Abstract

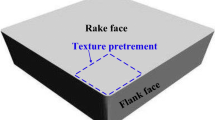

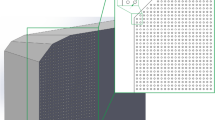

In this study, we investigated the effects of composite nano-Cu/WS2 lubricating oil and single-point diamond indentation-textures on improving the cutting performance of YG8 cemented carbide tools, which is crucial for textures tool applications. The aims of the study were to improve wear resistance and reduce chip adhesion at the tool’s rake face in cutting of titanium alloys. Dot textures with different spacings were fabricated on the surface of YG8 cemented carbide tools through the single-point diamond indentation method, and composite nano-Cu/WS2 lubricating oil was prepared. Orthogonal cutting tests were carried out under dry cutting and minimal quantity lubricated (MQL) conditions. Investigate the effect of different texture spacing on the cutting performance in the light of cutting forces, friction coefficient, the deformed chip thickness, tool adhesions, and chip morphology. The results show that the dot texture effectively improved the lubrication conditions in machining titanium alloys under the MQL conditions. The dot texture is effective at low speed in the dry cutting conditions. With the increase of cutting speed, the friction coefficient of dot texture tool is affected by texture spacing, and the friction coefficient of DT-200 tool is the smallest. In addition, composite nano Cu/WS2 lubricating oil forms a lubricating film on the wear path by atomizing the lubricating oil and stores it in the dot texture, which enhances the anti-wear performance in the cutting process and reduces the cutting force and friction coefficient at the tool chip interface. By evaluating cutting force, friction coefficient, chip and tool morphology, it is concluded that DT-100 tool is more effective in improving lubrication conditions.

Similar content being viewed by others

Abbreviations

- v c :

-

Cutting speed

- a p :

-

Cutting depth

- f :

-

Feed rate

- μ :

-

Friction coefficient

- F c :

-

The main cutting force

- F f :

-

Feed force

- F p :

-

Radial force

References

H. M. Ortner, P. Ettmayer and H. Kolaska, The history of the technological progress of hardmetals, Int. J. Refract. Met. Hard Mater, 44 (2014) 148–159.

J. García et al., Cemented carbide microstructures: a review, Int. J. Refract. Met. Hard Mater, 80(August 2018) (2019) 40–68.

J. Moravčíková et al., Influence of laser surface texturing on tribological performance of tool steels, J. Mater. Eng. Perform, 27(10) (2018) 5417–5426.

O. Hatt et al., The effect of titanium alloy chemistry on machining induced tool crater wear characteristics, Wear, 408–409 (May) (2018) 200–207.

A. Pramanik, Problems and solutions in machining of titanium alloys, Int. J. Adv. Manuf. Technol., 70(5–8) (2014) 919–928.

R. Andreas et al., Synergetic effects of surface texturing and solid lubricants to tailor friction and wear-A review, Tribol. Int., 155 (2021) 106792.

E. Izhak, State of the art in laser surface texturing, ASME, J. Tribol., 127 (2005) 248.

J. Kümmel et al., Study on micro texturing of uncoated cemented carbide cutting tools for wear improvement and built-up edge stabilisation, J. Mater. Process. Technol., 215 (2015) 62–70.

D. Jianxin et al., Performance of carbide tools with textured rake-face filled with solid lubricants in dry cutting processes, Int. J. Refract. Met. Hard Mater, 30(1) (2012) 164–172.

W. Chang et al., Investigation of microstructured milling tool for deferring tool wear, Wear, 271(9–10) (2011) 2433–2437.

D. Arulkirubakaran, V. Senthilkumar and V. Kumawat, Effect of micro-textured tools on machining of Ti-6Al-4V alloy: an experimental and numerical approach, Int. J. Refract. Met. Hard Mater, 54 (2016) 165–177.

D. M. Kim et al., Influence of a micropatterned insert on characteristics of the tool-workpiece interface in a hard turning process, J. Mater. Process. Technol., 229 (2016) 160–171.

T. Obikawa et al., Micro-texture at the coated tool face for high performance cutting, Int. J. Mach. Tools Manuf., 51(12) (2011) 966–972.

T. Enomoto et al., Highly wear-resistant cutting tools with textured surfaces in steel cutting, CIRP Ann.-Manuf. Technol., 61(1) (2012) 571–574.

D. Vasumathy and A. Meena, Influence of micro scale textured tools on tribological properties at tool-chip interface in turning AISI 316 austenitic stainless steel, Wear, 376–377 (2017) 1747–1758.

Y. Xing et al., Experimental assessment of laser textured cutting tools in dry cutting of aluminum alloys, J. Manuf. Sci. Eng. Trans. ASME, 138(7) (2016) 1–10.

X. Hao et al., Experiment on cutting performance of textured cemented carbide tools with various wettability levels, Int. J. Adv. Manuf. Technol., 103(1–4) (2019) 757–768.

K. Zhang et al., Improving dry machining performance of TiAlN hard-coated tools through combined technology of femtosecond laser-textures and WS2 soft-coatings, J. Manuf. Process, 30 (2017) 492–501.

N. Zhang, F. Yang and G. Liu, Cutting performance of micro-textured WC/Co tools in the dry cutting of Ti-6Al-4V alloy, Int. J. Adv. Manuf. Technol., 107(9–10) (2020) 3967–3979.

K. Orra and S. K. Choudhury, Tribological aspects of various geometrically shaped micro-textures on cutting insert to improve tool life in hard turning process, J. Manuf. Process, 31 (2018) 502–513.

J. Xie et al., Experimental study on cutting temperature and cutting force in dry turning of titanium alloy using a non-coated micro-grooved tool, Int. J. Mach. Tools Manuf., 73 (2013) 25–36.

S. Yang et al., Micro-texture design criteria for cemented carbide ball-end milling cutters, J. Mech. Sci. Technol., 34(1) (2020) 127–136.

H. Yu et al., Tribological properties and lubricating mechanisms of Cu nanoparticles in lubricant, T. Nonferr. Metal. Soc., 18 (2008) 636–641.

P. Aldana et al., WS2 nanoparticles anti-wear and friction reducing properties on roughsurfaces in the presence of ZDDP additive, Tribol. Int., 102 (2016) 213–221.

S. Mishra et al., Machining performance evaluation of Ti6Al4V alloy with laser texturedtools under MQL and nano-MQL environments, J. Manuf. Process, 53 (2020) 174–189.

T. Sugihara et al., Direct observations of tribological behavior in cutting with textured cutting tools, Int. J. Mach. Tool. Manu., 168 (2021) 103726.

R. Duan et al., Effect of derivative cutting on machining performance of micro textured tools, J. Manuf. Process, 45 (2019) 544–556.

H. Shi, Metal Cutting Theory, Springer, Cham (2018-01-01).

Z. Fang and T. Obikawa, Cooling performance of microtexture at the tool flank face under high pressure jet coolant assistance, Precis. Eng., 49 (2017) 41–51.

L. V. Colwell, Predicting the angle of chip flow for single-point cutting tools, Trans. ASME, 76 (1954) 199–204.

J. Ma et al., Assessment of microgrooved cutting tool in dry machining of AISI 1045 Steel, J. Manuf. Sci. Eng., ASME, 137 (2015) 031001–031009.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Project Nos. 51775469, 91860133).

Author information

Authors and Affiliations

Corresponding author

Additional information

Gaofeng Zhang is a Professor in the Engineering Training Center, Xiangtan University in China. His main research interest is the advanced processing technology and tools of hard-to-cut materials.

Rights and permissions

About this article

Cite this article

Zhang, G., Chen, B., Wu, G. et al. Experimental assessment of textured tools with nano-lubricants in orthogonal cutting of titanium alloy. J Mech Sci Technol 36, 2489–2497 (2022). https://doi.org/10.1007/s12206-022-0431-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-022-0431-0