Abstract

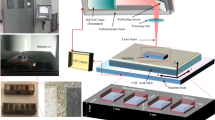

Micro-machining of dental ceramics namely as zirconium oxide is carried out through laser beam machining. Micro-channels of different sizes are fabricated under different laser parameters. The laser process performance is evaluated by considering the geometrical and quality responses associated with micro-channels. Laser intensity, pulse frequency, scanning speed and layer thickness per laser scan are opted as the influential controlling parameters. Geometrical characteristics of micro-channels include upper width (WU), lower width (WL), depth (D), taper angle of micro-channel’s sidewalls at right side (θR), and taper angle at left side (θR ). Quality of the machined micro-channels is evaluated by means of surface roughness (Ra of the bottom surface. Effects of each of the laser parameters on each of the geometrical and quality responses are studied in order to get the influential trends of laser parameters. SEM analysis is further performed to assess the micro-details of machining results. The results reveals that the shape and size of micro-channel are very sensitive to the variation in laser parameters. Two types of micro-channels shapes are obtained having V-shaped and U-shaped cross-sections. Furthermore, it is quite challenging to achieve the micro-channels with reasonable amount of lower width (WL).

Similar content being viewed by others

References

S. Xu, Z. Yao and M. Zhang, Material removal behavior in scratching of zirconia ceramic surface treated with laser thermal shock, Int. J. Adv. Manuf. Technol, 85 (9–12) (2016) 2693–2701.

K. Oblov et al., Fabrication of microhotplates based on laser micromachining of zirconium oxide, Phys. Procedia, 72 (Supplement C) (2015) 485–489.

R. Jafari et al., Modeling and analysis of surface roughness of microchannels produced by U.-WEDM using an ANN and Taguchi method, J. Mech. Sci. Technol, 31 (11) (2017) 5447–5457.

D. S. Oh et al., Effect of capillary action on bone regeneration in micro-channeled ceramic scaffolds, Ceram. Int., 40 (7, Part A) (2014) 9583–9589.

D. S. Oh et al., Bone marrow absorption and retention properties of engineered scaffolds with micro-channels and nano-pores for tissue engineering: A proof of concept, Ceram. Int., 39 (7) (2013) 8401–8410.

H.-J. Hong, S. K. Sarkar and B.-T. Lee, Formation of TiO2 nano fibers on a micro-channeled Al2O3-ZrO2/TiO2 porous composite membrane for photocatalytic filtration, J. Eur. Ceram. Soc., 32 (3) (2012) 657–663.

K. Kowsari et al., CFD-aided prediction of the shape of abrasive slurry jet micro-machined channels in sintered ceramics, Ceram. Int., 42 (6) (2016) 7030–7042.

A. Banu, M. Y. Ali and M. A. Rahman, Micro-electro discharge machining of non-conductive zirconia ceramic: Investigation of MRR and recast layer hardness, Int. J. Adv. Manuf. Technol, 75 (1-4) (2014) 257–267.

P. Hou et al., Influence of open-circuit voltage on high-speed wire electrical discharge machining of insulating Zirconia, Int. J. Adv. Manuf. Technol, 73 (1–4) (2014) 229–239.

Y. Guo et al., Multi-response optimization of the electrical discharge machining of insulating zirconia, Mater. Manuf. Process., 32 (3) (2017) 294–301.

S. Sun, M. Brandt and M. Dargusch, Review of laser assisted machining of ceramics, Zhongguo Jiguang/Chinese J. Lasers, 36 (12) (2009) 3299–3307.

J. Kim and B. Kang, Machining characteristics of micro lens mold in laser-assisted micro-turning, J. Mech. Sci. Technol, 32 (4) (2018) 1769–1774.

T.-W. Kim and C.-M. Lee, A study on the development of milling process for silicon nitride using ball end-mill tools by laser-assisted machining, Int. J. Adv. Manuf. Technol, 77 (5–8) (2015) 1205–1211.

J. Do Kim, S. J. Lee and J. Suh, Characteristics of laser assisted machining for silicon nitride ceramic according to machining parameters, J. Mech. Sci. Technol, 25 (4) (2011) 995–1001.

T. Kizaki et al., Lase-assisted machining of zirconia ceramics using a diamond bur, Procedia CIRP, 42 (Supplement C) (2016) 497–502.

S. Xu et al., An experimental investigation of grinding force and energy in laser thermal shock-assisted grinding of zirconia ceramics, Int. J. Adv. Manuf. Technol, 91 (9–12) (2017)3299–3306.

J. P. Parry et al., Nanosecond-laser postprocessing of millisecond- laser-machined zirconia (Y-TZP) surfaces, Int. J. Appl. Ceram. Technol, 5 (3) (2008) 249–257.

F. C. Dear et al., Pulsed laser micromachining of yttria - stabilized zirconia dental ceramic for manufacturing, Int. J. Appl Ceram. Technol, 5 (2) (2008) 188–197.

A. N. Samant and N. B. Dahotre, Absorptivity transition in the 106 urn wavelength laser machining of structural ceramics, Int. J. Appl. Ceram. Technol., 8 (1) (2011) 127–139.

J. P. Parry et al., Laser micromachining of zirconia (Y-TZP) ceramics in the picosecond regime and the impact on material strength, Int. J. Appl. Ceram. Technol, 8 (1) (2011) 163–171.

M. Noda et al., Surface damages of zirconia by Nd:YAG dental laser irradiation, Dent. Mater. J., 29 (5) (2010) 536–541.

S. Guarino et al., Laser milling of yttria-stabilized zirconia by using a Q-switched Yb:YAG fiber laser: experimental analysis, The International Journal of Advanced Manufacturing Technology, 94 (1–4) (2018) 1373–1385.

H. D. Vora et al., One-dimensional multipulse laser machining of structural alumina: Evolution of surface topography, Int. J. Adv. Manuf. Technol, 68 (1–4) (2013) 69–83.

M. K. Mohammed and U. Umer, Optimization of laser micro milling of alumina ceramic using radial basis functions and MOGA-II, The International J. of Advanced Manufacturing Technology (2017) 2017–2029.

H. Vora and N. Dahotre, Laser machining of structural alumina: influence of moving laser beam on the evolution of surface topography, Int. J. Appl. Ceram. Technol, 12 (3) (2015) 665–678.

CeramTec — The Ceramic Experts.

B. M. A. Abdo et al., Laser micro-milling of bio-lox forte ceramic: An experimental analysis, Precis. Eng, 53 (April) (2018) 179–193.

B. M. A. Abdo et al., Experimental investigation and multi-objective optimization of Nd:YAG laser micro-channeling process of zirconia dental ceramic, Int. J. Adv. Manuf. Technol, 98 (2018) 1–18.

Y. Liu et al., Fabrication of micro-scale textured grooves on green ZrO2 ceramics by pulsed laser ablation, Ceram. Int., 43 (8) (2017) 6519–6531.

C. Leone et al., Experimental investigation on laser milling of aluminium oxide using a 30 W Q-switched Yb: YAG fiber laser, Opt. Laser Technol, 76 (2016) 127–137.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Yongho Jeon

Basem M. A. Abdo is a researcher at Advanced Manufacturing Institute, King Saud University, Riyadh, Saudi Arabia. He received M.Sc. degree in industrial engineering from King Saud University in 2013. His research interests mainly include advanced manufacturing technologies; micro-machining, CAD/CAM, optimization of manufacturing processes.

Rights and permissions

About this article

Cite this article

Abdo, B.M.A., Ahmed, N., El-Tamimi, A.M. et al. Laser beam machining of zirconia ceramic: An investigation of micro-machining geometry and surface roughness. J Mech Sci Technol 33, 1817–1831 (2019). https://doi.org/10.1007/s12206-019-0334-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0334-x