Abstract

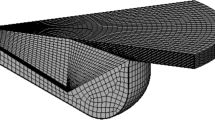

The flow characteristics in the exhaust manifold and close-coupled catalytic converter (CCC) system of a spark-ignition engine have a major influence on its performance and emission characteristics. In particular, understanding the exhaust flow characteristics during engine operation is crucial in terms of shortening the catalyst light-off and enhancing its conversion efficiency. In this study, to understand the pulsating nature of the exhaust flow under engine firing conditions, transient velocity measurements using laser Doppler velocimetry were performed inside an exhaust system with CCC. First, the effects of engine parameters (speed and load) on the pulsating behavior of the exhaust flow were investigated. Moreover, the effects of the exhaust manifold geometric configuration on the pulsating flow characteristics are presented. It is expected that the data obtained from this study can be used to improve exhaust system design for robust emission control in terms of catalyst light-off and durability.

Similar content being viewed by others

Abbreviations

- ABDC:

-

After bottom dead center

- ATDC:

-

After top dead center

- BBDC:

-

Before bottom dead center

- BMEP:

-

Brake mean effective pressure

- BTDC:

-

Before top dead center

- CA:

-

Crank angle

- CCC:

-

Close-coupled catalytic converter

- CFD:

-

Computational fluid dynamics

- DOHC:

-

Double over head camshaft

- EVC:

-

Exhaust valve closing

- EVO:

-

Exhaust valve opening

- LDV:

-

Laser Doppler velocimetry

- TWC:

-

Three-way catalytic converter

- UCC:

-

Underfloor catalytic converter

- WOT:

-

Wide open throttle

References

B. Kawaguchi, K. Umemoto, S. Misawa, A. Hirooka and T. Kawai, ICE vehicle challenge toward zero emissions: future technology harmonization in electrified powertrain system, SAE Technical Paper (2019) 01–2217.

J. Warkins, T. Tao, M. Shen and S. Lyu, Application of low-mass Corning FLORA substrates for cold-start emissions reduction to meet upcoming LEV III SULEV30 regulation requirement, SAE Technical Paper (2020) 01–0652.

A. G. des Buttes, B. Jeanneret, A. Kéromnès, L. L. Moyne and S. Pélissier, Energy management strategy to reduce pollutant emissions during the catalyst light-off of parallel hybrid vehicles, Applied Energy, 266 (2020) 114866.

R. Host, P. Moilanen, M. Fried and B. Bogi, Exhaust system thermal management: A process to optimize exhaust enthalpy for cold start emissions reduction, SAE Technical Paper (2017) 01–0141.

H. Welten, H. Bressler, F. Terres, H. Neumaier and D. Rammoser, Optimization of catalytic converter gas flow distribution by CFD prediction, SAE Technical Paper No. 930780 (1993).

H. Bressler, D. Rammoser, H. Neumaier and F. Terres, Experimental and predictive investigation of a close coupled catalytic converter with pulsating flow, SAE Technical Paper No. 960564 (1996).

L. Bai, F. Q. Zhao, Y. Liu, M. C. Lai and K. S. Lee, Transient flow and pressure characteristics inside a closed-coupled catalytic converter, SAE Technical Paper No. 982548 (1998).

F. Q. Zhao, L. Lai, X. Xie and M. C. Lai, An experimental study of the flow structure inside the catalytic converter of a gasoline engine, SAE Technical Paper No. 950784 (1995).

H.-S. Kim, K. Min, C.-L. Myung and S. Park, A combined experimental and computational approach to improve catalyst flow uniformity and light-off behaviour, Proc. of the Institution of Mechanical Engineers. Part D, J. Automobile Engineering, 216(7) (2002) 413–430.

D. N. Tsinoglou and G. C. Koltsakis, Modeling the effect of flow pulsations in close-coupled catalytic converter light-off, SAE Technical Paper (2004) 01–1835.

M. McMackin, G. McCullough and A. P. N. McDowell, Simulation of the unsteady gas flow through a three-way automotive catalyst: A preliminary study, SAE Technical Paper (2005) 01–2216.

X. Zhang, T. Gomulka and M. Romzek, Numerical optimization of flow uniformity inside an F-oval substrate, SAE Technical Paper (2007) 01–1088.

S. Slasc, E. Barrieu and V. Leroy, Impact of manifold design on flow distribution of a close-coupled catalytic converter, SAE Technical Paper (2005) 01–1626.

H. A. Ibrahim, W. H. Ahmed, S. Abdou and V. Blagojevic, Experimental and numerical investigations of flow through catalytic converters, Int. Journal of Heat and Mass Transfer, 127 (2018) 546–560.

R. Host, P. Moilanen, B. Anderson, M. Collareno, G. Tapos and C. Henderson, Reducing catalyst zone flow for robust emissions performance in the presence of engine air fuel ratio imbalance, SAE Technical Paper (2017) 01–0961.

T. Shamin, The effect of engine exhaust temperature modulations on the performance of automotive catalytic converters, Journal of Engineering for Gas Turbines and Power, 130 (2008) 012801–1–012801–6.

C. Burgess, T. Collier, M. Brogan, A. Leong, B. Campbell, A. Finch, C. Hubbard and Y. Graves, The effect of different ageing conditions on spatial variations in emissions across the radius of a close-coupled aftertreatment system, SAE Technical Paper (2005) 01–1095.

Z. Liu, S. F. Benjamin and C. A. Roberts, Pulsating flow maldistribution within an axisymmetric catalytic converter — flow rig experiment and transient CFD simulation, SAE Technical Paper (2003) 01–3070.

S. F. Benjamin, Z. Liu and C. A. Roberts, A shielded hot-wire probe to detect flow reversals with one-dimensional pulsating flow, Proc. of the Institution of Mechanical Engineers. Part C, J. Mechanical Engineering Science, 218(7) (2004) 797–801.

S. Jeong and T. Kim, CFD investigation of the 3-dimensional unsteady flow in the catalytic converter, SAE Technical Paper No. 971025 (1997).

K. Yoshizawa, K. Mori, K. Arai and A. Liyama, Numerical analysis of unsteady exhaust flow and its application for lambda control improvement modulations on the performance of automotive catalytic converters, Journal of Engineering for Gas Turbines and Power, 125 (2003) 555–562.

W. Guojiang and T. Song, CFD simulation of the effect of upstream flow distribution on the light-off performance of a catalytic converter, Energy Conversion and Management, 46 (2005) 2010–2031.

S. J. Jeong, A full transient three-dimensional study on the effect of pulsating exhaust flow under real running conditions on the thermal and chemical behavior of closed-coupled catalyst, Chemical Engineering Science, 117 (2014) 18–30.

M. Badami, F. Millo, A. Zuarini and M. Gambarotto, CFD analysis and experimental validation of the inlet flow distribution in close coupled catalytic converters, SAE Technical Paper (2003) 01–3072.

S. F. Benjamin, W. Disdale, Z. Liu, C. A. Roberts and H. Zhao, Velocity predictions from a coupled one-dimensional/three-dimensional computational fluid dynamics simulation compared with measurements in the catalyst system of a firing engine, International Journal of Engine Research, 7 (2006) 28–40.

Acknowledgments

This study was supported by the Research Program funded by the SeoulTech (Seoul National University of Science and Technology).

Author information

Authors and Affiliations

Corresponding author

Additional information

Han-Sang Kim received his B.S. and M.S. degrees from the Department of Mechanical Engineering at Seoul National University in 1989 and 1991, respectively. He then obtained his Ph.D. degree from Seoul National University in 2005. He is currently an Associate Professor in the Department of Mechanical and Automotive Engineering at Seoul National University of Science and Technology. His research interests include thermal management for eco-friendly powertrain systems, and engine exhaust systems.

Rights and permissions

About this article

Cite this article

Kim, HS. Effect of exhaust manifold geometry and engine parameters on flow pulsations inside the exhaust system with CCC under firing conditions. J Mech Sci Technol 35, 805–813 (2021). https://doi.org/10.1007/s12206-021-0141-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-0141-z