Abstract

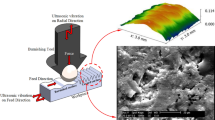

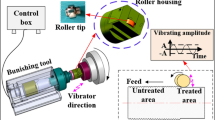

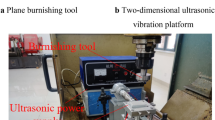

A 2D ultrasonic burnishing technology was employed to strengthen 7075 aluminum alloy. The running-in experiments for original and burnished samples were implemented, and the running-in performance was explored qualitatively and quantitatively. The results show that the worn surface of an original sample exhibited the peelings, scratches, and abrasive particles, yet the wear form of a burnished sample was relatively single, mainly with scratches. The quantitative parameter “maximum distance between phase points dmax” was calculated. During the friction and wear process, the dmax of friction coefficient signal displayed the variation of first decreasing and then stabilizing, which was consistent with the running-in and steady-state stages of the friction system. Compared with the original sample, the burnished sample had a less dmax, which indicated that the phase trajectory had a more convergence, and the friction system had a better stability. This study can guide surface strengthening and running-in performance analysis.

Similar content being viewed by others

References

Z. Y. Li, H. Y. Yu and D. B. Sun, The tribocorrosion mechanism of aluminum alloy 7075-T6 in the deep ocean, Corrosion Science, 183 (2021) 109306.

P. Vasanthakumar, K. Sekar and K. Venkatesh, Recent development in powder metallurgy based aluminium alloy composite for aerospace applications, Materials Today Proceedings, 18 (2019) 5400–5409.

C. Priyadarsini, V. S. N. Ramana, K. A. Prabha and S. Swetha, A review on ball, roller, low plasticity burnishing process, Materials Today Proceedings, 18 (2019) 5087–5099.

M. H. El-Axir, O. M. Othman and A. M. Abodiena, Study on the inner surface finishing of aluminum alloy 2014 by ball burnishing process, J. of Materials Processing Technology, 202(1–3) (2008) 435–442.

J. L. Lv, H. Y. Luo and T. X. Liang, Investigation of microstructure and corrosion behavior of burnished aluminum alloy by TEM, EWF, XPS and EIS techniques, Materials Research Bulletin, 83 (2016) 148–154.

S. Khalilpourazary and J. Salehi, How alumina nanoparticles impact surface characteristics of Al7175 in roller burnishing process, J. of Manufacturing Processes, 39 (2019) 1–11.

R. Teimouri, Optimization of residual stress field in ultrasonic assisted burnishing process, International J. of Lightweight Materials and Manufacture, 2(4) (2019) 346–354.

H. W. Liu, J. X. Zheng, Y. L. Guo and L. X. Zhu, Residual stresses in high-speed two-dimensional ultrasonic rolling 7050 aluminum alloy with thermal-mechanical coupling, International J. of Mechanical Sciences, 186 (2020) 105824.

Z. Y. Zhou, Q. Y. Zheng, C. Ding, J. Y. Yan, G. J. Peng and Z. Y. Piao, Research on the promotion mechanism of surface burnishing process by two-dimensional ultrasonic vibration, J. of Materials Research and& Technology, 13 (2021) 1068–1082.

Z. Y. Zhou, G. L. Yu, Q. Y. Zheng, G. Z. Ma, S. B. Ye, C. Ding and Z. Y. Piao, Wear behavior of 7075-aluminum after ultrasonic-assisted surface burnishing, J. Manufacturing Processes, 51 (2020) 1–9.

W. Xia, F. L. Li, Z. Q. Tang, Z. Y. Zhou and Q. Zhao, Influence of burnishing on fretting wear behaviors of aluminum alloy 6061, J. of South China University of Technology, 39(1) (2011) 84–89.

M. Urbakh, J. Klafter, D. Gourdon and J. Israelachvili, The nonlinear nature of friction, Nature, 430 (2004) 525–528.

D. Schuldberg and S. Guisinger, Nonlinear dynamical systems, chaos theory, and creativity, Encyclopedia of Creativity, Third Edition, Academic Press (2020) 245–254.

Y. K. Zhou, H. Zhu, X. Zuo, L. Yan and N. X. Chen, The nonlinear nature of friction coefficient in lubricated sliding friction, Tribology International, 88 (2015) 8–16.

S. Ghatrehsamani, S. Akbarzadeh and M. M. Khonsari, Experimental and numerical study of the running-in wear coefficient during dry sliding contact, Surface Topography Metrology and Properties, 9(1) (2020) 015009.

S. Z. Wen, P. Huang, Y. Tian and L. R. Ma, Principles of Tribology, Fifth Edition, Tsinghua University Press, Beijing, China (2018).

P. J. Blau, Friction and Wear Transitions of Materials, Noyes Publications, New Jersey, USA (1989).

M. M. Khonsari, S. Ghatrehsamani and S. Akbarzadeh, On the running-in nature of metallic tribo-components: a review, Wear, 474–475 (2021) 203871.

P. J. Blau, On the nature of running-in, Tribology International, 38 (2005) 1007–1012.

Y. K. Zhou, X. Zuo, H. Zhu and W. Tang, Development of prediction models of running-in attractor, Tribology International, 117 (2018) 98–106.

H. Zhu, S. R. Ge, X. C. Cao and W. Tang, The changes of fractal dimensions of frictional signals in the running-in wear process, Wear, 263 (2007) 1502–1507.

C. Ding, Property and evolution of the running-in attractor in an actual dynamic system, Nonlinear Dynanmics, 102 (2020) 1019–1031.

F. Takens, Detecting strange attractors in turbulence, Dynamical Systems and Turbulence, Springer (1980) 366–381.

M. T. Rosenstein, J. J. Collins and C. J. Deluca, Reconstruction expansion as a geometry-based framework for choosing proper delay times, Physica D: Nonlinear Phenomena, 73(1–2) (1994) 82–98.

M. B. Kennel, R. Brown and H. D. I. Abarbanel, Determining embedding dimension for phase space reconstruction using a geometrical reconstruction, Physical Review A, 45(6) (1992) 3403–3411.

Y. K. Zhou, X. Zuo and H. Zhu, Application of chaos theory to optimize the running-in parameters by using a running-in attractor, Wear, 420 (2019) 1–8.

C. Ding, H. Zhu, G. D. Sun, Y. Jiang and C. L. Wei, Characteristic parameter and evolution of the running-in attractor, International J. of Bifurcation and Chaos, 29(4) (2019) 1950044.

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant Nos. 52105215, 52175194), Zhejiang Provincial Natural Science Foundation of China (Grant No. LQ22E050016, No. LR23E050002), the Science Fund of State Key Laboratory of Engine Reliability (No. SKLER-202110), Key Laboratory of E&M (Zhejiang University of Technology), Ministry of Education & Zhejiang Province (No. EM2021120103).

Author information

Authors and Affiliations

Corresponding author

Additional information

Cong Ding received her Ph.D. in Mechanical Engineering from China University of Mining and Technology. She is a lecturer at the College of Mechanical Engineering, Zhejiang University of Technology, Hangzhou, China. Her current research interests include surface strengthening, tribology, signal processing, and fault monitoring.

Zhongyu Piao received his Ph.D. in Mechanical Design and Theory from Yanshan University, Qinhuangdao. He is a Professor of Mechanical Engineering, Zhejiang University of Technology, Hangzhou, China. His current research interests include tribology, surface engineering, state perception and intelligent manufacturing technology.

Rights and permissions

About this article

Cite this article

Ding, C., Feng, S., Qiao, Z. et al. Running-in performance of 7075 aluminum alloy strengthened by burnishing technology. J Mech Sci Technol 37, 2545–2553 (2023). https://doi.org/10.1007/s12206-023-0430-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-023-0430-9