Abstract

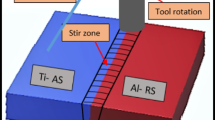

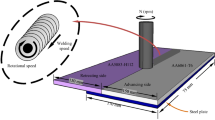

Solid state welding processes are one of the growing principal technologies used to join similar and dissimilar materials. Friction crush welding (FCW) is a recently developed solid state welding process to overcome the difficulties in fusion welding of thin sheet metal workpieces. In this communication, dissimilar aluminium and stainless steel (Al − SS) welds prepared by FCW technique at different levels of process parameters, i.e., feed rate (15, 30, 45 mm/min) and tool rotation (2000, 3000, 4000 rpm) are investigated in terms of mechanical properties and micro-structural features. Tensile test investigation along with microscopic study gives the optimum welding conditions. Optical inverted microscopic study shows that deformation of material increases with increase in feed rate and tool rotation. Energy dispersive spectroscope (EDS) indicates the formation of intermetallic compounds, i.e., FeAl2, FeAl3 and Fe2Al5 in the weld zone. The successful demonstration of joining Al − SS dissimilar materials justifies the potential of FCW process.

Similar content being viewed by others

References

K. Mori, N. Bay, L. Fratini, F. Micari and A. E. Tekkaya, Joining by plastic deformation, CIRP Ann.-Manuf. Techn., 62(2) (2013) 673–694.

P. Cavaliere, R. Nobile, F. W. Panella and A. Squillace, Mechanical and microstructural behaviour of 2024–7075 aluminium alloy sheets joined by friction stir welding, Int. J. Mach. Tool Manuf., 46(6) (2006) 588–594.

M. Dehghani, A. Amadeh and S. A. A. A. Mousavi, Investigations on the effects of friction stir welding parameters on intermetallic and defect formation in joining aluminum alloy to mild steel, Mater. Design, 49 (2013) 433–441.

T. Nishida, T. Ogura, H. Nishida, M. Fujimoto, M. Takahashi and A. Hirose, Formation of interfacial microstructure in a friction stir welded lap joint between aluminium alloy and stainless steel, Sci. Technol. Weld Joi., 19(7) (2014) 609–616.

M. S. Senthil, H. A. Noorul and P. Sathiya, Effect of welding parameters on the microstructure and mechanical properties of the friction-welded dissimilar joints of AA6063 alloy and faying surface-tapered AISI304L alloy, Weld World, 64 (2020) 483–499.

E. Taban, J. E. Gould and J. C. Lippold, Dissimilar friction welding of 6061-T6 aluminum and AISI 1018 steel: properties and microstructural characterization, Mater. Design, 31(5) (2010) 2305–2311.

G. Sharma and D. K. Dwivedi, Study on microstructure and mechanical properties of dissimilar steel joint developed using friction stir welding, Int. J. Adv. Manuf. Tech., 88 (2017) 1299–1307.

Y. C. Chen, A. Gholinia and P. B. Prangnell, Interface structure and bonding in abrasion circle friction stir spot welding: a novel approach for rapid welding aluminium alloy to steel automotive sheet, Mater. Chem. Phys., 134(1) (2012) 459–463.

T. Wang, H. Sidhar, R. S. Mishra, Y. Hovanski, P. Upadhyay and B. Carlson, Friction stir scribe welding technique for dissimilar joining of aluminium and galvanized steel, Sci. Technol. Weld Joi., 23(3) (2018) 249–255.

R. Palanivel, P. K. Mathews, I. Dinaharan and N. Murugan, Mechanical and metallurgical properties of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys, Trans. Nonferrous Met. Soc. China, 24(1) (2014) 58–65.

A. Astarita, M. Coppola, S. Esposito, M. Liberini, I. Papa, F. Scherillo and A. Squillace, Experimental characterization of Ti6Al4V T joints welded through linear friction welding technique: microstructure and NDE, Adv. Manuf., 4 (2016) 305–313.

M. W. Safeen, P. R. Spena, G. Buffa, D. Campanella, A. Masnata and L. Fratini, Effect of position and force tool control in friction stir welding of dissimilar aluminum-steel lap joints for automotive applications, Adv. Manuf., 8 (2020) 59–71.

M. Pourali, A. Abdollah-zadeh, T. Saeid and F. Kargar, Influence of welding parameters on intermetallic compounds formation in dissimilar steel/aluminum friction stir welds, J. Alloy Compd., 715 (2017) 1–8.

T. Ogura, T. Nishida, Y. Tanaka, H. Nishida, S. Yoshikawa, M. Fujimoto and A. Hirose, Micro scale evaluation of mechanical properties of friction stir welded A6061 aluminium alloy/304 stainless steel dissimilar lap joint, Sci. Technol. Weld Joi., 18(2) (2013) 108–113.

F. A. Besler, P. Schindele, R. J. Grant and M. J. R. Stegmuller, Friction crush welding of aluminium, copper and steel sheetmetals with flanged edges, J. Mater. Process. Tech., 234 (2016) 72–83.

F. A. Besler, R. J. Grant, P. Schindele and M. J. R. Stegmuller, Advanced process possibilities in friction crush welding of aluminum, steel, and copper by using an additional wire, Metal. Mater. Trans. B, 48 (2017) 2930–2948.

P. Singh, D. Deepak and G. S. Brar, Comparative evaluation of aluminum and stainless steel dissimilar welded joints, Mater. Today: Proc., 33(3) (2020) 1488–1492.

M. E. Abdullah, H. T. Elmetwally, N. G. Yakoub, M. N. El-sheikh and A. A. Abd-Eltwab, Effect of orbital friction crush welding parameters on aluminum tubes, Int. J. Sci. Tech. Res., 9(2) (2020) 4483–4486.

P. Singh, D. Deepak and G. S. Brar, Optimizing friction crush welding of two dissimilar metals — aluminium 6061 T-6 and stainless steel — AISI 304, ASME 15 th International Manufacturing Science and Engineering Conference (2020) V002T06A 009.

P. Singh, D. Deepak and G. S. Brar, Optical micrograph and micro-hardness behavior of dissimilar welded joints of aluminum (Al 6061-T6) and stainless steel (SS 304) with friction crush welding, Mater. Today: Proc., 44(1) (2021) 1000–1004.

A. S. Jomah, F. A. Hashim and A. D. Subhi, Metallurgical investigation and mechanical properties of dissimilar friction crush welded Cu−Al sheets with flanged edge, IOP J. Phys.: Conf. Ser., 1973 (2021) 012116.

O. F. Sanchez-Femat, M. F. Delgado-Pamanes, L. A. Reyes-Osorio, M. A. Suarez-Rosales, J. F. Chavez-Alcala, R. Flores-Pinedo and J. D. Becerra-Marquez, Design and construction of an agglomeration friction welding machine, Weld Insp., 26 (2021) e2607.

A. Kumar and G. S. Brar, Numerical investigation of friction crush welding aluminium and copper sheet metals with flanged edges, E3S Web Conf. 2021, 309 (2021) 01015.

R. P. Mahto, R. Kumar, S. K. Pal and S. K. Panda, A comprehensive study on force, temperature, mechanical properties and micro-structural characterizations in friction stir lap welding of dissimilar materials (AA6061-T6 & AISI304), J. Manuf. Process., 31 (2018) 624–639.

H. Uzun, C. D. Donne, A. Argagnotto, T. Ghidini and C. Gambaro, Friction stir welding of dissimilar Al 6013-T4 to X5CrNi1810 stainless steel, Mater. Design, 26(1) (2005) 41–46.

Author information

Authors and Affiliations

Corresponding author

Additional information

Prem Singh is an Assistant Professor of Mechanical Engineering at Guru Nanak Dev Engineering College, Ludhiana, Punjab, India. He received his Bachelor’s and Master’s from Guru Nanak Dev Engineering College Ludhiana and Punjab Agricultural University, Ludhiana, respectively. He is currently pursuing the Ph.D. at Punjabi University, Patiala, Punjab, India.

Dharmpal Deepak is an Assistant Professor of Mechanical Engineering at Punjabi University, Patiala, Punjab, India. He received his Master’s degree from GNDEC Ludhiana and his Ph.D. from UCoE, Punjabi University, Patiala. His main research fields are design of experiments, mechanics of composite materials and non-conventional machining.

Gurinder Singh Brar is an Associate Professor of Mechanical Engineering at NIT Uttarakhand, Srinagar (Garhwal), Uttarakhand, India. He received his Master’s degree from GNDEC Ludhiana and Ph.D. from UNCC, USA. His main research fields are welding, non-conventional machining and design.

Rights and permissions

About this article

Cite this article

Singh, P., Deepak, D. & Brar, G.S. Investigations on the effect of friction crush welding parameters in joining 6061 aluminium alloy to 304 stainless steel. J Mech Sci Technol 37, 1999–2008 (2023). https://doi.org/10.1007/s12206-023-0336-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-023-0336-6