Abstract

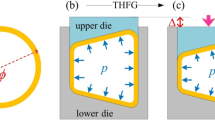

The tube hydroforming process uses a pressurized fluid as the forming medium, and the sealing efficiency of the internal fluid has an important influence on the hydroformability. This study investigates the applicability of segmented rubber rings to prevent pressure leakage in hydroforming. When the target shape is non-axisymmetric, the possibility of pressure leakage is increased due to the biased stress distribution on the punch. A sealing system is proposed, which is composed of segmented rubber rings, a cylindrical sleeve, and a punch with an end fillet. When the rubber rings are compressed, the reaction force acting on the rings contributes to the prevention of pressure leakage. The circumference of the tube end becomes more tightly sealed by the axial pressure between the punch and sleeve. A deformation analysis was conducted using a compression test, which revealed that the combined use of a steel ring with a rubber ring was more efficient in preventing fluid leakage. The enhanced sealing effect of the proposed system with rubber and steel rings was confirmed by comparing the experimental results with a conventional hydroforming process.

Similar content being viewed by others

References

H. K. Park, H. K. Yi, C. J. Van Tyne and Y. H. Moon, Strain hardening behavior during manufacturing of tube shapes by hydroforming, Metals and Materials International, 15 (6) (2009) 897–902.

S. Y. Kim, B. D. Joo, S. G. R. Shin, C. J. Van Tyne and Y. H. Moon, Discrete layer hydroforming of three-layered tubes, International Journal of Machine Tools and Manufacture, 68 (2013) 56–62.

V. Modanloo, A. Gorji and M. Bakhshi-Jooybari, Effects of forming media on hydrodynamic deep drawing, Journal of Mechanical Science and Technology, 30 (6) (2016) 2237–2242.

S. M. Sohn, B. J. Kim, K. S. Park and Y. H. Moon, Evaluation of the crash energy absorption of hydroformed bumper stays, Journal of Materials Processing Technology, 187–188 (2007) 283–286.

Y. Aue-U-Lan, G. Ngaile and T. Altan, Optimizing tube hydroforming using process simulation and experimental verification, Journal of Materials Processing Technology, 146 (1) (2004) 137–143.

K. J. Fann and P. Y. Hsiao, Optimization of loading conditions for tube hydroforming, Journal of Materials Processing Technology, 140 (1–3) (2003) 520–524.

H. K. Yi, E. J. Pavlina, C. J. Van Tyne and Y. H. Moon, Application of a combined heating system for a warm hydroforming of lightweight alloy tubes, Journal of Materials Processing Technology, 203 (1–3) (2008) 532–536.

S. J. Yuan, C. Han and X. S. Wang, Hydroforming of automotive structural components with rectangular-sections, International Journal of Machine Tools and Manufacture, 46 (11) (2006) 1201–1206.

M. Mirzaali, S. M. H. Seyedkashi, G. H. Liaghat, H. Moslemi Naeini, K. Shojaee and Y. H. Moon, Application of simulated annealing method to pressure and force loading optimization in tube hydroforming process, International Journal of Mechanical Science, 55 (1) (2012) 78–84.

A. Abdelkefi, N. Guermazi, N. Boudeau, P. Malécot and N. Haddar, Effect of the lubrication between the tube and the die on the corner filling when hydroforming of different crosssectional shapes, International Journal of Advanced Manufacturing Technology, 87 (1–4) (2016) 1169~1181.

L. Yang, C. Wu and Y. He, Dynamic frictional characteristics for the pulsating hydroforming of tubes, International Journal of Advanced Manufacturing Technology, 86 (1–4) (2016) 347–357.

J. S. Karami, M. M. Sheikhi, G. Payganeh and K. M. Fard, Experimental and numerical investigation of single and bilayered tube hydroforming using a new sealing technique, International Journal of Advanced Manufacturing Technology, 92 (9–12) (2017) 4169–4182.

P. Groche and M. Ertugrul, Process control at the sealing line during sheet metal hydroforming, Production Engineering, 2 (1) (2008) 3–8.

A. Fatemi, F. Biglari and M. R. Morovvati, Influences of inner pressure and tube thickness on process responses of hydroforming copper tubes without axial force, Proceeding of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 224 (12) (2010) 1866–1878.

R. Bihamata, Q.-H. Bui, M. Guillot, G. D’Amours, A. Rahem and M. Fafard, Global optimization of the production of complex aluminium tubes by the hydroforming process, CIRP Journal of Manufacturing Science and Technology, 9 (2015) 1–11.

J. Y. Park, S. W. Han, H. S. Jeong, J. R. Cho and Y. H. Moon, Advanced sealing system to prevent leakage in hydroforming, Journal of Materials Processing Technology, 247 (2017) 103–110.

S. M. H. Seyedkashi, V. Panahizadeh, H. B. Xu, S. Y. Kim and Y. H. Moon, Process analysis of two-layered tube hydroforming with analytical and experimental verification, Journal of Mechanical Science and Technology, 27 (1) (2013) 169–175.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Chongdu Cho

Jeong Hui Seok is a graduate student at School of Mechanical Engineering, Pusan National University, Republic of Korea. His research interests are process design of tube hydroforming process.

Young Hoon Moon is a Professor at School of Mechanical Engineering, Pusan National University, Republic of Korea. His research interests are development of advanced processing technology and process analysis of metal forming processes, such as hydroforming, flexible roll forming, sheet metal forming and laser processing.

Rights and permissions

About this article

Cite this article

Jeong, H.S., Han, S.W., Ra, J.H. et al. Application of segmented rubber rings to increase the sealing efficiency in hydroforming. J Mech Sci Technol 32, 3153–3159 (2018). https://doi.org/10.1007/s12206-018-0618-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0618-6