Abstract

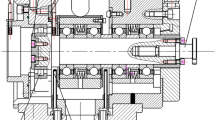

This paper deals with the effect of operating parameters on cage slip in cylindrical roller bearing. A cylindrical roller bearing test rig is developed to measure the running speed of bearing elements at various operating conditions. The effect of operating parameters namely shaft speed, radial load, viscosity of lubricating oil, number of rollers, and bearing temperature on cage slip are experimentally obtained. The critical load and magnitude of cage slip for various operating conditions are obtained. The non-dimensional number is derived based on the operating parameters. The region where cage slip occurs is developed from the derived non-dimensional number and the experimental data. The temperature raise is experimentally obtained during slip condition and its effect on viscosity is included for calculations. The frictional forces are experimentally obtained and are compared with the theoretical findings. The significant effect of operating parameters on cage slip of cylindrical roller bearing is discussed based on the experimental findings.

Similar content being viewed by others

References

Steve L, Hisashi K (1998) Bearings for aircraft gas turbine engines (part-1). NSK Tech J, Motion Control 5

Tassone BA (1975) Roller bearing slip and skidding damage. J Aircr 12:281–287

Hamer JC, Sayles RS, Ioannides E (1989) An experimental investigation into the boundaries of smearing failure in roller bearings. J Tribol 113(1):102 (8 pages) January 1991. doi:10.1115/1.2920573

Smith CF (1962) Some aspects of the performance of high-speed lightly-loaded cylindrical roller bearing. Proc Inst Mech Eng 176(227):566

Dowson D, Higginson GR (1963) Theory of roller bearing lubrication and deformation. Proc Inst Mech Eng 117:216–222

Harris TA (1966) An analytical method to predict skidding in high speed roller bearings. Tribol Trans 9(3):229–241

Poplawski JV (1972) Slip and cage forces in a high-speed roller bearing. ASME Jour, of hub. Tech., Paper, 71-LUB-17, 143–152

Boness RJ (1969) Cage and roller slip in high-speed roller bearings. J Mech Eng Sci 11(2):181

Hamrock BJ, BoO J (1984) Elastohydrodynamic lubrication of line contacts. Tribol Trans 27(4):275–287

Pinel SI, Signer HR, Zaretsky EV (2000) Design and operating characteristics of high speed, small bore cylindrical roller bearings, NASA TM, 209778.

Harris TA (1984) Rolling bearing analysis, 2nd edn. Wiley, New York

Bair S (2001) The variation of viscosity with temperature and pressure for various real lubricants. J Tribol 123(2):433–436

Hamrock Bernard J, Schmid Steven R, Jacobson BO (2004) Fundamentals of fluid film lubrication, 2nd edn. Mc Graw-Hill, New York, USA

Prashad H (1986) The effect of cage and roller slip on the measured defect frequency response of rolling element bearings. ASME Tribol Trans 30(3):360–367

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Selvaraj, A., Marappan, R. Experimental analysis of factors influencing the cage slip in cylindrical roller bearing. Int J Adv Manuf Technol 53, 635–644 (2011). https://doi.org/10.1007/s00170-010-2854-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2854-5