteries. J Power Sour 448:227456

Acker P, Rzesny L, Marchiori CFN et al (2019) π-conjugation enables ultra-high rate capabilities and cycling stabilities in phenothiazine copolymers as cathode-active battery materials. Adv Funct Mater 29(45):1906436

Chen HY, Armand M, Demailly G et al (2008) From biomass to a renewable LiXC6O6 organic electrode for sustainable Li-ion batteries. Chemsuschem 1(4):348–355

Poizot P, Gaubicher J, Renault S et al (2020) Opportunities and challenges for organic electrodes in electrochemical energy storage. Chem Rev 120(14):6490–6557

Suga T, Pu YJ, Oyaizu K et al (2004) Electron-transfer kinetics of nitroxide radicals as an electrode-active material. Bull Chem Soc Jpn 77(12):2203–2204

Hwang JY, Myung ST, Sun YK (2018) Recent progress in rechargeable potassium batteries. Adv Funct Mater 28(43):1802938

Tao L, Yang YP, Wang HL et al (2020) Sulfur-nitrogen rich carbon as stable high capacity potassium ion battery anode: performance and storage mechanisms. Energy Storage Mater 27:212–225

Xiong W, Zhang JQ, Xiao Y et al (2020) Oxygen-rich nanoflake-interlaced carbon microspheres for potassium-ion battery anodes. Chem Commun 56(23):3433–3436

Qiu HL, Zhao LN, Asif M et al (2020) SnO2 nanoparticles anchored on carbon foam as a freestanding anode for high performance potassium-ion batteries. Energy Environ Sci 13(2):571–578

Sada K, Barpanda P (2020) P3-type layered K0.48Mn0.4Co0.6O2: a novel cathode material for potassium-ion batteries. Chem Commun 56(15):2272–2275

Yuan K, Ning RQ, Bai MH et al (2020) Prepotassiated V2O5 as the cathode material for high-voltage potassium-ion batteries. Energy Technol 8(1):1900796

Choi JU, Kim J, Jo JH et al (2020) Facile migration of potassium ions in a ternary P3-type K0.5[Mn0.8Fe0.1Ni0.1]O2 cathode in rechargeable potassium batteries. Energy Storage Mater 25:714–723

Sun PF, Bai PX, Chen ZF et al (2020) A lithium-organic primary battery. Small 16(3):1906462

Zhou JW, Yu XZ, Zhou J et al (2020) Polyimide/metal-organic framework hybrid for high performance Al-organic battery. Energy Storage Mater 31:58–63

Häupler B, Wild A, Schubert US (2015) Carbonyls: powerful organic materials for secondary batteries. Adv Energy Mater 5(11):1402034

Chen YN, Luo W, Carter M et al (2015) Organic electrode for non-aqueous potassium-ion batteries. Nano Energy 18:205–211

Xing ZY, Jian ZL, Luo W et al (2016) A perylene anhydride crystal as a reversible electrode for K-ion batteries. Energy Storage Mater 2:63–68

Fan L, Ma RF, Wang J et al (2018) An ultrafast and highly stable potassium-organic battery. Adv Mater 30(51):1805486

Li BF, Zhao J, Zhang ZH et al (2018) Electrolyte-regulated solid-electrolyte interphase enables long cycle life performance in organic cathodes for potassium-ion batteries. Adv Funct Mater 29:1807137

Chen L, Zhao YM (2019) Exploration of p-Na2C6H2O6-based organic electrode materials for sodium-ion and potassium-ion batteries. Mater Lett 243:69–72

Chen L, Liu SH, Wang Y et al (2019) Ortho-di-sodium salts of tetrahydroxyquinone as a novel electrode for lithium-ion and potassium-ion batteries. Electrochim Acta 294:46–52

Zhao Q, Wang JB, Lu Y et al (2016) Oxocarbon salts for fast rechargeable batteries. Angew Chem Int Ed 55(40):12528–12532

Jian ZL, Liang YL, Rodríguez-Pérez IA et al (2016) Poly(anthraquinonyl sulfide) cathode for potassium-ion batteries. Electrochem Commun 71:5–8

Tang M, Wu YC, Chen Y et al (2019) An organic cathode with high capacities for fast-charge potassium-ion batteries. J Mater Chem A 7(2):486–492

Zhou M, Liu MY, Wang J et al (2019) Polydiaminoanthraquinones with tunable redox properties as high performance organic cathodes for K-ion batteries. Chem Commun 55(43):6054–6057

Xiong M, Tang W, Cao B et al (2019) A small-molecule organic cathode with fast charge–discharge capability for K-ion batteries. J Mater Chem A 7(35):20127–20131

Tong ZQ, Tian S, Wang H et al (2020) Tailored redox kinetics, electronic structures and electrode/electrolyte interfaces for fast and high energy-density potassium-organic battery. Adv Funct Mater 30(5):1907656

Hu YY, Ding HB, Bai YX et al (2019) Rational design of a polyimide cathode for a stable and high-rate potassium-ion battery. ACS Appl Mater Interfaces 11(45):42078–42085

Tian BB, Zheng J, Zhao CX et al (2019) Carbonyl-based polyimide and polyquinoneimide for potassium-ion batteries. J Mater Chem A 7(16):9997–10003

Hu Y, Tang W, Yu QH et al (2020) Novel insoluble organic cathodes for advanced organic K-ion batteries. Adv Funct Mater 30(17):2000675

Kapaev RR, Zhidkov IS, Kurmaev EZ et al (2019) Hexaazatriphenylene-based polymer cathode for fast and stable lithium-, sodium- and potassium-ion batteries. J Mater Chem A 7(39):22596–22603

Slesarenko A, Yakuschenko IK, Ramezankhani V et al (2019) New tetraazapentacene-based redox-active material as a promising high-capacity organic cathode for lithium and potassium batteries. J Power Sour 435:226724

Fan L, Liu Q, Xu Z et al (2017) An organic cathode for potassium dual-ion full battery. ACS Energy Lett 2(7):1614–1620

Obrezkov FA, Shestakov AF, Traven VF et al (2019) An ultrafast charging polyphenylamine-based cathode material for high rate lithium, sodium and potassium batteries. J Mater Chem A 7(18):11430–11437

Obrezkov FA, Ramezankhani V, Zhidkov I et al (2019) High-energy and high-power-density potassium ion batteries using dihydrophenazine-based polymer as active cathode material. J Phys Chem Lett 10(18):5440–5445

Li C, Xue J, Huang A et al (2019) Poly(N-vinylcarbazole) as an advanced organic cathode for potassium-ion-based dual-ion battery. Electrochim Acta 297:850–855

Gao HC, Xue LG, Xin S et al (2018) A high-energy-density potassium battery with a polymer-gel electrolyte and a polyaniline cathode. Angew Chem Int Ed 57(19):5449–5453

Xue Q, Li DN, Huang YX et al (2018) Vitamin K as a high-performance organic anode material for rechargeable potassium ion batteries. J Mater Chem A 6(26):12559–12564

Wang C, Tang W, Yao ZY et al (2018) Using an organic acid as a universal anode for highly efficient Li-ion, Na-ion and K-ion batteries. Org Electron 62:536–541

Deng QJ, Pei JF, Fan C et al (2017) Potassium salts of para-aromatic dicarboxylates as the highly efficient organic anodes for low-cost K-ion batteries. Nano Energy 33:350–355

Li C, Deng QJ, Tan HC et al (2017) Para-conjugated dicarboxylates with extended aromatic skeletons as the highly advanced organic anodes for K-ion battery. ACS Appl Mater Interfaces 9(33):27414–27420

Wang C, Tang W, Yao ZY et al (2019) Potassium perylene-tetracarboxylate with two-electron redox behaviors as a highly stable organic anode for K-ion batteries. Chem Commun 55(12):1801–1804

Li C, Xue J, Ma J et al (2018) Conjugated dicarboxylate with extended naphthyl skeleton as an advanced organic anode for potassium-ion battery. J Electrochem Soc 166(3):A5221–A5225

Liang YJ, Luo C, Wang F et al (2019) An organic anode for high temperature potassium-ion batteries. Adv Energy Mater 9(2):1802986

Bai YF, Fu WB, Chen WH et al (2019) Perylenetetracarboxylic diimide as a high-rate anode for potassium-ion batteries. J Mater Chem A 7(42):24454–24461

Chen XD, Zhang H, Ci CG et al (2019) Few-layered boronic ester based covalent organic frameworks/carbon nanotube composites for high-performance K-organic batteries. ACS Nano 13(3):3600–3607

Li SY, Li WH, Wu XL et al (2019) Pore-size dominated electrochemical properties of covalent triazine frameworks as anode materials for K-ion batteries. Chem Sci 10(33):7695–7701

Fan C, Zhao MJ, Li C et al (2017) Investigating the electrochemical behavior of cobalt(II) terephthalate (CoC8H4O4) as the organic anode in K-ion battery. Electrochim Acta 253:333–338

An YL, Fei HF, Zhang Z et al (2017) A titanium-based metal–organic framework as an ultralong cycle-life anode for PIBs. Chem Commun 53(59):8360–8363

Deng QJ, Feng SS, Hui P et al (2020) Exploration of low-cost microporous Fe(III)-based organic framework as anode material for potassium-ion batteries. J Alloy Compd 830:154714

Bhosale ME, Chae SD, Kim JM et al (2018) Organic small molecules and polymers as an electrode material for rechargeable lithium ion batteries. J Mater Chem A 6(41):19885–19911

Strietzel C, Sterby M, Huang H et al (2020) An aqueous conducting redox-polymer-based proton battery that can withstand rapid constant-voltage charging and sub-zero temperatures. Angew Chem Int Ed 59(24):9631–9638

Lee J, Kim H, Park MJ (2016) Long-life, high-rate lithium-organic batteries based on naphthoquinone derivatives. Chem Mater 28(7):2408–2416

Huang WW, Zheng SB, Zhang XQ et al (2020) Synthesis and application of Calix[6]quinone as a high-capacity organic cathode for plastic crystal electrolyte-based lithium-ion batteries. Energy Storage Mater 26:465–471

Kim H, Kwon JE, Lee B et al (2015) High energy organic cathode for sodium rechargeable batteries. Chem Mater 27(21):7258–7264

Guo CY, Zhang K, Zhao Q et al (2015) High-performance sodium batteries with the 9,10-anthraquinone/CMK-3 cathode and an ether-based electrolyte. Chem Commun 51(50):10244–10247

Kwabi DG, Lin KX, Ji YL et al (2018) Alkaline quinone flow battery with long lifetime at pH 12. Joule 2(9):1894–1906

Hu B, Luo J, Hu MW et al (2019) A pH-neutral, metal-free aqueous organic redox flow battery employing an ammonium anthraquinone anolyte. Angew Chem Int Ed 58(46):16629–16636

Zhao Q, Huang WW, Luo ZQ et al (2018) High-capacity aqueous zinc batteries using sustainable quinone electrodes. Sci Adv 4(3):eaao1761

Petronico A, Bassett KL, Nicolau BG et al (2018) Toward a four-electron redox quinone polymer for high capacity lithium ion storage. Adv Energy Mater 8(5):1700960

Song ZP, Qian YM, Liu XZ et al (2014) A quinone-based oligomeric lithium salt for superior Li–organic batteries. Energy Environ Sci 7(12):4077–4086

Wang DP, Zhang ZA, Hong B et al (2019) Self-sacrificial organic lithium salt enhanced initial Coulombic efficiency for safer and greener lithium-ion batteries. Chem Commun 55(72):10737–10739

Zhao Q, Guo CY, Lu Y et al (2016) Rechargeable lithium batteries with electrodes of small organic carbonyl salts and advanced electrolytes. Ind Eng Chem Res 55(20):5795–5804

Li D, Tang W, Wang C et al (2019) A polyanionic organic cathode for highly efficient K-ion full batteries. Electrochem Commun 105:106509

Zhao J, Yang JX, Sun PF et al (2018) Sodium sulfonate groups substituted anthraquinone as an organic cathode for potassium batteries. Electrochem Commun 86:34–37

Yokoji T, Matsubara H, Satoh M (2014) Rechargeable organic lithium-ion batteries using electron-deficient benzoquinones as positive-electrode materials with high discharge voltages. J Mater Chem A 2(45):19347–19354

Wan W, Lee H, Yu XQ et al (2014) Tuning the electrochemical performances of anthraquinone organic cathode materials for Li-ion batteries through the sulfonic sodium functional group. RSC Adv 4(38):19878–19882

Segura JL, Juárez R, Ramos M et al (2015) Hexaazatriphenylene (HAT) derivatives: from synthesis to molecular design, self-organization and device applications. Chem Soc Rev 44(19):6850–6885

Wang M, Tang YB (2018) Dual-ion batteries: a review on the features and progress of dual-ion batteries. Adv Energy Mater 8(19):1870088

Shea JJ, Luo C (2020) Organic electrode materials for metal ion batteries. ACS Appl Mater Interfaces 12(5):5361–5380

Rodríguez-Pérez IA, Ji XL (2017) Anion hosting cathodes in dual-ion batteries. ACS Energy Lett 2(8):1762–1770

Ma T, Liu LJ, Wang JQ et al (2020) Charge storage mechanism and structural evolution of viologen crystals as the cathode of lithium batteries. Angew Chem Int Ed 59(28):11533–11539

Lei KX, Li FJ, Mu CN et al (2017) High K-storage performance based on the synergy of dipotassium terephthalate and ether-based electrolytes. Energy Environ Sci 10(2):552–557

Yu A, Pan QG, Zhang M et al (2020) Fast rate and long life potassium-ion based dual-ion battery through 3D porous organic negative electrode. Adv Funct Mater 30(24):2001440

Luo C, Borodin O, Ji X et al (2018) Azo compounds as a family of organic electrode materials for alkali-ion batteries. Proc Natl Acad Sci U S A 115(9):2004–2009

Luo C, Xu GL, Ji X et al (2018) Reversible redox chemistry of azo compounds for sodium-ion batteries. Angew Chem Int Ed 57(11):2879–2883

Geng KY, He T, Liu RY et al (2020) Covalent organic frameworks: design, synthesis, and functions. Chem Rev 120(16):8814–8933

Zhao R, Liang ZB, Zou RQ et al (2018) Metal-organic frameworks for batteries. Joule 2(11):2235–2259

Wang LP, Mou CX, Sun Y et al (2015) Structure-property of metal organic frameworks calcium terephthalates anodes for lithium-ion batteries. Electrochim Acta 173:235–241

Sun D, Tang YG, Ye DL et al (2017) Tuning the morphologies of MnO/C hybrids by space constraint assembly of Mn-MOFs for high performance Li ion batteries. ACS Appl Mater Interfaces 9(6):5254–5262

Gou L, Hao LM, Shi YX et al (2014) One-pot synthesis of a metal–organic framework as an anode for Li-ion batteries with improved capacity and cycling stability. J Solid State Chem 210(1):121–124

Aragón MJ, León B, Pérez Vicente C et al (2009) Cobalt oxalate nanoribbons as negative-electrode material for lithium-ion batteries. Chem Mater 21(9):1834–1840

Wang LP, Zhao MJ, Qiu JL et al (2017) Metal organic framework-derived cobalt dicarboxylate as a high-capacity anode material for lithium-ion batteries. Energy Technol 5(4):637–642

Armand M, Grugeon S, Vezin H et al (2009) Conjugated dicarboxylate anodes for Li-ion batteries. Nat Mater 8(2):120–125

Schwan S, Schröder D, Wegner HA et al (2020) Substituent pattern effects on the redox potentials of quinone-based active materials for aqueous redox flow batteries. ChemSusChem:cssc.202000454

Gottis S, Barrès AL, Dolhem F et al (2014) Voltage gain in lithiated enolate-based organic cathode materials by isomeric effect. ACS Appl Mater Interfaces 6(14):10870–10876

Oyaizu K, Kawamoto T, Suga T et al (2010) Synthesis and charge transport properties of redox-active nitroxide polyethers with large site density. Macromolecules 43(24):10382–10389

Sconocchia S, Tossici R, Marassi R et al (1998) A plastic KC8/LiMn2O4 lithium-ion battery. Electrochem Solid-State Lett 1(4):159–161

Gabaudan V, Berthelot R, Sougrati MT et al (2019) SnSb versus Sn: improving the performance of Sn-based anodes for K-ion batteries by synergetic alloying with Sb. J Mater Chem A 7(25):15262–15270

Gabaudan V, Berthelot R, Stievano L et al (2018) Inside the alloy mechanism of Sb and Bi electrodes for K-ion batteries. J Phys Chem C 122(32):18266–18273

Vaalma C, Giffin GA, Buchholz D et al (2016) Non-aqueous K-ion battery based on layered K0.3MnO2 and hard carbon/carbon black. J Electrochem Soc 163(7):A1295–A1299

Patra J, Huang HT, Xue WJ et al (2019) Moderately concentrated electrolyte improves solid–electrolyte interphase and sodium storage performance of hard carbon. Energy Storage Mater 16:146–154

Zhang XQ, Cheng XB, Chen X et al (2017) Fluoroethylene carbonate additives to render uniform Li deposits in lithium metal batteries. Adv Funct Mater 27(10):1605989

Wu BR, Ren YH, Li N (2011) LiFePO4 cathode material. Electric vehicles-the benefits and barriers. IntechOpen, pp 199–216

Huang YS, Li K, Liu JJ et al (2017) Three-dimensional graphene/polyimide composite-derived flexible high-performance organic cathode for rechargeable lithium and sodium batteries. J Mater Chem A 5(6):2710–2716

Long HW, Zeng W, Wang H et al (2018) Self-assembled biomolecular 1D nanostructures for aqueous sodium-ion battery. Adv Sci 5(3):1700634

Dong XL, Guo ZW, Guo ZY et al (2018) Organic batteries operated at − 70 °C. Joule 2(5):902–913

Xl Dong, Chen L, Liu JY et al (2016) Environmentally-friendly aqueous Li (or Na)-ion battery with fast electrode kinetics and super-long life. Sci Adv 2(1):e1501038

Acknowledgements

The authors sincerely acknowledge CAS-DOE Collaborative Project (121421KYSB20170032), DICP funding (ZZBS201707) and National Natural Science Foundation of China (21706253).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, M., Lu, W., Zhang, H. et al. Organic Electrode Materials for Non-aqueous K-Ion Batteries. Trans. Tianjin Univ. 27, 1–23 (2021). https://doi.org/10.1007/s12209-020-00274-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-020-00274-4