Abstract

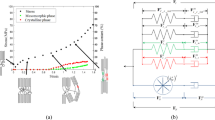

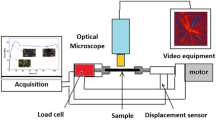

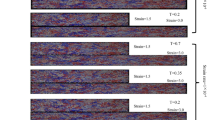

This work provide theoretical understandings for the enzyme-degradable PCL, and assist its structural designs and engineering applications. An energy-dependent evolution model is developed to reflect the enzyme-triggered decrystallization of crystals and the further dissolution by applying a chain-broken chemical reaction. Then, the mechanical properties of the enzyme-degradable semicrystalline PCL is modelled through the homogenization-based procedure by the volume-average of a collection of laminated inclusions with crystals and amorphous phase. A dual-phase-lag diffusion model is advanced to solve the enzyme concentrations in the PCL. The model is calibrated by the experiments and then applied for the chemomechanical properties of the PCL when under enzyme conditions. Some numerical examples are conducted to discuss effects of the enzyme concentration and the crystallinity on the crystallographic axe evolution as well as the overall chemomechanical properties of the semicrystalline PCL.

Similar content being viewed by others

References

B. Feng et al., Engineering cartilage tissue based on cartilage-derived extracellular matrix cECM/PCL hybrid nanofibrous scaffolds, Materials and Design, 193 (2020) 108773.

M. G. Gandolfi et al., Highly porous polycaprolactone scaffolds doped with calcium silicate and dicalcium phosphate dihydrate designed for bone regeneration, Materials Science and Engineering: C, 102 (2019) 341–361.

L. G. Griffith, Polymeric biomaterials, Acta. Mater., 48 (2000) 263–277.

K. P. Andriano et al., Technical note: biomechanical analysis of two absorbable fracture fixation pins after long-term canine implantation, J. Biomed. Mater. Res. Part B, 48 (1999) 528–533.

S. L. Buffington et al., Enzymatically triggered shape memory polymers, Acta Biomaterialia, 84 (2019) 88–97.

B. Narasimhan and S. K. Mallapragada, Dissolution of amorphous and semicrystalline polymers: mechanisms and novel applications, Recent Res. Dev. Macromol Res., 3 (2) (1998) 1–24.

W. H. Lee et al., Kinetics of solvent-induced crystallization of poly(ethylene terephthalate) at the final stage, Journal of Polymer Research, 10 (2) (2003) 133–137.

H. Chen et al., Highly pH-sensitive polyurethane exhibiting shape memory and drug release, Polymer Chemistry, 5 (17) (2014) 5168.

F. He, S. Li, M. Vert and R. Zhuo, Enzyme-catalyzed polymerization and degradation of copolymers prepared from ∊-caprolactone and poly(ethylene glycol), Polymer, 44 (18) (2003) 5145–5151.

M. F. Herman and S. F. Edwards, A reptation model for polymer dissolution, Macromolecules, 23 (15) (1990) 3662–3671.

E. Kaunisto et al., A mechanistic modelling approach to polymer dissolution using magnetic resonance microimaging, Journal of Controlled Release, 147 (2) (2010) 232–241.

B. A. MillerChou and J. L. Koenig, A review of polymer dissolution, Progress in Polymer Science, 28 (8) (2003) 1223–1270.

B. Narasimhan and N. A. Peppas, The physics of polymer dissolution: modeling approaches and experimental behavior, Polymer Analysis Polymer Physics. Advances in Polymer Science, 128 (1997).

S. K. Mallapragada and N. A. Peppas, Dissolution mechanism of semicrystalline poly(vinyl alcohol) in water, Journal of Polymer Science, Part B: Polymer Physics, 34 (7) (1996) 1339–1346.

C. M. Hassan, J. H. Ward and N. A. Peppas, Modeling of crystal dissolution of poly(vinyl alcohol) gels produced by freezing/thawing processes, Polymer, 41 (18) (2000) 6729–6739.

K. Yu et al., Dissolution of covalent adaptable network polymers in organic solvent, Journal of the Mechanics and Physics of Solids, 109 (2017) 78–94.

F. Bedoui et al., Micromechanical modeling of isotropic elastic behavior of semicrystalline polymers, Acata. Materialia, 54 (2006) 1513–1523.

J. A. W. V. Dommelen et al., Micromechanical modeling of the elasto-viscoplastic behavior of semi-crystalline polymers, Journal of the Mechanics and Physics of Solids, 51 (2003) 519–541.

M. Ghasemi et al., Dissolution of semicrystalline polymer fibers: numerical modeling and parametric analysis, AIChE Journal (2017) 63.

B. J. Lee, D. M. Parks and S. Ahzi, Micromechanical modeling of large plastic deformation and texture evolution in semicrystalline polymers, Journal of the Mechanics and Physics of Solids, 41 (10) (1993) 1651–1687.

S. K. Mallapragada and N. A. Peppas, Crystal unfolding and chain disentanglement during semicrystalline polymer dissolution, Aiche Journal, 43 (4) (1997) 870–876.

S. Nikolov et al., Multi-scale constitutive modeling of the small deformations of semi-crystalline polymers, Journal of the Mechanics and Physics of Solids, 50 (11) (2002) 2275–2302.

S. Nikolov, R. A. Lebensohn and D. Raabe, Self-consistent modeling of large plastic deformation, texture and morphology evolution in semi-crystalline polymers, Journal of the Mechanics and Physics of Solids, 54 (7) (2006) 1350–1375.

S. Felder et al., Incorparating crystallinity distributions into a thermo-mechancially coupled constitutive model for semi-crystalline polymers, International Journal of Plasticity (2020) (In Press).

J. Li, I. Romero and J. Segurado, Development of a thermo-mechanically coupled crystal plasticity modeling framework: application to polycrystalline homogenization, International Journal of Plasticity, 119 (2019) 313–330.

A. M. Pantel et al., A thermo-mechanical large deformation constitutive model for polymers based on material network description: application to a semi-crystalline polyamide 66, International Journal of Plasticity, 67 (2015) 102–126.

C. M. Popa et al., Formulation and implementation of a constitutive model for semicrystalline polymers, International Journal of Plasticity, 61 (2014) 128–156.

H. Wang et al., Confined crystallinzaiton of polyethylene oxide in anolayer assemblies, Science, 323 (2009) 757–760.

S. Cheng, D. M. Smith and C. Y. Li, How does nanoscale crystalline structure affect ion transport in solid polymer electrolyte?, Macromolecules, 47 (2014) 3978–3986.

B. C. Hancock and G. Zografi, Characteristics and significance of the amorphous state in pharmaceutical systems, Journal of Pharmaceutical Science, 86 (1997) 1–12.

A. Gros et al., A physically-based model for strain-induced crystallization in natural rubber, part I: life cycle of a crystallite, Journal of the Mechanics and Physics of Solids, 125 (2019) 164–177.

J. A. W. van Dommelen et al., Micromechanical modeling of the thermo-elasto-viscoplastic behavior of semi-crystalline polymers, Journal of the Mechanics and Physics of Solids, 51 (3) (1999) 519–541.

C. Miehe, J. Schotte and M. Lambrecht, Homogenization of inelastic solid materials at finite strains based on incremental minimization principles, Application to the texture analysis of polycrystals, Journal of the Mechanics and Physics of Solids, 50 (10) (2002) 2123–2167.

G. Qi et al., Thermomechanical behavior of shape memory elastomeric composites, Journal of the Mechanics and Physics of Solids, 60 (1) (2012) 67–83.

C. Yang et al., Chemo-thermomechanical behaviors of enzyme-degradable shape memory composite and its heat-enzyme triggered shape memory properties, Computational Materials Science, 193 (2) (2021) 110382.

Y. Mao et al., A viscoelastic model for hydrothermally activated malleable covalent network polymer and its application in shape memory analysis, Journal of the Mechanics and Physics of Solids (2019).

S. A. Chester and L. Anand, A thermo-mechanically coupled theory for fluid permeation in elastomeric materials: Application to thermally responsive gels, Journal of the Mechanics & Physics of Solids, 59 (10) (2011) 1978–2006.

H. Yang et al., A chemo-mechanical model of lithiation in silicon, Journal of the Mechanics and Physics of Solids, 70 (2014) 349–361.

D. Y. Tzou, The generalized lagging response in small-scale and high-rate heating, International Journal of Heat and Mass Transfer, 38 (17) (1995) 3231–3240.

J. K. Chen, J. E. Beraun and D. Y. Tzou, A dual-phase-lg diffusion model for interfacial layer growth in metal matrix composites, Journal of Materials Science, 34 (24) (1999) 6183–6187.

Y. Mao et al., Thermoviscoplastic behaviors of anisotropic shape memory elastomeric composites for cold programmed non-affine shape change, Journal of the Mechanics and Physics of Solids, 85 (2015) 219–244.

J. K. Chen, J. E. Beraun and D. Y. Tzou, A dual-phase-lag diffusion model for interfacial layer growth in metal matrix composites, Journal of Materials Science, 34 (24) (1999) 6183–6187.

A. Sedighiamiri et al., Micromechanical Modeling of The Deformation Kinetics of Semicrystalline Polymers, Eindhoven: Technische Universiteit Eindhoven (2012) (Doi: https://doi.org/10.6100/IR735441).

Q. Ge et al., Thermomechanical behavior of shape memory elastomeric composites, Journal of the Mechanics and Physics of Solids, 60 (1) (2012) 67–83.

S. L. Buffington et al., Enzymatically triggered shape memory polymers, Acta Biomaterialia, 84 (2019) 88–97.

V. Speranza et al., Characterization of the polycaprolactone melt crystallization: complementary optical microscopy, DSC, and AFM studies, The Scientific World Journal (2014).

T. Patrício and P. Bártolo, Thermal stability of PCL/PLA blends produced by physical blending process, Procedia Engineering, 59 (2013) 292–297.

J. M. Robertson, H. Birjandi Nejad and P. T. Mather, Dual-spun shape memory elastomeric composites, ACS Macro Letters, 4 (4) (2015) 436–440.

Acknowledgments

The authors would like to acknowledge with great gratitude for the supports of the National Science Foundation of China (Grant No: 11772124), the Science Foundation of Hunan Province (Grant No: 2018JJ3027) and National Science Foundation of China for Outstanding Youth (Grant No: 11922206).

Author information

Authors and Affiliations

Corresponding author

Additional information

Yiqi Mao is an Associate Professor of Hunan University. He received his Ph.D. in Engineering Mechanics from Hunan University. His research interests include shape-memory polymer, self-healing materials, deformation theory and etc.

Rights and permissions

About this article

Cite this article

Yang, X., Yang, C., Hou, S. et al. Micromechanical modeling for viscoplastic properties of enzyme degradable semi-crystalline poly (ε-caprolactone). J Mech Sci Technol 35, 5081–5097 (2021). https://doi.org/10.1007/s12206-021-1025-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-1025-y