Abstract

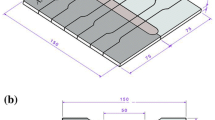

This study focuses on evaluating the effects of welding process parameters and material properties on the intermetallic compound formation and the resulted strength of a tri-dissimilar structure. The structure is made from dissimilar materials. Hardened (5083) and tempered (6061) Al alloys were in a butt configuration jointed to steel in a lap configuration by friction stir welding using a short pin, i.e., the pin did not plunge the steel plate. Single pass welding is employed to join these three dissimilar materials together. Therefore, the study has assessed the characterization of the promoted intermetallic compounds at the two dissimilar interfaces. The results disclose that the intermetallic layer thickness and the weld defects are the main affected factors on the shear strength. These factors are suspended foremost on welding process parameters while the dissimilarities in the Al Alloys properties were considerably contributed to the layer thickness. The superior shear strength could attain 92% of the steel base material.

Similar content being viewed by others

References

Chen CM, Kovacevic RÃ (2004) Joining of Al 6061 alloy to AISI 1018 steel by combined effects of fusion and solid state welding. Int J Mach Tools Manuf 44:1205–1214

Ayob F (2010) Joining of dissimilar materials by diffusion bonding/ diffusion welding for ship application. Marine Frontire 1(2):69–73

Kusuda Y (2013) Feature article Honda develops robotized FSW technology to weld steel and aluminum and applied it to a mass-production vehicle. Ind Robot Int J 40(3):208–212

Coelho RS, Kostka A, Santos JF, Kaysser-pyzalla A (2012) Materials Science and Engineering A Friction-stir dissimilar welding of aluminium alloy to high strength steels : Mechanical properties and their relation to microstructure. Mater Sci Eng, A 556:175–183

Liu X, Lan S, Ni J (2014) Analysis of process parameters effects on friction stir welding of dissimilar aluminum alloy to advanced high strength steel. J Mater Des 59:50–62

Pouranvari M, Abbasi M (2018) Dissimilar gas tungsten arc weld-brazing of Al / steel using Al-Si fi ller metal : Microstructure and strengthening mechanisms. J Alloy Compd 749:121–127

Bozzi S, Helbert-etter AL, Baudin T, Criqui B, Kerbiguet JG (2010) Intermetallic compounds in Al 6016 / IF-steel friction stir spot welds. Mater Sci Eng, A 527(16–17):4505–4509

Sun YF, Fujii H, Takaki N, Okitsu Y (2013) Microstructure and mechanical properties of dissimilar Al alloy / steel joints prepared by a flat spot friction stir welding technique. Mater Des 47:350–357

Liu W, Ma J, Atabaki MM, Kovacevic R (2015) Joining of advanced high-strength steel to AA 6061 alloy by using Fe / Al structural transition joint. Mater Des 68:146–157

Hussein SA, Tahir AS, Hadzley AB (2015) Characteristics of aluminum-to-steel joint made by friction stir welding : a review. Mater Today Commun 5:32–49

Yazdipour A, Heidarzadeh A (2016) Dissimilar butt friction stir welding of Al 5083–H321 and 316L stainless steel alloys. Int J Adv Manuf Technol 87(9):3105–3112

Zheng Q, Feng X, Shen Y, Huang G, Zhao P (2016) Dissimilar friction stir welding of 6061 Al to 316 stainless steel using Zn as a filler metal. J Alloy Compd 686:693–701

Dehghani M, Amadeh A, Akbari Mousavi SAA (2013) Investigations on the effects of friction stir welding parameters on intermetallic and defect formation in joining aluminum alloy to mild steel. Mater Des 49:433–441

ASTM Standard E8/E8M: Standard test methods for tension testing of metallic materials, ASTM International, West Conshohohocken, PA, 2009

Chen ZW, Yazdanian S, Littlefair G (2013) Effects of tool positioning on joint interface microstructure and fracture strength of friction stir lap Al-to-steel welds. J Mater Sci 48(6):2624–2634

Liu HJ, Hou JC, Guo H (2013) Effect of welding speed on microstructure and mechanical properties of self-reacting friction stir welded 6061–T6 aluminum alloy. Mater Des 50:872–878

Elangovan K, Balasubramanian V (2007) Influences of pin profile and rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminium alloy. Mater Sci Eng, A 459:7–18

Chang C, Uan J (2008) Ductile-to-brittle transition for the aluminum alloy contacting to liquid gallium metal. J Alloy Compd 464:146–149

Lotfi AH, Nourouzi S (2014) Effect of welding parameters on microstructure, thermal, and mechanical properties of friction-stir welded joints of AA7075-T6 Aluminum Alloy. Metall and Mater Trans A 45A:2792–2807

Shigematsu I, Kwon Y, Suzuki K, Imai T, Saito N (2003) Joining of 5083 and 6061 aluminum alloys by friction stir welding. J Mater Sci Lett 22:353–356

Frigaard Ø, Grong Ø, Midling OT (2001) A Process model for friction stir welding of age hardening aluminum alloys”. Metall and Mater Trans A 32A:1189–1200

Li D, Yang X, Cui L, He F, Zhang X (2015) Investigation of stationary shoulder friction stir welding of aluminum alloy 7075–T651. J Mater Processing Tech 222:391–398

Jacquin D, de Meester B, Simar A, Deloison D, Montheillet F, Desrayaud C (2011) A simple Eulerian thermomechanical modeling of friction stir welding. J Mater Process Technol 211(1):57–65

Nandan R, Roy GG, Debroy T (2006) Numerical simulation of three-dimensional heat transfer and plastic flow during friction stir welding. Metall and Mater Trans A 37A:1247–1259

Buffa G, De Lisi M, Barcellona A, Fratini L (2016) Material flow analysis in dissimilar friction stir welding of AA2024 and Ti6Al4V butt joints. MATEC Web of Conferences 80:1–7

Hamilton C, Kopyściański M, Węglowska A, Dymek S, Pietras A (2016) A Numerical simulation for dissimilar aluminum alloys joined by friction stir welding. Metall Mater Trans A 47(9):4519–4529

Pouranvari M (2017) Critical assessment 27: dissimilar resistance spot welding of aluminium/steel: challenges and opportunities. Mater Sci Technol 33(15):1705–1712

Kobayashi S, Yakou T (2002) Control of intermetallic compound layers at interface between steel and aluminum by diffusion-treatment. Mater Sci Eng, A 338:44–53

Ogura T, Saito Y, Nishida T, Nishida H, Yoshida T, Omichi N, Fujimoto M, Hirose A (2012) Partitioning evaluation of mechanical properties and the interfacial microstructure in a friction stir welded aluminum alloy / stainless steel lap joint. Scripta Mater 66(8):531–534

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Recommended for publication by Commission II - Arc Welding and Filler Metals

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hussein, S.A., Tahir, A.S.M. & Al-Obaidi, M.A. Evaluation the effects of welding parameters on tri-dissimilar friction stir welds aluminum/steel. Weld World 66, 2315–2332 (2022). https://doi.org/10.1007/s40194-022-01360-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01360-y