Abstract

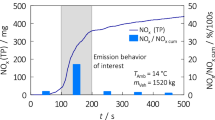

In this paper, the effects of inlet valve closing temperature (TIVC) and exhaust gas recirculation (EGR) on the emissions and the performance of a reactivity controlled compression ignition (RCCI) engine have been numerically investigated. The numerical results were obtained for TIVC variations from 293 to 353 K and the EGR variations from 0 to 25%. For this purpose, the natural gas was injected in inlet port as a low reactivity fuel, while the diesel fuel was directly injected in the cylinder as a high reactivity fuel. For the numerical simulation validation, the results were compared to the reference data. The comparison shows that the in-cylinder pressure, rate of heat release (RoHR), soot and nitrogen oxide (NOx) emissions results are in good agreement with the reference data. According to the results, with increasing the EGR, the maximum in-cylinder pressure and also the maximum RoHR will be decreased. Moreover, increasing the EGR can considerably reduce NOx and soot emissions. When EGR increases from 0 to 25%, the NOx emission decreases from 0.47 to 0.02 g kW−1 h−1, while soot decreases from 0.009 to 0.0005 g kW−1 h−1. Also, increasing the TIVC will significantly increase the maximum pressure, RoHR and NOx and soot emissions. When TIVC increases from 293 to 353 k, the NOx emission increases from 0.01 to 0.41 g kW−1 h−1 and also soot from 0.0005 to 0.011 g kW−1 h−1. Finally, the results show that both of the TIVC and the EGR play important roles in controlling the combustion phase of an RCCI engine.

Similar content being viewed by others

References

Shadloo MS, Poultangari R, MS MS, Rashidi MM. A new and efficient mechanism for spark ignition engines. J Energy Convers Manag. 2015. https://doi.org/10.1016/j.enconman.2015.03.017.

Kimura S, Aoki O, Kitahara Y, Aiyoshizawa E. Ultra-clean combustion technology combining a low-temperature and premixed combustion concept for meeting future emission standards. SAE Technical Paper 2001-01-0200.

Resitoglu IA, Altinisik K, Keskin A. The pollutant emissions from diesel–engine vehicles and exhaust aftertreatment systems. Clean Techn Environ Policy. 2015;17:15–27.

Zhang J, Wong VW, Shuai S, Chen Y, Sappok A. Quantitative estimation of the impact of ash accumulation on diesel particulate filter related fuel penalty for a typical modern on-road heavy-duty diesel engine. Appl Energy. 2018;229:1010–23.

Fleischman R, Amiel R, Czerwinski J, Mayer A, Tartakovsky L. Buses retrofitting with diesel particle filters: real-world fuel economy and roadworthiness test considerations. J Environ Sci. 2018;67:273–86.

Reihani A, Fisherb GB, Hoard JW, Theis JR, Pakko JD, Lambert CK. Rapidly pulsed reductants for diesel NOx reduction with lean NOx traps: effects of pulsing parameters on performance. Appl Catal B. 2018;223:177–91.

Praveena V, Martin MLJ. A review on various after treatment techniques to reduce NOx emissions in a CI engine. J Energy Inst. 2018;91:704–20.

Xu H, Lou ZQ, Wang N, Qu ZG. An Experimental study of the selective catalytic reduction after-treatment for the exhaust emission of a diesel engine. Appl Therm Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2018.10.067.

Gao J, Tian G, Sorniotti A, Karci AE, Palo RD. Review of thermal management of catalytic converters to decrease engine emissions during cold start and warm up. Appl Therm Eng. 2019;147:177–87.

Bendu H, Murugan S. Homogeneous charge compression ignition (HCCI) combustion: mixture preparation and control strategies in diesel engines. Renew Sustain Energy Rev. 2014;38:732–46.

Cerit M, Soyhan HS. Thermal analysis of a combustion chamber surrounded by deposits in an HCCI engine. Appl Therm Eng. 2013;50:81–8.

Uyumaz A. An experimental investigation into combustion and performance characteristics of an HCCI gasoline engine fueled with n-heptane, isopropanol and n-butanol fuel blends at different inlet air temperatures. Energy Convers Manag. 2015;98:199–207.

Gowthaman S, Sathiyagnanam AP. Analysis the optimum inlet air temperature for controlling homogeneous charge compression ignition (HCCI) engine. Alex Eng J. 2018;57:2209–14.

Machrafi H, Cavadiasa S. An experimental and numerical analysis of the influence of the inlet temperature, equivalence ratio and compression ratio on the HCCI auto-ignition process of Primary Reference Fuels in an engine. Fuel Process Technol. 2008;89:1218–26.

Oh CH, Jamsran N, Lim OT. A numerical investigation about the EGR effect under the condition of boost pressure on HCCI autoignition. Energy Proc. 2015;68:398–408.

Canakci M. Combustion characteristics of a DI-HCCI gasoline engine running at different boost pressures. Fuel. 2012;96:546–55.

Cinar C, Uyumaz A, Solmaz H, Topgul T. Effects of valve lift on the combustion and emissions of a HCCI gasoline engine. Energy Conver Manag. 2015;94:159–68.

Çınar C, Uyumaz A, Polat S, Yılmaz E, Solmaz H. Combustion and performance characteristics of an HCCI engine utilizing trapped residual gas via reduced valve lift. Appl Therm Eng. 2016;100:586–94.

Bessonette PW, Schleyer CH, Duffy KP, Hardy WL, Liechty MP. Effects of fuel property changes on heavy-duty HCCI combustion. SAE Paper, 2007-01-0191.

Kalghatgi G, Risberg P, Ångström H. Partially pre-mixed auto-ignition of gasoline to attain low smoke and low NOx at high load in a compression ignition engine and comparison with a diesel fuel. 2007; https://doi.org/10.4271/2007-01-0006.

Hanson R, Splitter D, Reitz R. Operating a heavy-duty direct-injection compression-ignition engine with gasoline for low emissions. 2009; https://doi.org/10.4271/2009-01-1442.

Lewander CM, Johansson B, Tunestal P. Extending the operating region of multi-cylinder partially premixed combustion using high octane number fuel. SAE World Congress & Exhibition. 2011; https://doi.org/10.4271/2011-01-1394.

Splitter DA, Reitz R. Fuel reactivity effects on the efficiency and operational window of dual-fuel compression ignition engines. Fuel. 2014;118:163–75.

Lia Y, Jia M, Chang Y, Xie M, Reitz RD. Towards a comprehensive understanding of the influence of fuel properties on the combustion characteristics of a RCCI (reactivity controlled compression ignition) engine. J Energy. 2016;99:69–82.

Li Y, Jia M, Chang Y, Xu Z, Xu G, Liu H, Wang T. Principle of determining the optimal operating parameters based on fuel properties and initial conditions for RCCI engines. Fuel. 2018;216:284–95.

Qian Y, Ouyang L, Wang X, Zhu L, Lu X. Experimental studies on combustion and emissions of RCCI fueled with n-heptane/alcohols fuels. J Fuel. 2015;162:239–50.

Qian Y, Wang X, Zhu L, Lu X. Experimental studies on combustion and emissions of RCCI (reactivity controlled compression ignition) with gasoline/n-heptane and ethanol/n-heptane as fuels. J Energy. 2015;88:584–94.

Ansari E, Shahbakhti M, Naber J. Optimization of performance and operational cost for a dual mode diesel-natural gas RCCI and diesel combustion engine. J Appl Energy. 2018;231:549–61.

Rahnama P, Paykani A, Bordbar V, Reitz RD. A numerical study of the effects of reformer gas composition on the combustion and emission characteristics of a natural gas/diesel RCCI engine enriched with reformer gas. Fuel. 2017;209:742–53.

Jiaqiang E, Pham M, Zhao D, Deng Y, Le D, Zuo W, Zhu H, Liu T, Peng Q, Zhang Z. Effect of different technologies on combustion and emissions of the diesel engine fueled with biodiesel: a review. J Renew Sustain Energy Rev. 2017;80:620–47.

Kakaee AH, Paykani A. Research and development of natural-gas fueled engines in Iran. Renew Sustain Energy Rev. 2013;26:805–21.

Nieman D, Dempsey A, Reitz RD. Heavy-duty RCCI operation using natural gas and diesel. SAE Int J Engines. 2012. https://doi.org/10.4271/2012-01-0379.

Splitter D, Wissink M, DelVescovo D, Reitz RD. Improving the understanding of intake and charge effects for increasing RCCI engine efficiency. SAE Int J Engines 2014;7.2:913–27.

Khatamnejad H, Khalilarya S, Jafarmadar S, Mirsalim M. Effect of intake charge temperature on combustion and emissions characteristics in a natural gas–diesel reactivity controlled compression ignition engine. Gas Process J. 2017;5:75–84.

Inagaki K, Fuyuto T, Nishikawa K, Nakakita K. Dual-fuel PCI combustion controlled by in-cylinder stratification of ignitability. SAE Technical Paper 2006- 01-0028.

Kokjohn SL, Hanson RM, Splitter DA, Reitz RD. Experiments and modeling of dual-fuel HCCI and PCCI combustion using in-cylinder fuel blending. SAE Int J Engines. 2010. https://doi.org/10.4271/2009-01-2647.

Wu Y, Reitz RD. Effects of exhaust gas recirculation and boost pressure on reactivity controlled compression ignition engine at high load operating conditions. J Energy Resour Technol. 2015. https://doi.org/10.1115/1.4029866.

Yu C, Wang J, Yu W, Liu J, Gao D. Research on low temperature combustion of homogeneous charge induced ignition (HCII) in a light-duty diesel engine. In: Proceedings of the FISITA 2012 world automotive congress. p. 195–204.

Liu H, Wang X, Zheng Z, Gu J, Wang H, Yao M. Experimental and simulation investigation of the combustion characteristics and emissions using n-butanol/biodiesel dual-fuel injection on a diesel engine. Energy 2014;74:741-752.

Hanson R, Ickes A, Wallner T (2016) Use of adaptive injection strategies to increase the full load limit of RCCI operation. J Eng Gas Turbines Power. https://doi.org/10.1115/1.4032847.

Ducoin A, Shadloo MS, Roy S. Direct numerical simulation of flow instabilities over Savonius style wind turbine blades. Renew Energy. 2017;105:374–85.

Shadloo MS, Hadjadj A. Laminar-turbulent transition in supersonic boundary layers with surface heat transfer: a numerical study. Numer Heat Transf A Appl. 2017;72:40–53. https://doi.org/10.1080/10407782.2017.1353380.

Ben-Nasr O, Hadjadj A, Chaudhuri A, Shadloo MS. Assessment of subgrid-scale modeling for large-eddy simulation of a spatially-evolving compressible turbulent boundary layer. Comput Fluids. 2017;151:144–58.

Sharma S, Shadloo MS, Hadjadj A. Laminar-to-turbulent transition in supersonic boundary layer: effects of initial perturbation and wall heat transfer. Numer Heat Transf A Appl. 2018;73:583–603.

Ansari E, Poorghasemi K, Irdmousa B, Shahbakhti M, Naber J. Efficiency and emissions mapping of a light duty diesel—natural gas engine operating in conventional diesel and RCCI modes. SAE Int. 2016. https://doi.org/10.4271/2016-01-2309.

Hanjalić K, Popovac M, Hadžiabdić M. A robust near-wall elliptic-relaxation eddy-viscosity turbulence model for CFD. J Heat Fluid Flow. 2004;25:1047–51.

Dukowicz JK. A particle-fluid numerical model for liquid sprays. J Comput Phys. 2004;35:229–53.

Beale JC, Reitz RD. Modelling spray atomization with the Kelvin-Helmholtz/Rayleigh-Taylor hybrid model. J Atom Sprays. 1999. https://doi.org/10.1615/atomizspr.v9.i6.40.

Wang Z, Shuai SJ, Wang JX, Tian Gh. A computational study of direct injection gasoline HCCI engine with secondary injection. Fuel. 2006;85:1831–41.

Sjöberg M, Dec E. Effects of EGR and its constituents on HCCI autoignition of ethanol. Proc Combust Inst. 2011;33:3031–8.

Agrawal A, Singh S, Sinha S, Shukla M. Effect of EGR on the exhaust gas temperature and exhaust opacity in compression ignition engines. J Sadhana. 2004;29:275–84.

Kalghatgi G, Morganti K, Algunaibet I, Sarathy M, et al. Knock prediction using a simple model for ignition delay. SAE Technical Paper 2016-01-0702; 2016. https://doi.org/10.4271/2016-01-0702.

Jia M, Dempsey AB, Wang H, Li Y, Reitz RD. Numerical simulation of cyclic variability in reactivity-controlled compression ignition combustion with a focus on the initial temperature at intake valve closing. Int J Engine Res. 2014. https://doi.org/10.1177/1468087414552088.

Zel’dovich YB. The oxidation of nitrogen in combustion explosions. Eur Phys J A Hadrons Nucl. 1946;21:577–628.

Barenblatt G. Mathematical theory of combustion and explosions. ISBN 978-1-4612-9439-9; 1985.

Kittelson DB. Engines and nanoparticles a review. J Aerosol Sci. 1998;29:575–88.

Gowthaman S, Sathiyagnanam AP. Analysis the optimum inlet air temperature for controlling homogeneous charge compression ignition (HCCI) engine. Alexandria eng j 2018;57(4):2209–2214.

Tanaka S, Ayala F, Keck JC, Heywood JB. Two stage ignition in HCCI combustion and HCCI control by fuels and additives. J Combust Flame. 2003;132:219–39.

Ezoji H, Shafaghat R, Jahanian O. Numerical simulation of dimethyl ether/natural gas blend fuel HCCI combustion to investigate the effects of operational parameters on combustion and emissions. J Therm Calorim. 2018. https://doi.org/10.1007/s10973-018-7271-2.

Kumar MS, Arul K, Sasikumar N. Impact of oxygen enrichment on the engine’s performance, emission and combustion behaviour of a biofuel based reactivity controlled compression ignition engine. Energy Inst. 2019;92:51–61.

Ma S, Zheng Z, Liu H, Zhang Q, Yao M. Experimental investigation of the effects of diesel injection strategy on gasoline/diesel dual-fuel combustion. Appl Energy. 2013;109:202–12.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Motallebi Hasankola, S.S., Shafaghat, R., Jahanian, O. et al. Numerical investigation of the effects of inlet valve closing temperature and exhaust gas recirculation on the performance and emissions of an RCCI engine. J Therm Anal Calorim 139, 2465–2474 (2020). https://doi.org/10.1007/s10973-019-08513-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08513-0