Abstract

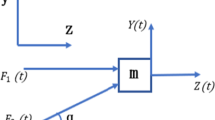

This paper presents a new ultrasonic elliptical vibration cutting (UEVC) device based on a sandwiched and symmetrical structure. The proposed UEVC device is able to work with the third resonant mode of longitudinal vibration and the sixth resonant mode of bending vibration. Also, the vibration nodes of the two resonant modes were completely superposed at the center of the flange. Therefore, the single-node fixed method was employed, which was practical and had no interference to the resonance mode of the UEVC device. The modal analysis of the designed UEVC device was performed by using finite element method (FEM). The results revealed that the modal degeneration can be realized by optimizing design parameters. Based on the optimized results, a prototype UEVC device was manufactured, and its vibration characteristics were evaluated by an impedance analyzer and a laser displacement sensor. The measurement results indicated that the resonant frequencies were close to the simulation frequencies and an elliptical trajectory was generated at the tool tip. Finally, the proposed UEVC device was integrated into an ultra-precision machine tool to confirm the feasibility of the designed UEVC in the practical application.

Similar content being viewed by others

References

Shore P, Morantz P (2012) Ultra-precision: enabling our future. Phil Trans R Soc A 370:3993–4014. https://doi.org/10.1098/rsta.2011.0638

Paul E, Evans CJ, Mangamelli A, McGlauflin ML, Polvani RS (1996) Chemical aspects of tool wear in single point diamond turning. Precis Eng 18(1):4–19

Casstevens JM (1983) Diamond turning of steel in carbon-saturated atmospheres. Precis Eng 5(1):9–15

Evans C, Bryan JB (1991) Cryogenic diamond turning of stainless steel. CIRP Ann Manuf Technol 40(1):571–575

Moriwaki T, Shamoto E (1995) Ultrasonic elliptical vibration cutting. CIRP Ann Manuf Technol 44(1):31–34

Shamoto E, Moriwaki T (1999) Ultaprecision diamond cutting of hardened steel by applying elliptical vibration cutting. CIRP Ann Manuf Technol 48(1):441–444

Wang X, Zhou M, Gan GK, Ngoi B (2002) Theoretical and experimental studies of ultraprecision machining of brittle materials with ultrasonic vibration. Int J Adv Manuf Technol 20(2):99–102

Zhao H, Li S, Zou P, Kang D (2017) Process modeling study of the ultrasonic elliptical vibration cutting of Inconel 718. Int J Adv Manuf Technol 92:2055–2068

Huang S, Liu X, Chen FZ, Zheng HX, Yang XL, Wu LB, Song JL, Xu WJ (2016) Diamond-cutting ferrous metals assisted by cold plasma and ultrasonic elliptical vibration. Int J Adv Manuf Technol 85:673–681

Suzuki N, Haritani M, Yang J, Hino R, Shamoto E (2007) Elliptical vibration cutting of tungsten alloy molds for optical glass parts. CIRP Ann Manuf Technol 56(1):127–130

Liu K, Li XP, Rahman M (2008) Characteristics of ultrasonic vibration-assisted ductile mode cutting of tungsten carbide. Int J Adv Manuf Technol 35:833–841

Song YC, Park CH, Moriwaki T (2010) Mirror finishing of Co–Cr–Mo alloy using elliptical vibration cutting. Precis Eng 34:784–789

Brehl DE, Dow TA, Garrard K, Sohn A (2006) Microstructure fabrication using elliptical vibration-assisted machining. In: Proceedings of the 21th Annual Meeting of the ASPE, Monterey, USA, 39, pp 511–514

Kim GD, Loh BG (2010) Machining of micro-channels and pyramid patterns using elliptical vibration cutting. Int J Adv Manuf Technol 49(9–12):961–968

Zhang J, Suzuki N, Wang Y, Shamoto E (2015) Ultra-precision nano-structure fabrication by amplitude control sculpturing method in elliptical vibration cutting. Precis Eng 39:86–99

Guo P, Ehmann KF (2013) Development of a tertiary motion generator for elliptical vibration texturing. Precis Eng 37(2):364–371

Zhang J, Cui T, Ge C, Sui Y, Yang H (2016) Review of micro/nano machining by utilizing elliptical vibration cutting. Int J Mach Tools Manuf 106:109–126

Zhang C, Shi G, Ehmann KF, Li Y (2016) Modeling and simulation of micro-groove topography on cylindrical surface by elliptical vibration-assisted turning. Int J Adv Manuf Technol 86:1407–1424

Yang Y, Pan Y, Guo P (2017) Structural coloration of metallic surfaces with micro/nano-structures induced by elliptical vibration texturing. Appl Surf Sci 402:400–409

Lu Y, Guo P, Pei P, Ehmann KF (2015) Experimental studies of wettability control on cylindrical surfaces by elliptical vibration texturing. Int J Adv Manuf Technol 76:1807–1817

Zhang J, Suzuki N, Wang Y, Shamoto E (2014) Fundamental investigation of ultra-precision ductile machining of tungsten carbide by applying elliptical vibration cutting with single crystal diamond. J Mater Process Technol 214:2644–2659

Kim GD, Loh BG (2007) An ultrasonic elliptical vibration cutting device for micro V-groove machining: kinematical analysis and micro V-groove machining characteristics. J Mater Process Technol 190:181–188. https://doi.org/10.1016/j.jmatprotec.2007.02.047

Kim GD, Loh BG (2011) Direct machining of micro patterns on nickel alloy and mold steel by vibration assisted cutting. Int J Precis Eng Manuf 12(4):583–588

Yang X, Liu Y, Chen W, Liu J (2013) Longitudinal and bending hybrid linear ultrasonic motor using bending PZT elements. Ceram Int 39(Supplement 1):S691–S694

Zhou M, Hu L (2015) Development of an innovative device for ultrasonic elliptical vibration cutting. Ultrasonics 60:76–81

Yang Y, Gao S, Chen K, Pan Y, Guo P (2017) Vibration analysis and development of an ultrasonic elliptical vibration tool based on a portal frame structure. Precis Eng 50:421–432

Li X, Zhang D (2006) Ultrasonic elliptical vibration transducer driven by single actuator and its application in precision cutting. J Mater Process Technol 180:91–95

Yin Z, Fu Y, Xu J, Li H, Cao Z, Chen Y (2017) A novel single driven ultrasonic elliptical vibration cutting device. Int J Adv Manuf Technol 90:3289–3300

Jiao F, Zhang X, Zhao L, Li FB, Zhao B (2012) Development of ultrasound elliptical cutting device and study on its cutting performance. International Conference on Automation and Computing (ICAC 12): 202–206

Lin S (1995) Coupled vibration in hollow cylinders of longitudinally polarized piezoelectric ceramics. J Acoust Soc Am 97(6):3599–3604

Lin S (2005) Analysis of the sandwich piezoelectric ultrasonic transducer in coupled vibration. J Acoust Soc Am 117(2):653–661

Lin S (1997) Study on the longitudinal–torsional composite vibration of a sectional exponential horn. J Acoust Soc Am 102(3):1388–1393

Funding

The present work was supported by the Science Challenge Project of China (Grant No. TZ2018006) and the National Safe Academic Foundation of National Natural Science Foundation of China (Grant No. U1530106).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOC 27 kb)

Rights and permissions

About this article

Cite this article

Tan, R., Zhao, X., Zou, X. et al. A novel ultrasonic elliptical vibration cutting device based on a sandwiched and symmetrical structure. Int J Adv Manuf Technol 97, 1397–1406 (2018). https://doi.org/10.1007/s00170-018-2015-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2015-9