Abstract

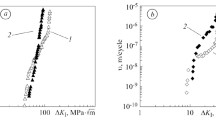

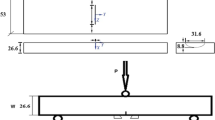

The paper presents the results of verification calculation on the crack resistance of a high-pressure cylinder taken out of service due to the detection of crack-like defect. The critical dimensions of cracks, at which brittle failure of the cylinder can occur, and the safety coefficient of the cylinder in terms of crack resistance, are determined. Based on the provisions of linear fracture mechanics, back in the XIX century it was established that the causes of the failure of high-strength materials are crack-like defects of the operational or the technological origin. The causes of these defects can be operational impacts (vibration, cyclic loading and aggressive environments) and design and technological factors (welding, rolling, heat treatment, etc.). One of the actual problems of theoretical and experimental research of reliability of structural materials in industrial equipment is to study influence of the internal and the surface semi-elliptic cracks on safety of their operation.

Similar content being viewed by others

References

I. S. Raju and J. C. Newman Jr, Stress-intensity factors for a wide range of semi-elliptical surface cracks in finite-thickness plates, Engineering Fracture Mechanics, 11 (4) (1979) 817–829, https://doi.org/10.1016/0013-7944(79)90139-5.

N. Lautrou, D. Thevenet and J. Y. Cognard, Fatigue crack initiation life estimation in a steel welded joint by the use of a two - scale damage model, Fatigue and Fracture of Engineering Materials and Structures, 32 (5) (2009) 403–417, https://doi.org/10.1111/j.1460-2695.2009.01344.x.

J. Martinsson, Automatic 3D crack propagation in complex welded structures, 15th European Conference on Fracture, Sweden (2004) 1–9, http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.866.3121&rep=rep1&type=pdf.

D. F. Sarzosa, L. B. Godefroid and C. Ruggieri, Fatigue crack growth assessments in welded components including crack closure effects: experiments and 3-D numerical modeling, International Journal of Fatigue, 47 (2013) 279–291, https://doi.org/10.1016/j.ijfatigue.2012.09.009.

A. A. Gerasimenko, Prediction of the residual life of vertical steel tanks by the parameters of cyclic crack resistance under biaxial loading, Dessertation, Saint Petersburg Mining University, Saint Petersburg, Russia (2014) https://www.elibrary.ru/item.asp?id=30409344.

A. K. Head, XCVIII. The growth of fatigue cracks, The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, 44 (356) (1953) 925–938, https://doi.org/10.1080/14786440908521062.

B. N. Arzamasov, I. I. Sidorin and G. F. Kosolapov, Materials Science: Textbook for Higher Technical Educational Institutions, Mechanical Engineering, Moscow, Russia (1986) https://obuchalka.org/20210511132274/materialovedenie-uchebnik-dlyavisshih-tehnicheskih-uchebnih-zavedenii-arzamasov-b-n-sidorin-i-i-kosolapov-g-f-1986.html.

C. S. Kim, K. S. Hong and M. K. Kim, Nonlinear robust control of a hydraulic elevator, Control Engineering Practice, 13 (6) (2005) 789–803.

A. P. Guriev, D. V. Kozlov and N. V. Khanov, Analysis of the materials of the act of technical investigation of the causes of the accident at the sayano-shushenskaya hydroelectric power plant, Hydropower Engineering, 4 (2011) 40, http://lib.hydropower.ru/books/doc_00040061.pdf.

State Standard GOST 25.506-85, Design, Calculation and Strength Testing, Methods of Mechanical Testing of Metals, Determination of Fracture Toughness Characteristics Under the Static Loading, Moscow, USSR (1986) https://docs.cntd.ru/document/1200004652.

P. Paris and F. Erdogan, A critical analysis of crack propagation laws, Journal of Basic Engineering, 85 (4) (1963) 528–534, https://doi.org/10.1115/1.3656900.

P. M. Scott and T. W. Thorpe, A critical review of crack tip stress intensity factors for semi - elliptic cracks, Fatigue and Fracture of Engineering Materials and Structures, 4 (4) (1981) 291–309, https://doi.org/10.1111/j.1460-2695.1981.tb01127.x.

R. S. Chandel and S. R. Bala, Effect of welding parameters and groove angle on the soundness of root beads deposited by the SAW process, Proceedings of an International Conference on Trends in Welding Research, Gatlinburg, Tennessee, USA (1986) 479–385.

K. G. Kodancha and S. K. Kudari, Variation of stress intensity factor and elastic T-stress along the crack-front in finite thickness plates, Frattura ed Integrità Strutturale, 3 (8) (2009) 45–51, https://doi.org/10.3221/IGF-ESIS.08.04.

J. Qu and X. Wang, Solutions of T-stresses for quarter-elliptical corner cracks in finite thickness plates subject to tension and bending, International Journal of Pressure Vessels and Piping, 83 (8) (2006) 593–606, https://doi.org/10.1016/j.ijpvp.2006.04.003.

Y. Murakami, Handbook on Stress Intensity Factors, Mir, Moscow, USSR, 2 (1990) https://dl.booksee.org/genesis/835000/70af400a9a5dbbbc2618306d5915cdc5/_as/[Murakami_YUkitaki;_Goldshtein,_R.V.;_Mahutov,_N.A(BookSee.org).pdf.

K. A. Vansovich, Elastoplastic model of surface fatigue crack growth in thick-walled structures under biaxial loading, Engineering Journal: Science and Innovations, 3 (63) (2017) 4, https://cyberleninka.ru/article/n/uprugoplasticheskaya-model-rosta-ustalostnyh-poverhnostnyh-treschin-v-tolstostennyh-konsstruktsiyah-pri-dvuhosnom-nagruzhenii.

S. Kalpakjian and S. R. Schmid, Manufacturing Processes for Engineering Materials, 2nd Ed., Addison-Wesley Publishing Company, New York, USA (1992).

State Standard GOST 12247-80, Large Seamless Steel Gas Cylinders for Operating Pressure of 31, 4 and 39, 2 MPa (320 and 400 kgf/cm), Specifications, Moscow, USSR (1982) https://docs.cntd.ru/document/1200007364.

State Standard GOST 4543-71, Structural Alloy Steel Bars. Specifications, Moscow, USSR (1973) https://docs.cntd.ru/document/1200005485.

N. A. Makhutov, Industrial Safety and Risk Monitoring: Tanks for the Storage of Explosive and Fire Hazardous Substances, Science, Moscow, Russia (2012) https://search.rsl.ru/ru/record/01005429071.

R. C. Shah and A. S. Kobayashi, Stress intensity factors for an elliptical crack approaching the surface of a semi-infinite solid, International Journal of Fracture, 9 (2) (1973) 133–146, https://link.springer.com/article/10.1007/BF00041855.

F. W. Smith and D. R. Sorensen, The semi-elliptical surface crack—A solution by the alternating method, International Journal of Fracture, 12 (1) (1976) 47–57, https://link.springer.com/article/10.1007/BF00036008.

K. Hayashi and H. Abe, Stress intensity factors for a semi-elliptical crack in the surface of a semi-infinite solid, International Journal of Fracture, 16 (3) (1980) 275–285, https://link.springer.com/article/10.1007/BF00013383.

M. Abramovitz and I. Stigan, Special Functions Reference with Formulas, Graphs and Tables, Science, Moscow, USSR (1979) https://www.nehudlit.ru/books/spravochnik-pospetsialnym-funktsiyam-s-formulami-grafikami-i-tablitsami.html.

State Standard GOST 9.903-81, Unified System of Corrosion and Ageing Protection, High-Strength Steels and Alloys, Accelerated Test Methods for Corrosion Cracking, Moscow, USSR (1982) https://docs.cntd.ru/document/1200015050.

V. I. Ivanov and V. M. Belov, Acoustic Emission Control of Welding and Welded Joints, Mashinostroenie (1981) https://www.studmed.ru/ivanov-vi-belov-vm-akustikoemissionnyy-kontrol-svarki-i-svarnyh-soedineniy_1cde1c8c0c7.html.

S. S. Kuleshov, V. P. Kosarev and O. A. Merenkov, Evaluation of the technical condition and forecasting of the residual life of lifting machines, In Situ, 1–2 (2016) 91–93, https://cyberleninka.ru/article/n/otsenka-tehnicheskogo-sostoyaniya-i-prognozirovanie-ostatochnogo-resursa-gruzopodemnyh-mashin.

A. I. Gnevko, Fundamentals of Technical Diagnostics of Military Equipment, Military Academy of Strategic Missile Forces named after Peter the Great, Moscow (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Valery V. Spiryagin is Ph.D. in Technical Sciences, Senior Lecturer of Moscow Aviation Institute (National Research University), Moscow, Russian Federation. His research interests include environmental protection and rational use and ecology.

Rights and permissions

About this article

Cite this article

Spiryagin, V.V. Method for assessing the effect of crack-like defects on the performance of high-pressure cylinders. J Mech Sci Technol 37, 2903–2909 (2023). https://doi.org/10.1007/s12206-023-0516-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-023-0516-4