Abstract

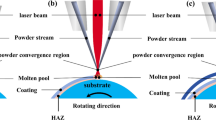

A practical method is proposed to control the direction of crack propagation and to generate a crack-growth-proof (CGP) zone on a metal plate using laser induced line patterns: heat treatment and cladding. To evaluate the effect on crack propagation by the line patterns, we fabricated and tested diverse line-pattern shapes on a thin SUS316 plate of 1 mm thickness, such as single vertical line; one, three, and five horizontal lines; one and three 45°-tilted lines; X-shaped lines; and rectangular box lines by both laser heat treatment and cladding process. For description of metallurgical change via the pattern and its effect on the crack growth, we did a microstructural analysis of the treated SUS316 specimen. For example, ultimate tensile stress (σu) and fracture strain changed according to the pattern shapes. A specimen treatiing a rectangular line pattern of 4×20 mm showed an increase of σu to about 8.8 %, and fracture strain also increased by 10 % compared to that of a SUS316 plate. Through this work, we verified that the CGP zone could be controlled on a thin metal plate using the proposed method for protection of highly valuable mechanical parts mounted on it.

Similar content being viewed by others

References

A. C. Pickard, R. O. Ritchie and J. F. Knott, Fatigue crack propagation in a type 316 stainless steel weldment, Metals Technology, 2 (1975) 253–263.

D. H. Jeong, Laser heat treatment for automobile parts, The Korean Society of Automotive Engineers, 24(4) (2002) 22–26.

H. Hadi, S. Kourosh, F. M. Mohammad and M. Parviz, Experimental and numerical study of crack propagation and coalescence in precracked rock-like disks, International J. of Rock Mechanics & Mining Sciences, 67 (2014) 20–28.

A. Manouchehrian, M. Sharifzadeh, M. F. Marji and J. Gholamneja, A bonded particle model for analysis of the flaw orientation effect on crack propagation mechanism in brittle materials under compression, Archives of Civil and Mechanical Engineering, 14 (2014) 40–52.

A. Ghazvinian, H. R. Nejati, V. Sarfarazi and M. R. Hadei, Mixed mode crack propagation in low brittle rocklike materials, Arabian J. of Geosciences, 6 (2013) 4435–4444.

V. Cain, L. Thijs, J. Van Humbeeck, B. Van Hooreweder and R. Knutsen, Crack propagation and fracture toughness of Ti6Al4V alloy produced by selective laser melting, Additive Manufacturing, 5 (2015) 68–76.

B. Van Hooreweder, D. Moens, R. Boonen, J. Kruth and P. Sas, Analysis of fracture toughness and crack propagation of Ti6Al4V produced by selective laser melting, Advanced Engineering Materials, 14 (2012) 92–97.

S. V. Tarandhe, J. Bhagyaraj, S. Mishra and S. Karagadde, A new approach to control and optimize the laser surface heat treatment of materials, J. of Materials Processing Technology, 262 (2018) 492–502.

G. Telasang, J. D. Majumdar, G. Padmanabhan, M. Tak and I. Manna, Effect of laser parameters on microstructure and hardness of laser clad and tempered AISI-H13 tool steel, Surface and Coatings Technology, 258 (2014) 1108–1118.

C. Navas, A. Conde, B. J. Fernández, F. Zubiri and J. Damborenea, Laser coatings to improve wear resistance of mould steel, Surface and Coatings Technology, 194 (2005) 136–142.

E. G. Kang, H. Z. Xhoi, B. K. Min and S. J. Lee, Plasma diode electron beam heat treatment of cast iron: effect of direct preheating, International J. of Precision Engineering and Manufacturing, 18(10) (2017) 1339–1345.

H. L. Chien and Y. C. Lee, A ball valve micro-pump based on axially symmetrical nozzle fabricated by excimer laser micromachining technology, International J. of Precision Engineering and Manufacturing, 18(10) (2017) 1315–1320.

J. U. Cho, C. D. Cho and M. S. Han, Study of dynamic crack propagation in 3PB steel specimens loaded by impact, International J. of Precision Engineering and Manufacturing, 10 (2009) 67–72.

Y. S. Chai, C. Y. Lee and M. Pak, Analysis of mixed-mode crack propagation by the movable cellular automata method, International J. of Precision Engineering and Manufacturing, 9(4) (2008) 66–70.

M. S. Kang and J. S. Kim, Crack initiation and propagation at the gas turbine blade with antioxidation and thermal barrier coating, J. of the Korean Society for Precision Engineering, 27(12) (2010) 99–106.

S. Fu, L. Yang, H. Wang and G. Chi, Analyses of effects of process parameters on laser bending of stiffened panels, International J. of Precision Engineering and Manufacturing, 19(4) (2018) 593–604.

H. M. Lee, J. H. Choi and S. J. Moon, Effect of the chemical composition on the ablation characteristics of glass substrates in femtosecond laser machining, International J. of Precision Engineering and Manufacturing, 18(11) (2017) 1495–1499.

ASTM E8/E8M-09, Standard Test Methods for Tension Testing of Metallic Materials, ASTM International, West Conshohocken (2011).

J. Moon, J. Lee and C. Lee, Prediction for the austenite grain size in the presence of growing particles in the weld HAZ of Timicroalloyed steel, Materials Science and Engineering A, 459 (2007) 40–46.

ASTM E384-17, Standard Test Method for Microindentation Hardness of Materials, ASTM International, West Conshohocken (2016).

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2019R1A5A808320112), and also was granted financial support from the Basic Science Research Program through the NRF (No. 2020R1F1A106937411).

Author information

Authors and Affiliations

Corresponding author

Additional information

Yeong Kwan Jo is currently a Ph.D. student in Mechanical Engineering at Pusan National University. His research topics are development of cladding process and its application to surface mechanical characteristics.

Jae Hyun Yu is a researcher in Advanced Surface Process Group at the Korea Institute of Industrial Technology. He earned his Ph.D. in Mechanical Engineering at Pusan National University in 2019. His research fields are development of additive manufacturing and its application to repairing.

Ki Yong Lee is a Principal Researcher in Smart Mobility Material Parts R&D Group at Korea Institute of Industrial Technology. He earned his M.S. and Ph.D. in Mechanical Engineering at Pusan National University in 1994 and 2001. His research fields are the engineering for additive manufacturing, especially direct energy deposition (DED).

Do Sik Shim received his Ph.D. in Mechanical Engineering from KAIST, Korea in 2010. He has been an Assistant Professor at Korea Maritime and Ocean University (KMOU) since 2017. His research interests include incremental and roll forming for sheet metal, direct energy deposition (DED) and structural analysis as well as optimal design.

Sang Hu Park is a Professor of Mechanical Engineering at Pusan National University. He earned his M.S. and Ph.D. in Mechanical Engineering at KAIST in 1996 and 2006, respectively. His research fields are the engineering for additive manufacturing, sheet metal forming, and nanofabrication.

Rights and permissions

About this article

Cite this article

Jo, YK., Yu, JH., Lee, KY. et al. Control of crack propagation on SUS316 plate by laser-induced patterning: heat treatment and cladding. J Mech Sci Technol 34, 4711–4719 (2020). https://doi.org/10.1007/s12206-020-1028-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-1028-0