Abstract

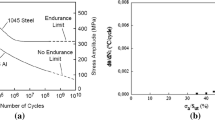

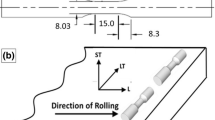

This study focuses on analyzing the thermal response induced by the self-heating effect during cyclic loading of additively manufactured (AM) specimens made from AlSi10Mg aluminum alloy and on its correlation with their fatigue life performance. Four different specimen designs were tested to assess the applicability of various thermographic methods for predicting the fatigue response. These methods focus on estimating the fatigue limit (the Luong method and its versions) or the S-N curve (the Fargione method) from the temperature response of one specimen which is loaded on multiple subsequently increasing levels of the stress amplitude. Such methods could reduce the costs of fatigue experiments by speeding up the estimation of fatigue life performance. The analyses documented in this paper show their large potential (above all in the case of the Fargione method), but also their weaknesses and the need for a more rigorous and broader validation on new experimental data.

Similar content being viewed by others

Abbreviations

- Φ :

-

Limiting energy

- ΔT :

-

Stabilized temperature increase

- R o :

-

Initial temperature rate

- R Y :

-

Ending temperature rate

- N f :

-

Number of cycles to failure

- σ a :

-

Amplitude of stress

- σ FL :

-

Fatigue limit

References

J. J. Braam and S. van der Zwaag, A statistical evaluation of the staircase and the ArcSin√P methods for deTermining the fatigue limit, J. of Testing and Evaluation, 26(2) (1998) 125–131.

M. P. Luong, Fatigue limit evaluation of metals using an infrared thermographic, Mechanics of Materials, 28(1–4) (1998) 155–163.

G. La Rosa and A. Risitano, Thermographic methodology for rapid deTermination of the fatigue limit of materials and mechanical components, Int. J. Fatigue, 22(1) (2000) 66–73.

M. Khonsari and M. Amiri, Introduction to Thermodynamics of Mechanical Fatigue, Taylor and Francis, Boca Raton, FL (2013).

M. Klesnil and P. Lukáš, Fatigue of Metallic Materials, 2nd Rev. Ed., Elsevier, Amsterdam (1992).

A. Fernández-Canteli, E. Castillo, A. Argüelles, P. Fernández and M. Canales, Checking the fatigue limit from thermographic techniques by means of a probabilistic model of the epsilon-N field, Int. J. Fatigue, 39 (2012) 109–115.

J. Huang, M.-L. Pastor, C. Garnier and X. Gong, Rapid evaluation of fatigue limit on thermographic data analysis, Int. J. Fatigue, 104 (2017) 293–301.

G. Fargione, Rapid deTermination of the fatigue curve by the thermographic method, Int. J. Fatigue, 24(1) (2001) 11–19.

C. Yang, A comparative study of fatigue energy dissipation of additive manufactured and cast AlSi10Mg alloy, Metals, 11 (8) (2021).

M. Amiri and M. Khonsari, Life prediction of metals undergoing fatigue load based on temperature evolution, Materials Science and Engineering: A, 527(6) (2010) 1555–1559.

R. Prochazka and J. Dzugan, Fatigue limit evaluation of structure materials based on thermographic analysis, Procedia Structural Integrity, 7 (2017) 315–320.

G. Meneghetti, Analysis of the fatigue strength of a stainless steel based on the energy dissipation, Int. J. Fatigue, 29(1) (2007) 81–94.

J. Kohout and S. Věchet, A new function for fatigue curves characterization and its multiple merits, Int. J. Fatigue, 23(2) (2001) 175–183.

Acknowledgments

The support of The Bavarian-Czech Academic Agency (BTHA-JC-2022-30 project), ESIF, EU Operational Programme Research, Development and Education, from the Center of Advanced Aerospace Technology (CZ.02.1.01/0.0/0.0/16_019/0000826), Faculty of Mechanical Engineering, Czech Technical University in Prague is appreciated and Grant Agency of the Czech Technical University in Prague, under grant No. SGS20/158/OHK2/3T/12. Jan Papuga thanks for the financial support of European Social Fund, grant “Mobility CTU—STA” CZ.02.2.69/0.0/0.0/18_053/0016980.

Author information

Authors and Affiliations

Corresponding author

Additional information

Martin Matušů is a Ph.D. student at the Czech Technical University in Prague (since 2019). He received a Master’s in Applied Mechanics. His research interest includes fatigue of additively manufacture metals, additive manufacturing in general, and infrared thermography.

Rights and permissions

About this article

Cite this article

Matušů, M., Dimke, K., Šimota, J. et al. Energy-based method for analyzing fatigue properties of additively manufactured AlSi10Mg. J Mech Sci Technol 37, 1131–1137 (2023). https://doi.org/10.1007/s12206-022-2110-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-022-2110-6