Abstract

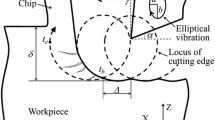

In this study, we suggest a novel tool holder design for simple and cost-effective ultrasonic vibration shaping to provide improvements such as low cutting force, smooth chip exhaust, and better surface quality in the cutting performance. An ultrasonic vibration tool actuated by a single actuator, which was designed by asymmetrically installing a single PZT actuator inside a cylindrical tool holder, generated the synchronized two-axis ultrasonic vibration motion on the tool tip along the cutting and thrust directions. By conducting dynamic structural analysis and simulating the tool tip movement trajectory using finite element method, the resonance mode, amplitude, and frequency of the model were optimized to achieve the vibration characteristics required for precision micro-shaping processes. According to the experimental evaluations, the vibration of the tool holder was characterized by a resonance mode of 24 kHz. The cutting performance of the tool was evaluated by comparing the cutting force, machined surface, and chip shape with those using a non-vibration micro-shaping tool. The cutting force was reduced more than 90 %, and the machined shape and chip exhaust were improved compared with that in conventional shaping processes.

Similar content being viewed by others

References

Y. S. Xu, F. Gao, P. Zou and Q. J. Zhang, Theoretical and experimental investigations of surface roughness, surface topography, and chip shape in ultrasonic vibration-assisted turning of Inconel 718, Journal of Mechanical Science and Technology, 34(9) (2020) 3791–3806.

S. M. Son, H. S. Lim, I. H. Paik and J. H. Ahn, A study on critical depth of cuts in micro grooving, KSME International Journal, 17(2) (2003) 239–245.

J. S. Lee, D. W. Lee, Y. H. Jung and W. S. Chung, A study on micro-grooving characteristics of planar lightwave circuit and glass using ultrasonic vibration cutting, Journal of Materials Processing Technology, 130–131(20) (2002) 396–400.

S. J. Kim, D. Le, S. W. Lee, K. H. Song and D. Y. Lee, Experiment-based statistical prediction on diamond tool wear in micro grooving Ni-P alloys, Diamond and Related Materials, 41 (2014) 6–13.

R. Kurniawan, G. Kiswanto and T. J. Ko, Micro-dimple pattern process and orthogonal cutting force analysis of elliptical vibration texturing, International Journal of Machine Tools and Manufacture, 106 (2016) 127–140.

W. Cao, J. Zha and Y. Chen, Cutting force prediction and experiment verification of paper honeycomb materials by ultrasonic vibration-assisted machining, Applied Science, 10(13) (2020) 4676.

N. Suzuki, M. Haritani, J. Yang, R. Hino and E. Shamoto, Elliptical vibration cutting of tungsten alloy molds for optical glass parts, Annals of the CIRP, 56(1) (2007) 127–130.

X. Liu, T. F. Zhou, S. Q. Pang, J. Q. Xie and X. B. Wang, Burr formation mechanism of ultraprecision cutting for microgrooves on nickel phosphide in consideration of the diamond tool edge radius, The International Journal of Advanced Manufacturing Technology, 94(12) (2018) 3929–3935.

J. Guo, H. J. H. Jong, R. Kang and D. Guo, Novel localized vibration-assisted magnetic abrasive polishing method using loose abrasives for V-groove and Fresnel optics finishing, Optics Express, 26(9) (2018) 11608–11619.

R. Tan, X. Zhao, T. Sun, X. Zou and Z. Hu, Experimental investigation on micro-groove manufacturing of Ti-6Al-4V alloy by using ultrasonic elliptical vibration assisted cutting, Materials, 12(19) (2019) 3086.

G. D. Kim and B. G. Loh, An ultrasonic elliptical vibration cutting device for micro V-groove machining: kinematical analysis and micro V-groove machining characteristics, Journal of Materials Processing Technology, 190(1–3) (2007) 181–188.

J. Kim and B. Kang, Machining characteristics of micro lens mold in laser-assisted micro-turning, Journal of Mechanical Science and Technology, 32(4) (2018) 1769–1774.

J. D. Kim, S. J. Lee and J. Suh, Characteristics of laser assisted machining for silicon nitride ceramic according to machining parameters, Journal of Mechanical Science and Technology, 25(4) (2011) 995–1001.

X. Li and D. Y. Zhang, Ultrasonic elliptical vibration transducer driven by single actuator and its application in precision cutting, Journal of Materials Processing Technology, 180(1–3) (2006) 91–95.

X. Q. Zhang, A. S. Kumar, M. F. Rahman, C. Nath and K. Liu, Experimental study on ultrasonic elliptical vibration cutting of hardened steel using PCD tools, Journal of Materials Processing Technology, 211(11) (2011) 1701–1709.

E. Shamoto, N. Suzuki, T. Moriwaki and Y. Naoi, Development of ultrasonic elliptical vibration controller for elliptical vibration cutting, CIRP Annals, 51(1) (2002) 327–330.

R. Kurniawan, T. J. Ko, L. C. Ping, S. T. Kumaran, G. Kiswanto, P. Guo and K. F. Ehmann, Development of a two-frequency, elliptical-vibration texturing device for surface texturing, Journal of Mechanical Science and Technology, 31(7) (2017) 3465–3473.

J. Lin, J. Han, M. Lu, Y. Gu and W. Zhu, Development of nonresonant elliptical vibration cutting device based on parallel piezoelectric actuator, AIP Advances, 7(035304) (2017) 1–16.

R. Tan, X. Zou, X. Zou and T. Sun, A novel ultrasonic elliptical vibration cutting device based on a sandwiched and symmetrical structure, The International Journal of Advanced Manufacturing Technology, 97 (2018) 1397–1406.

L. H. Xu, H. B. Na and G. C. Han, Machinability improvement with ultrasonic vibration-assisted micro-milling, Advances in Mechanical Engineering, 10(12) (2018) 1–12.

Y. He, P. Zou, W. L. Zhu and K. F. Ehmann, Ultrasonic elliptical vibration cutting of hard materials: simulation and experimental study, International Journal of Advanced Manufacturing Technology, 91 (2017) 363–374.

F. Chen, G. Mei, B. Zhao, W. Bie and G. Li, Study on the characteristics of zirconia ceramic in three-dimensional ultrasonic vibration-assisted ELID internal grinding, Journal of Mechanical Science and Technology, 34(1) (2020) 333–344.

Y. Zhang, B. Zhao, Y. Wang and F. Chen, Effect of machining parameters on the stability of separated and unseparated ultrasonic vibration of feed direction assisted milling, Journal of Mechanical Science and Technology, 31(2) (2017) 851–858.

K. L. Kuo, Design of rotary ultrasonic milling tool using FEM simulation, Journal of Materials Processing Technology, 201(1–3) (2008) 48–52.

K. Vivekananda, G. N. Arka and S. K. Sahoo, Design and analysis of ultrasonic vibratory tool (UVT) using FEM, and experimental study on ultrasonic vibration-assisted turning (UAT), Procedia Engineering, 97 (2014) 1178–1186.

G. Shi, C. Zhang, Y. Li, K. Ehmann, Y. Song and M. Lu, The finite element analysis and optimization of an elliptical vibration assisted cutting device, Journal of Applied Mechanical Engineering, 4(4) (2015) 1000170.

Acknowledgments

We would like to acknowledge the financial support from the platform R&D program of KITECH (Korea Institute of Industrial Technology) of Republic of Korea (Grant PEO20580) and National Research Foundation of Korea (NRFK) (Grant 2020R1A2C1004784).

Author information

Authors and Affiliations

Corresponding author

Additional information

Bongchul Kang is an Associate Professor of the School of Mechanical Engineering at Kookmin University. He received his Ph.D. degree in Mechanical Engineering from Korea Advanced Institute of Science and Technology (KAIST), Korea. His research interests include laser-nanomaterial interactions, laser processing, ultra-precision engineering, and nontraditional manufacturing.

Rights and permissions

About this article

Cite this article

Kim, J., Lee, J. & Kang, B. Ultrasonic vibration micro-shaping using single PZT actuator-embedded tool holder. J Mech Sci Technol 35, 3123–3129 (2021). https://doi.org/10.1007/s12206-021-0634-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-0634-9