Abstract

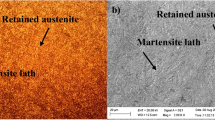

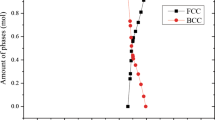

Skid damage to mainshaft bearings on aeroengines severely reduces aircraft reliability. In this study, a batch of cylindrical roller bearings extracted from mainshaft of inservice aeroengines with, skid damage after a certain service period, were collected, and damage features of the bearings were characterized and compared with those of the undamaged bearings and the new ones. Microscopic feature evaluation, elemental analysis as well as the composition distribution of the bearings were conducted using scanning electron microscopy with energy-dispersive X-ray spectroscopy, X-ray diffractometry, X-ray photo-electron spectroscopy, transmission electron microscopy and surface profilometry. Analysis results reveal that skidding itself is a very complex process initiated by the action of different mechanisms, and manifest in different wear types. The damage mechanism of skid damaged bearings was the joint consequence of abrasive wear, oxidation wear and delamination wear. All the aforementioned damage and wear led to severe aircraft failures.

Similar content being viewed by others

References

W. Tu, Y. Shao and C. Mechefske, An analytical model to investigate skidding in rolling element bearings during acceleration, Journal of Mechanical Science and Technology, 26 (2012) 2451–2458.

G. Cavallaro, D. Nelias and F. Bon, Analysis of high-speed intershaft cylindrical roller bearing with flexible rings, Tribology Transactions, 48 (2005) 154–164.

N. Ghaisas, C. Wassgren and F. Sadeghi, Cage instabilities in cylindrical roller bearing, Journal of Tribology, 126 (2004) 681–689.

Y. Wang et al., Investigation of skidding in angular contact ball bearings under high speed, Tribology International, 92 (2015) 404–417.

L. Oktaviana, V. Tong and S. Hong, Skidding analysis of angular contact ball bearing subjected to radial load and angular misalignment, Journal of Mechanical Science and Technology, 33 (2019) 837–845.

Q. Han and F. Chu, Nonlinear dynamic model for skidding behavior of angular contact ball bearings, Journal of Sound and Vibration, 354 (2015) 219–235.

S. Deng et al., Cage slip characteristics of a cylindrical roller bearing with a trilobe-raceway, Chinese Journal of Aeronautics, 31 (2018) 351–362.

J. Li, W. Chen and Y. Xie, Experimental study on skid damage of cylindrical roller bearing considering thermal effect, Proceedings of the Institution of Mechanical Engineers Part P-Journal of Sports Engineering and Technology, 228 (2014) 1036–1046.

A. Selvaraj and R. Marappan, Experimental analysis of factors influencing the cage slip in cylindrical roller bearing, Int J Adv Manuf Technol, 53 (2011) 635–644.

T. Xu et al., A preload analytical method for ball bearings utilising bearing skidding criterion, Tribology International, 67 (2013) 44–50.

S. Gürgen, M. Kuşhan and S. Diltemiz, Fatigue failure in aircraft structural components, Handbook of Materials Failure Analysis with Case Studies from the Aerospace and Automotive Industries (2016) 261–277.

S. Gürgen, I. Saçkesen and M. Kuşhan, Fatigue and corrosion behavior of in-service AA7075 aircraft component after thermo-mechanical and retrogression and re-aging treatments, Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 233 (2018) 1764–1772.

A. Toms and K. Cassidy, Filter debris analysis for aircraft engine and gearbox health management, Journal of Failure Analysis and Prevention, 8 (2008) 183–187.

F. Cakir et al., Maintenance error detection procedure and a case study of failure analysis locomotive diesel engine bearings, Journal of Failure Analysis and Prevention, 18 (2018) 356–363.

F. Çakir and O. Çelik, The effects of cryogenic treatment on the toughness and tribological behaviors of eutectoid steel, Journal of Mechanical Science and Technology, 31 (2017) 3233–3239.

S. Diltemiz et al., Effect of dent geometry on fatigue life of aircraft structural cylinder part, Engineering Failure Analysis, 16 (2009) 1203–1207.

Anish, A. Kumar and A. Chakrabarti, Failure mode analysis of laminated composite sandwich plate, Engineering Failure Analysis, 104 (2019) 950–976.

A. Kumar et al., Efficient failure analysis of laminated composites and sandwich cylindrical shells based on higher-order zigzag theory, Journal of Aerospace Engineering, 28 (2015) 1–14.

S. Bazazzadeh, M. Zaccariotto and U. Galvanetto, Fatigue degradation strategies to simulate crack propagation using peridynamic based computational methods, Latin American Journal of Solids and Structures, 16 (2019) e163.

S. Bazazzadeh, F. Mossaiby and A. Shojaei, An adaptive thermo-mechanical peridynamic model for fracture analysis in ceramics, Engineering Fracture Mechanics, 223 (2020) 106708.

B. Averbach and E. Bamberger, Analysis of bearing incidents in aircraft gas turbine mainshaft bearings, Tribology Transactions, 34 (1991) 241–247.

N. Ejaz, I. Salam and A. Tauqir, Failure analysis of an aero engine ball bearing, Journal of Failure Analysis and Prevention, 6 (2006) 25–31.

G. Jacobs and M. Plogmann, Rolling bearing damages, Encyclopedia of Lubricants and Lubrication, Springer (2014) 1600–1618.

T. Yamashita and P. Hayes, Analysis of XPS spectra of Fe2+ and Fe3+ ions in oxide materials, Applied Surface Science, 254 (2008) 2441–2449.

J. Gegner, Tribological aspects of rolling bearing failures, Tribology-Lubricants and Lubrication, InTech, Rijeka, Croatia (2011).

P. K. Gupta, Current status of and future innovations in rolling bearing modeling, Tribology Transactions, 54 (2011) 394–403.

Q. Gao et al., Cause analysis and risk assessment of skidding stripe on aeroengine cylindrical roller bearing, Mechanical Research & Application, 32 (2019) 85–88.

F. Xu et al., Microstructure modifications and corrosion behaviors of cr4mo4v steel treated by high current pulsed electron beam, Materials Chemistry and Physics, 126 (2011) 904–908.

D. Luo et al., The microstructure of ta alloying layer on m50 steel after surface alloying treatment induced by high current pulsed electron beam, Vacuum, 136 (2016) 121–128.

J. Zou et al., Mechanisms of nanostructure and metastable phase formations in the surface melted layers of a hcpebtreated D2 steel, Acta Materialia, 54 (2006) 5409–5419.

Z. Cai et al., Development of a novel cycling impact-sliding wear rig to investigate the complex friction motion, Friction, 7 (2019) 32–43.

B. Bhushan, Principles and Applications of Tribology, John Wiley and Sons, New Jersey, USA (1999).

H. Zhang et al., Modeling of elastic finite-length space rolling-sliding contact problem, Tribology International, 113 (2017) 224–237.

S. Wen and P. Huang, Tribology Principle, Tsinghua University Press, Beijing, China (2002).

L. Cui and Y. He, A new logarithmic profile model and optimization design of cylindrical roller bearing, Industrial Lubrication and Tribology, 67 (2015) 498–508.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 51605105), Guizhou Excellent Youth Scientific and Technological Talent Program of China (Grant No. [2017]5628), Major Science and Technology Project in Guizhou Province (Grant No. Q.K.H.Z.D.Z.X.Z [2019]3016), Discipline and Master’s Site Construction Project of Guiyang University by Guiyang City Financial Support Guiyang University (HC-2020).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Recommended by Editor Chongdu Cho

Xiangyu Xie received his master degree in Mechanical Engineering in 2017 from Guizhou University, China. Now, he is currently a lab master at Guiyang University, China. His research interest is tribology of bearing and failure analysis.

Jin Xu received his Ph.D. degree from Southwest Jiaotong University in 2003. His current position is the assistant research fellow and tutor of master degree candidates in Guizhou University, China. His research interests include tribology and surface engineering.

Jun Luo received his Ph.D. degree from Southwest Jiaotong University in 2011. His current position is a Professor at Guiyang University, China. His research interests include surface engineering and wear.

Rights and permissions

About this article

Cite this article

Xie, X., Xu, J. & Luo, J. Analysis of skid damage to cylindrical roller bearing of mainshaft of aeroengine. J Mech Sci Technol 34, 3239–3247 (2020). https://doi.org/10.1007/s12206-020-0716-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-0716-0