Abstract

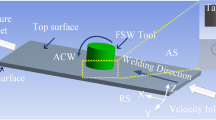

The generalized energy equation was investigated for an incompressible fluid film in homogeneous deformation phase of axisymmetric upsetting process with a perfectly plastic material. A reduced form of energy equation was used for the heat transfer problem of convection coupled with conduction mode in the lubricant film. The effect of convection denoted by Peclet number and the temperature difference between tool and workpiece was parametrically investigated on the temperature distribution and inhomogeneous shear motion in the film. The results of present model problem indicate that the localized thermal shear across the lubricant film depends mainly on the reduction in height and the degree of convection induced by sliding motion between tool and workpiece.

Similar content being viewed by others

References

T. Iwama and Y. Morimoto, Die life and lubrication in warm forging, J. Mater. Process. Technol., 71 (1) (1997) 43–48.

Z. Kang, Y. Fu, D. M. Kim, H. E. Joe, X. Fu, T. Gabor, H. W. Park and M. B. Jun, From macro to micro, evaluation of surface structures on cutting tools: A review, JMST Advances, 1 (1–2) (2019) 89–106.

P. Armandoost, M. Bayareh and A. A. Nadooshan, Study of the motion of a spheroidal drop in a linear shear flow, J. of Mechanical Science and Technology, 32 (5) (2018) 2059–2067.

W. Lee, K. D. Kihm and S. H. Ko, Thermal conductivity reduction of multilayer grapheme with fine grain sizes, JMST Advances, 1 (1–2) (2019) 191–195.

W. R. D. Wilson, Transient tribology in metal forming, Transient Processes in Tribology (2004).

M. Oyane and K. Osakada, The mechanism of lubricant trapping under dynamic compression, Bull. JSME, 12 (49) (1969) 149–155.

W. R. D. Wilson and S. M. Mahdavian, A thermal reynolds equation and its application in the analysis of plastohydrodynamic inlet zones, ASME J. of Lubr. Technol., 96 (4) (1974) 572–578.

T. A. Dow, J. W. Kannel and S. S. Bupara, A hydrodynamic lubrication theory for strip rolling including thermal effects, ASME J. of Lubr. Technol., 97 (series F) (1975) 4–13.

V. K. Bhatt and D. K. Sangupta, Analysis of thermal effects in the yield phase of hydrodynamic lubricant film in plane forging, ASME J. Tribol., 118 (4) (1996) 880–885.

V. K. Bhatt, Thermal analysis of flow in the deformation phase of liquid lubricated plane strain forging, ASME J. Tribol., 122 (4) (2000) 746–751.

L. Chang, A parametric analysis of the thermal shear localization in elastohydrodynamic lubrication films, ASME J. Tribol., 128 (1) (2006) 79–84.

W. R. D. Wilson, Friction and lubrication in bulk metalforming, J. Applied Metal Working, 1 (1) (1979) 7–19.

P. Montmitonnet and J. L. Chenot, Coupling of fluid film lubricartion and plastic deformation: Finite element approach of plastohydrodynamics in cold forging, Numerical Tech. for Engg. Analysis and Design, 1 (1987) 3–11.

Acknowledgments

This work was supported by Inha University Research Grant and by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (No. 2010- 0022439).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Chongdu Cho

Beong Bok Hwang received his B.S. degree in Mechanical Engineering from Inha University, Incheon, Korea, in 1981. He received his M.S. and then Ph.D. degrees from Univ. of Michigan, Ann Arbor and U.C. Berkeley in 1985 and 1991, respectively. Dr. Hwang is currently a Professor at the School of Mechanical Engineering at Inha University in Incheon, Korea. Dr. Hwang’s research interests include metal forming processes and lubrication.

Jeong Hoon Noh received his B.S. degree in Mechanical Engineering from Inha University, Incheon, Korea, in 2008. He received his M.E. degree from Inha University in 2010. Mr. Noh is currently a Ph.D. candidate at the Department of Mechanical Engineering at Inha University in Incheon, Korea.

Rights and permissions

About this article

Cite this article

Hwang, B.B., Noh, J.H. Thermal shear behavior in deformation phase of axisymmetric upsetting. J Mech Sci Technol 33, 5851–5860 (2019). https://doi.org/10.1007/s12206-019-1015-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-1015-5