Abstract

FePS3, a classical 2D layered material with transition metal phosphorous trichalcogenides, was investigated as an anode material for Mg ion batteries. We used density functional theory to calculate the Mg storage properties of FePS3, such as Mg adsorption energy, theoretical specific capacity, average voltage, diffusion energy barriers, volume change, and electronic conductivity. The theoretical specific capacity of the FePS3 monolayer is 585.6 mA h/g with a relatively low average voltage of 0.483 V (vs. Mg/Mg2+), which is favorable to a high energy density. The slight change in volume and good electronic conductivity of bulk FePS3 are beneficial to electrode stability during cycling.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The growing demand for energy sources results in the excessive consumption of limited and nonrenewable fossil fuels, and consequential environmental problems have become increasingly prominent. To address this urgent issue, researchers focused on renewable energies and efficient energy storage systems [1, 2]. As one of the most successful technology for energy storage, rechargeable lithium-ion batteries (LIBs) have been widely applied to scalable energy storage systems, electric vehicles, and portable electronic devices [3,4,5]. Although LIBs have become advanced and widely available rechargeable batteries, they have not been regarded as ideal sustainable sources of energy storage equipment because of the scarcity, high cost, and safety problems of lithium [6, 7]. Magnesium-ion batteries (MIBs) have attracted increasing attention because of their low cost, safety, and natural abundance. The price of Mg (35 $/kg) is lower than that of Li (1500 $/kg), and Mg reserves in the crust (2.33%) are around 350 times larger than Li (0.0065%) [8]. In addition, MIBs exhibit more advantages in the electrochemical process [9, 10]. First, the theoretical volumetric capacity of magnesium (3832 mA h/cm3) is higher than that of lithium (2062 mA h/cm3) [11] because of the divalent nature of Mg ion. Second, dendrite is a serious problem for lithium metal anodes, whereas magnesium metal used as an anode can achieve a dendrite-free deposition during cycling, resulting in a relatively safe cycling process [12]. As such, MIBs have been suggested as possible alternatives to battery technology. However, the reaction of Mg metal with electrolyte species causes an unstable solid electrolyte interface (SEI) and constant electrolyte consumption. Sluggish Mg ion diffusion in host materials due to the divalent nature of the Mg ion results in slow insertion/extraction reaction kinetics [13, 14].

Many efforts have been devoted to developing cathode materials, such as Mo6S8 [15], TiS2 [16], and V2O5 [17], but a few works have designed anode materials, such as Ga [18], Sn [19], and Bi [20, 21], to replace Mg metal. Mo6S8 is one of the best cathode materials because of its good electrochemical performance and compatibility with electrolytes, but the cycling performance of MIBs remains poor because of the anode side of Mg metal, such as the large volume change during the discharge/charge process and sluggish Mg ion diffusion in a dense SEI layer [22]. To our knowledge, the use of layered materials in LIBs can significantly buffer the change in volume and promote Li-ion transfer in an interlayer space [23, 24], and this strategy can be used in MIBs. For example, layered Na2Ti3O7 nanoribbons exhibit an actual reversible capacity of 78 mA h/g at 20 mA/g after 100 cycles [25]. Luo et al. [26] reported that layered Na2Ti6O13 nanowires display a stable capacity of 51.2 mA h/g at 100 mA/g after 300 cycles. Many theoretical calculations have verified that layered materials, such as arsenene [27], MnSb2S4 [28], MXene [29], phosphorene [8], WS2 [30], and C3N4 [31], can be promising anode materials for MIBs. Furthermore, 2D layered transition metal phosphorous trichalcogenides (MPX3, where M = Mn, Fe, Ni, etc., and X = S, Se) have been widely explored because of their interesting physicochemical features, including electronic, magnetic, and superconductive properties [32, 33]. Hitherto, materials from the MPX3 family serve as good candidates for LIBs because of their reversible lithium storage capacity and fast lithium ion/electron conduction [34,35,36]. However, no study has explored the magnesium storage capacity of MPX3 materials.

In this work, theoretical studies on FePS3 anode for MIB application were presented. FePS3, a classical MPX3 material, is expected to be a promising anode for MIBs because of its large specific surface area, abundant active sites, and fast ion diffusion. FePS3 has a moderate electronic conductivity of 10−5 S/cm, which is significantly higher than that of other MPX3 materials, such as MnPS3, NiPS3, and ZnPS3 (around 10−9 S/cm). Herein, density functional theory (DFT) calculations were conducted to analyze Mg adsorption and diffusion properties in an FePS3 monolayer, and the volume change and electronic conductivity of the bulk FePS3 for its potential applications as an anode candidate for MIBs.

Computational Details

All calculations were carried out using the Cambridge Sequential Total Energy (CASTEP) package within the DFT framework in the Materials Studio Version 5.5. Generalized gradient approximation with Perdew–Burke–Ernzerhof functional (GGA–PBE) was used for the exchange correlation energy. An ultrasoft pseudopotential was used and the energy tolerance in the self-consistent field (SCF) calculations was 2 × 10−6 eV/atom. The convergence conditions were set as 2 × 10−5 eV/atom for the energy change, 0.05 eV/Å for the force change, 2 × 10−3 Å for the atomic displacement and 0.05 Å−1 for the K-point separations. The structure was relaxed using 4 × 4 × 1 (monolayer FePS3) and 4 × 4 × 3 (bulk FePS3) K-point meshes.

Results and Discussion

Adsorption of Mg on an FePS3 Monolayer

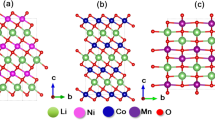

The relaxed structure of the FePS3 monolayer is displayed in Fig. 1a, b. Similar to other MPX3 materials, FePS3 shows a sandwich structure with Fe atoms in the middle of monolayer. Each Fe atom bonds with three S atoms on the upper side of the FePS3 monolayer and three S atoms on the lower side. Each P atom bonds with three S atoms and another P atom. Each S atom is situated in the same chemical environment with two S–Fe bonds and one S–P bond. The lengths of S–Fe, S–P, and P–P bonds are about 2.520, 2.045, and 2.195 Å, respectively. The lattice constants of the primitive FePS3 cell is a = b=5.932 Å. A 2 × 2 supercell was used to explore the adsorption properties of the FePS3 monolayer. A Mg atom was initially placed at different sites on the surface of the FePS3 monolayer with a certain distance of 1.50 Å. Figure 1a shows the possible sites at Fe, P, and S atoms and a hollow position, which are denoted as Fe, P, S, and H sites, respectively. Figure 1c illustrates the structures of the FePS3 monolayer loaded with a Mg atom before and after geometric optimization. Mg adsorbed at S and H sites moves to the same position after structure relaxation. Adsorption energy (Eads) was calculated with the following expression to find the most stable structure of the FePS3 monolayer loaded with Mg:

where EFePS3 and Etotal represent the energy of the FePS3 monolayer before and after loading Mg, respectively, and EMg is the energy of single Mg atom. In Table 1, the largest adsorption energy (−4.45 eV) occurs at the Fe site, and the second stable adsorption energy (−4.39 eV) corresponds to the H site. The spatial distribution of the difference in the charge density of the FePS3 monolayer (Fig. 1d) was used to explain the reason for the most stable structure of Mg adsorbed at the Fe site. Blue and yellow correspond to electron-accumulated and electron-depleted regions, respectively. Obviously, the electron-accumulated regions are at S atoms around Fe sites, which are beneficial to Mg loading. Therefore, the most stable structure is Mg adsorbed at the Fe site with three Mg–S bonds. The distances between Mg and adjacent S atoms are summarized in Table 1. The smallest distances of Mg atom with surrounded S atoms are at the Fe site, further indicating that the most stable structure is Mg adsorbed at the Fe site. The charge density difference slice map (Fig. 1e) was used to explore the nature of the Mg–S bond. Electrons tend to move close to S, indicating that the Mg–S bond approaches a polar ionic bond. The Mulliken charge of Mg (Table 1) was calculated to confirm the charge transfer from S to Mg. The Mulliken charge value of Mg at the Fe site is 1.08 |e|, which is apparently larger than that of other sites, proving that more charge transfers occur. In summary, Mg prefers to be adsorbed at the Fe site of the FePS3 monolayer to form the most stable structure.

a Top and b side views of the optimized structures of the FePS3 monolayer and the possible sites for Mg adsorption, c Structures of the FePS3 monolayer with Mg loaded at different sites before (left) and after structure relaxation (right), d Spatial distribution of charge density difference of the FePS3 monolayer, e The charge density difference slice map of the FePS3 monolayer absorbed with Mg. Blue, yellow, pink, and green balls represent Fe, S, P, and Mg atoms, respectively

Theoretical Specific Capacity and Voltage Profile of the FePS3 Monolayer

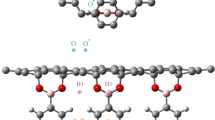

In MgxFePS3, x represents the concentration of Mg in the FePS3 monolayer. The optimized structures of MgxFePS3 with different x values are depicted in Fig. 2a. Mg atoms are initially placed at Fe sites on one side of the FePS3 monolayer by using a 2 × 2 supercell. Obviously, all the Fe sites on one side are successfully occupied with eight Mg atoms corresponding to the formula of MgFePS3. Afterward, the meta-stable H sites on the same side are also considered to load Mg after the Fe sites are fully occupied. However, the Mg atoms cannot be embedded at the H sites because all Mg atoms at H sites are extruded out of the FePS3 surface after structure relaxation (Fig. 2b). Mg storage on the double sides of the FePS3 monolayer was calculated on the basis of the basic structure (MgFePS3) in which Fe sites were fully occupied with Mg atoms on one side to obtain the maximum capacity. On the other side, both H sites and Fe sites can absorb Mg ion. In Fig. S1, the structure of the FePS3 monolayer irreversibly deforms when the H sites are fully occupied with Mg, indicating thermodynamic instability. By contrast, the structure of the FePS3 monolayer slightly changes when the Fe sites on both sides are fully occupied with Mg. This result indicates a stable structure, corresponding to the formula of Mg2FePS3 (Figs. 2c and S1). Figure 2d shows the adsorption energies of MgxFePS3 with an increasing absolute x (from 1/8 to 2). Obviously, the absolute value of adsorption energy gradually decreases as Mg concentration increases due to repulsive interactions between adjacent Mg cations. As a consequence, the maximum Mg concentration in the FePS3 monolayer corresponds to the formula of Mg2FePS3 with a theoretical specific capacity of 585.6 mA h/g.

a Configurations of the schematic of MgxFePS3 with Mg adsorbed on one side of the FePS3 monolayer (x = 1/8 ~ 1); b Optimized structure of the FePS3 monolayer with Mg adsorbed on both Fe and H sites on the same side; c Configurations of the schematic of Mg2FePS3 with Mg adsorbed on both sides of the FePS3 monolayer; d Adsorption energies with respect to Mg concentration; e Voltage profile with respect to Mg content from 0 to 2

Open-circuit voltage (OCV) is another important parameter for evaluating the electrochemical properties of rechargeable batteries. OCV can be obtained by calculating the average voltage (Vavg) within the range of x1 < x<x2 in MgxFePS3. Vavg was calculated with the following expression:

where E(\({\text{Mg}}_{{x_{2} }} {\text{FePS}}_{3}\)) and \(E\left( {{\text{Mg}}_{{x_{1} }} {\text{FePS}}_{3} } \right)\) represent the energies of \({\text{Mg}}_{{x_{2} }} {\text{FePS}}_{3}\) and \({\text{Mg}}_{{x_{1} }} {\text{FePS}}_{3}\), respectively; E(Mg) is the energy of Mg; and e is the fundamental charge. In Fig. 2e, Vavg decreases as Mg concentration increases, and Vavg of the FePS3 monolayer is ~ 0.483 V (vs. Mg/Mg2+). This result indicates that the FePS3 monolayer is a suitable anode material for Mg ion batteries. Besides, Vavg of the FePS3 monolayer is relatively lower than that of other anode materials, such as arsenene monolayer 0.83 V (vs. Mg/Mg2+) [24], phosphorene 0.833 V (vs. Mg/Mg2+) [8], and MnSb2S4 monolayer 0.77 V (vs. Mg/Mg2+) [25], which is beneficial to achieving a high power density in full batteries.

Mg Diffusion on the FePS3 Monolayer Surface

The transport property of Mg ion affects the electrochemical reaction kinetics of Mg ion batteries. Therefore, the diffusion behavior of Mg ion on the surface of an FePS3 monolayer should be understood. In this work, the linear synchronous transit/quadratic synchronous transit (LST/QST) method was used to evaluate the energy barriers of Mg ion diffusion through different paths. In Fig. 3a–c, three possible diffusion paths are found between two equilibrium Fe sites in the FePS3 monolayer. Path 1 is between the adjacent Fe sites (Fig. 3a), path 2 corresponds to adjacent secondary Fe sites (Fig. 3b), and path 3 connects the two Fe sites at the diagonal side of a hexagon (Fig. 3c). The calculated energy profiles of three diffusion paths are shown in Fig. 3d–f. Obviously, the results show that path 3 has a minimum energy barrier of 1.183 eV. The diffusion energy barriers of Mg ion along paths 1 and 2 are 1.426 eV and 1.620 eV, respectively. Accordingly, Mg ion tends to migrate between the Fe sites at the diagonal side of the hexagon, and the relatively low energy barrier contributes to fast ionic diffusion and electrochemical reaction kinetics.

Mg Storage Properties of Bulk FePS3

The Mg storage properties in bulk FePS3 were also tested. In Fig. 4a, bulk FePS3 exhibits an A–A stacking model after structure relaxation. Mg was placed at the middle of the Fe sites at two consecutive layers in bulk FePS3 in consideration of the characteristics of Mg storage in the FePS3 monolayer. The maximum Mg storage capacity corresponds to the formula of MgFePS3 with a theoretical specific capacity of 292.8 mA h/g. The volumetric expansion of electrode materials causes the pulverization of electrodes and unstable SEI films. The change in volume was investigated on the basis of the changes in crystal cell parameters and interlamellar space in bulk FePS3. In Fig. 4a, the distance between two Fe atoms in the two adjacent layers in the original bulk FePS3 is 7.356 Å. After Mg insertion, the distance between the two Fe atoms decreases to 5.979 Å (Fig. 4b), indicating the volume reduction in the z axial direction. Lattice constant is also an important parameter to express the change in the volume of the bulk FePS3. The lattice constants (1 × 1 cell) of FePS3 and MgFePS3 are summarized in Fig. 4e. In particular, the constants increase by 15.6% and 8.0% for a and b, respectively, whereas the constant decreases by 18.7% for c. This finding is consistent with the decrease in the interlayer space. The lattice volume of bulk FePS3 changes from 215.48 to 206.70 Å3 after Mg insertion, indicating that the volume of FePS3 has a little shrink but not expansion for magnesiation process. The small volumetric change is beneficial to the structural integrity of electrodes during the insertion/extraction of Mg ion.

Volume reduction mainly results from a decrease in the interlayer space in bulk FePS3. Electron localization function (ELF) slice maps (Fig. 4c, d) were used to explain the phenomenon of interlayer space reduction after Mg insertion. In Fig. 4c, almost no electrons are localized at the interlayer in bulk FePS3, illustrating that the interlayer interaction mainly belongs to van der Waals forces. When a Mg atom inserts into the interlayer of bulk FePS3, electrons tend to distribute between Mg atoms and FePS3 layers. The interlayer force becomes electrostatic interaction, which is stronger than van der Waals forces, leading to a reduction in the interlayer distance. The Mg diffusion behavior in the interlayer of bulk FePS3 was also calculated. In Fig. S2, unlike the Mg diffusion behavior on the surface of the FePS3 monolayer, Mg cannot diffuse along paths 2 and 3 but prefers to diffuse along path 1 during the transition state search process. Diffusion behavior differs possibly because the limited space between FePS3 layers restricts the diffusion of Mg ion at a long distance, such as paths 2 and 3. Therefore, Mg ion tends to migrate through path 1 with a short diffusion distance (Fig. S3), and the corresponding diffusion energy barrier is 1.557 eV. Another important parameter affecting the electrochemical performance of rechargeable batteries is the electronic conductivity of electrode materials. The electronic conductivities of bulk FePS3 and MgFePS3 were evaluated in terms of density of states (DOS). In Fig. 4f, the electronic state at a Fermi level is not zero for FePS3 and MgFePS3, indicating that they exhibit a metallic behavior. In Fig. S4, the band gap of bulk MgFePS3 (0.306 eV) is smaller than that of bulk FePS3 (0.550 eV), demonstrating that the insertion of Mg ion in the interlayer of bulk FePS3 can improve electronic conductivity.

Conclusions

In this work, DFT calculations were conducted to investigate various electrochemical properties of 2D layered FePS3 for Mg storage. FePS3 can be used as an anode material for Mg ion batteries because of the following advantages: (1) Mg can be loaded at Fe sites in FePS3 with a stable structure and high theoretical specific capacities of 585.6 mA h/g for monolayers and 292.8 mA h/g for bulk materials. (2) It can provide a relatively low voltage of 0.483 V (vs. Mg/Mg2+), contributing a high power density in full batteries. (3) The volumetric change in FePS3 is only 4.0% for full Mg insertion, and both FePS3 and its reduction products of MgFePS3 exhibit good electronic conductivity, which are beneficial to cycling stability and high-rate performance, respectively.

References

Dunn B, Kamath H, Tarascon JM (2011) Electrical energy storage for the grid: a battery of choices. Science 334(6058):928–935

Liu J, Zhang JG, Yang ZG et al (2013) Materials science and materials chemistry for large scale electrochemical energy storage: from transportation to electrical grid. Adv Funct Mater 23(8):929–946

Li H, Wang ZX, Chen LQ et al (2009) Research on advanced materials for Li-ion batteries. Adv Mater 21(45):4593–4607

Etacheri V, Marom R, Elazari R et al (2011) Challenges in the development of advanced Li-ion batteries: a review. Energy Environ Sci 4(9):3243

Liu C, Wang YH, Sun J et al (2020) A review on applications of layered phosphorus in energy storage. Trans Tianjin Univ 26(2):104–126

Li L, Lu Y, Zhang Q et al (2019) Recent progress on layered cathode materials for nonaqueous rechargeable magnesium batteries. Small. https://doi.org/10.1002/smll.201902767

Rashad M, Asif M, Wang YX et al (2020) Recent advances in electrolytes and cathode materials for magnesium and hybrid-ion batteries. Energy Storage Mater 25:342–375

Han XP, Liu C, Sun J et al (2018) Density functional theory calculations for evaluation of phosphorene as a potential anode material for magnesium batteries. RSC Adv 8(13):7196–7204

Wei LY, Lian RQ, Zhao YY et al (2020) Experimental investigation and first-principles calculations of a Ni3Se4 cathode material for Mg-ion batteries. ACS Appl Mater Interfaces 12(8):9316–9321

Asif M, Rashad M, Shah JH et al (2020) Surface modification of tin oxide through reduced graphene oxide as a highly efficient cathode material for magnesium-ion batteries. J Colloid Interface Sci 561:818–828

Kong L, Yan C, Huang JQ et al (2018) A review of advanced energy materials for magnesium-sulfur batteries. Energy Environ Mater 1(3):100–112

Li YQ, Zuo PJ, Li RN et al (2019) Electrochemically-driven interphase conditioning of magnesium electrode for magnesium sulfur batteries. J Energy Chem 37:215–219

Wu DH, Yang BC, Chen HY et al (2019) Mechanical deformation induced charge redistribution to promote the high performance of stretchable magnesium-ion batteries based on two-dimensional C2N anodes. Nanoscale 11(33):15472–15478

Deng XW, Xu YN, An QY et al (2019) Manganese ion pre-intercalated hydrated vanadium oxide as a high-performance cathode for magnesium ion batteries. J Mater Chem A 7(17):10644–10650

Lancry E, Levi E, Gofer Y et al (2004) Leaching chemistry and the performance of the Mo6S8 cathodes in rechargeable Mg batteries. Chem Mater 16(14):2832–2838

Tao ZL, Xu LN, Gou XL et al (2004) TiS2 nanotubes as the cathode materials of Mg-ion batteries. Chem Commun 18:2080

Drosos C, Jia CL, Mathew S et al (2018) Aerosol-assisted chemical vapor deposition of V2O5 cathodes with high rate capabilities for magnesium-ion batteries. J Power Sour 384:355–359

Wang L, Welborn SS, Kumar H et al (2019) High-rate and long cycle-life alloy-type magnesium-ion battery anode enabled through (De) magnesiation-induced near-room-temperature solid–liquid phase transformation. Adv Energy Mater 9(45):1902086

Yaghoobnejad Asl H, Fu JT, Kumar H et al (2018) In situ dealloying of bulk Mg2Sn in Mg-ion half cell as an effective route to nanostructured Sn for high performance Mg-ion battery anodes. Chem Mater 30(5):1815–1824

Kravchyk KV, Piveteau L, Caputo R et al (2018) Colloidal bismuth nanocrystals as a model anode material for rechargeable Mg-ion batteries: atomistic and mesoscale insights. ACS Nano 12(8):8297–8307

Lee J, Monserrat B, Seymour ID et al (2018) An ab initio investigation on the electronic structure, defect energetics, and magnesium kinetics in Mg3Bi2. J Mater Chem A 6(35):16983–16991

Huie MM, Bock DC, Takeuchi ES et al (2015) Cathode materials for magnesium and magnesium-ion based batteries. Coord Chem Rev 287:15–27

Julien C, Mauger A, Zaghib K et al (2016) Optimization of layered cathode materials for lithium-ion batteries. Materials 9(7):595

Deng YP, Wu ZG, Liang RL et al (2019) Layer-based heterostructured cathodes for lithium-ion and sodium-ion batteries. Adv Funct Mater 29(19):1808522

Chen CC, Wang JB, Zhao Q et al (2016) Layered Na2Ti3O7/MgNaTi3O7/Mg0.5NaTi3O7 nanoribbons as high-performance anode of rechargeable Mg-ion batteries. ACS Energy Lett 1(6):1165–1172

Luo L, Zhen YC, Lu YZ et al (2020) Structural evolution from layered Na2Ti3O7 to Na2Ti6O13 nanowires enabling a highly reversible anode for Mg-ion batteries. Nanoscale 12(1):230–238

Ye XJ, Zhu GL, Liu J et al (2019) Monolayer, bilayer, and heterostructurearsenene as potential anode materials for magnesium-ion batteries: a first-principles study. J Phys Chem C 123(25):15777–15786

Zhang ZZ, Zhang YF, Li Y et al (2018) MnSb2S4 monolayer as an anode material for metal-ion batteries. Chem Mater 30(10):3208–3214

Xie Y, Dall’Agnese Y, Naguib M et al (2014) Prediction and characterization of MXene nanosheet anodes for non-lithium-ion batteries. ACS Nano 8(9):9606–9615

Vakili-Nezhaad GR, Gujarathi AM, Al Rawahi N et al (2019) Performance of WS2 monolayers as a new family of anode materials for metal-ion (Mg, Al and Ca) batteries. Mater Chem Phys 230:114–121

Zhang JH, Liu G, Hu HC et al (2019) Graphene-like carbon–nitrogen materials as anode materials for Li-ion and Mg-ion batteries. Appl Surf Sci 487:1026–1032

Chittari BL, Park Y, Lee D et al (2016) Electronic and magnetic properties of single-layer MPX3 metal phosphorous trichalcogenides. Phys Rev B 94(18):184428

Kargar F, Coleman EA, Ghosh S et al (2020) Phonon and thermal properties of quasi-two-dimensional FePS3 and MnPS3 antiferromagnetic semiconductors. ACS Nano 14(2):2424–2435

Brec R, Schleich DM, Ouvrard G et al (1979) Physical properties of lithium intercalation compounds of the layered transition-metal chalcogenophosphites. Inorg Chem 18(7):1814–1818

Wang M, Tang KB (2019) A facile synthesis of FePS3@C nanocomposites and their enhanced performance in lithium-ion batteries. Dalton Trans 48(12):3819–3824

Fujii Y, Miura A, Rosero-Navarro NC et al (2018) Reaction mechanism of FePS3 electrodes in all-solid-state lithium secondary batteries using sulfide-based solid electrolytes. J Electrochem Soc 165(13):A2948–A2954

Acknowledgements

This work was supported by Tianjin Science and Technology Project (19YFSLQY00070), the National Natural Science Foundation of China (No. 21878216), the Opening Foundation of State Key Laboratory of Organic-Inorganic Composites, Beijing University of Chemical Technology (oic-201901004, oic-201801003).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cao, Y., Pan, F., Wang, H. et al. Density Functional Theory Calculations for the Evaluation of FePS3 as a Promising Anode for Mg Ion Batteries. Trans. Tianjin Univ. 26, 248–255 (2020). https://doi.org/10.1007/s12209-020-00253-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-020-00253-9